A device for recovering waste heat and moisture in flue gas

A flue gas and moisture technology, applied in the direction of household heating, heating methods, lighting and heating equipment, etc., can solve the problem of water vapor and air pollutants not being effectively treated and recovered, and reduce the emission of flue gas pollutants , high waste heat utilization efficiency, and the effect of reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

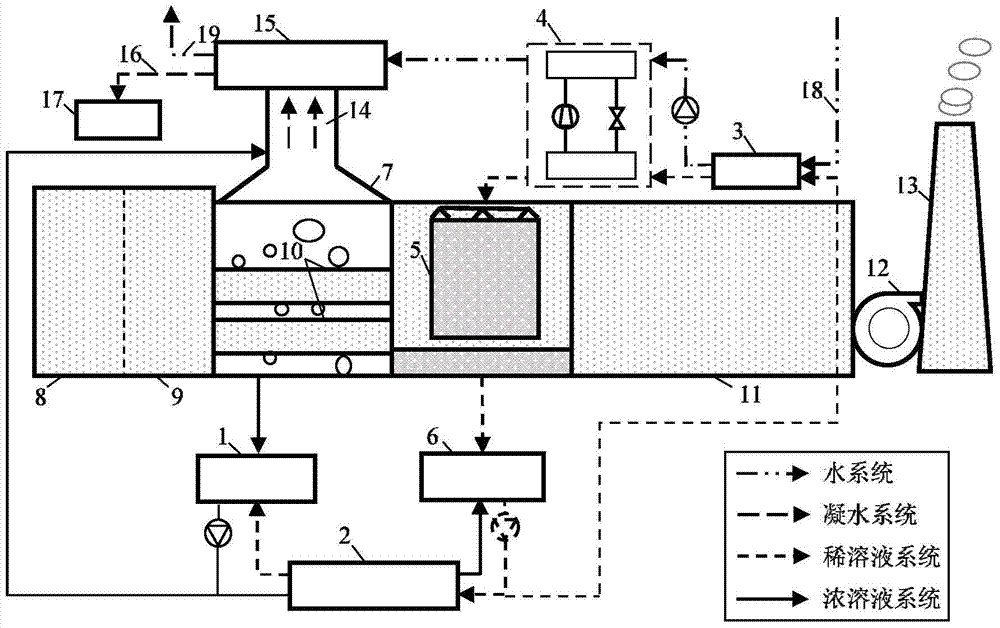

[0012] like figure 1 As shown, the present invention includes a concentrated solution storage tank 1, a dilute and concentrated solution heat exchanger 2, a solution-water heat exchanger 3, a heat pump 4, a dehumidification and dust collector 5, a dilute solution storage tank 6, a regenerator 7, and an economizer 9 , steam cooling heat exchanger 15 and condensed water collection tank 17. Wherein, the solution outlet of the regenerator 7 is connected with the concentrated solution storage tank 1, and the solution outlet of the concentrated solution storage tank 1 is divided into two branches after the circulation pump, one branch is connected with the inlet of the regenerator 7, and the other branch is It is connected with the concentrated solution inlet of the dilute concentrated solution heat exchanger 2. The concentrated solution outlet of the dil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com