Heating device for hydride vapor phase epitaxy (HVPE) growth

A hydride gas phase, heating device technology, applied in the direction of single crystal growth, crystal growth, chemical reactive gas, etc., can solve the problem of poor temperature uniformity, and achieve the effect of uniform temperature, large volume, and temperature realization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

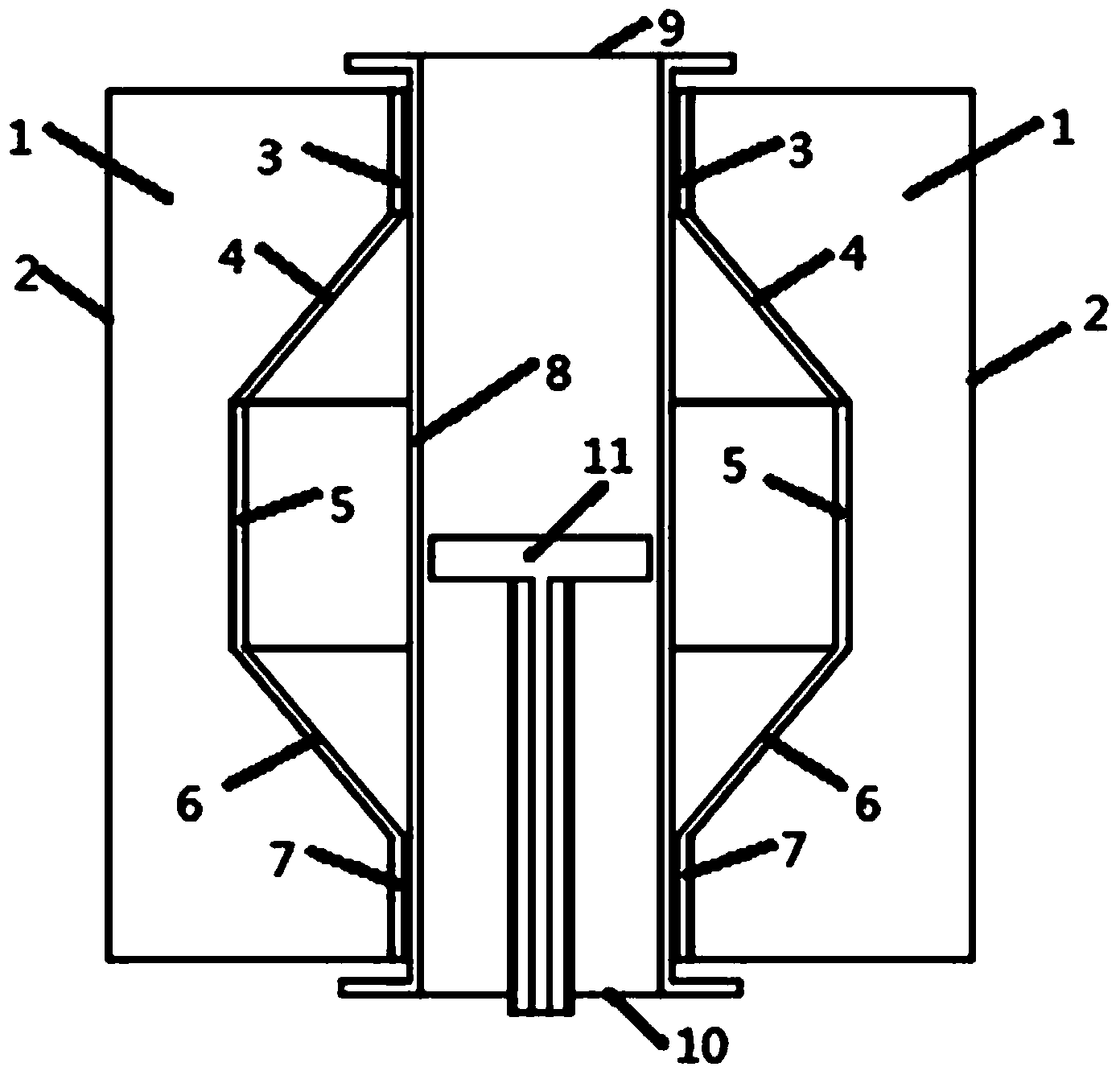

[0018] The present invention proposes a heating device for hydride vapor phase epitaxy (HVPE) growth, such as figure 1 As shown, the heating device includes a heating furnace and a heating module 11 in the furnace; the heating furnace includes a first heating temperature zone 3, a second heating temperature zone 4, a third heating temperature zone 5, a fourth heating temperature zone 6, The fifth heating temperature zone 7 and the heating furnace body 1 and the heating furnace shell 2 .

[0019] Such as figure 1 As shown, the upper and lower ends of the heating furnace are shorter, the first heating temperature zone 3 and the fifth heating temperature zone 7 are auxiliary heating temperature zones with independent temperature control, which are used to preheat the incoming gas and prevent premature formation of chlorination Ammonium dust helps maintain the stability of the temperature field inside the heating furnace.

[0020] Such as figure 1 As shown, between the upper an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com