Patents

Literature

205 results about "Hydride vapour phase epitaxy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

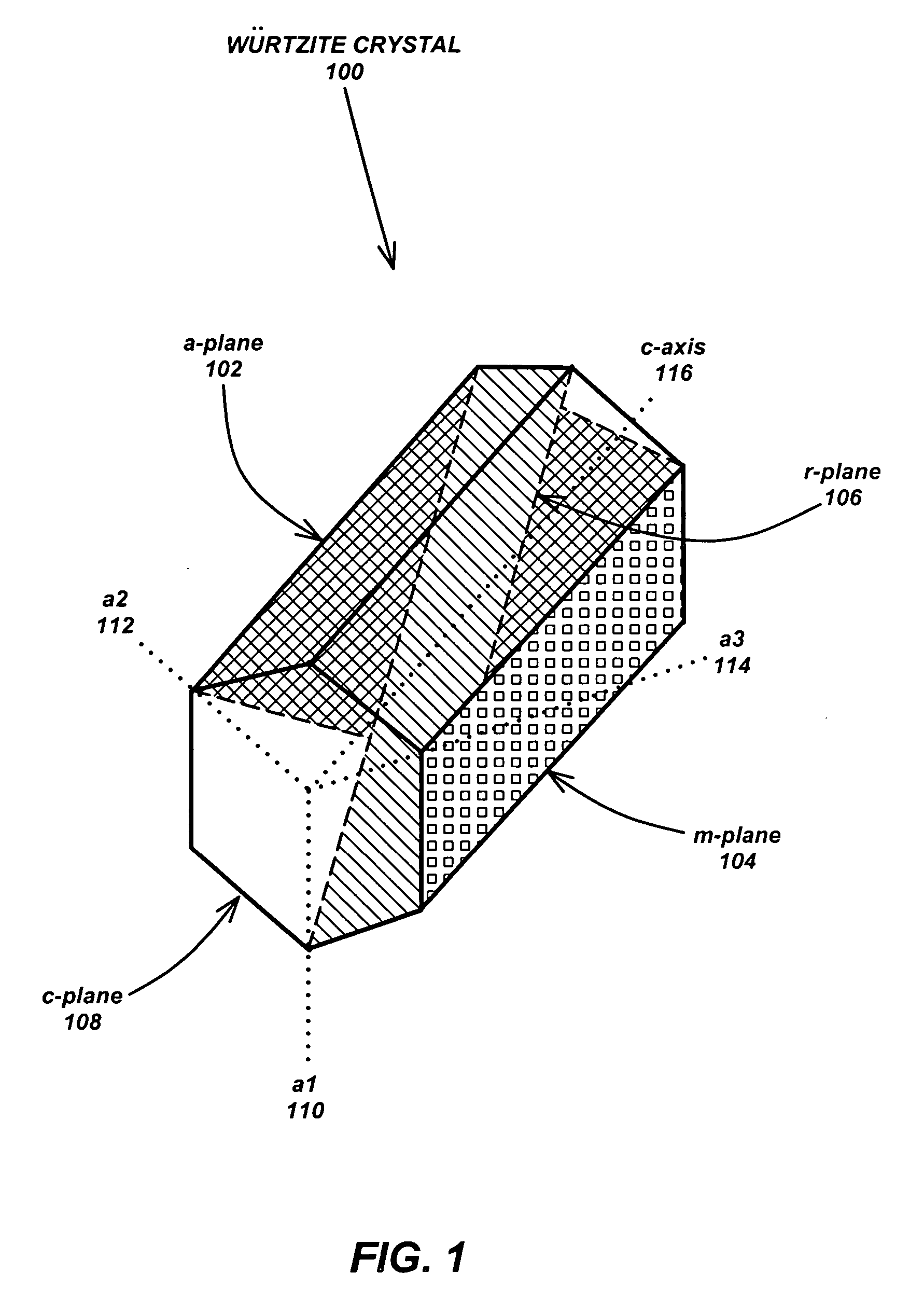

Hydride vapour phase epitaxy (HVPE) is an epitaxial growth technique often employed to produce semiconductors such as GaN, GaAs, InP and their related compounds, in which hydrogen chloride is reacted at elevated temperature with the group-III metals to produce gaseous metal chlorides, which then react with ammonia to produce the group-III nitrides. Carrier gasses commonly used include ammonia, hydrogen and various chlorides.

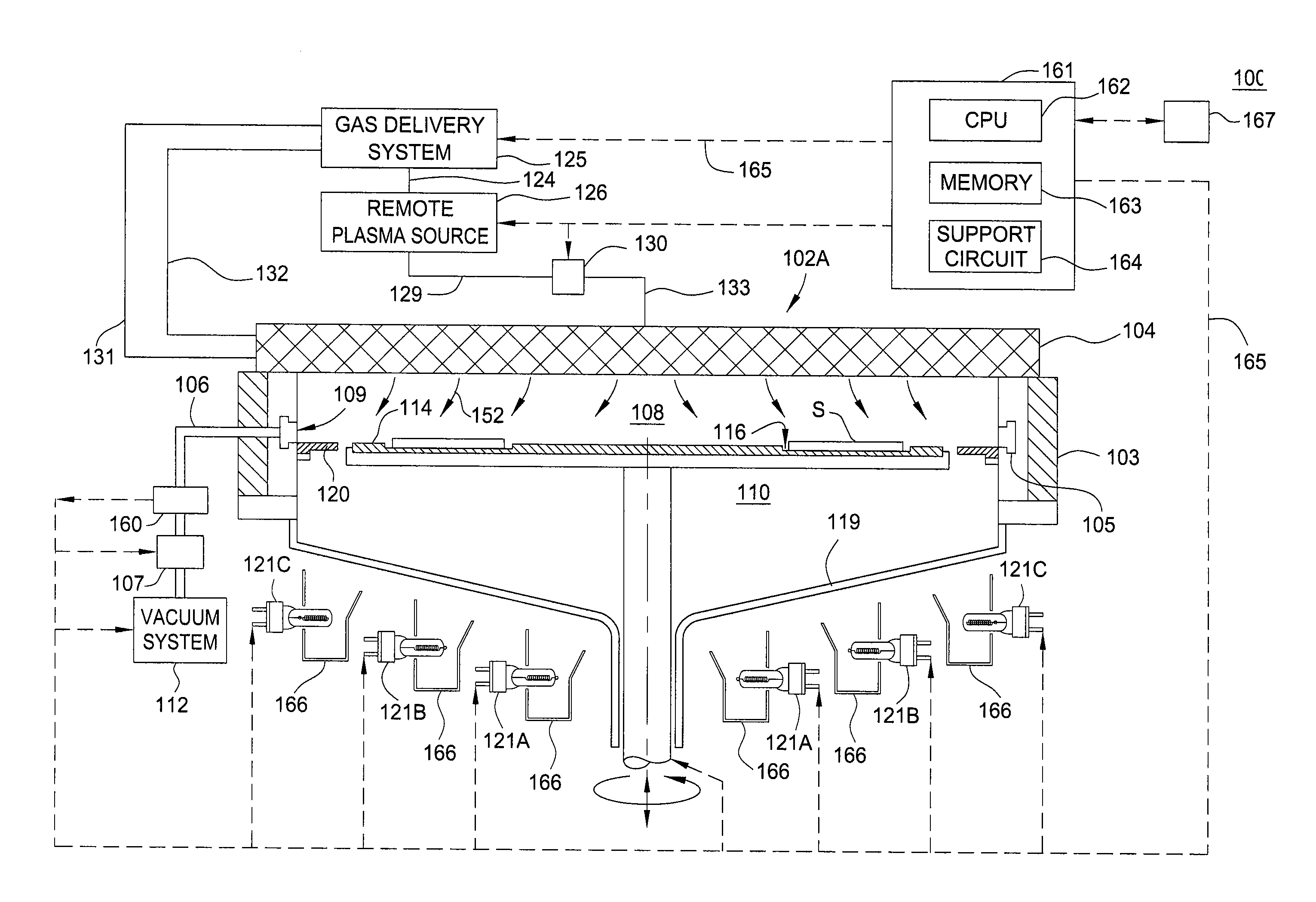

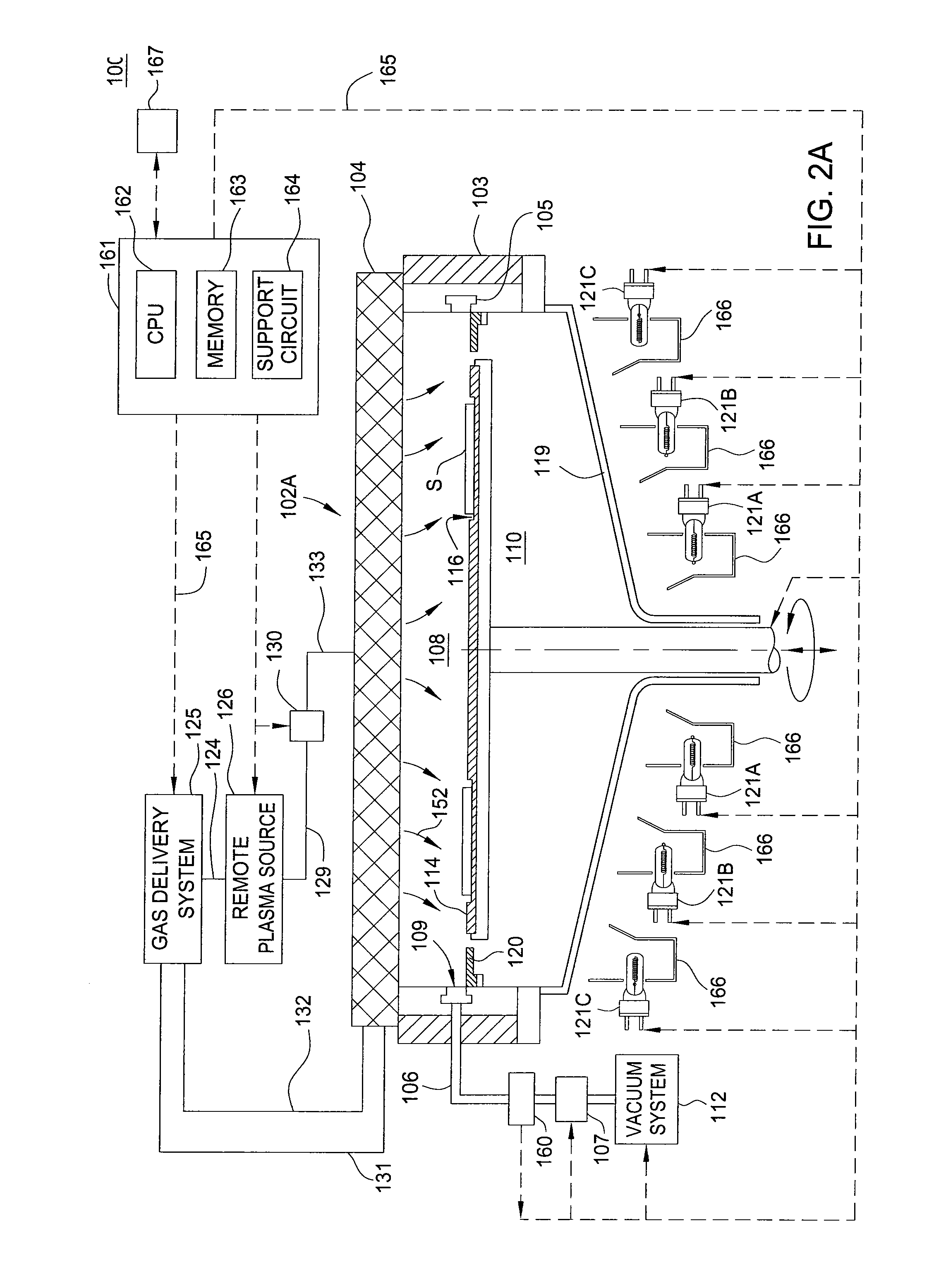

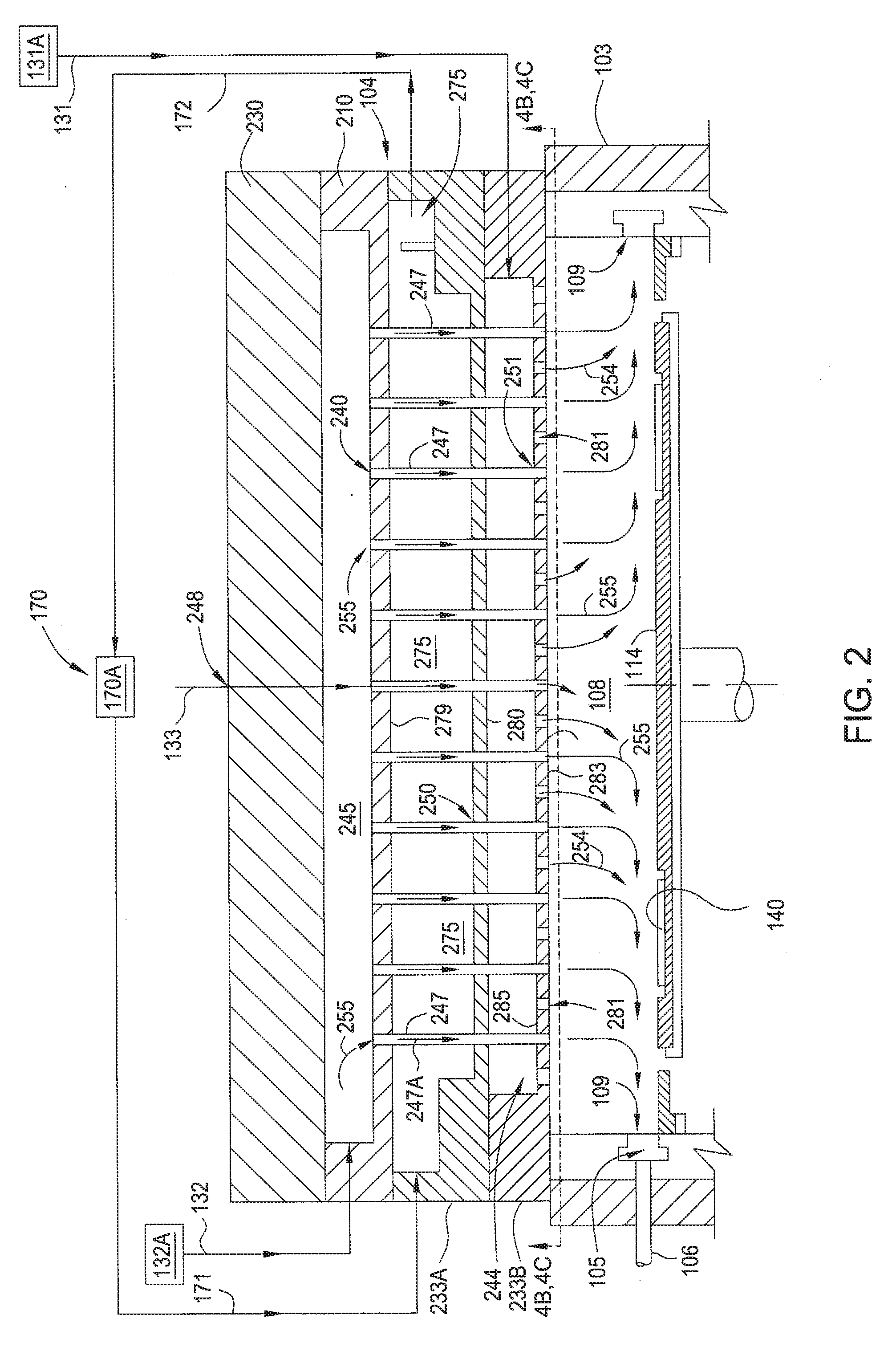

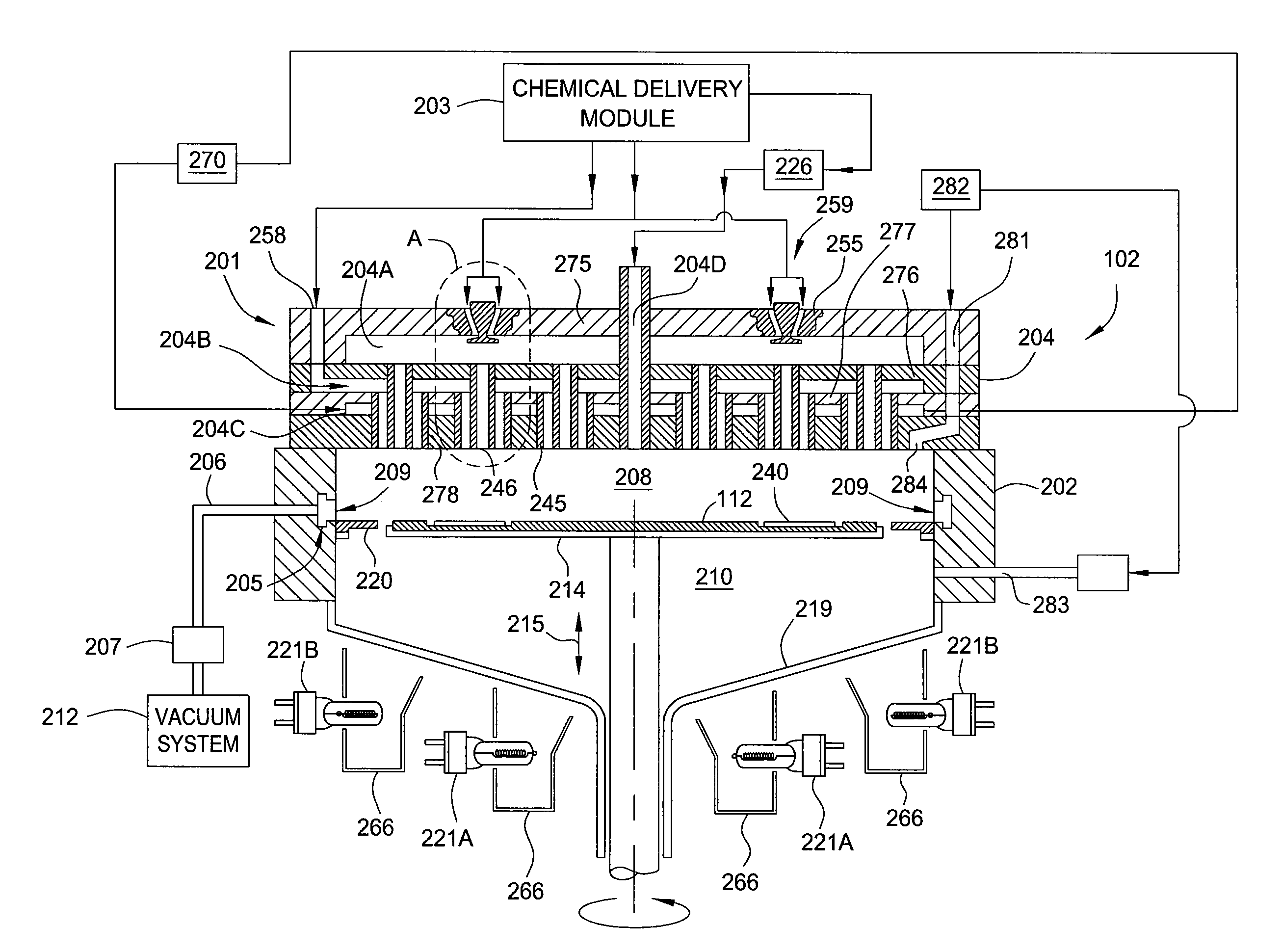

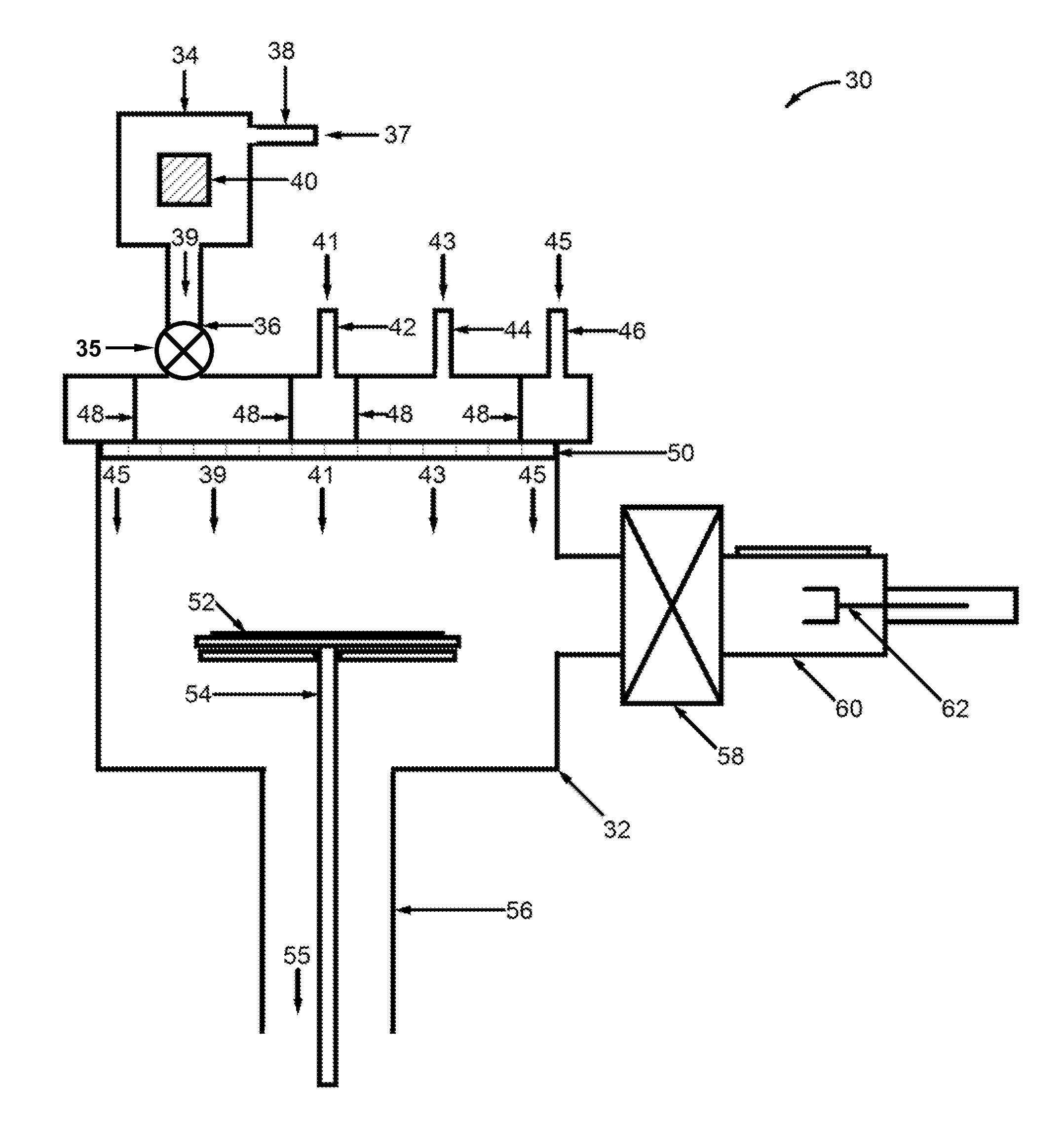

Closed loop mocvd deposition control

InactiveUS20110308453A1Liquid surface applicatorsSemiconductor/solid-state device manufacturingGas phaseControl system

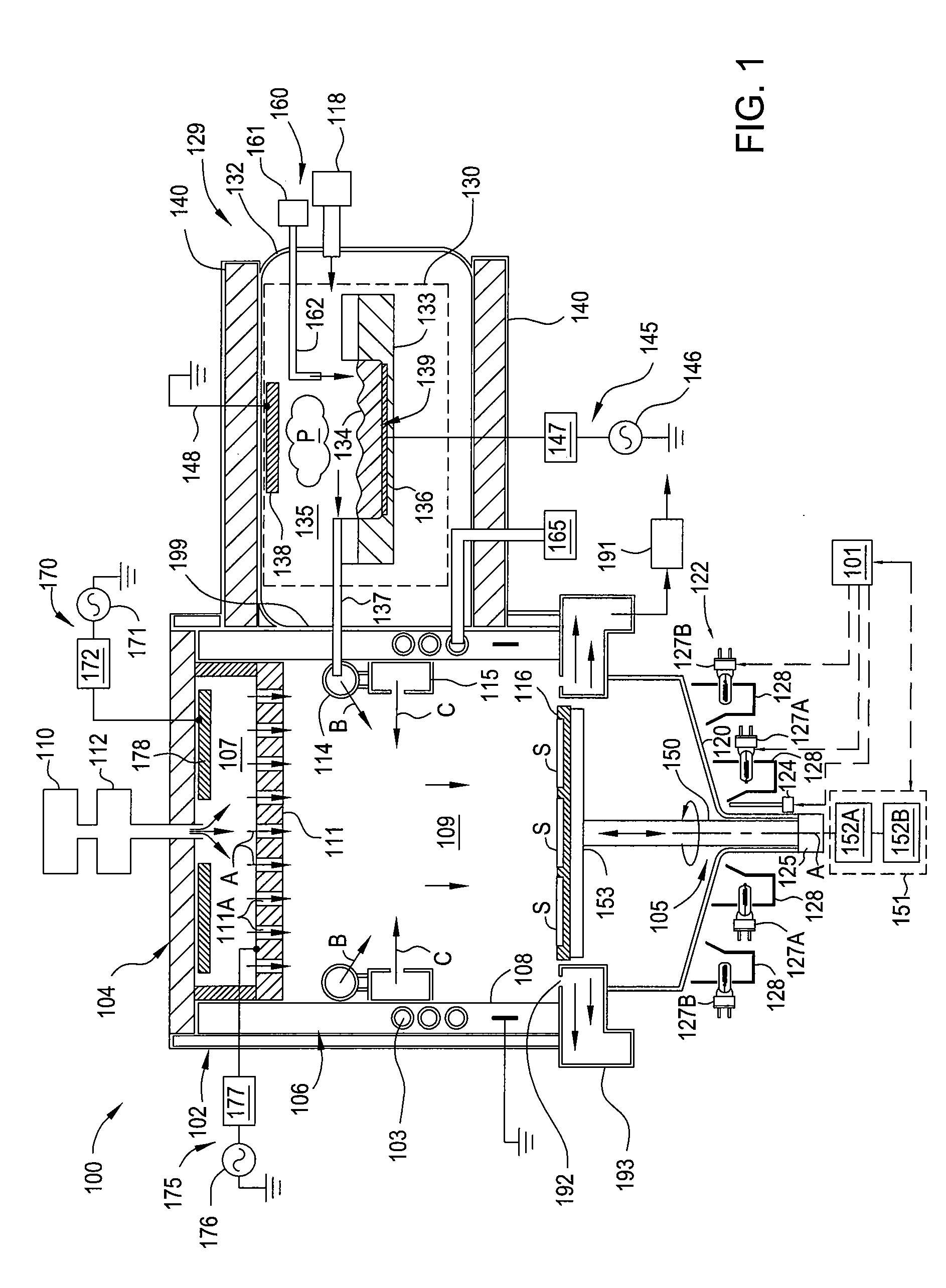

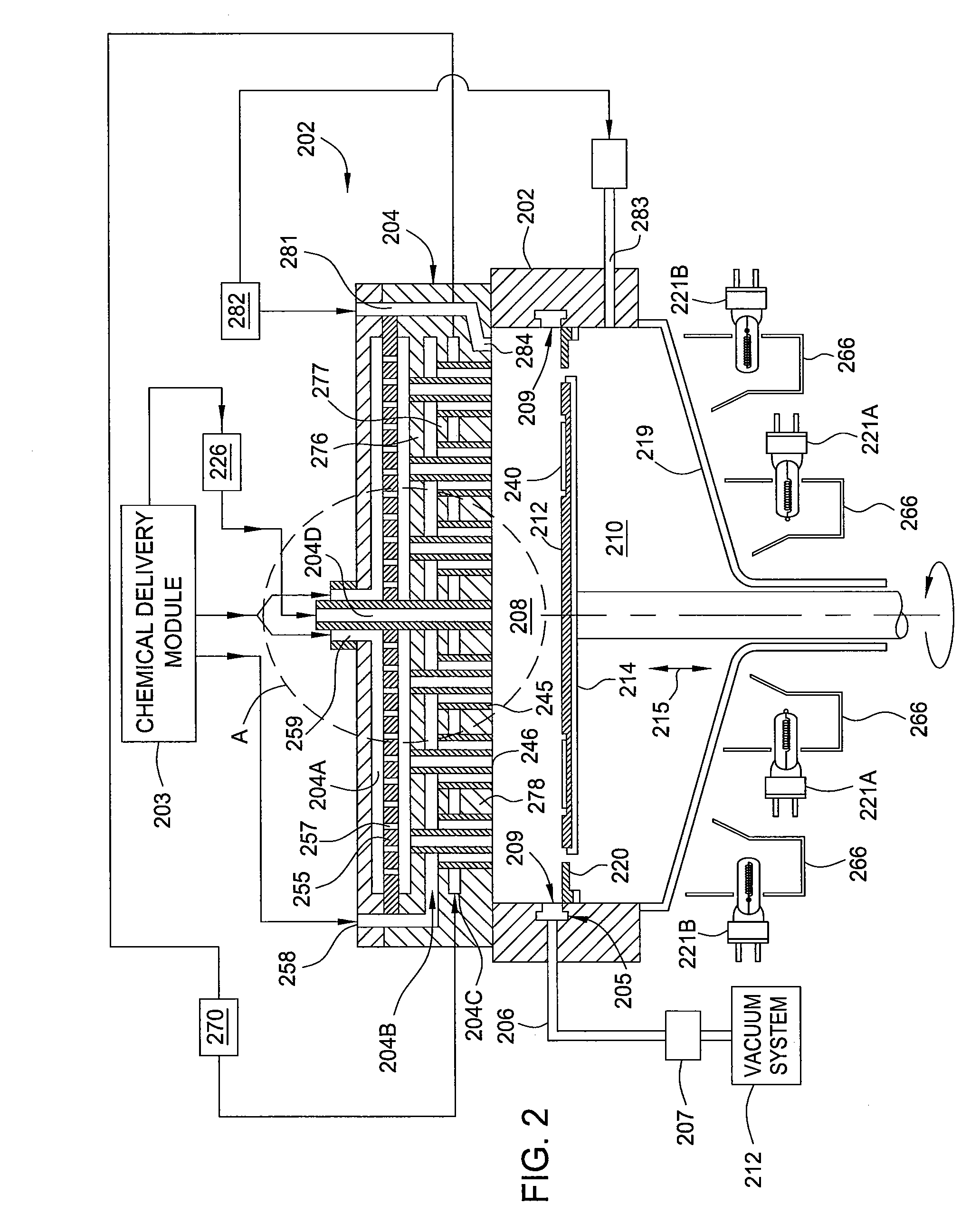

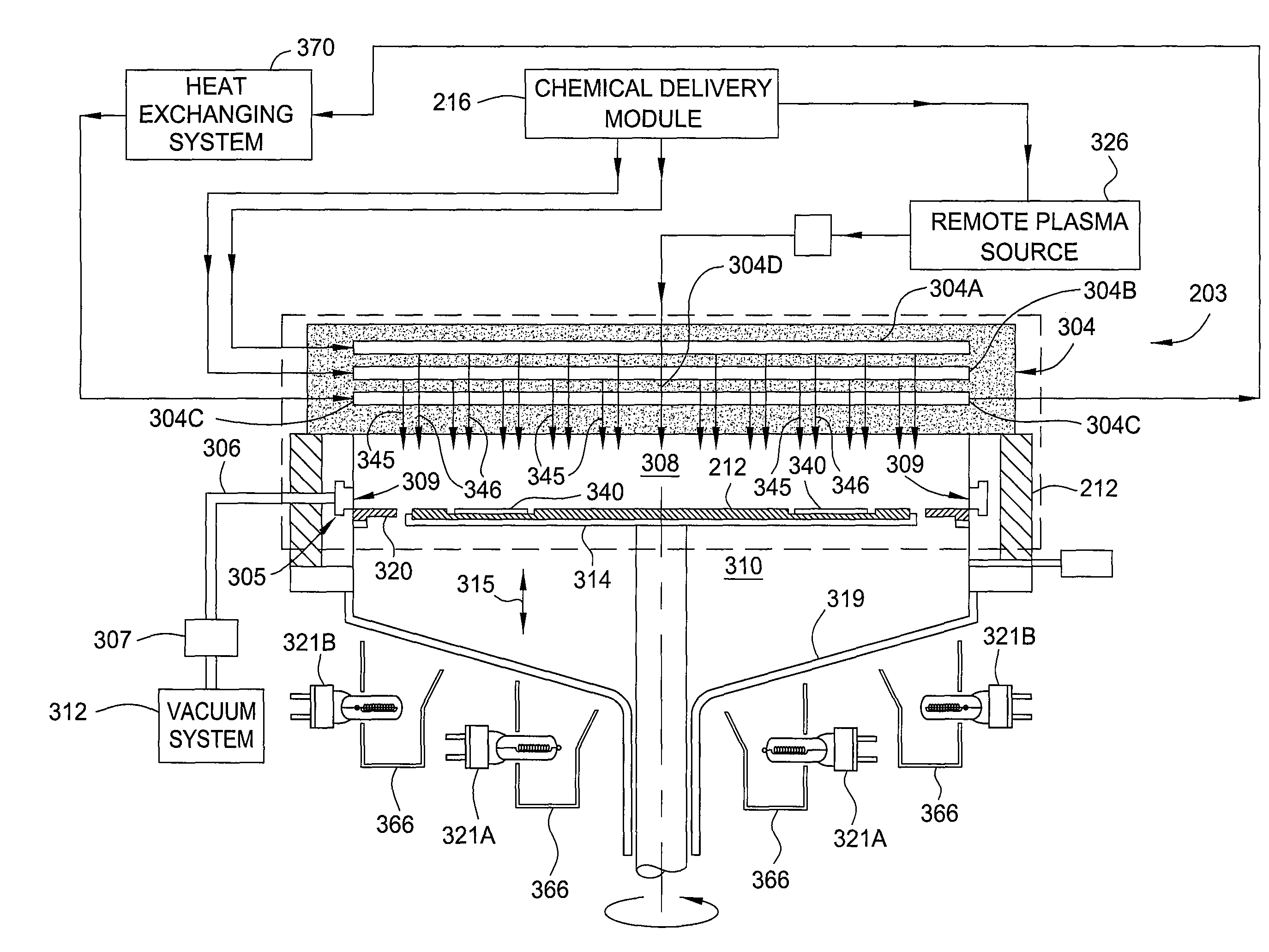

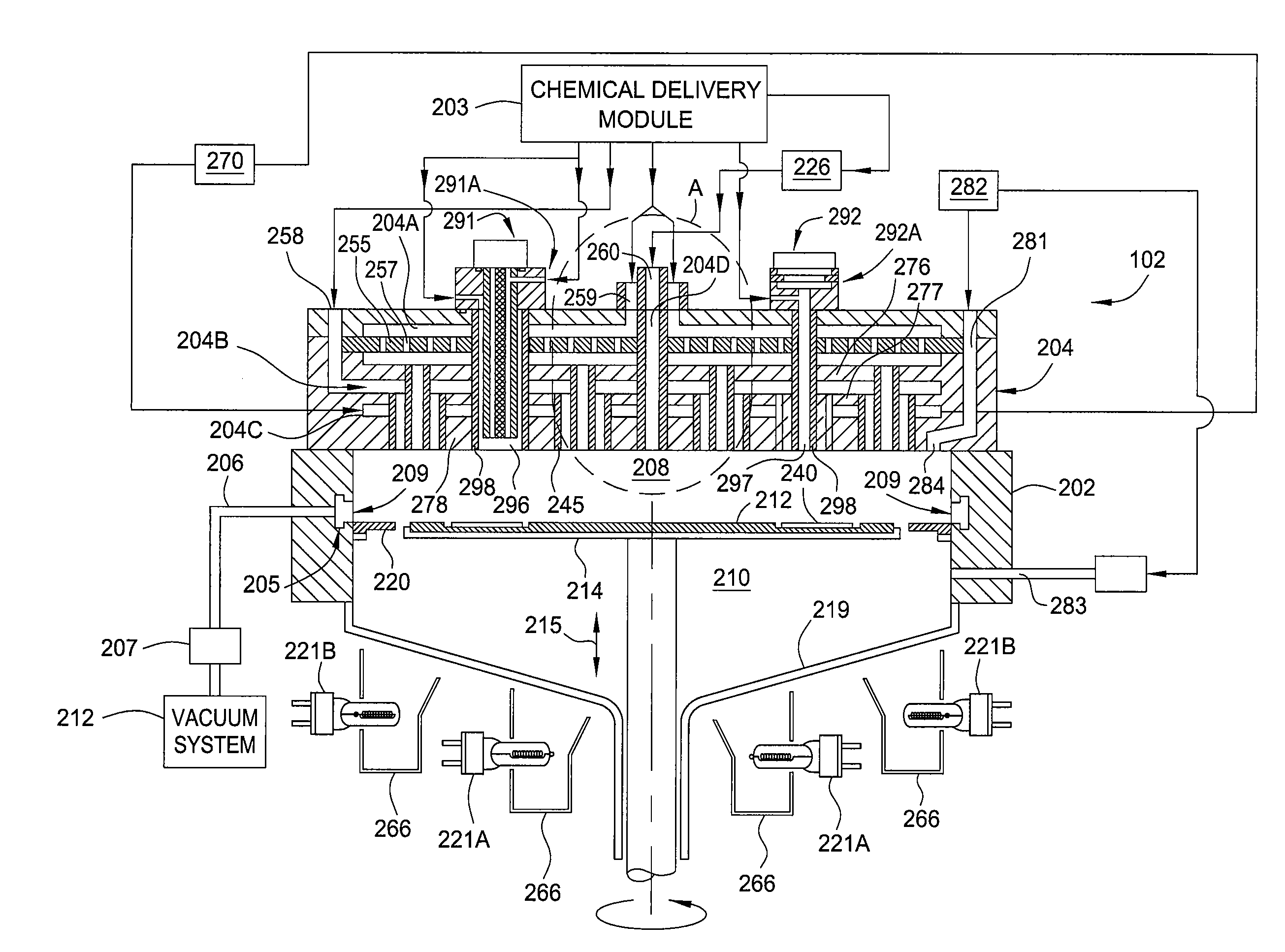

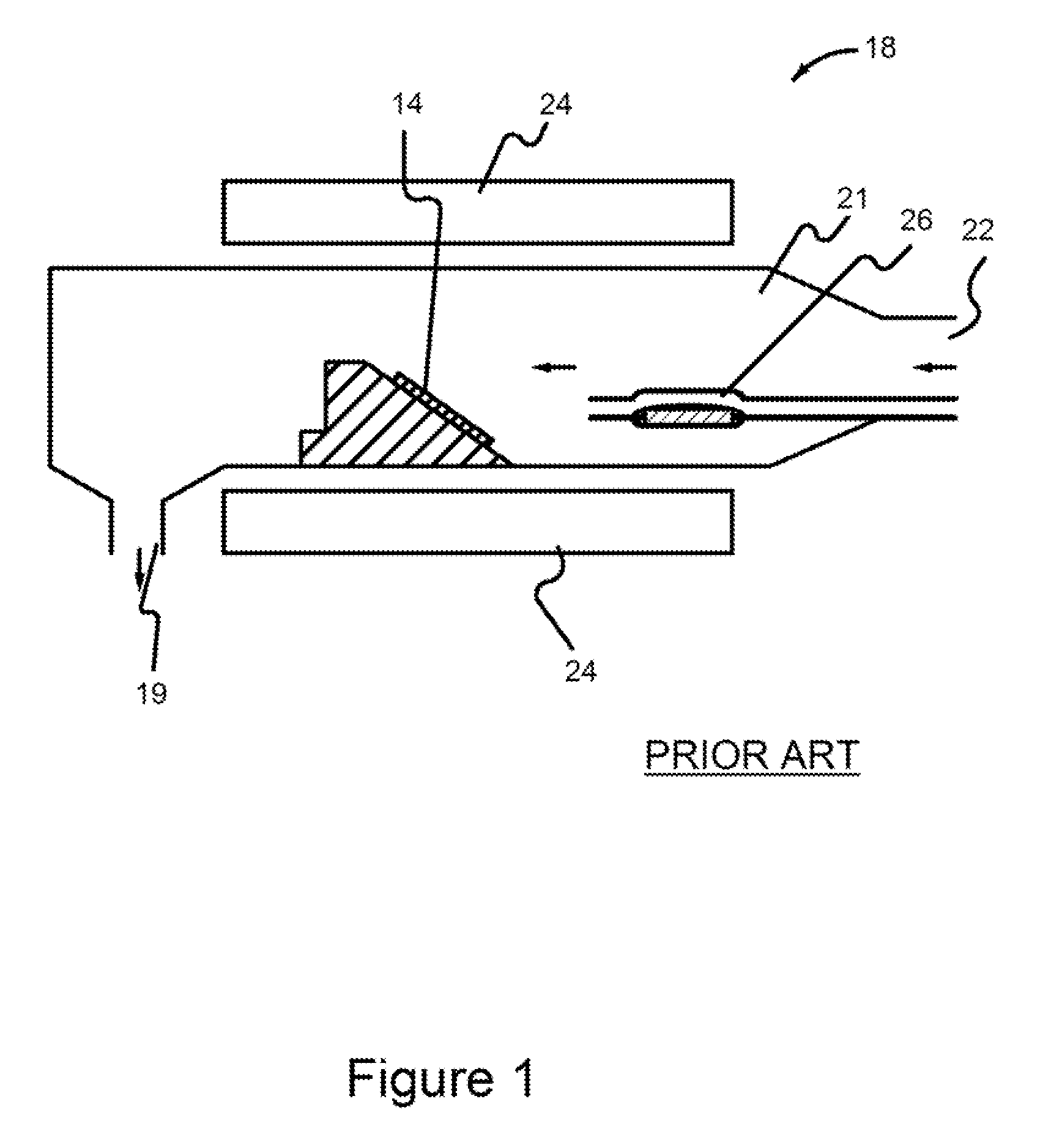

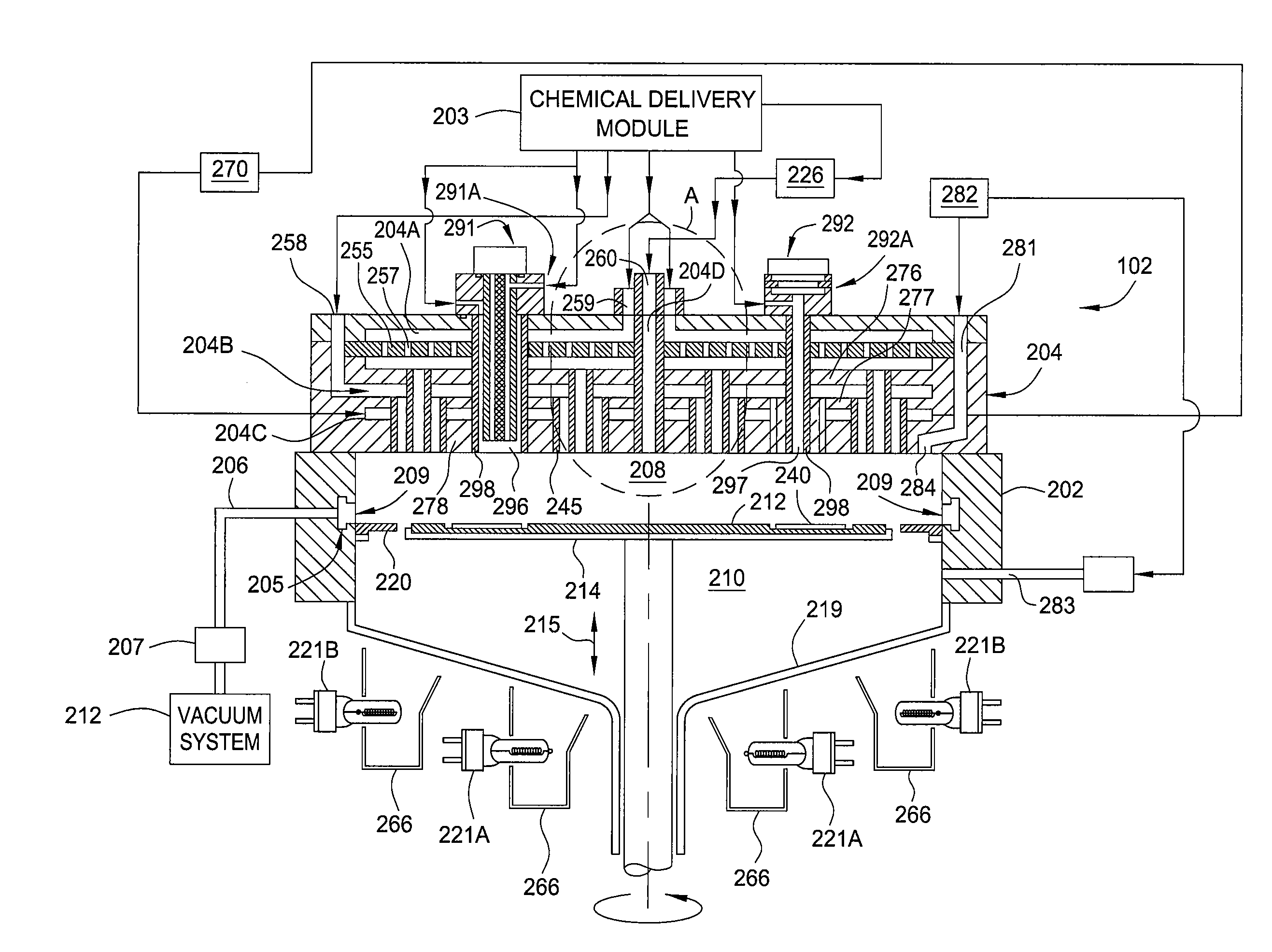

A method and apparatus are provided for monitoring and controlling substrate processing parameters for a cluster tool that utilizes chemical vapor deposition and / or hydride vapor phase epitaxial (HVPE) deposition. In one embodiment, a metal organic chemical vapor deposition (MOCVD) process is used to deposit a Group III-nitride film on a plurality of substrates within a processing chamber. A closed-loop control system performs in-situ monitoring of the Group III-nitride film growth rate and adjusts film growth parameters as required to maintain a target growth rate. In another embodiment, a closed-loop control system performs in-situ monitoring of film growth parameters for multiple processing chambers for one or more film deposition systems.

Owner:APPLIED MATERIALS INC

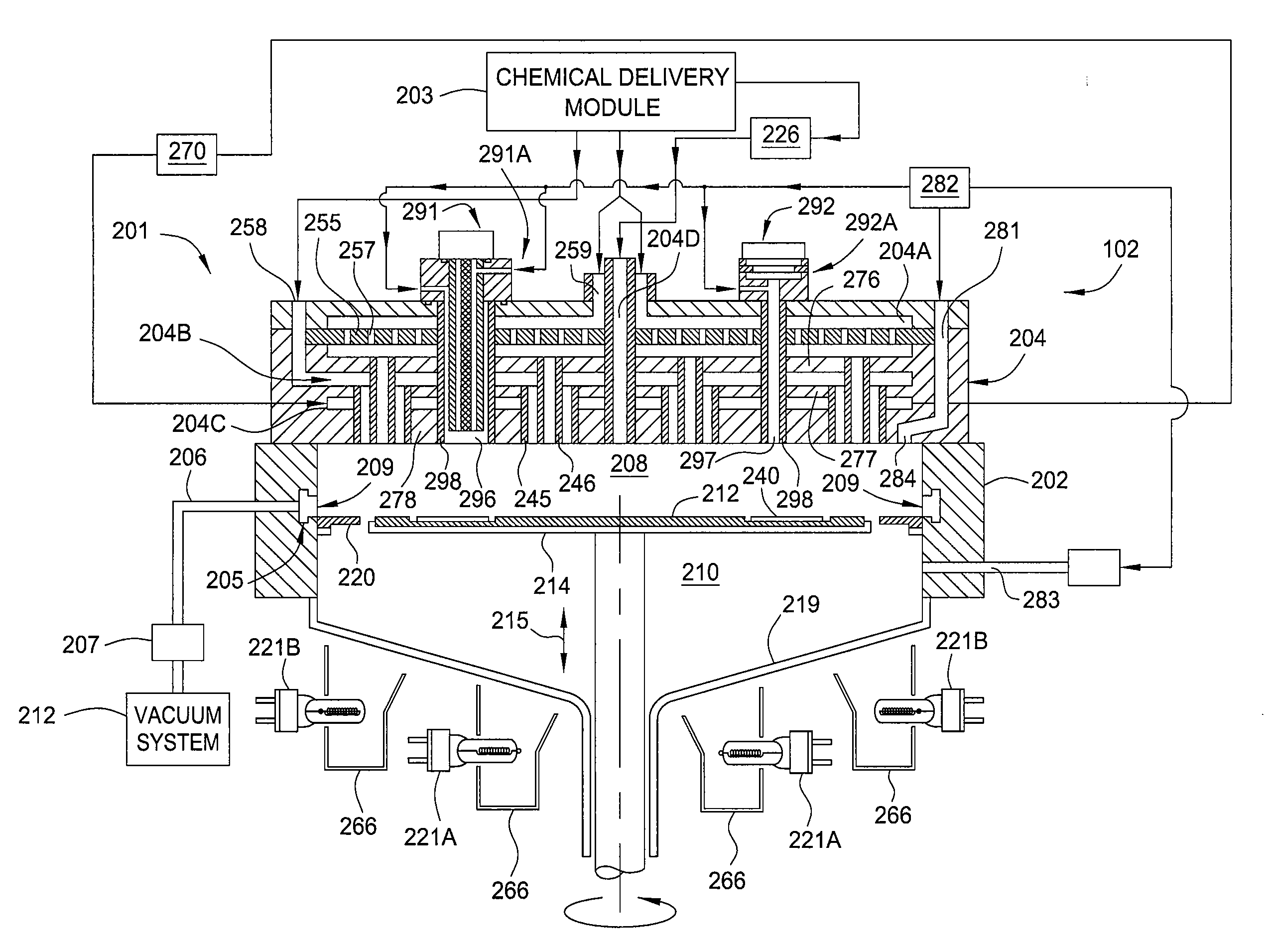

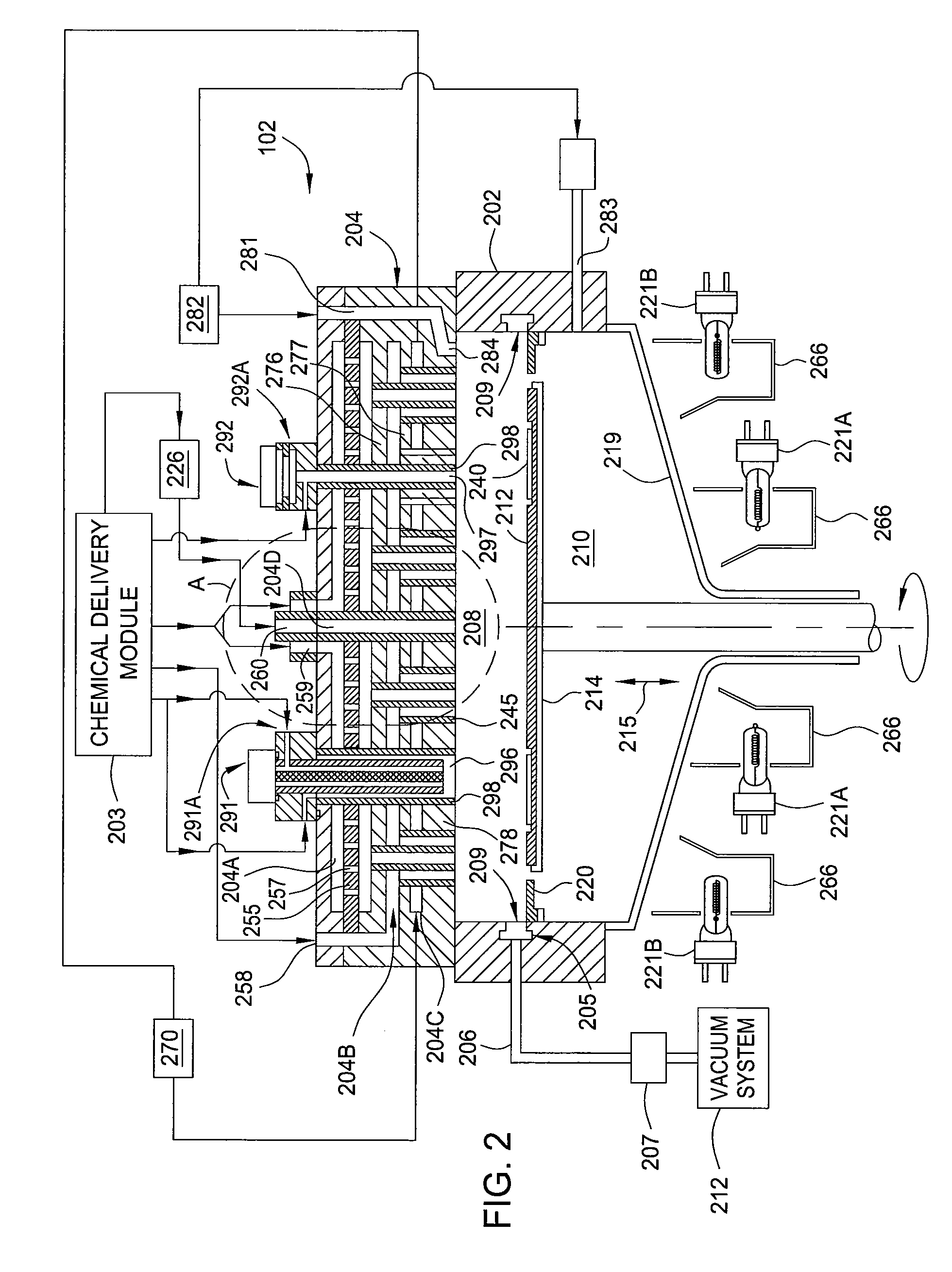

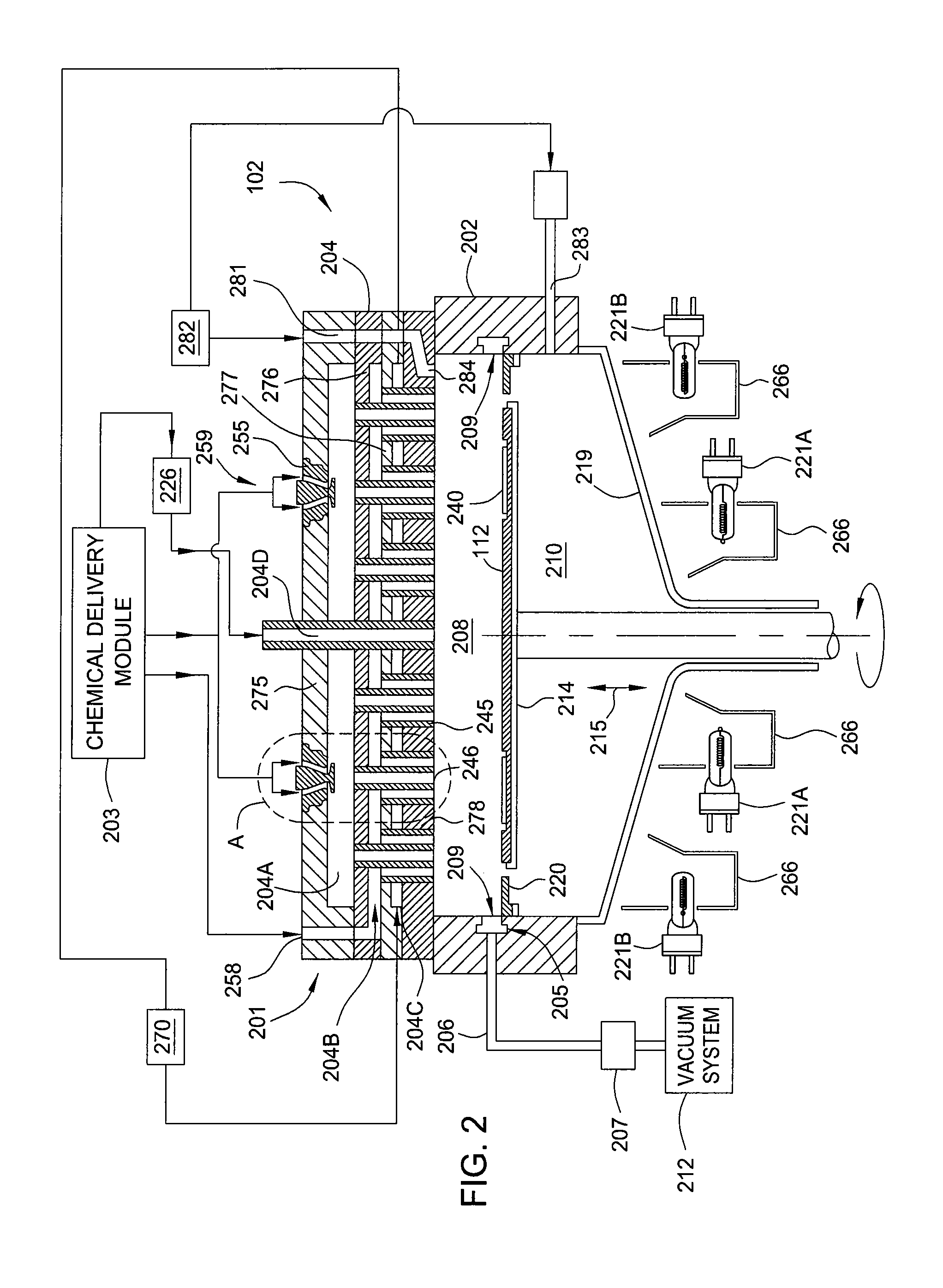

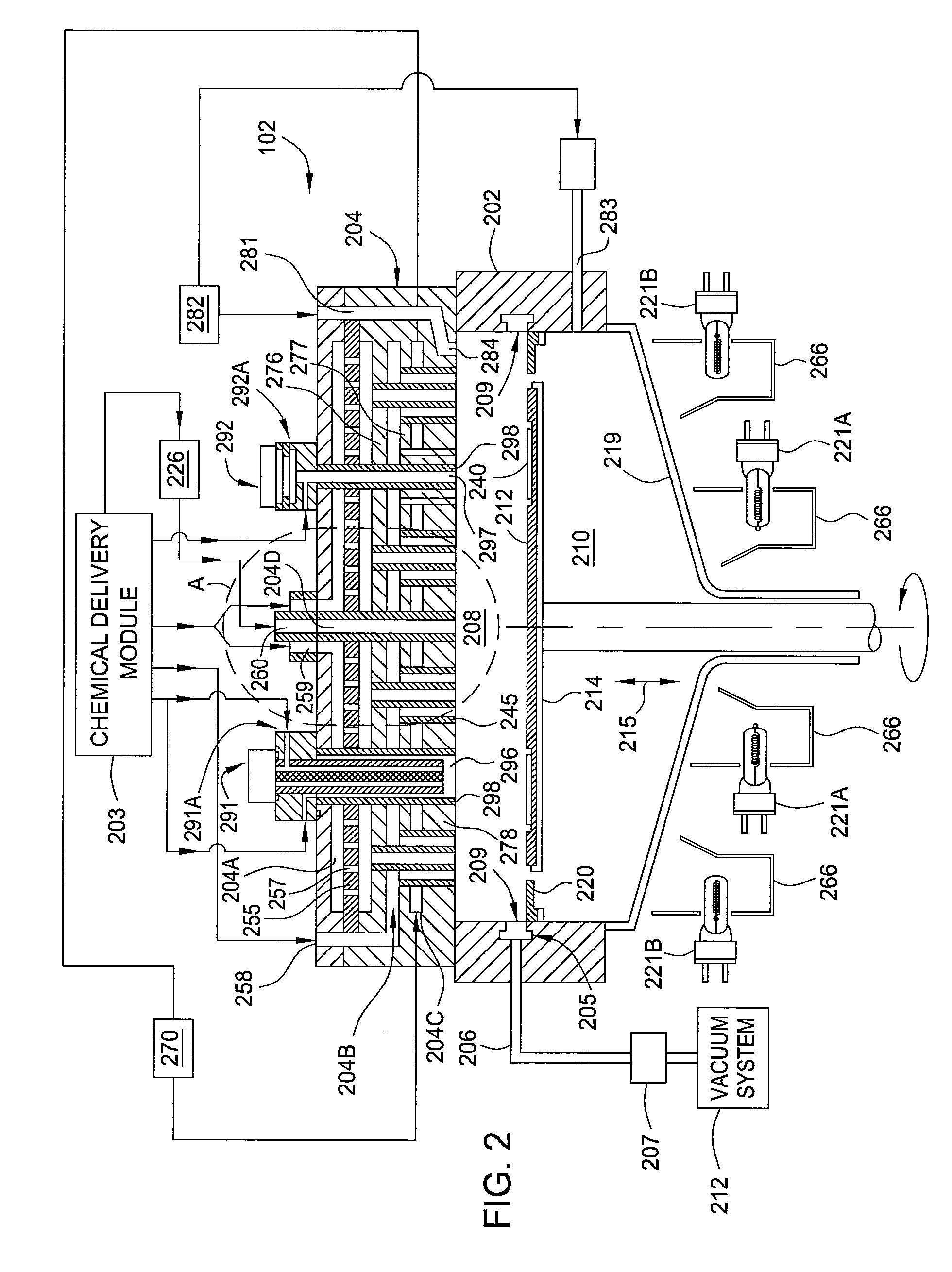

Showerhead assembly with metrology port purge

InactiveUS20110253044A1Avoid depositionLiquid surface applicatorsSpray nozzlesOptical measurementsChemical vapor deposition

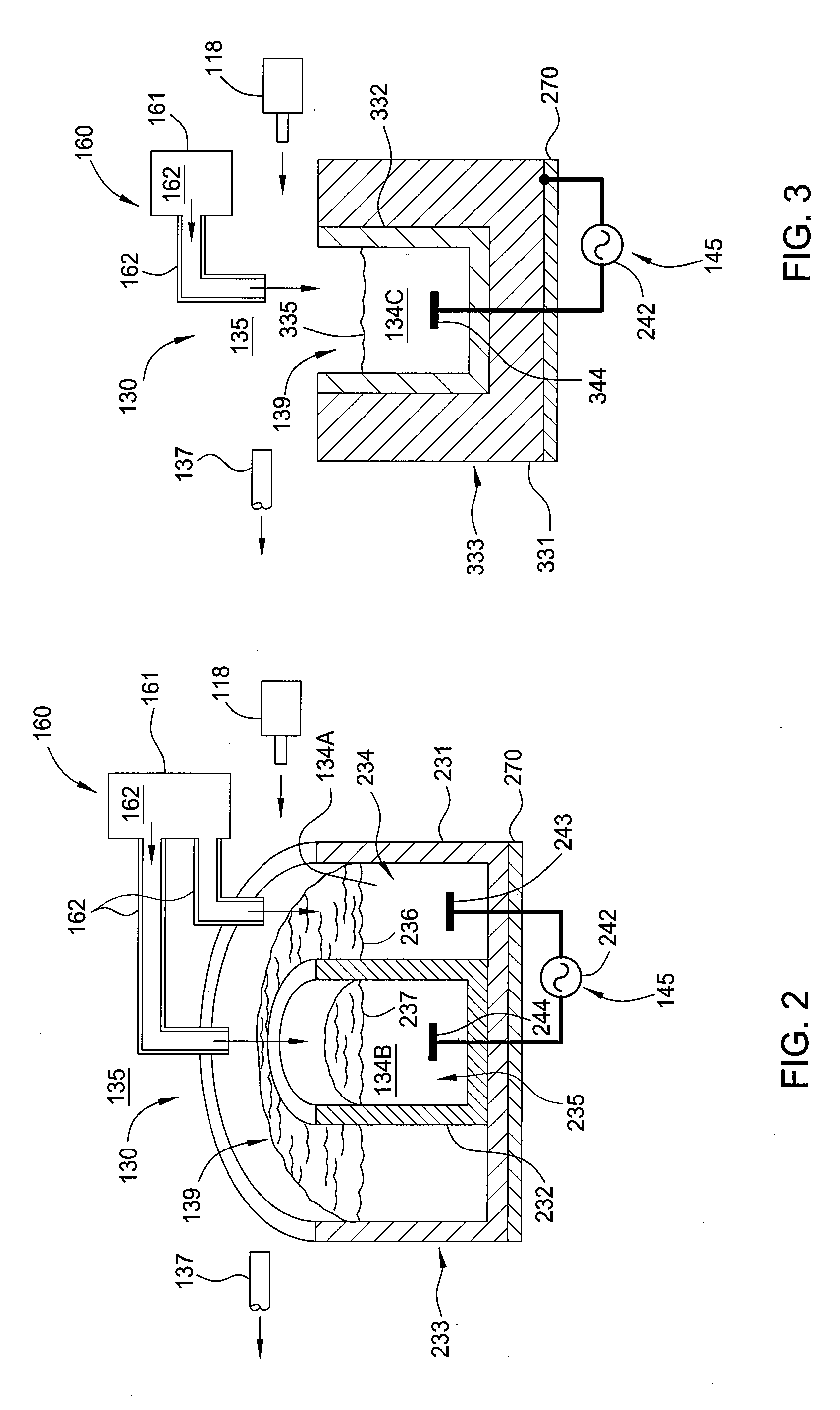

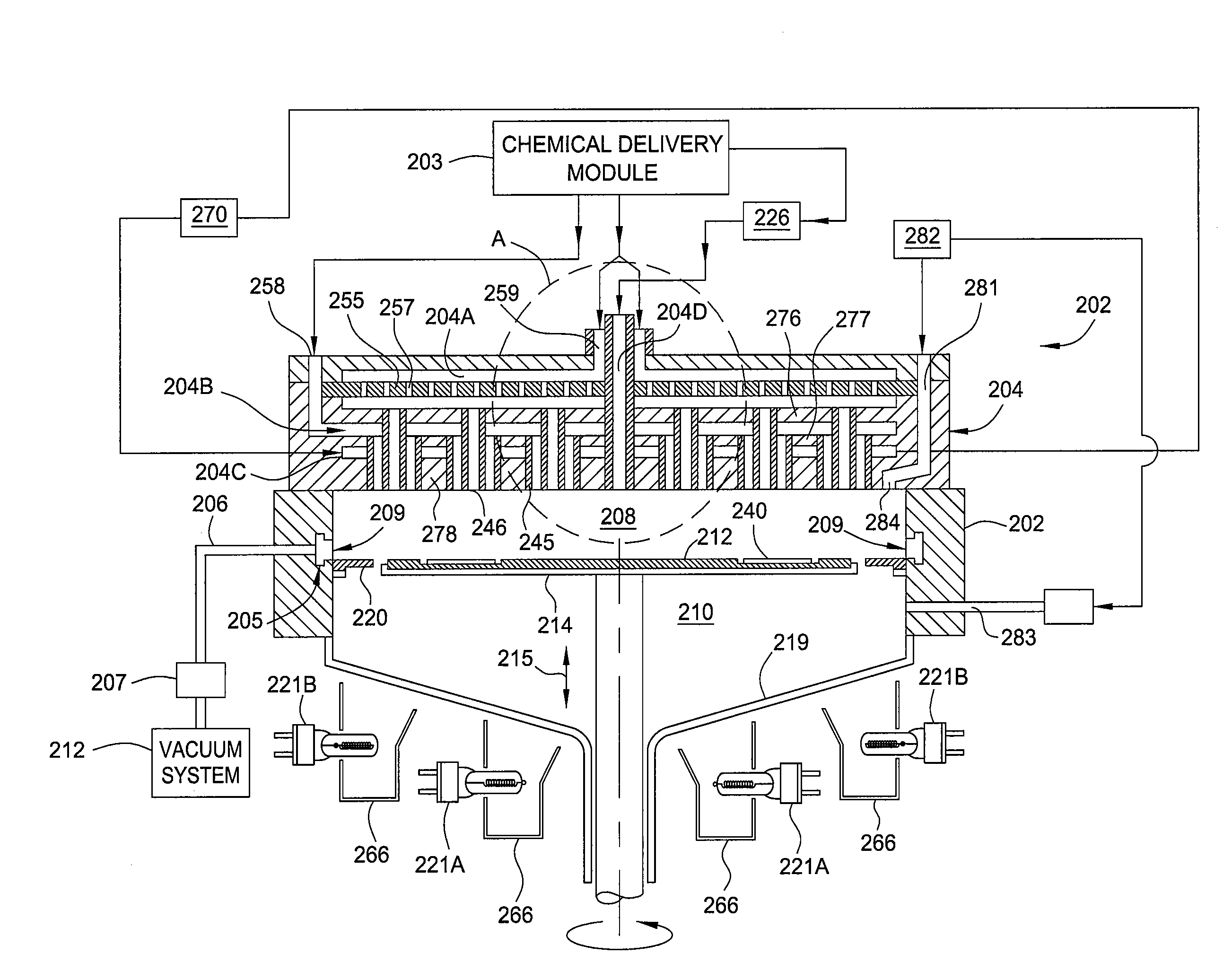

A method and apparatus that may be utilized for chemical vapor deposition and / or hydride vapor phase epitaxial (HVPE) deposition are provided. In one embodiment, the apparatus is a processing chamber that includes a showerhead with separate inlets and channels for delivering separate processing gases into a processing volume of the chamber without mixing the gases prior to entering the processing volume. In one embodiment, the showerhead includes metrology ports with purge gas assemblies configured and positioned to deliver a purge gas to prevent deposition thereon. In one embodiment, the metrology port is configured to receive a temperature measurement device, and the purge gas assembly is a concentric tube configuration configured to prevent deposition on components of the temperature measurement device. In one embodiment, the metrology port has a sensor window and is configured to receive an optical measurement device, and the purge gas assembly and sensor window are configured to prevent deposition on the sensor window.

Owner:APPLIED MATERIALS INC

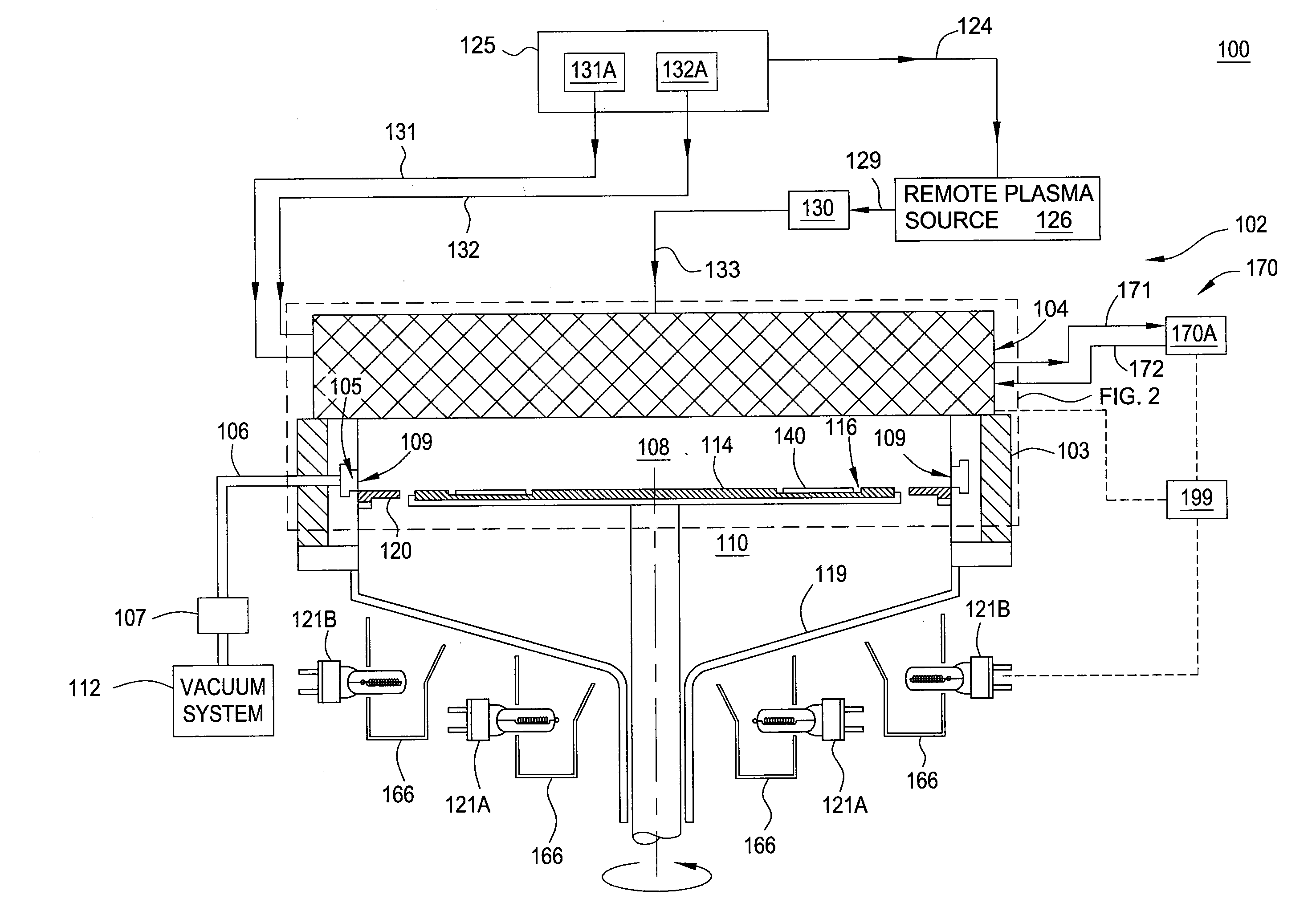

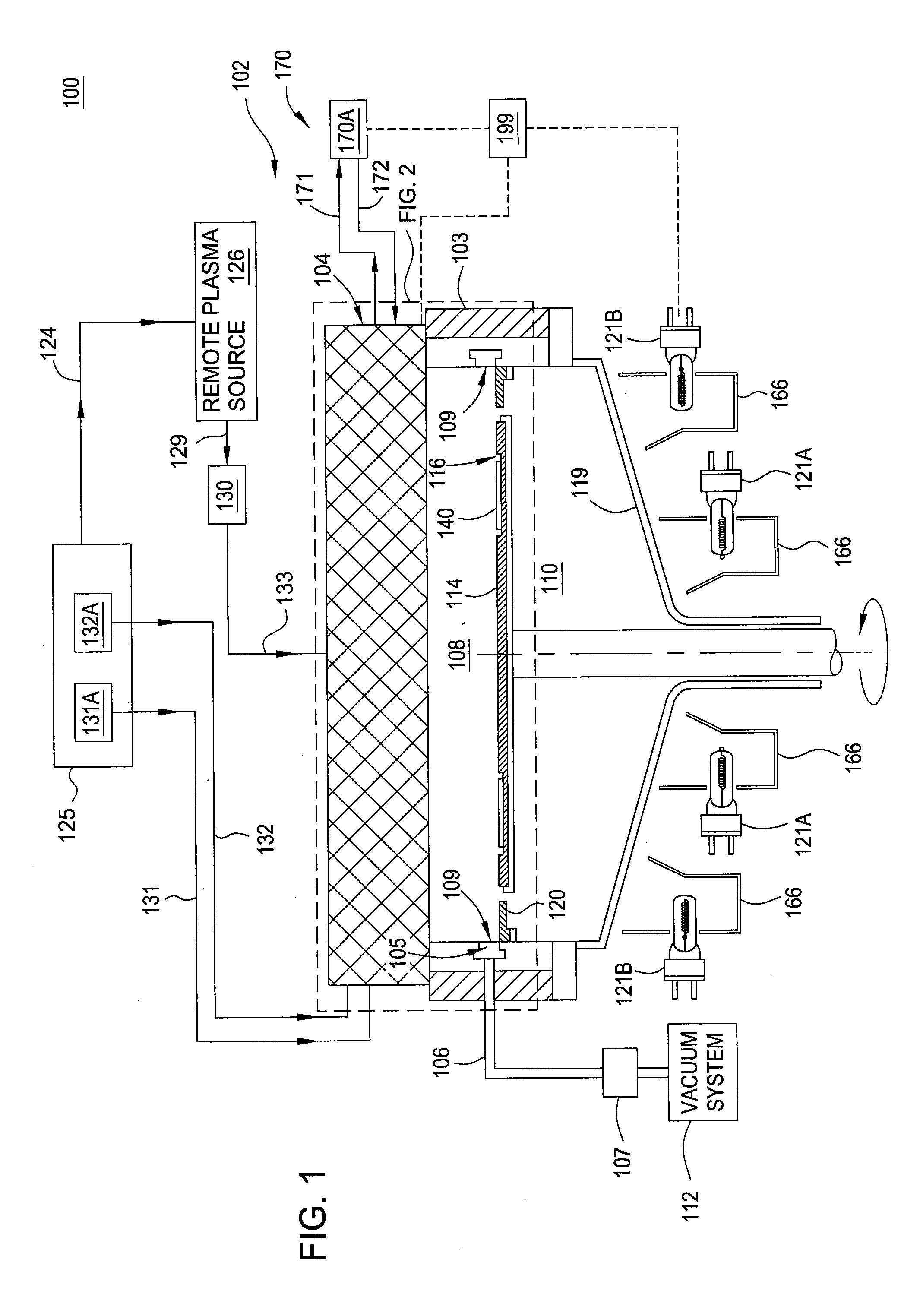

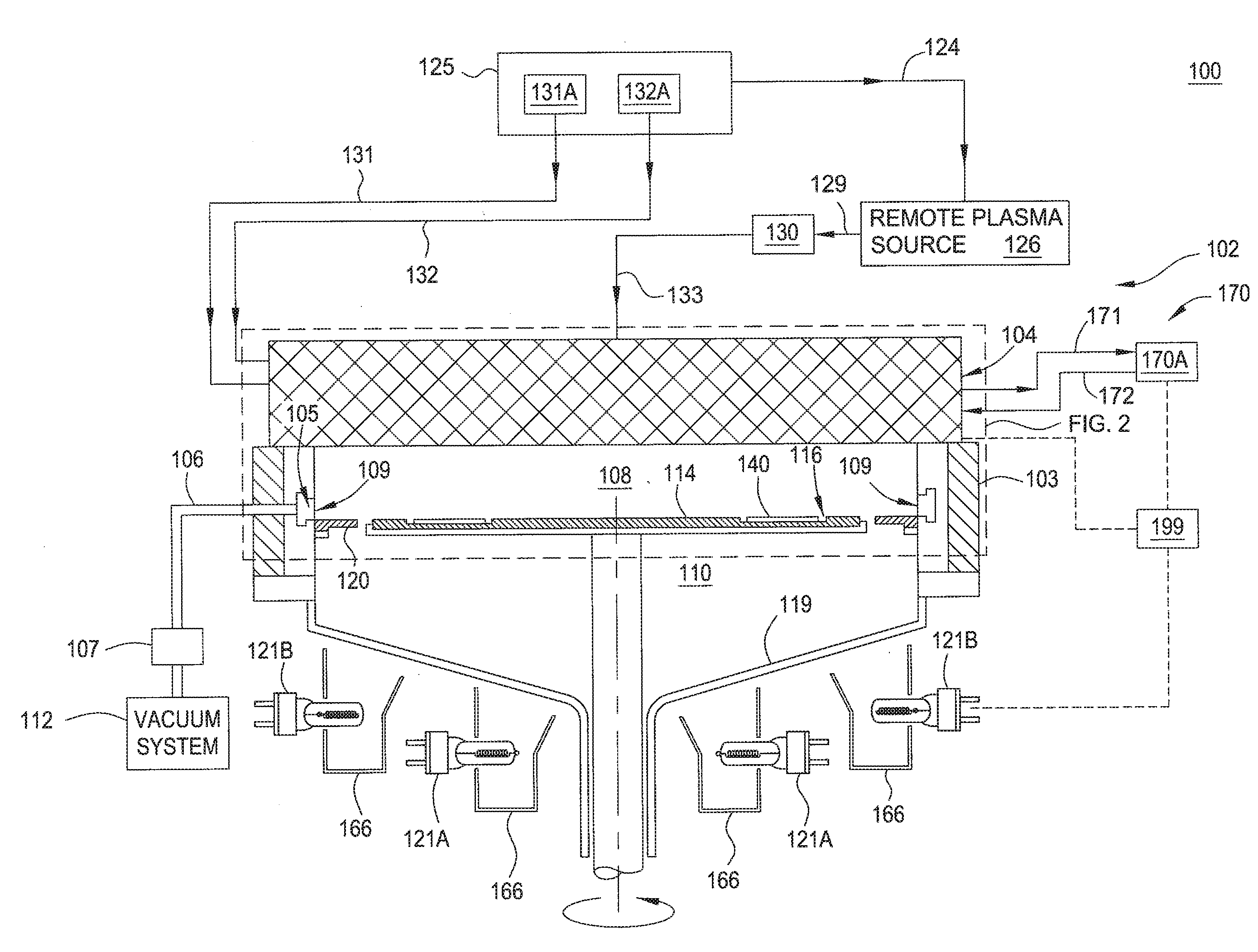

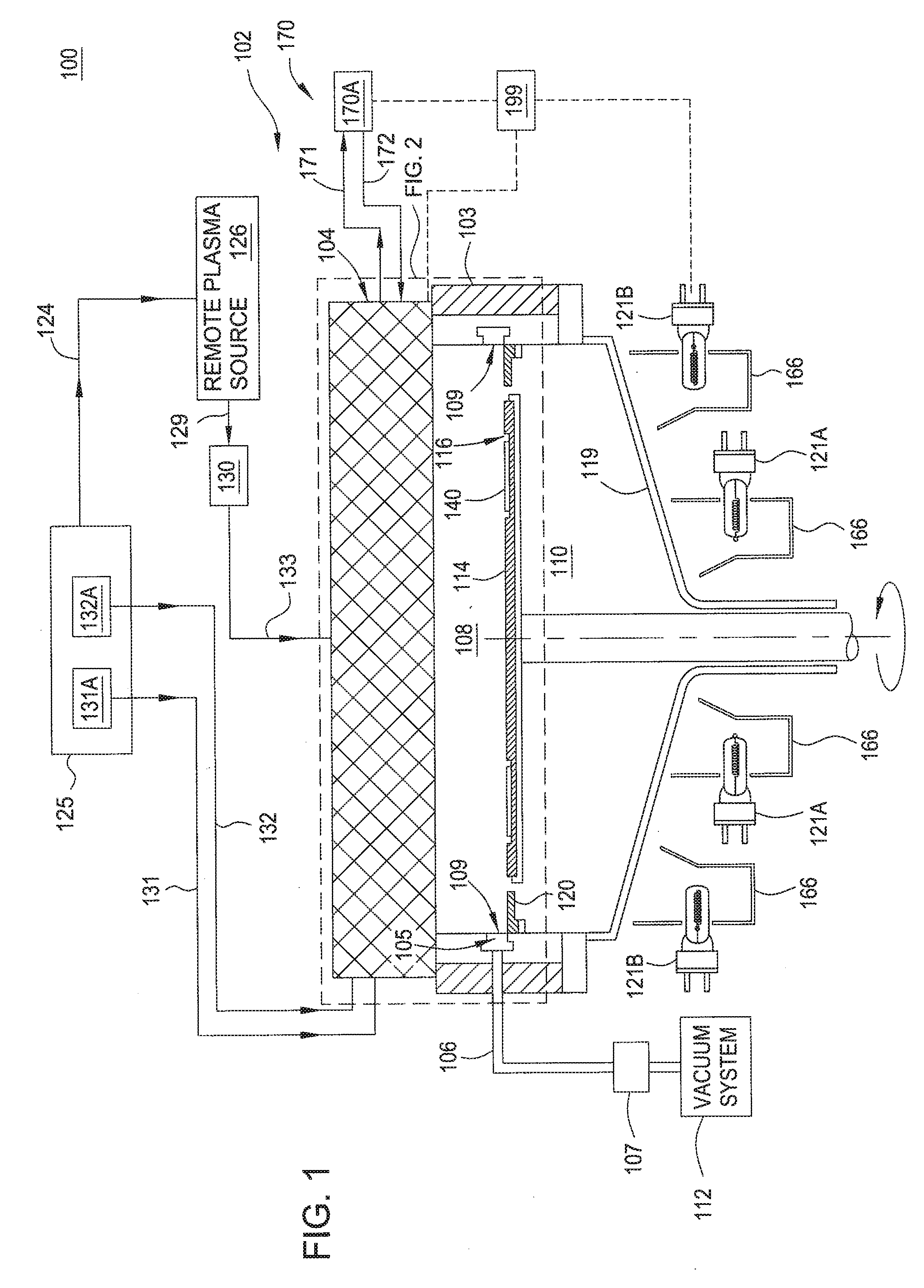

Plasma assisted hvpe chamber design

InactiveUS20130032085A1Enhance deposition reaction kineticsReduce processing timePolycrystalline material growthFrom chemically reactive gasesNitrogenVapor phase

Embodiments of the invention disclosed herein generally relate to a hydride vapor phase epitaxy (HVPE) deposition chamber that utilizes a plasma generation apparatus to form an activated precursor gas that is used to rapidly form a high quality compound nitride layer on a surface of a substrate. In one embodiment, the plasma generation apparatus is used to create a desirable group-III metal halide precursor gas that can enhance the deposition reaction kinetics, and thus reduce the processing time and improve the film quality of a formed group-III metal nitride layer. In addition, the chamber may be equipped with a separate nitrogen containing precursor activated species generator to enhance the activity of the delivered nitrogen precursor gases.

Owner:APPLIED MATERIALS INC

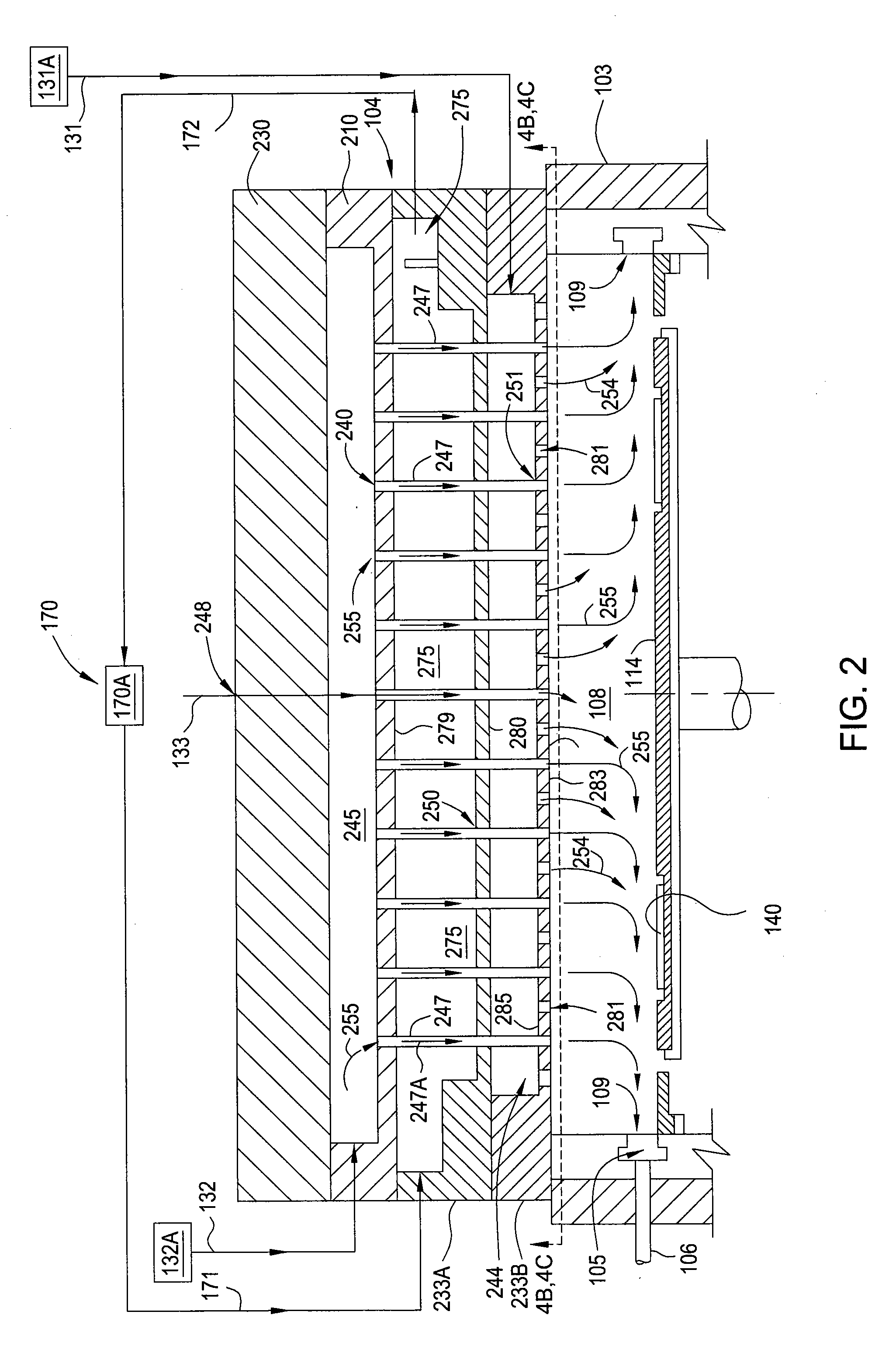

Multiple precursor concentric delivery showerhead

InactiveUS20110256692A1Simple methodSpray nozzlesSemiconductor/solid-state device manufacturingChemical vapor depositionVapor phase

A method and apparatus that may be utilized for chemical vapor deposition and / or hydride vapor phase epitaxial (HVPE) deposition are provided. In one embodiment, the apparatus provides a processing chamber that includes a showerhead with separate inlets and channels for delivering separate processing gases into a processing volume of the chamber without mixing the gases prior to entering the processing volume. In one embodiment, a plurality of concentric tube assemblies are disposed within the showerhead to separately deliver a first gas from a first gas channel and a second gas from a second gas channel into the processing volume of the chamber. In one embodiment, the showerhead further includes a heat exchanging channel through which the plurality of concentric tube assemblies is disposed.

Owner:APPLIED MATERIALS INC

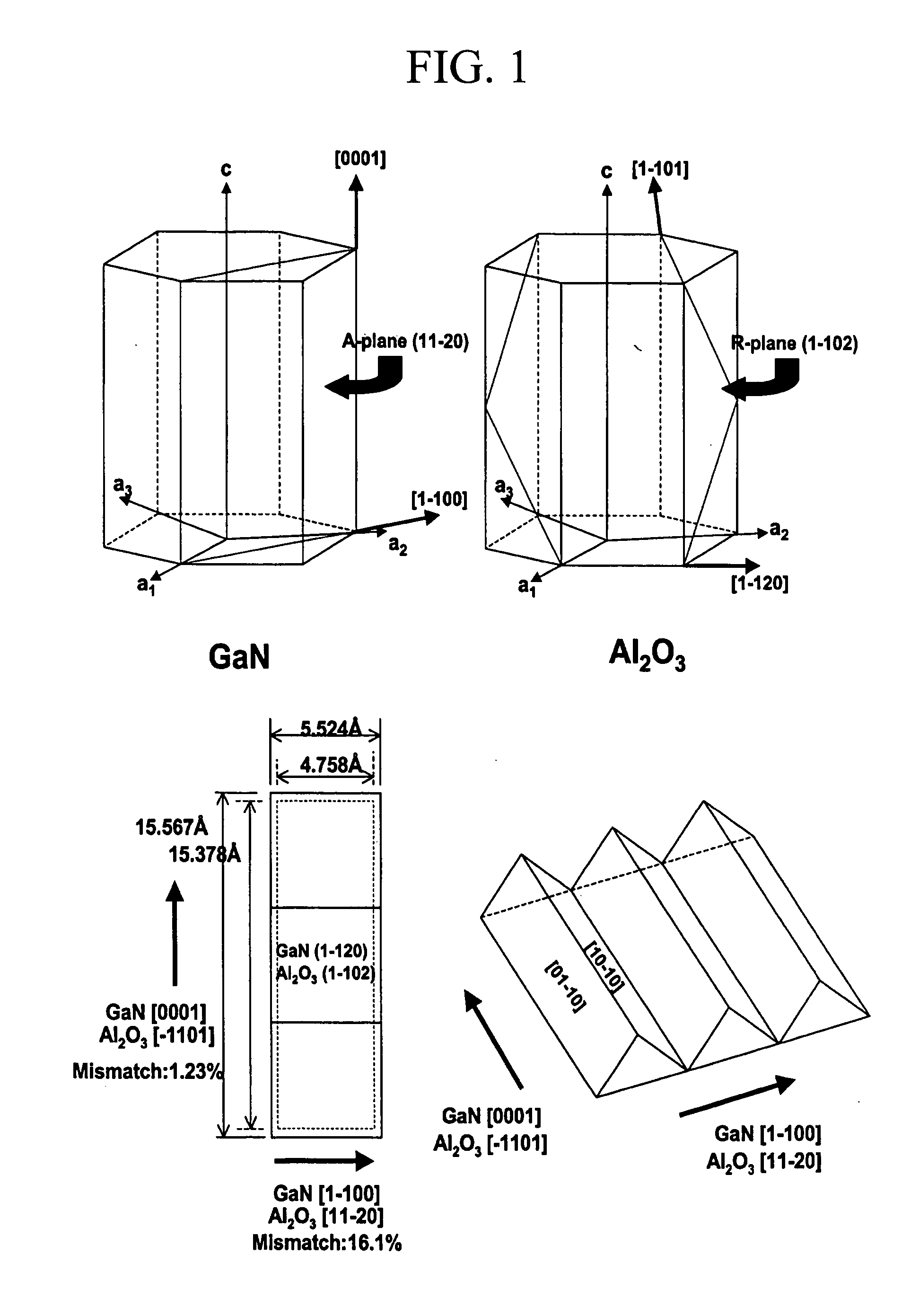

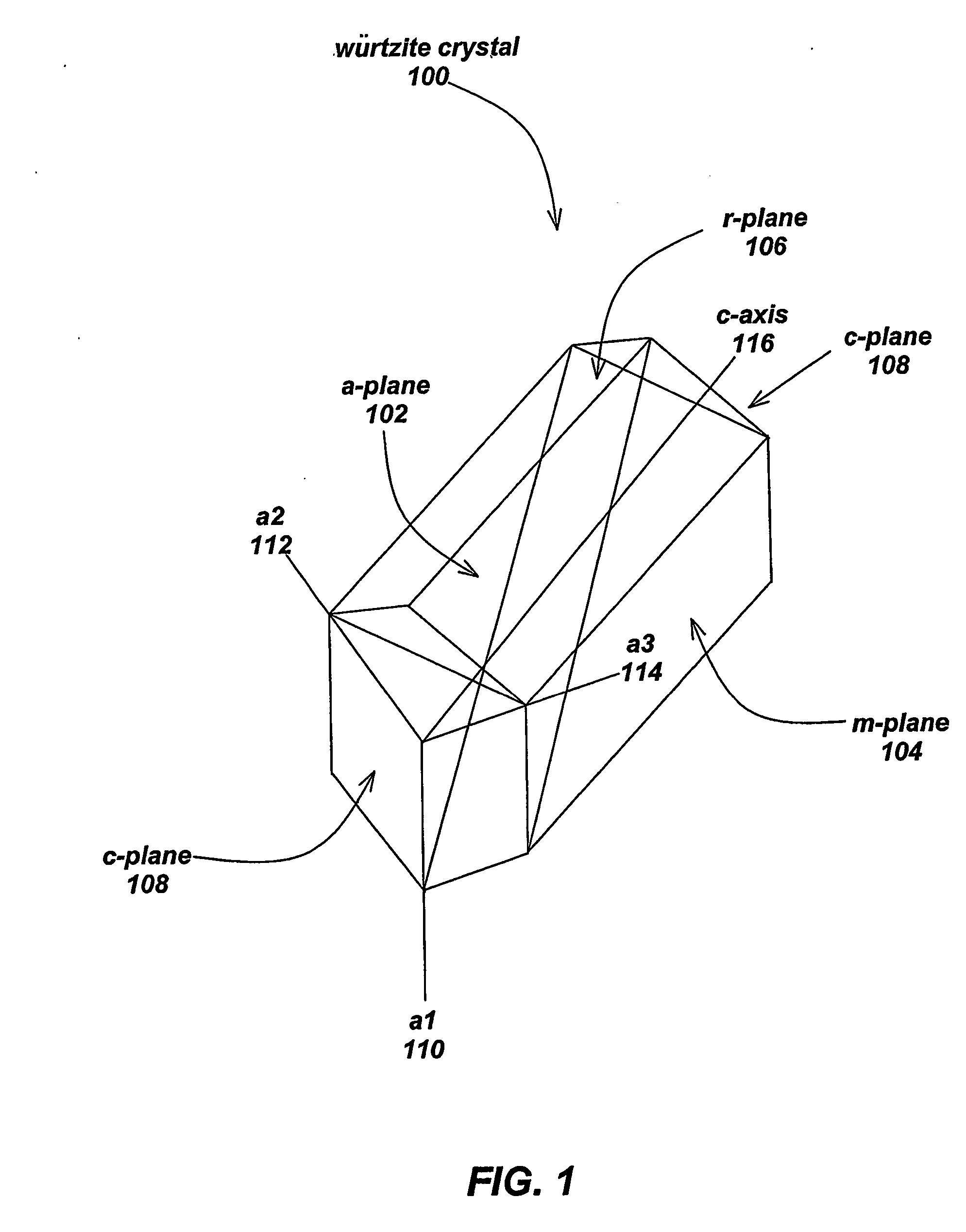

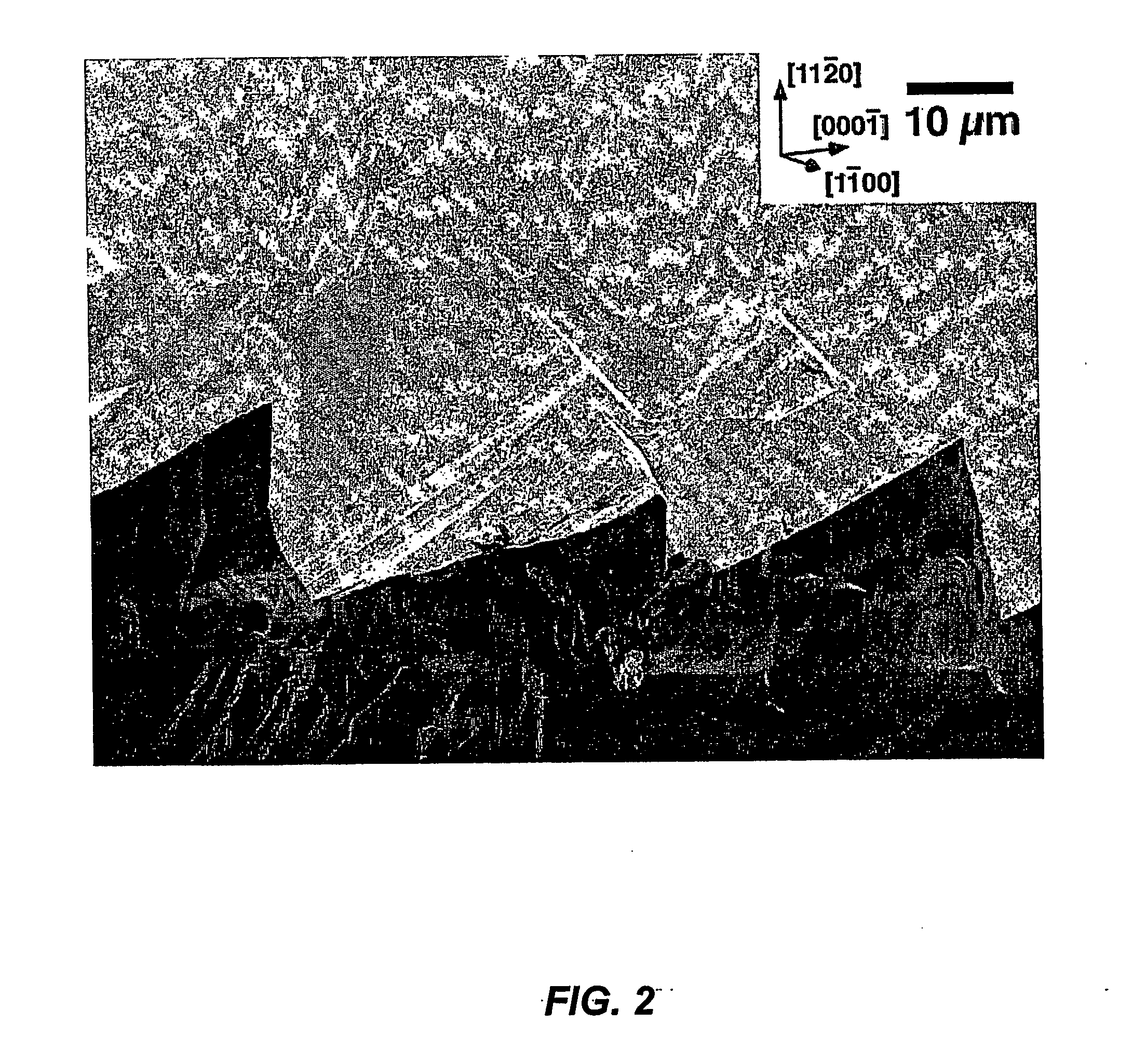

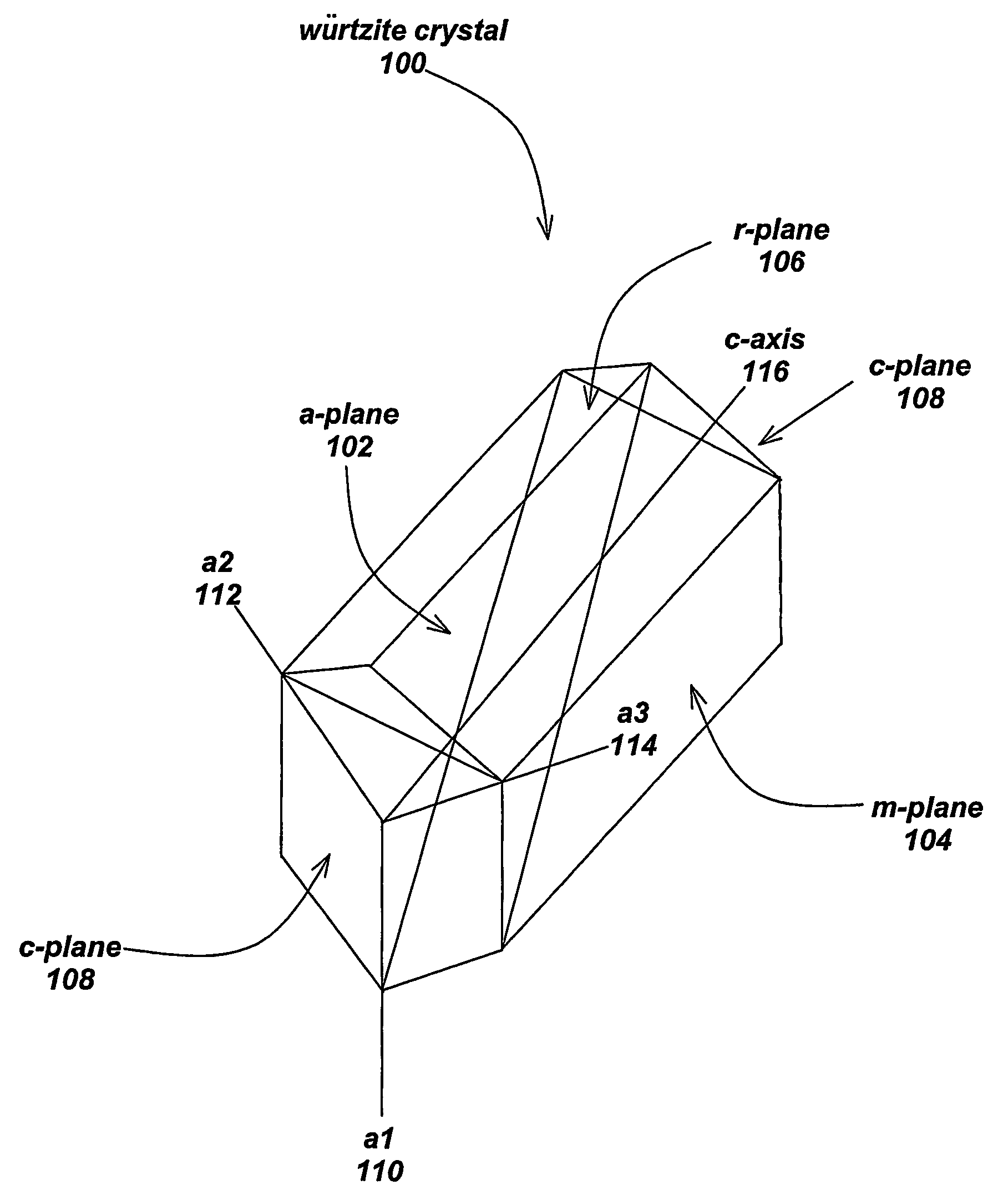

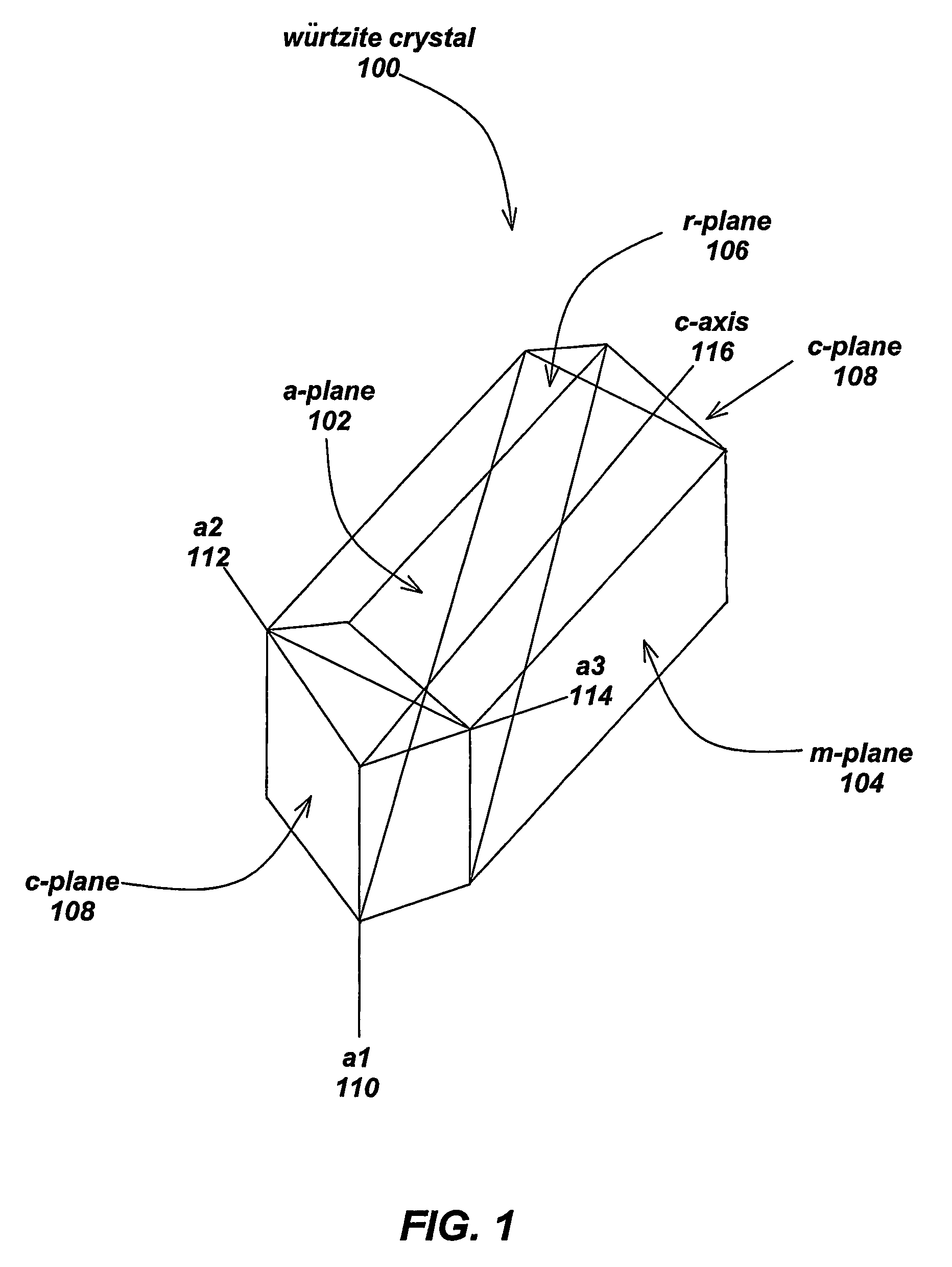

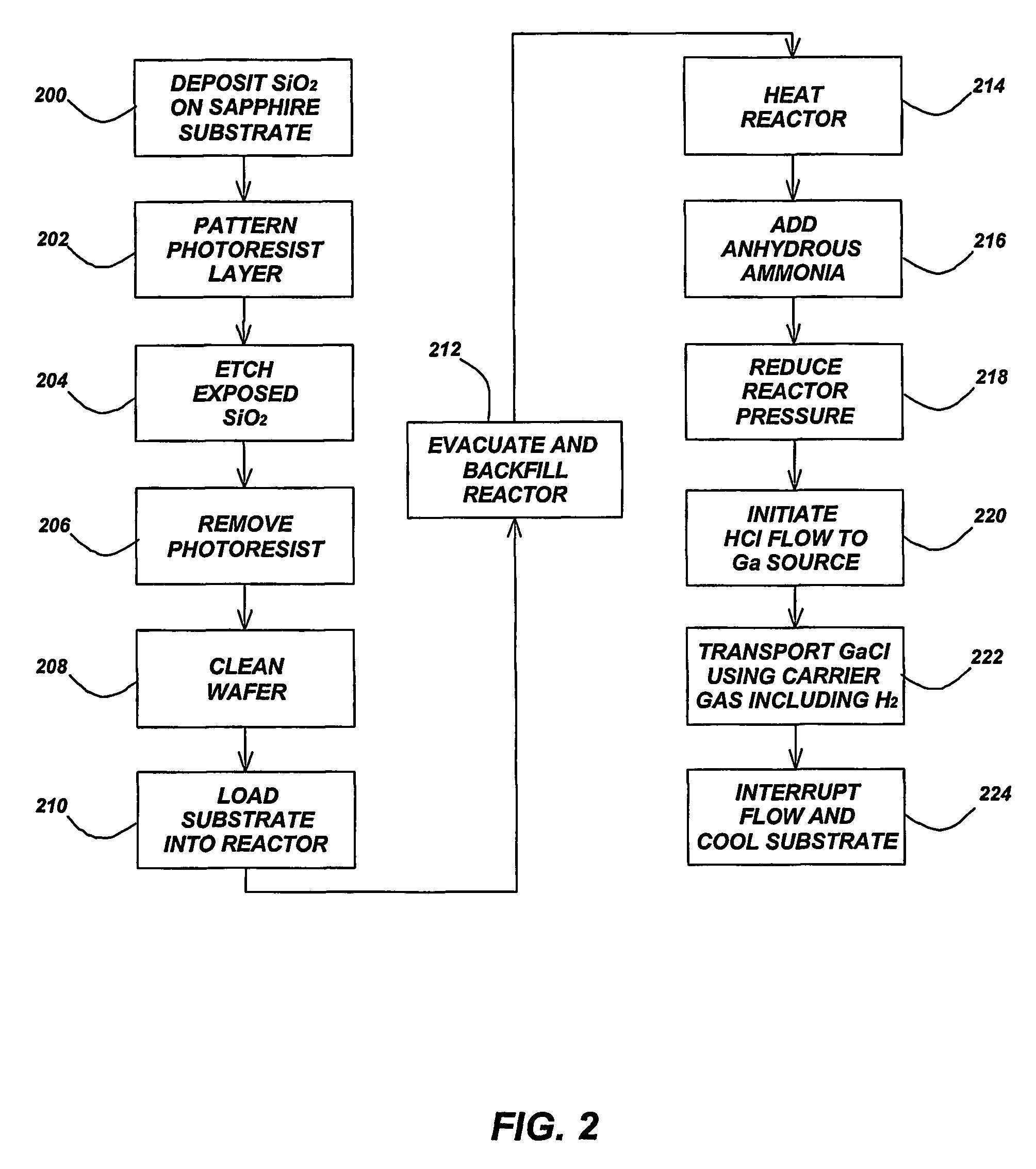

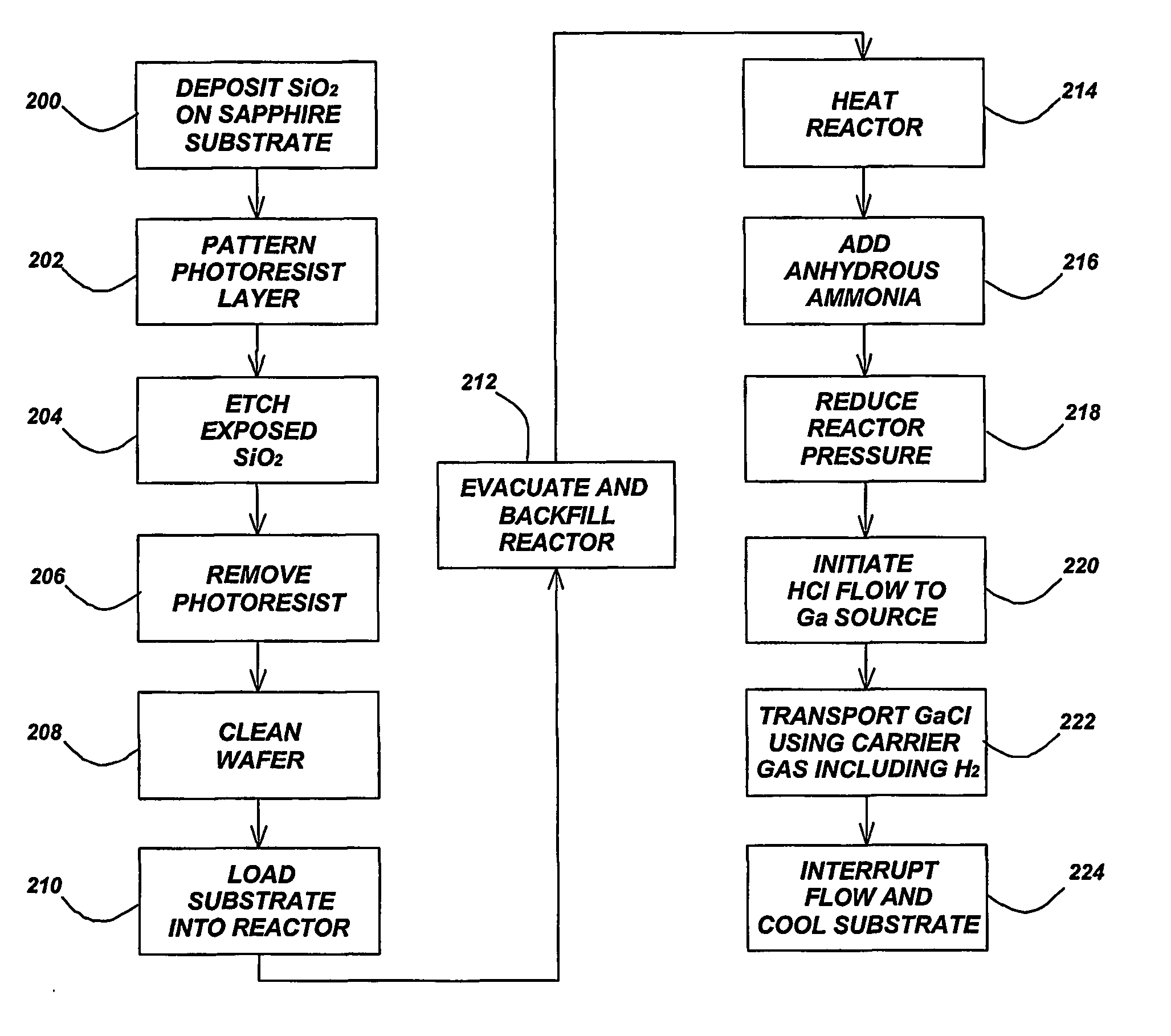

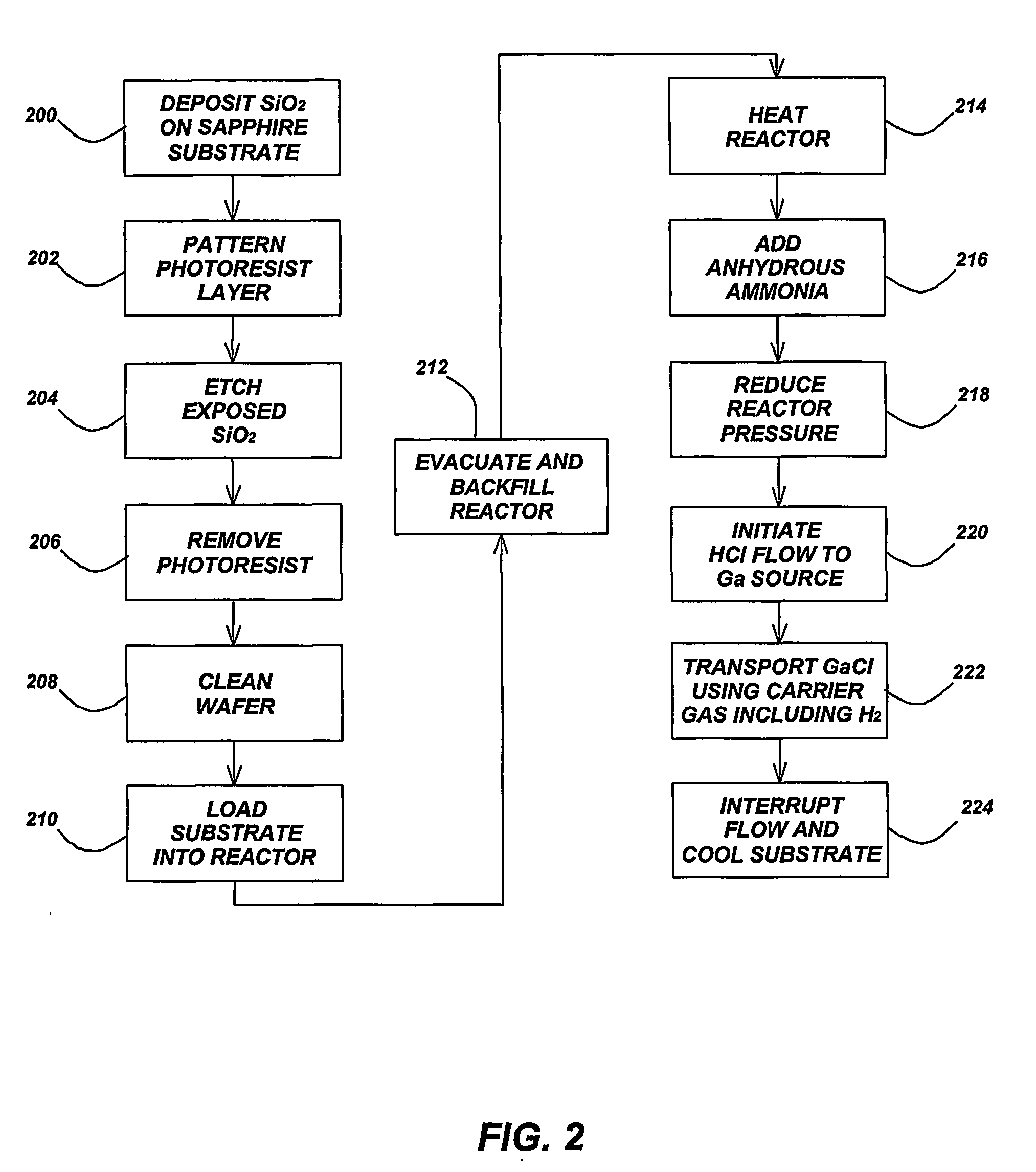

Growth of planar reduced dislocation density m-plane gallium nitride by hydride vapor phase epitaxy

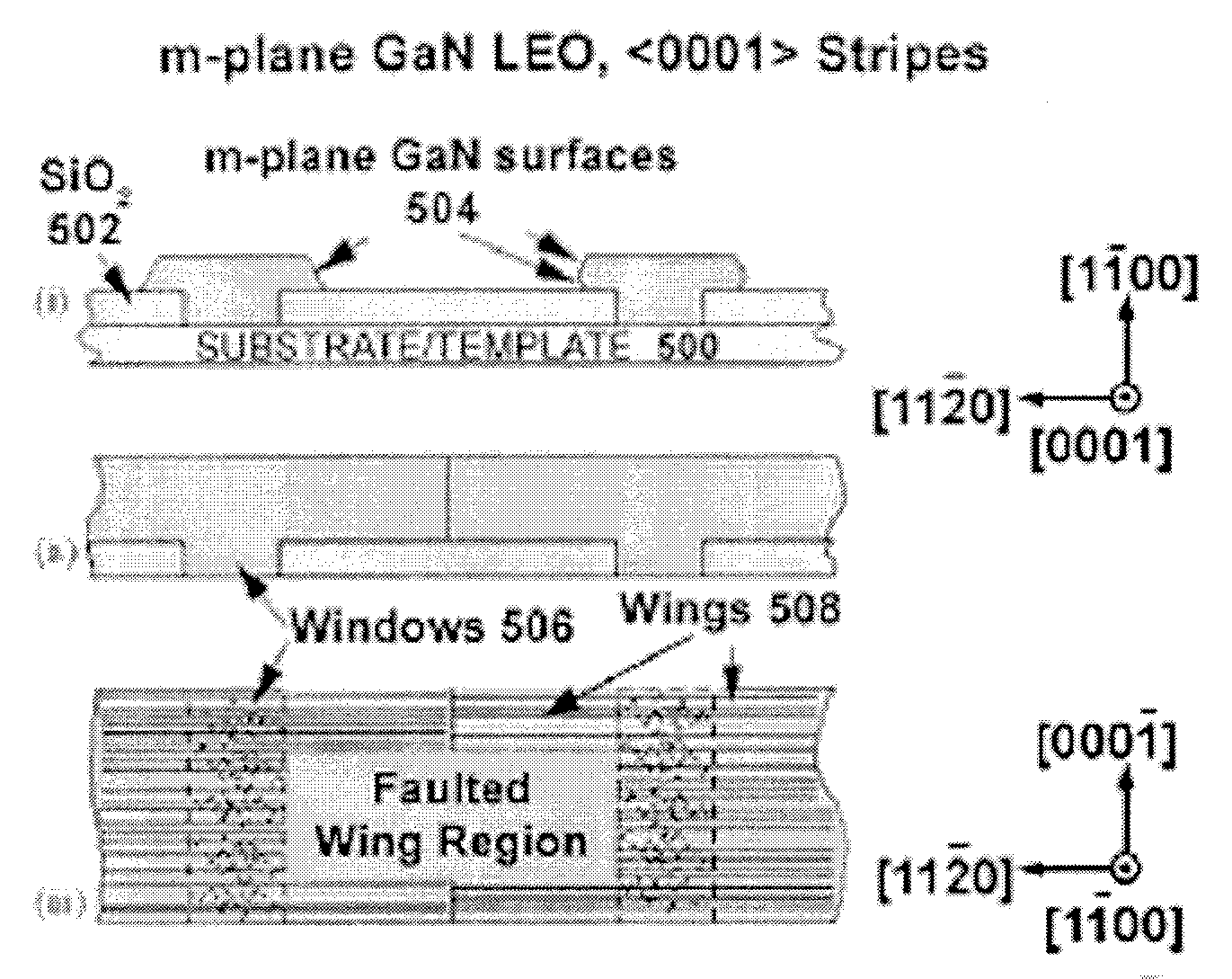

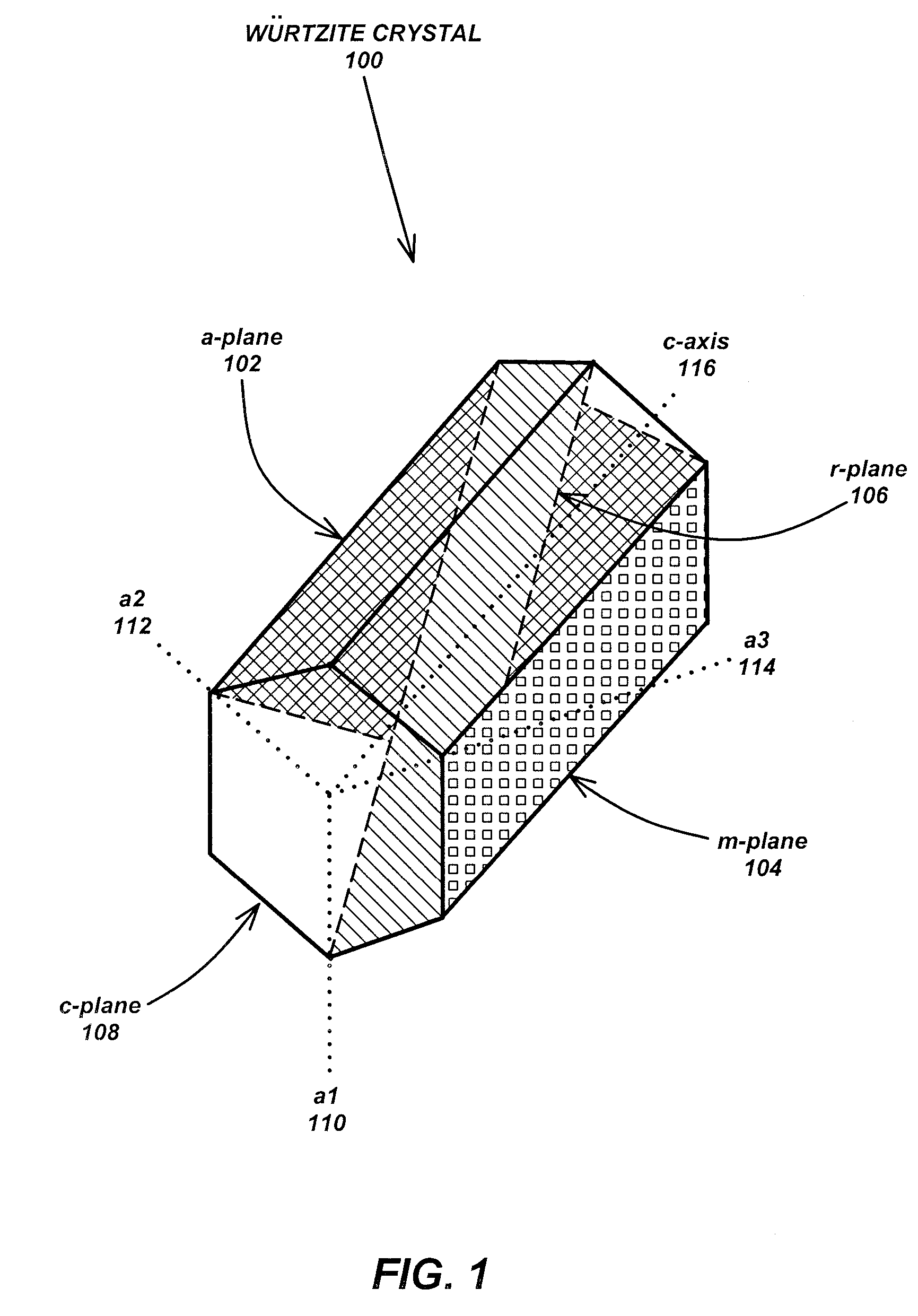

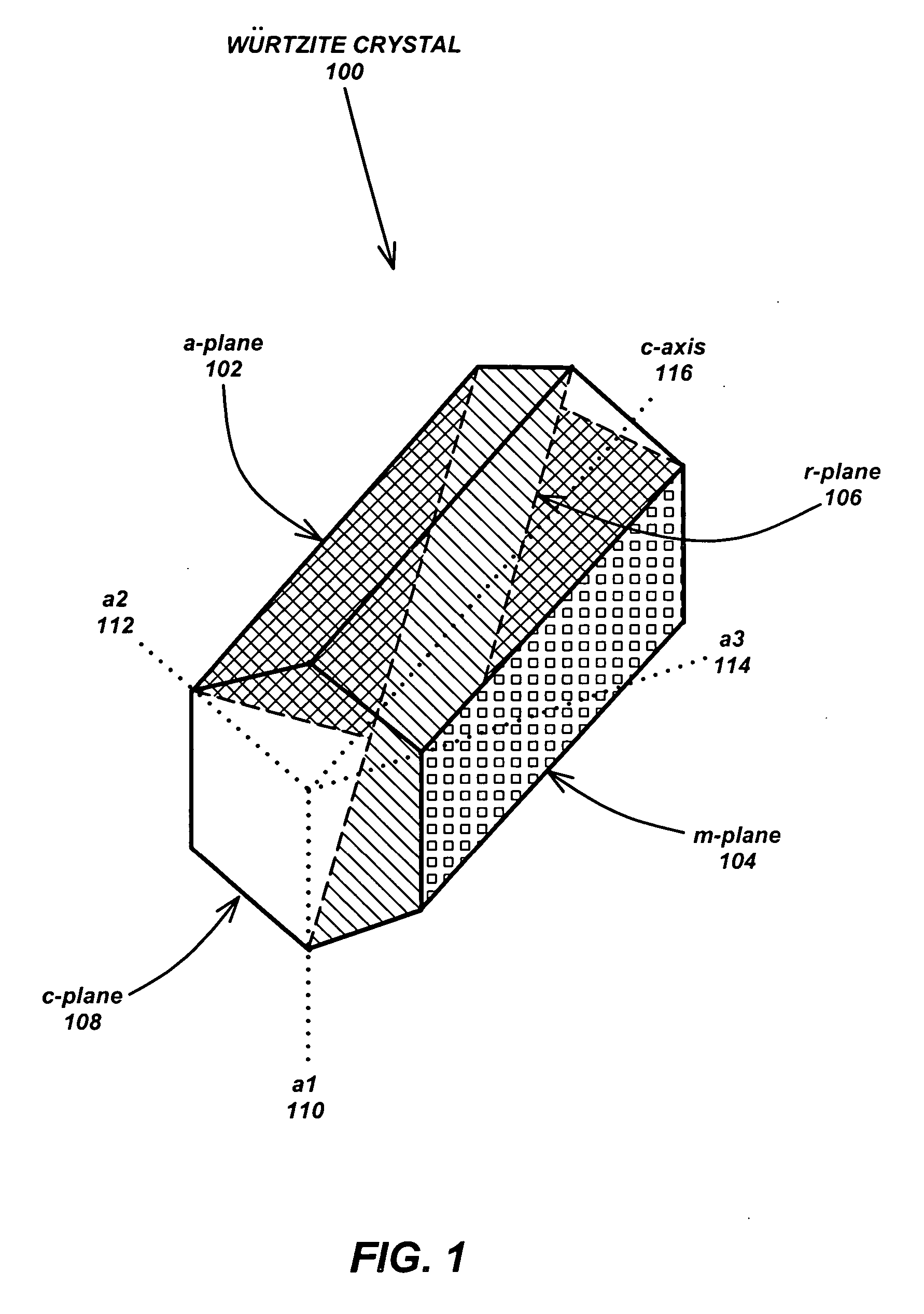

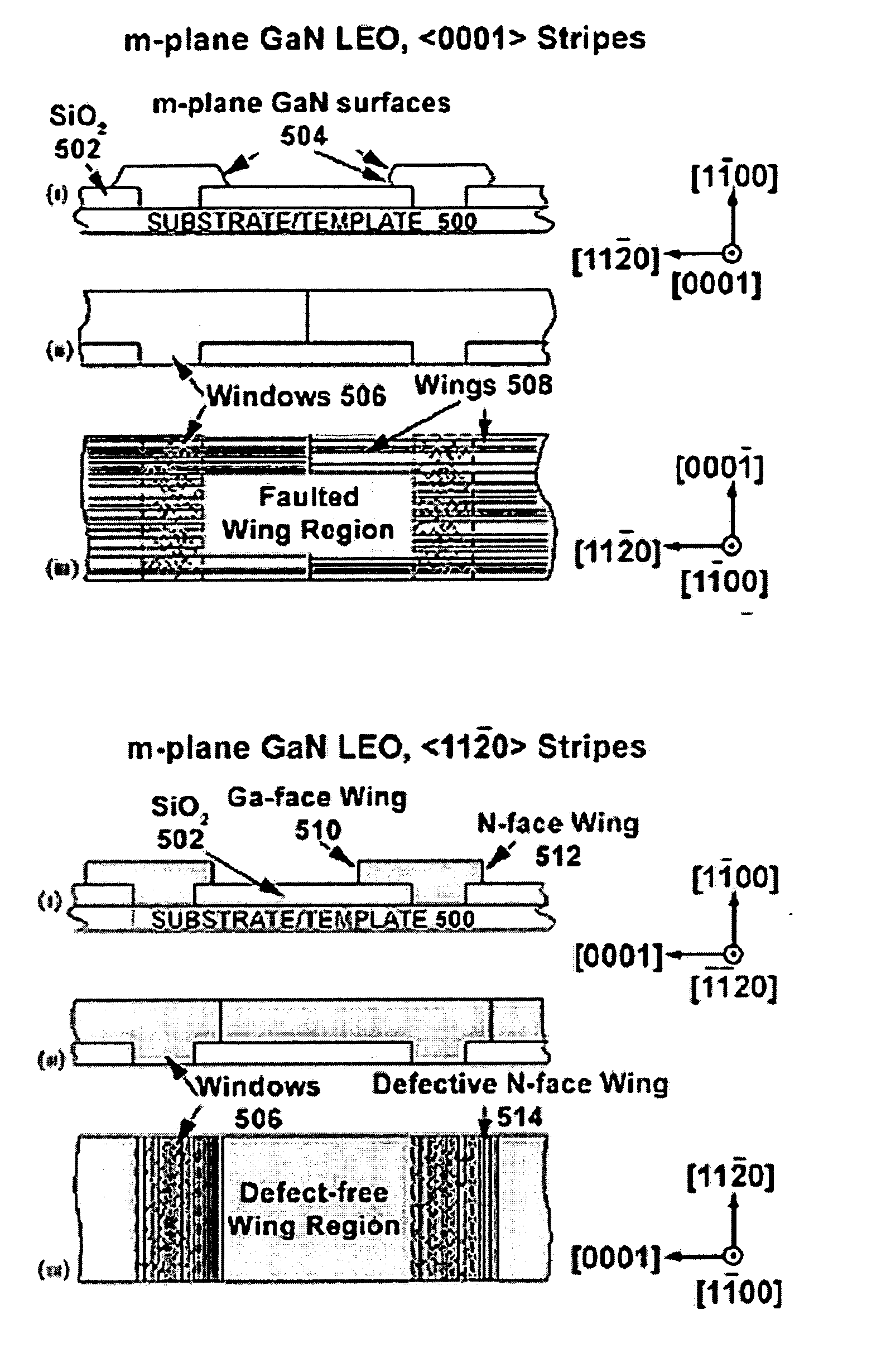

ActiveUS20070184637A1Reduction in structural defect densityReduce defect densitySemiconductor/solid-state device manufacturingSemiconductor devicesLateral overgrowthVolumetric Mass Density

A method of growing highly planar, fully transparent and specular m-plane gallium nitride (GaN) films. The method provides for a significant reduction in structural defect densities via a lateral overgrowth technique. High quality, uniform, thick m-plane GaN films are produced for use as substrates for polarization-free device growth.

Owner:JAPAN SCI & TECH CORP

Growth of planar reduced dislocation density m-plane gallium nitride by hydride vapor phase epitaxy

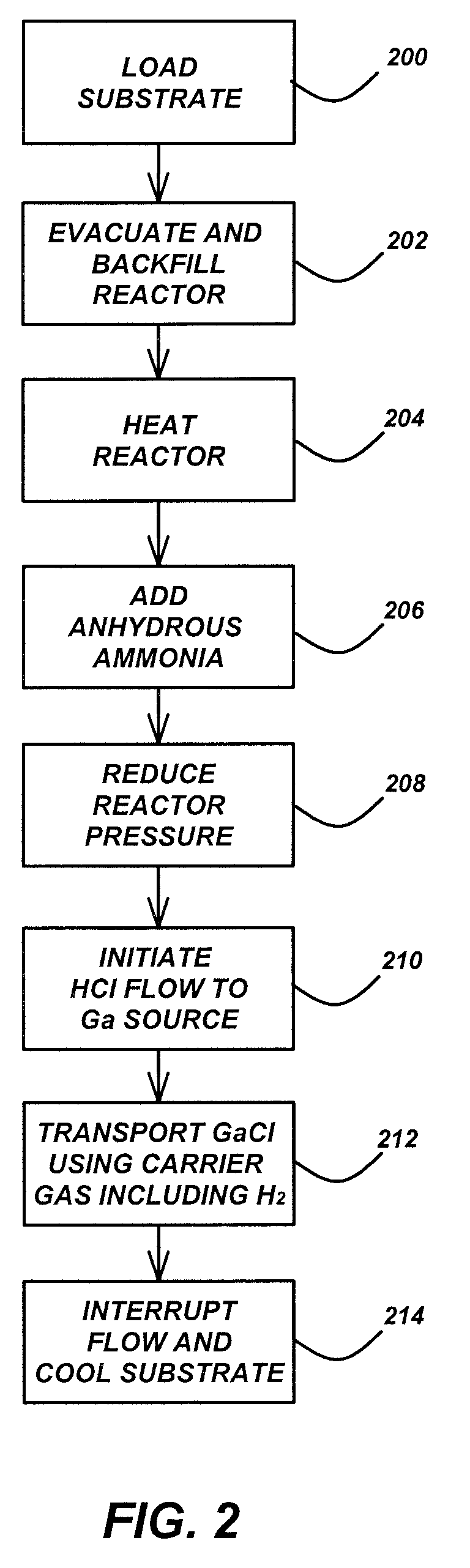

InactiveUS20050245095A1Reduction in structural defect densityReduce defect densityPolycrystalline material growthSemiconductor/solid-state device manufacturingLateral overgrowthGallium nitride

A method of growing highly planar, fully transparent and specular m-plane gallium nitride (GaN) films. The method provides for a significant reduction in structural defect densities via a lateral overgrowth technique. High quality, uniform, thick m-plane GaN films are produced for use as substrates for polarization-free device growth.

Owner:JAPAN SCI & TECH CORP

Multi-gas centrally cooled showerhead design

ActiveUS20130052804A1Polycrystalline material growthSpray nozzlesEngineeringChemical vapor deposition

A method and apparatus for chemical vapor deposition and / or hydride vapor phase epitaxial deposition are provided. The apparatus generally include a lower bottom plate and an upper bottom plate defining a first plenum. The upper bottom plate and a mid-plate positioned above the upper bottom plate define a heat exchanging channel. The mid-plate and a top plate positioned above the mid-plate define a second plenum. A plurality of gas conduits extend from the second plenum through the heat exchanging channel and the first plenum. The method generally includes flowing a first gas through a first plenum into a processing region, and flowing a second gas through a second plenum into a processing region. A heat exchanging fluid is introduced to a heat exchanging channel disposed between the first plenum and the second plenum. The first gas and the second gas are then reacted to form a film on a substrate.

Owner:APPLIED MATERIALS INC

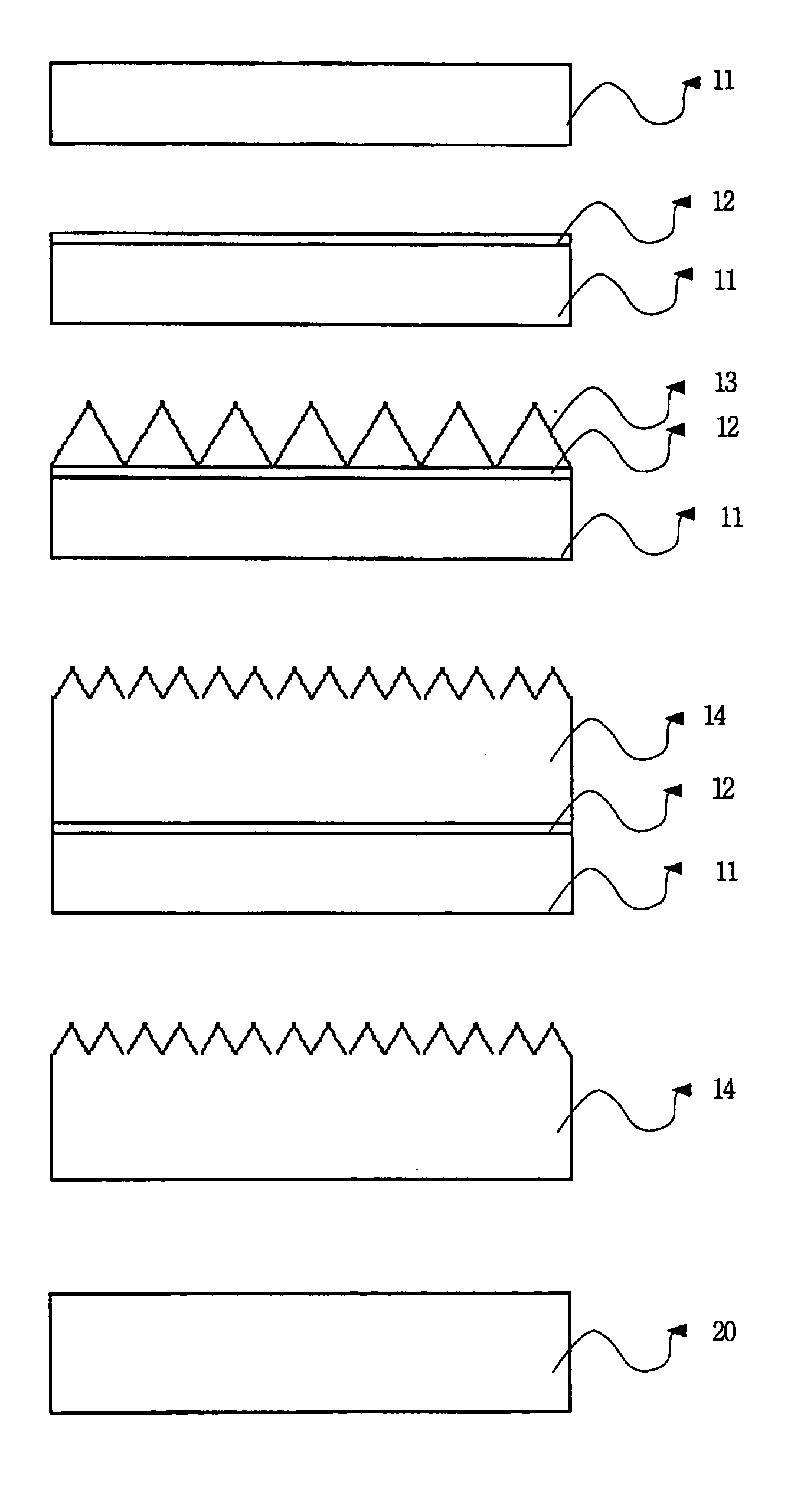

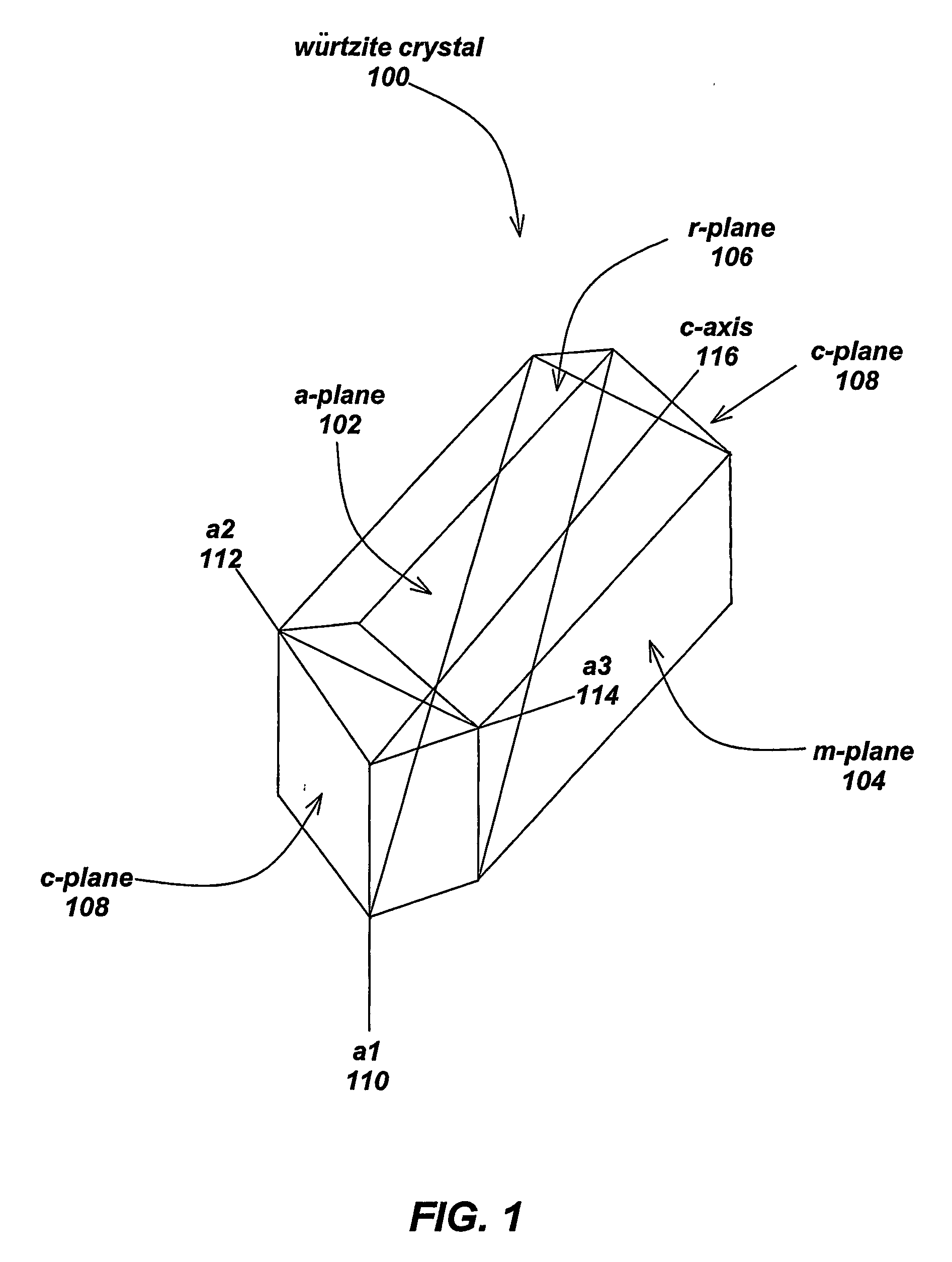

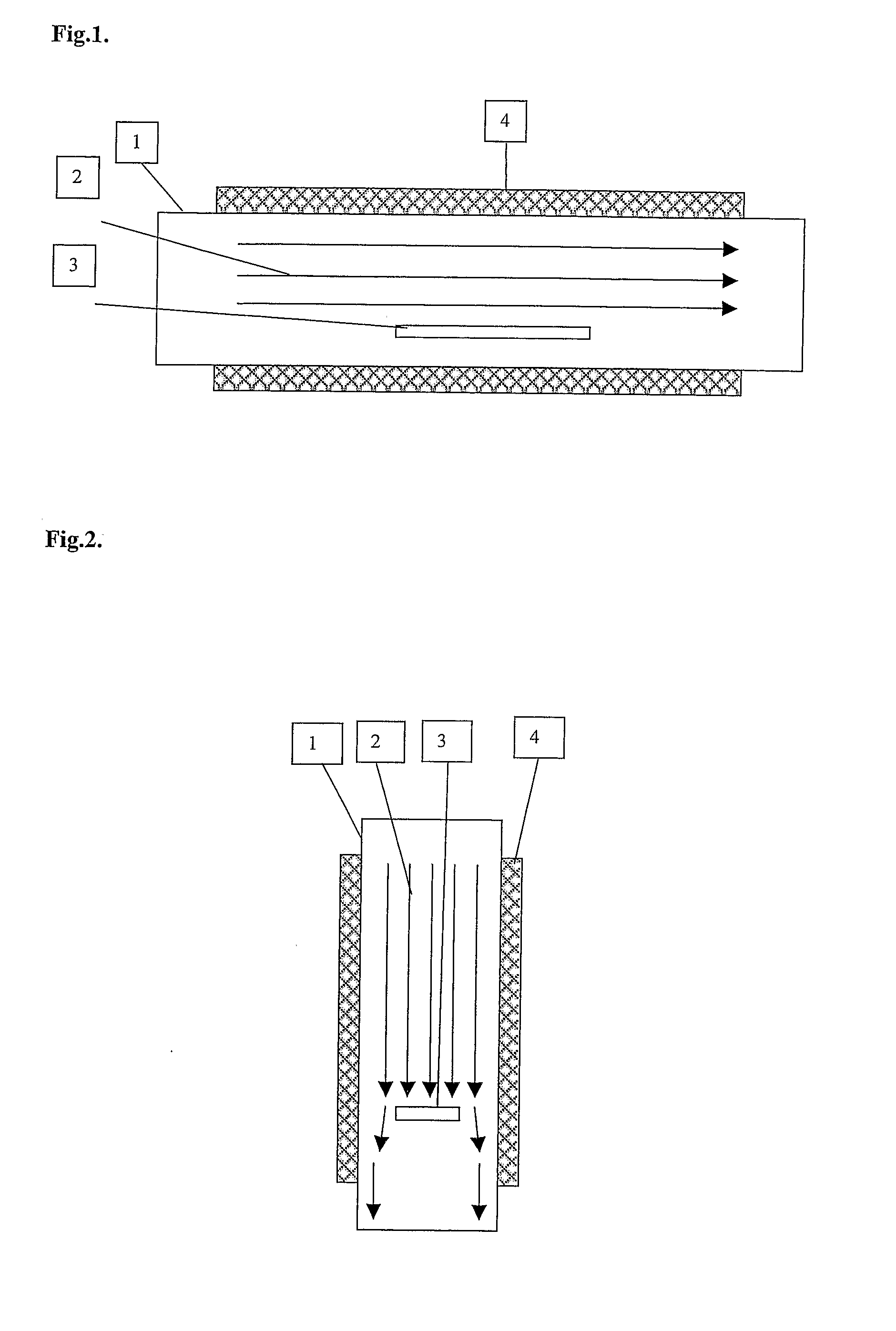

Non-polar single crystalline a-plane nitride semiconductor wafer and preparation thereof

InactiveUS20050247260A1Quality improvementEfficient methodPolycrystalline material growthCoupling device detailsWaferingSingle crystal

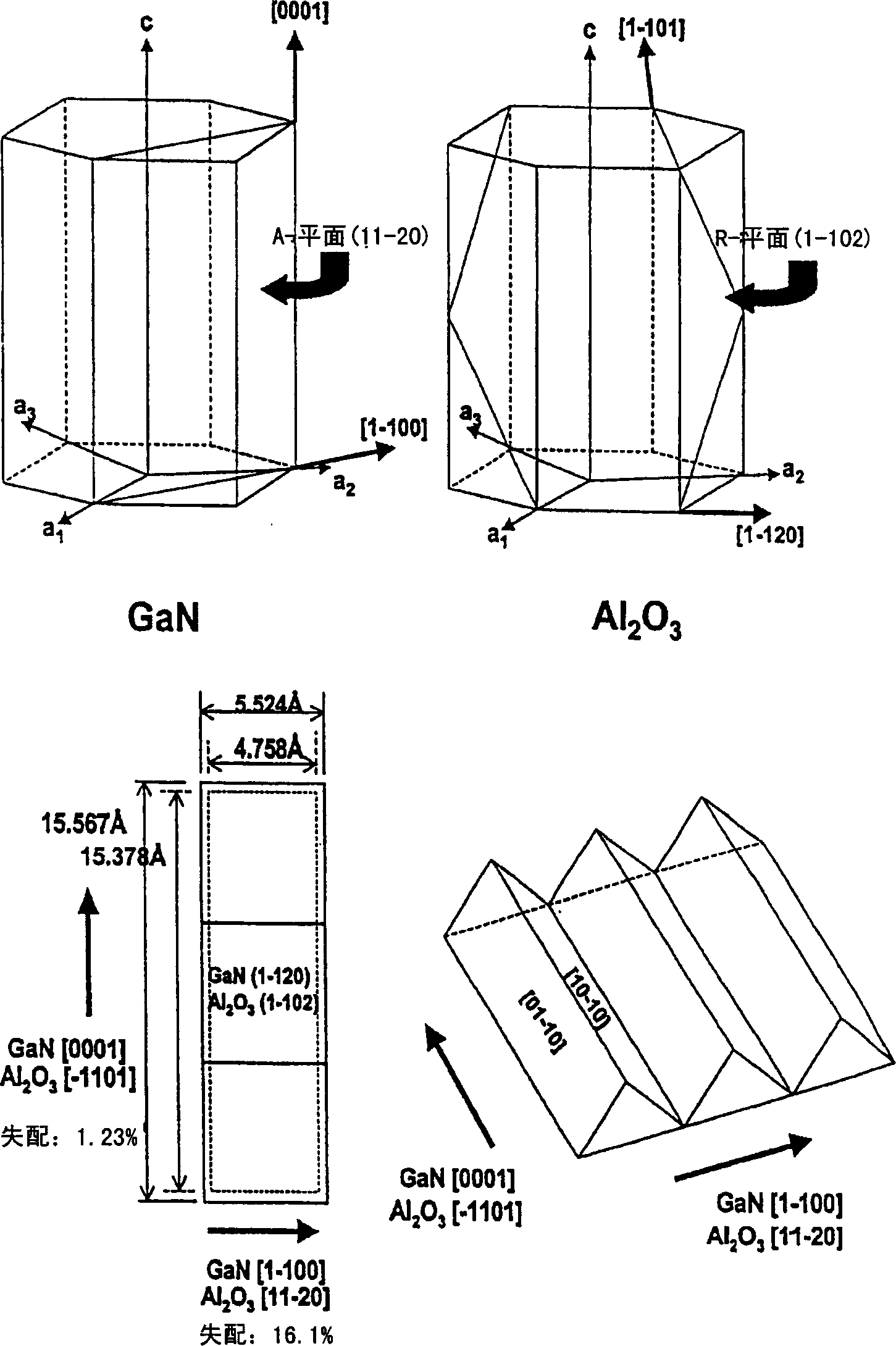

A single crystalline a-plane nitride semiconductor wafer having no voids, bending or cracks can be rapidly and effectively prepared by hydride vapor phase epitaxy (HVPE) growth of the a-plane nitride semiconductor film on a single crystalline r-plane sapphire substrate at a temperature ranging from 950 to 1,100° C. and at a rate ranging from 30 to 300 μm / hr.

Owner:SAMSUNG CORNING CO LTD

Decontamination of mocvd chamber using nh3 purge after in-situ cleaning

InactiveUS20100273291A1Solid-state devicesSemiconductor/solid-state device manufacturingDeposition processChemical vapor deposition

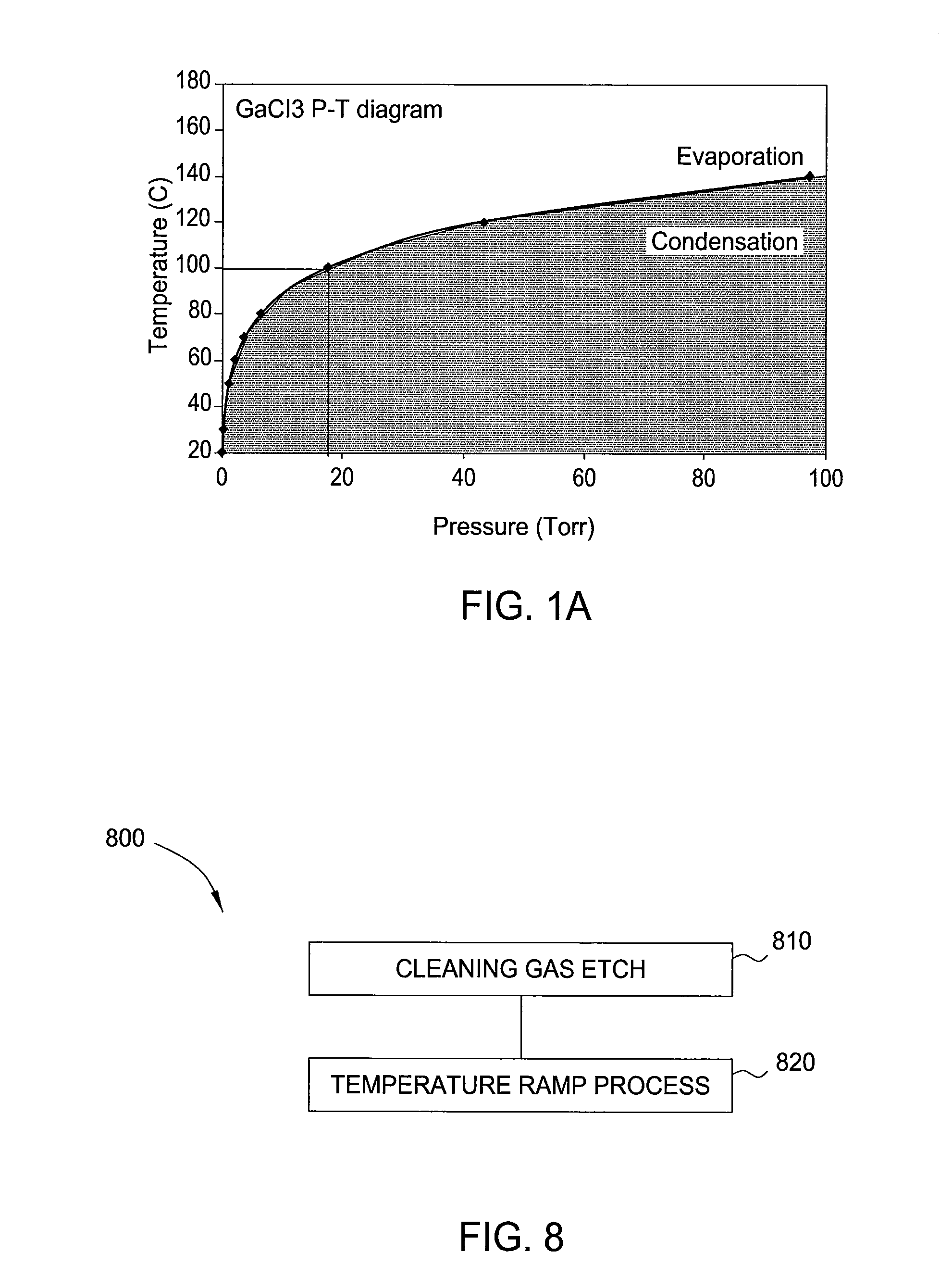

Embodiments of the present invention generally relate to methods and apparatus for removing unwanted deposition build-up from one more interior surfaces of a substrate processing chamber after a substrate is processed in a chamber to form, for example, Group III-V materials by metal-organic chemical vapor deposition (MOCVD) deposition processes and / or hydride vapor phase epitaxial (HVPE) deposition processes. In one embodiment, a method for removing unwanted deposition build-up from one or more interior surfaces of a substrate processing chamber is provided. The method comprises depositing one or more Group III containing layers over a substrate disposed in the substrate processing chamber, transferring the substrate out of the substrate processing chamber, and pulsing a halogen containing gas into the substrate processing chamber to remove at least a portion of the unwanted deposition build-up from one or more interior surfaces of the substrate processing chamber.

Owner:APPLIED MATERIALS INC

Non-polar single crystalline A-plane nitride semiconductor wafer and preparation thereof

InactiveCN1702836AQuality improvementPolycrystalline material growthCoupling device detailsSingle crystalVapor phase

A single crystalline a-plane nitride semiconductor wafer having no voids, bending or cracks can be rapidly and effectively prepared by hydride vapor phase epitaxy (HVPE) growth of the a-plane nitride semiconductor film on a single crystalline r-plane sapphire substrate at a temperature ranging from 950 to 1,100 DEG C and at a rate ranging from 30 to 300 mu m / hr.

Owner:SAMSUNG CORNING PRECISION MATERIALS CO LTD

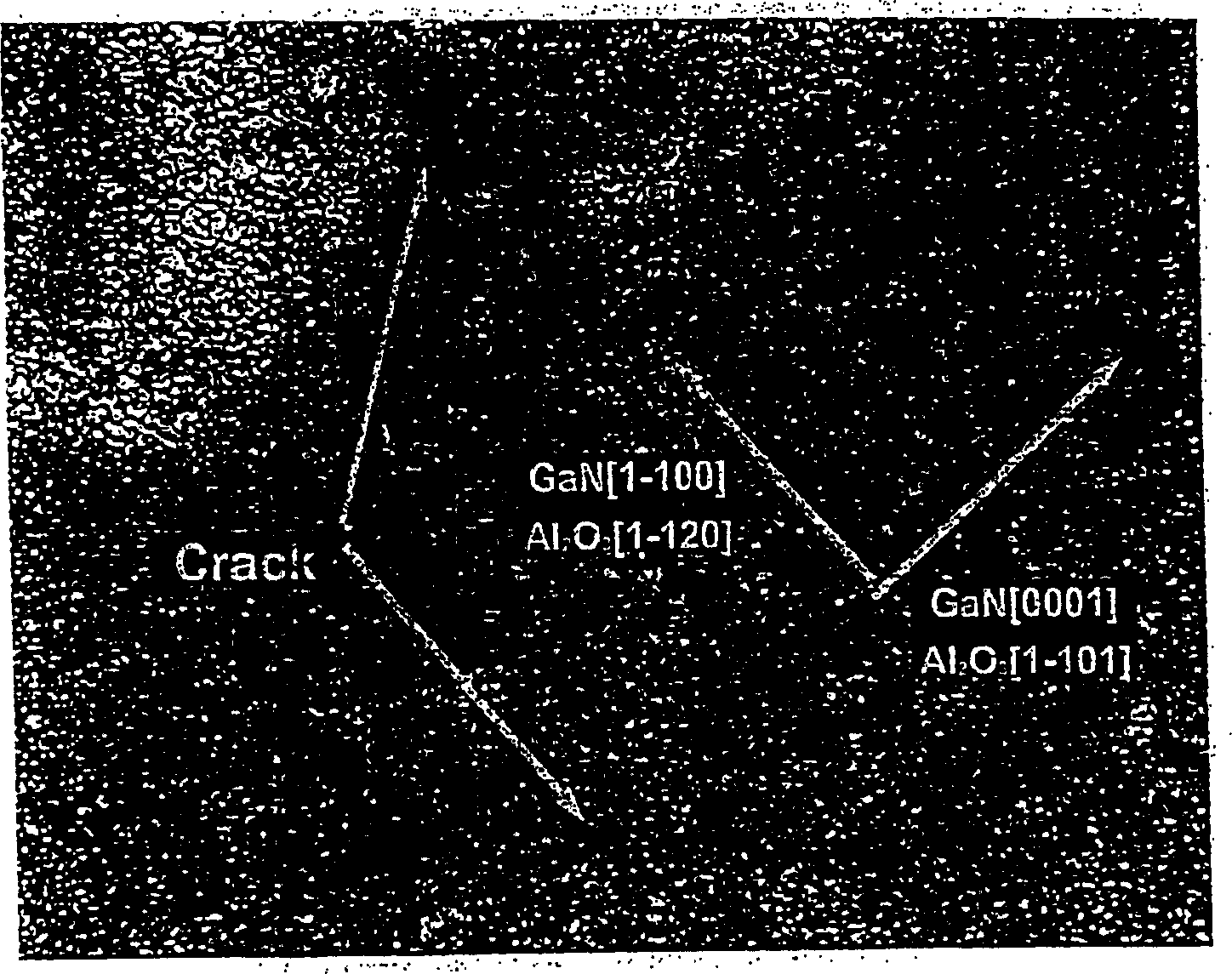

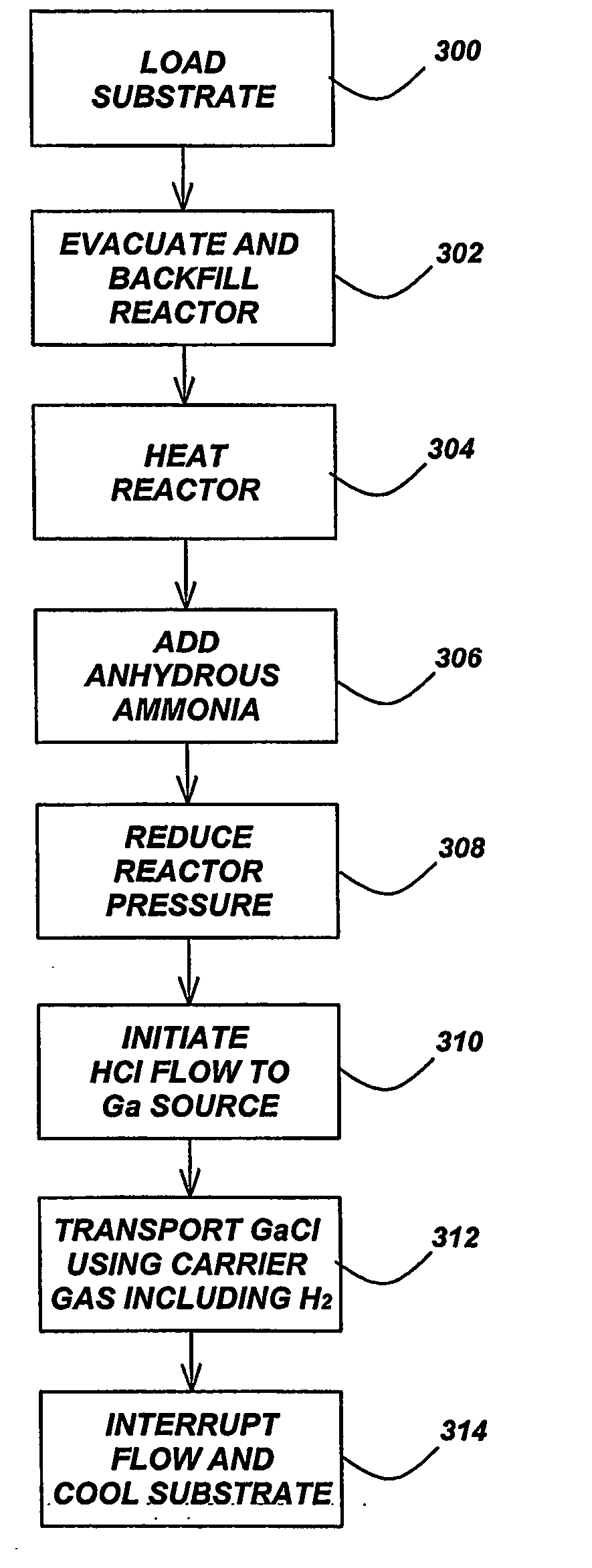

Growth of planar, non-polar a-plane gallium nitride by hydride vapor phase epitaxy

ActiveUS20060008941A1Avoid increased oxygen levelsReduce pressurePolycrystalline material growthSemiconductor/solid-state device manufacturingGallium nitrideVapor phase

Highly planar non-polar a-plane GaN films are grown by hydride vapor phase epitaxy (HVPE). The resulting films are suitable for subsequent device regrowth by a variety of growth techniques

Owner:JAPAN SCI & TECH CORP +1

Growth of planar reduced dislocation density m-plane gallium nitride by hydride vapor phase epitaxy

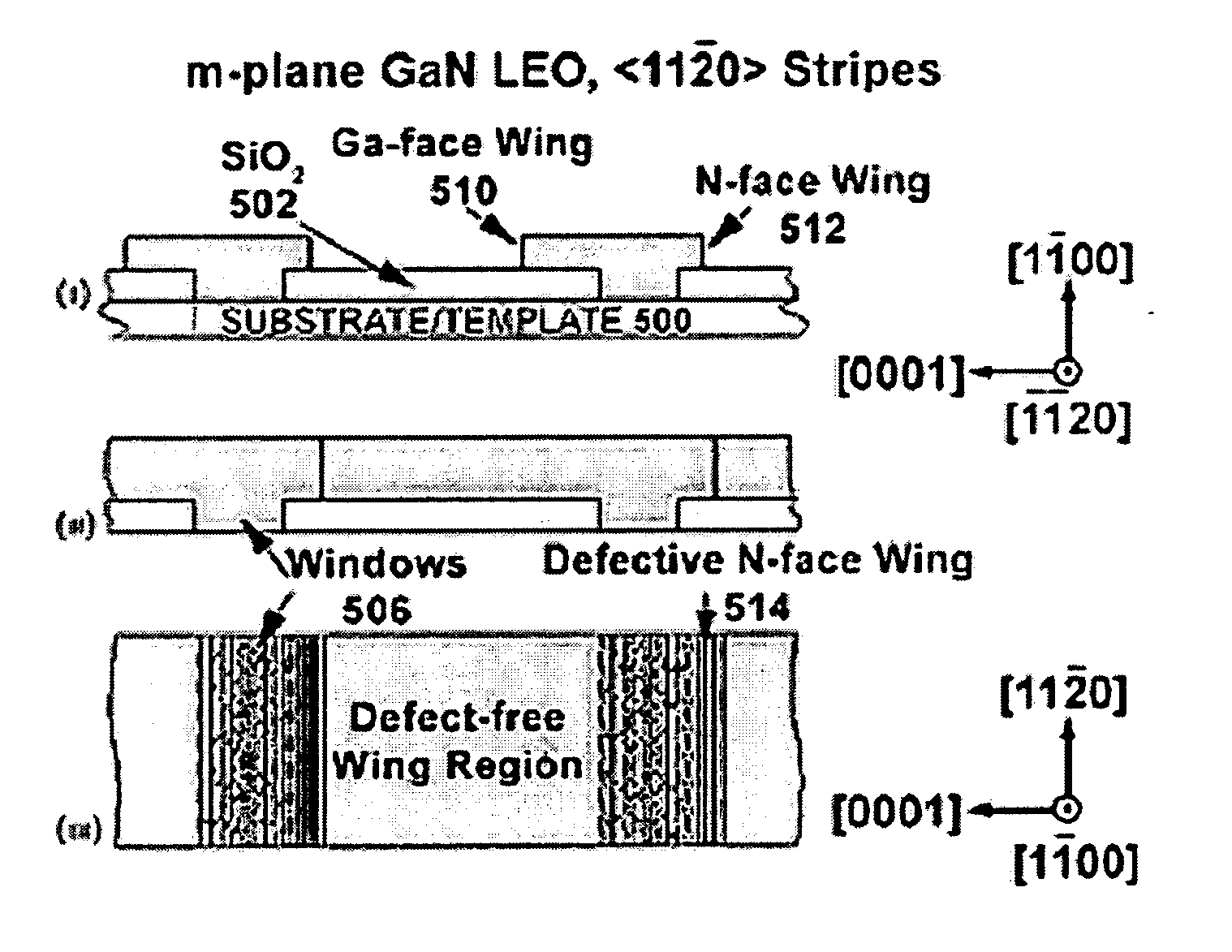

InactiveUS7208393B2Reduce defect densityPolycrystalline material growthSemiconductor/solid-state device manufacturingLateral overgrowthGallium nitride

A method of growing highly planar, fully transparent and specular m-plane gallium nitride (GaN) films. The method provides for a significant reduction in structural defect densities via a lateral overgrowth technique. High quality, uniform, thick m-plane GaN films are produced for use as substrates for polarization-free device growth.

Owner:JAPAN SCI & TECH CORP

Multiple precursor showerhead with by-pass ports

ActiveUS8361892B2Liquid surface applicatorsSemiconductor/solid-state device testing/measurementMetrologyEngineering

A method and apparatus that may be utilized for chemical vapor deposition and / or hydride vapor phase epitaxial (HVPE) deposition are provided. In one embodiment, the apparatus a processing chamber that includes a showerhead with separate inlets and channels for delivering separate processing gases into a processing volume of the chamber without mixing the gases prior to entering the processing volume. In one embodiment, the showerhead includes one or more cleaning gas conduits configured to deliver a cleaning gas directly into the processing volume of the chamber while by-passing the processing gas channels. In one embodiment, the showerhead includes a plurality of metrology ports configured to deliver a cleaning gas directly into the processing volume of the chamber while by-passing the processing gas channels. As a result, the processing chamber components can be cleaned more efficiently and effectively than by introducing cleaning gas into the chamber only through the processing gas channels.

Owner:APPLIED MATERIALS INC

Growth of reduced dislocation density non-polar gallium nitride by hydride vapor phase epitaxy

InactiveUS7220658B2Reduce threading dislocation densityPolycrystalline material growthSemiconductor/solid-state device manufacturingGallium nitrideVapor phase

Lateral epitaxial overgrowth (LEO) of non-polar a-plane gallium nitride (GaN) films by hydride vapor phase epitaxy (HVPE) results in significantly reduced defect density.

Owner:JAPAN SCI & TECH CORP +1

Growth of reduced dislocation density non-polar gallium nitride by hydride vapor phase epitaxy

InactiveUS20060128124A1Reduce threading dislocation densityPolycrystalline material growthSemiconductor/solid-state device manufacturingGallium nitrideVapor phase

Lateral epitaxial overgrowth (LEO) of non-polar a-plane gallium nitride (GaN) films by hydride vapor phase epitaxy (HVPE) results in significantly reduced defect density.

Owner:JAPAN SCI & TECH CORP +1

Solid-state light source

InactiveUS20090140272A1Solid-state devicesSemiconductor/solid-state device manufacturingInterconnectionVapor phase

A solid-state light source includes at least one stack of light emitting elements. The elements are an inorganic light emitting diode chip and at least one wavelength conversion chip or the elements are a plurality of light emitting diode chips and one or more optional wavelength conversion chips. The wavelength conversion chip may include an electrical interconnection means. The light emitting diode chip may include at least one GaN-based semiconductor layer that is at least ten microns thick and that is fabricated by hydride vapor phase epitaxy. A method is described for fabricating the solid-state light source.

Owner:GOLDENEYE

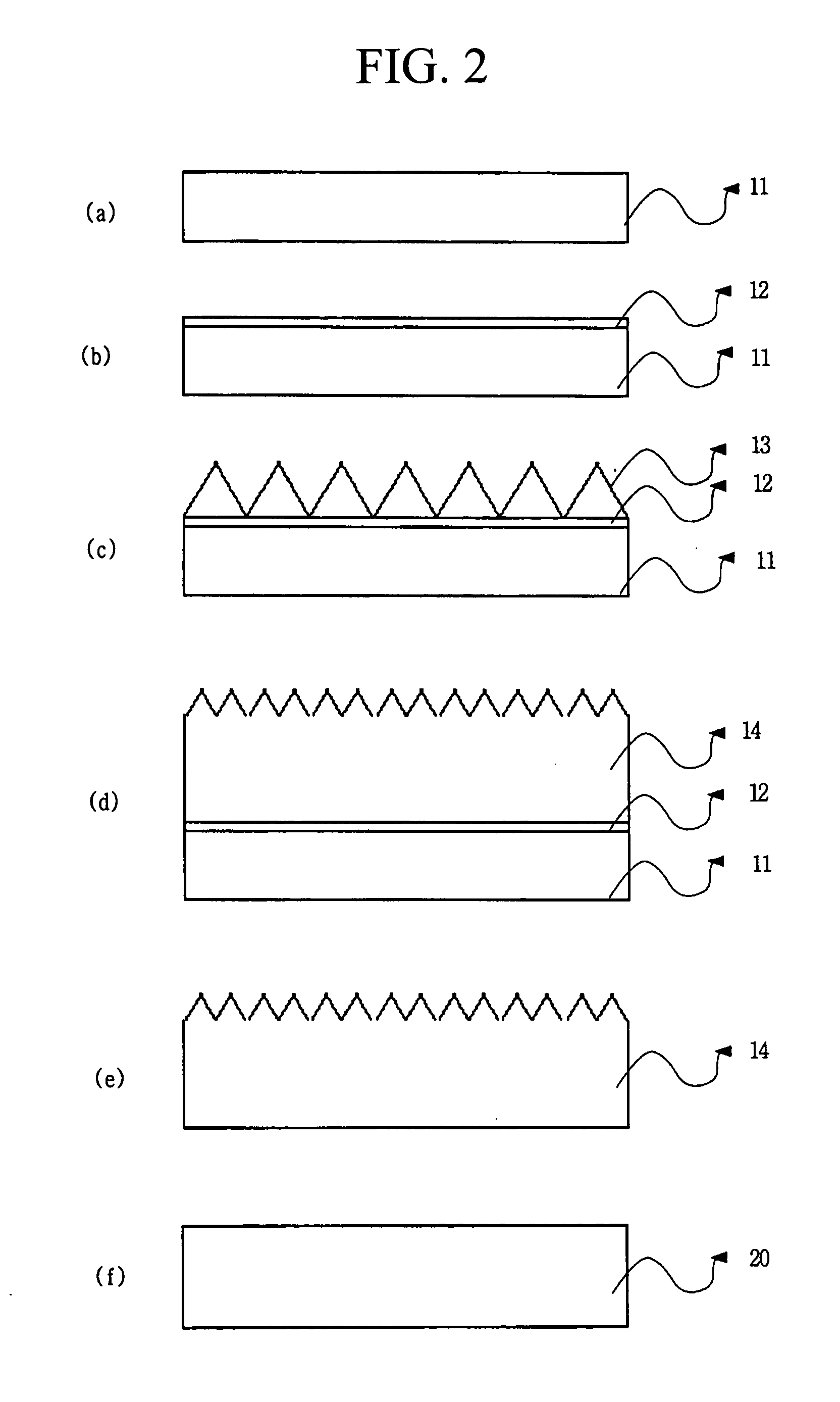

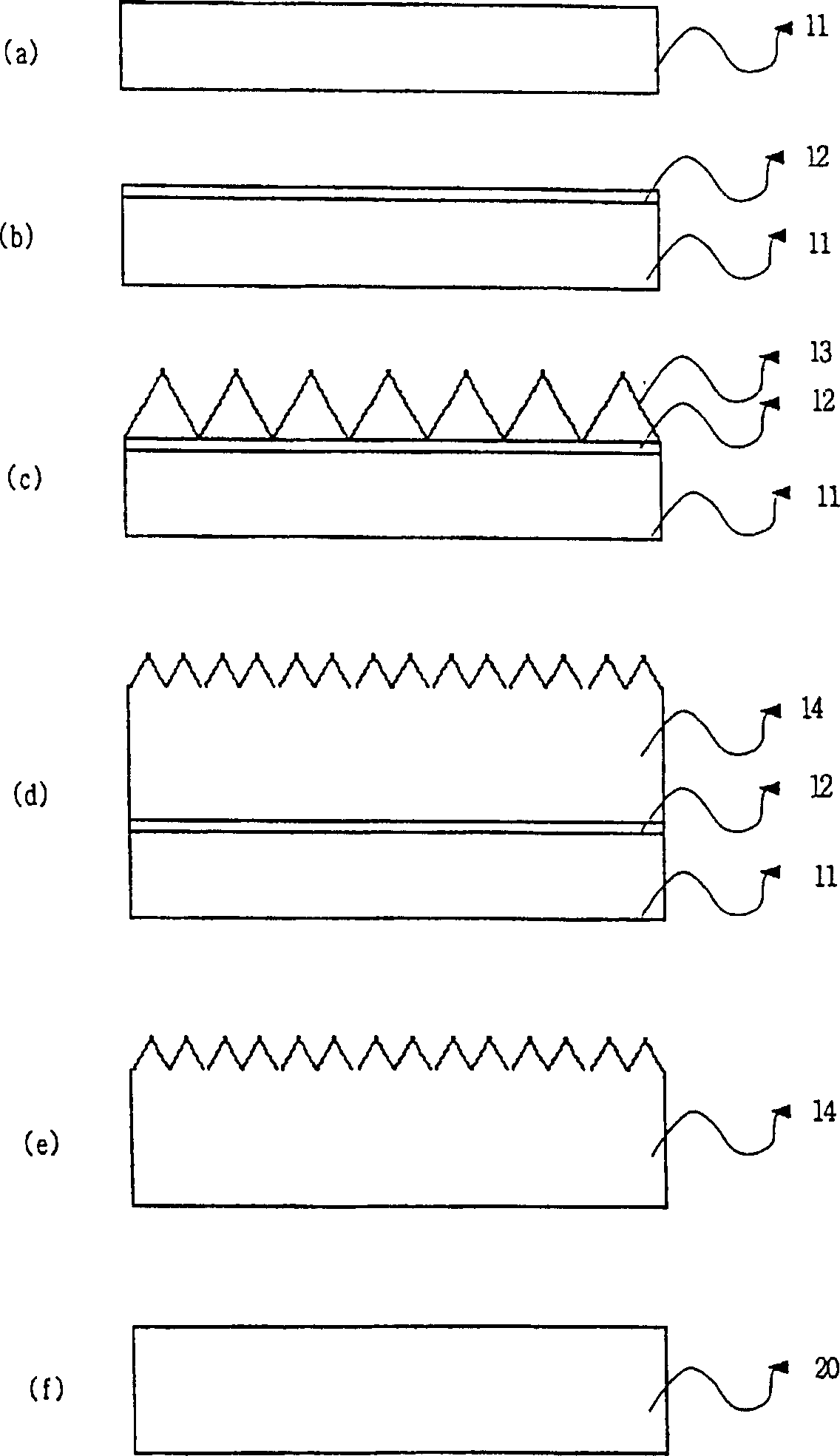

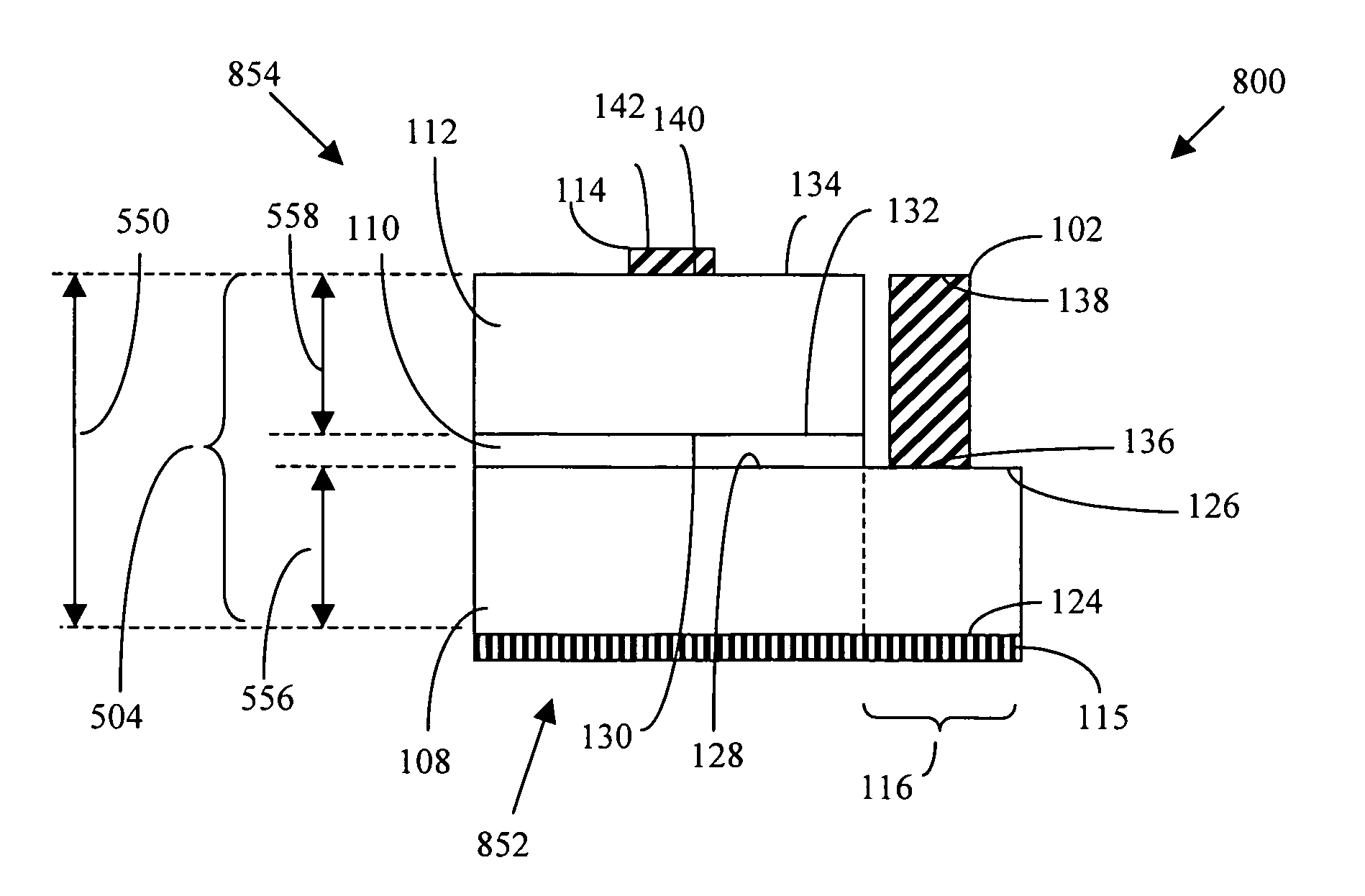

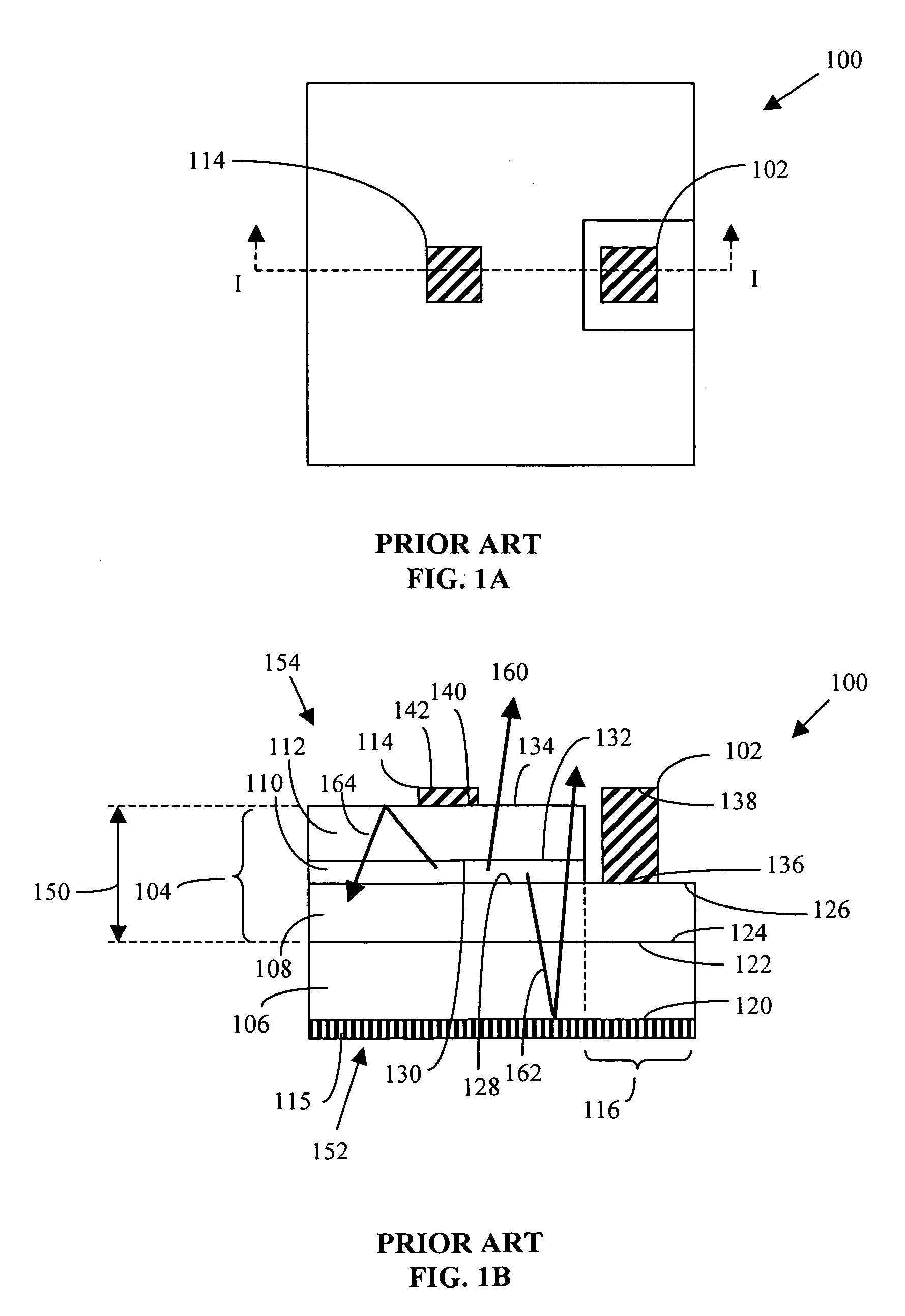

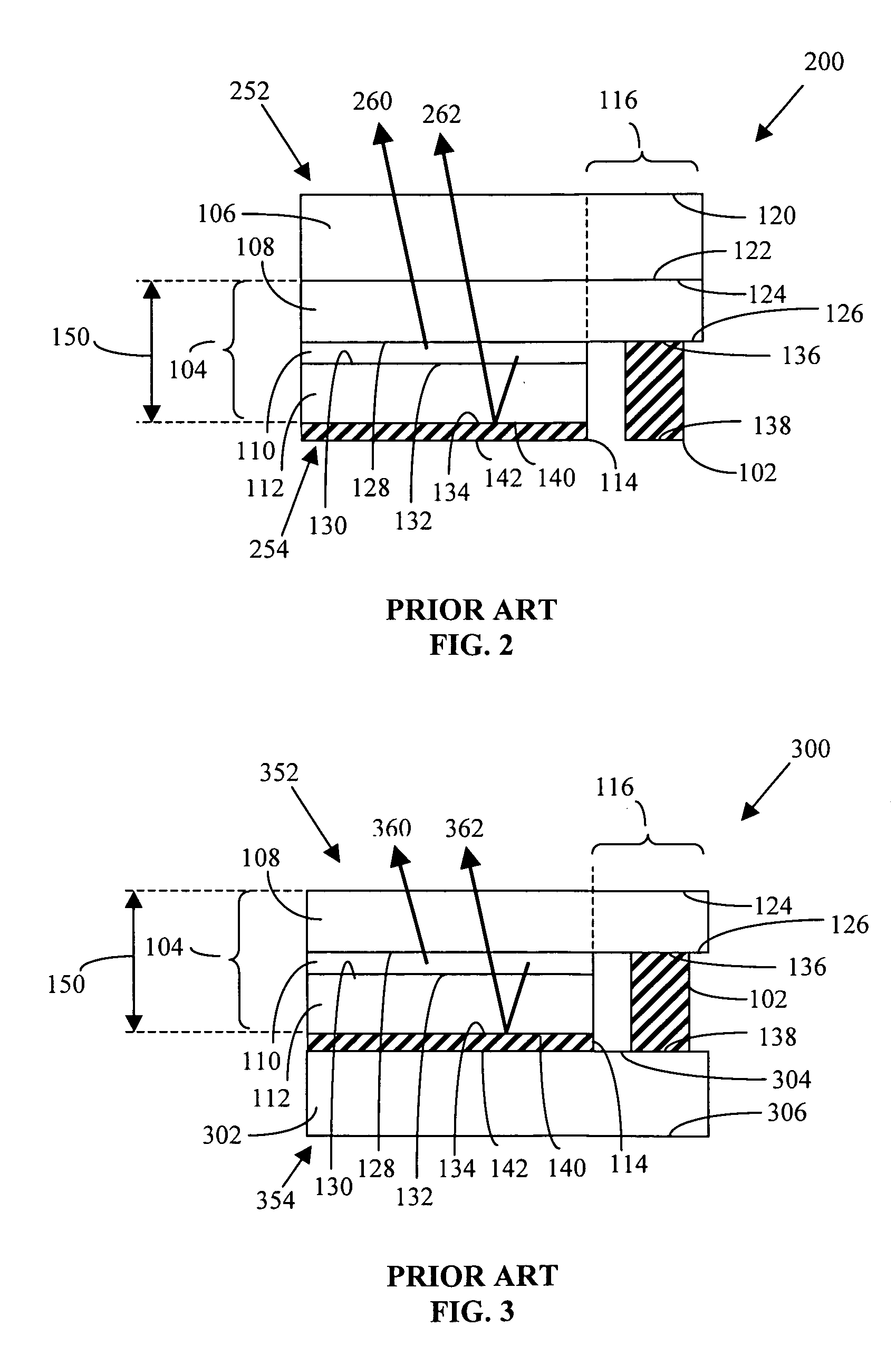

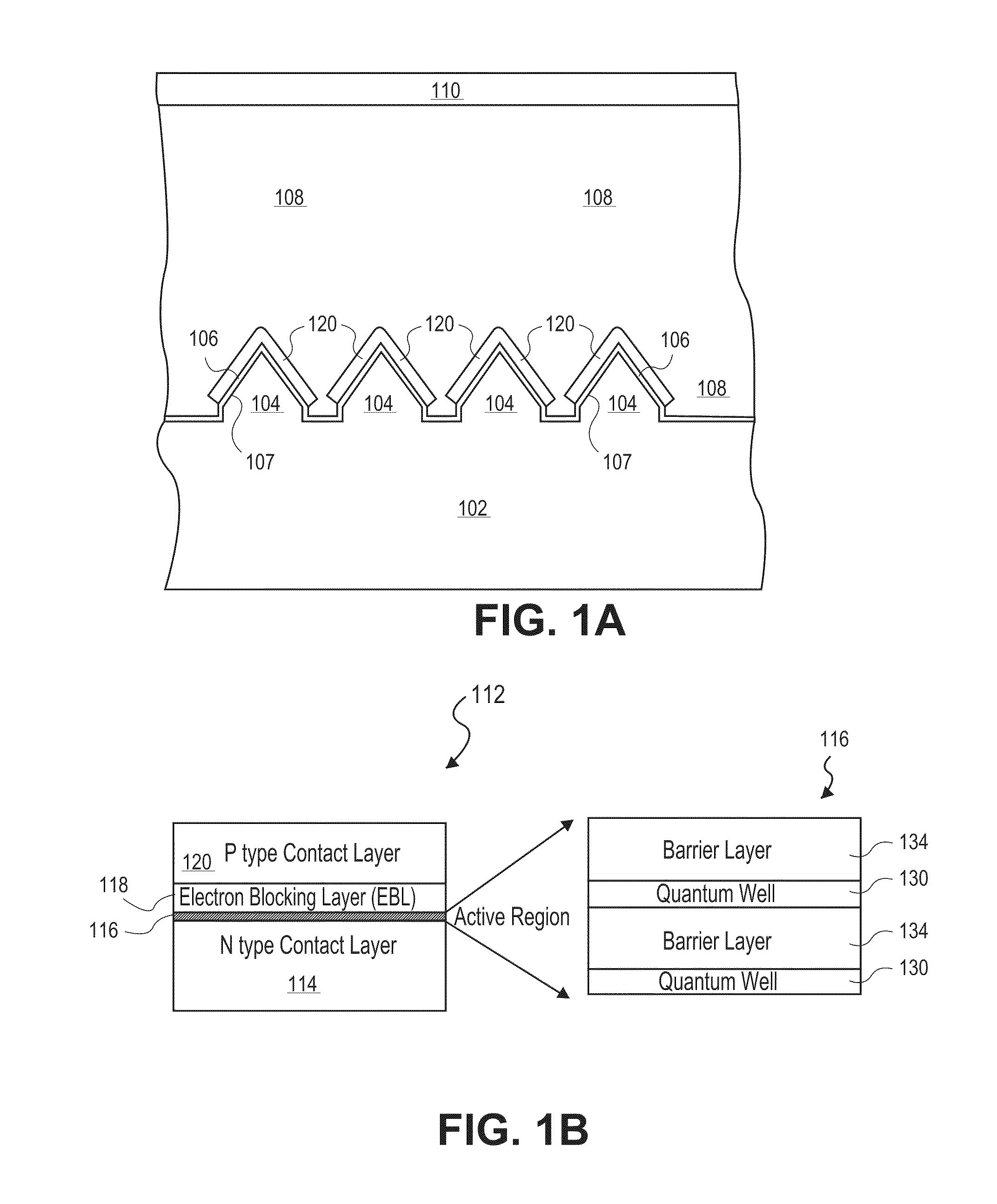

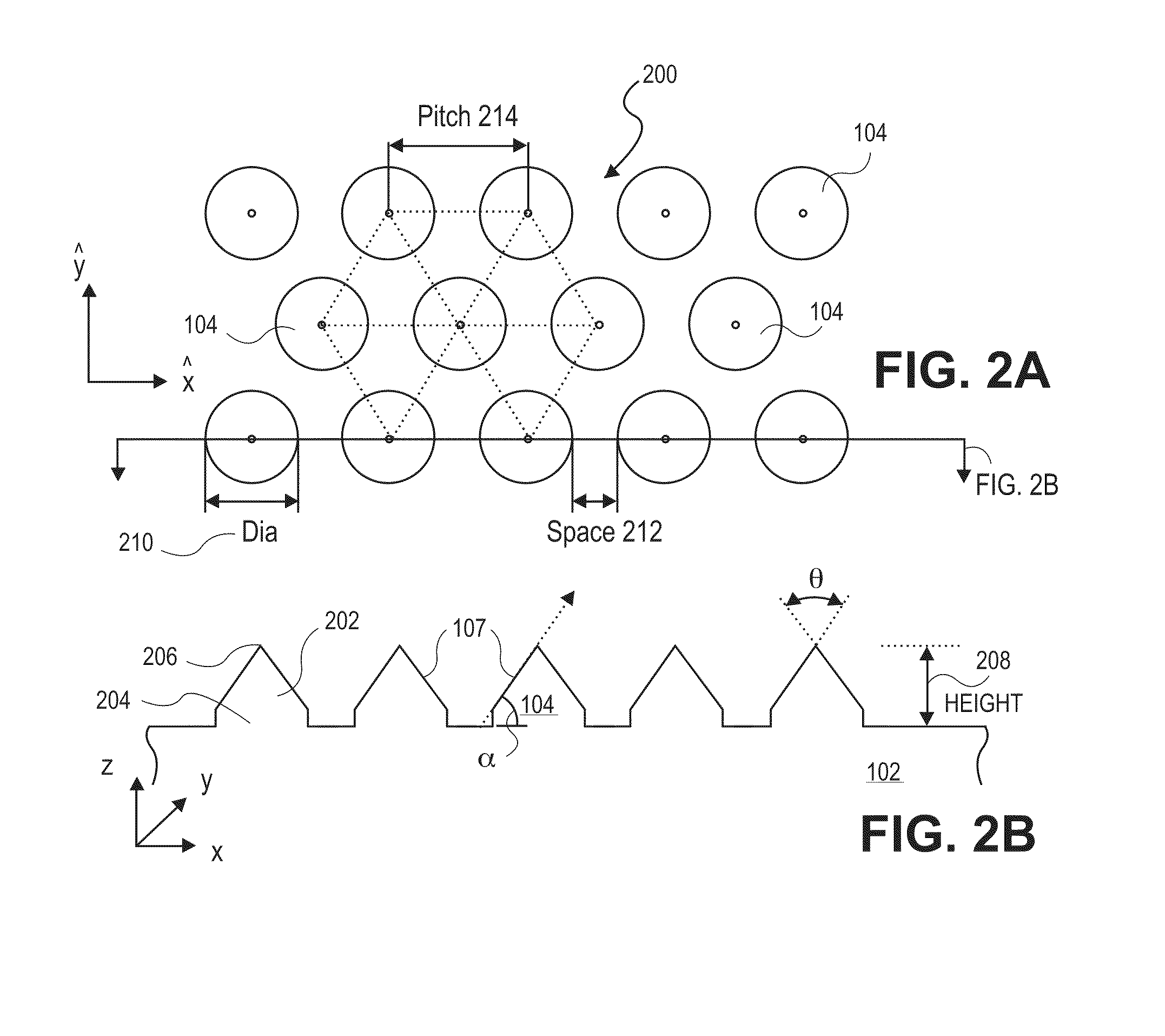

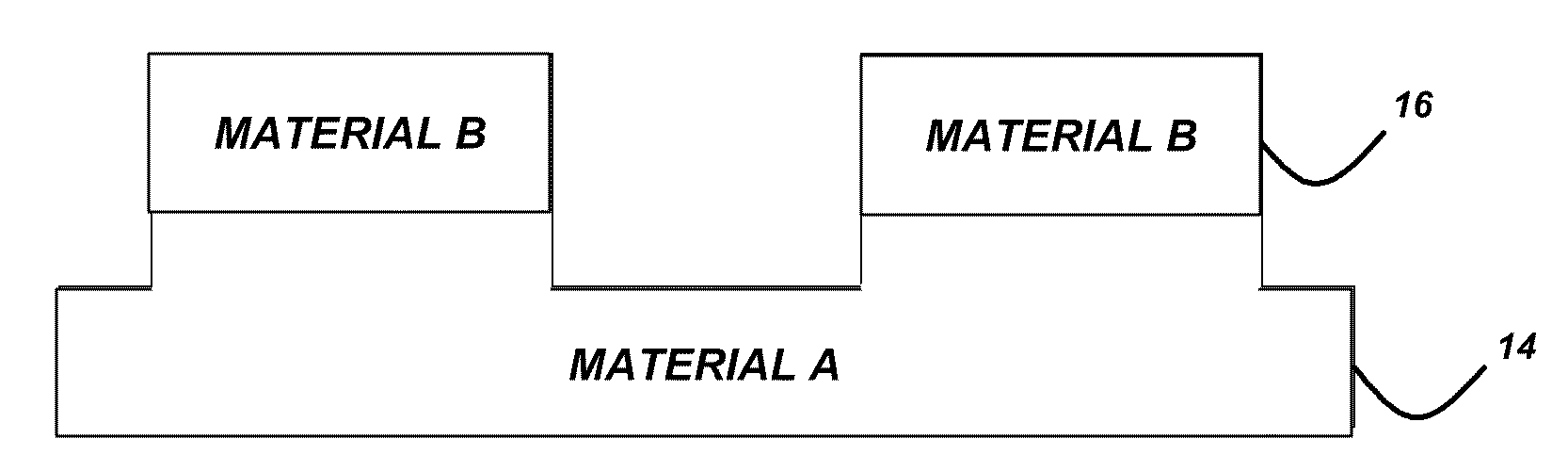

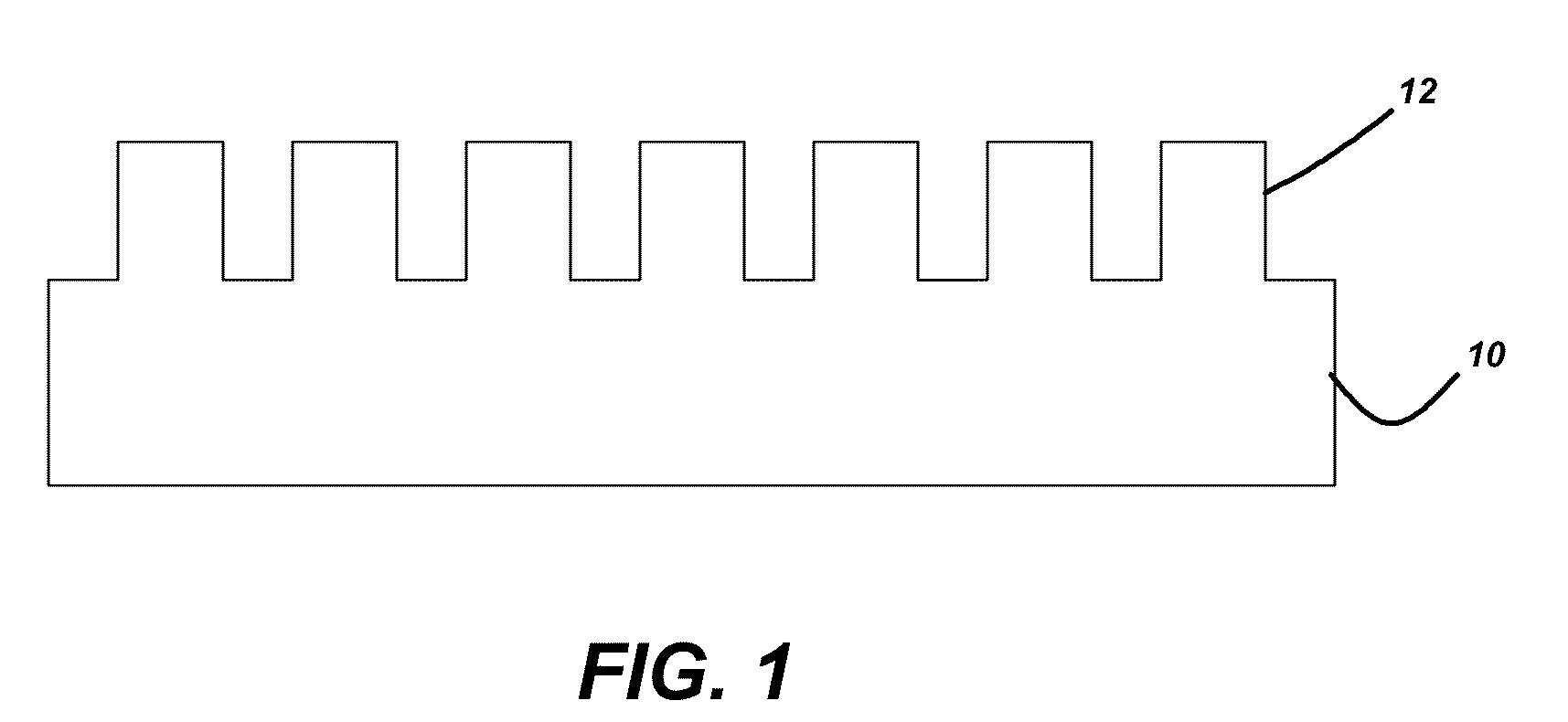

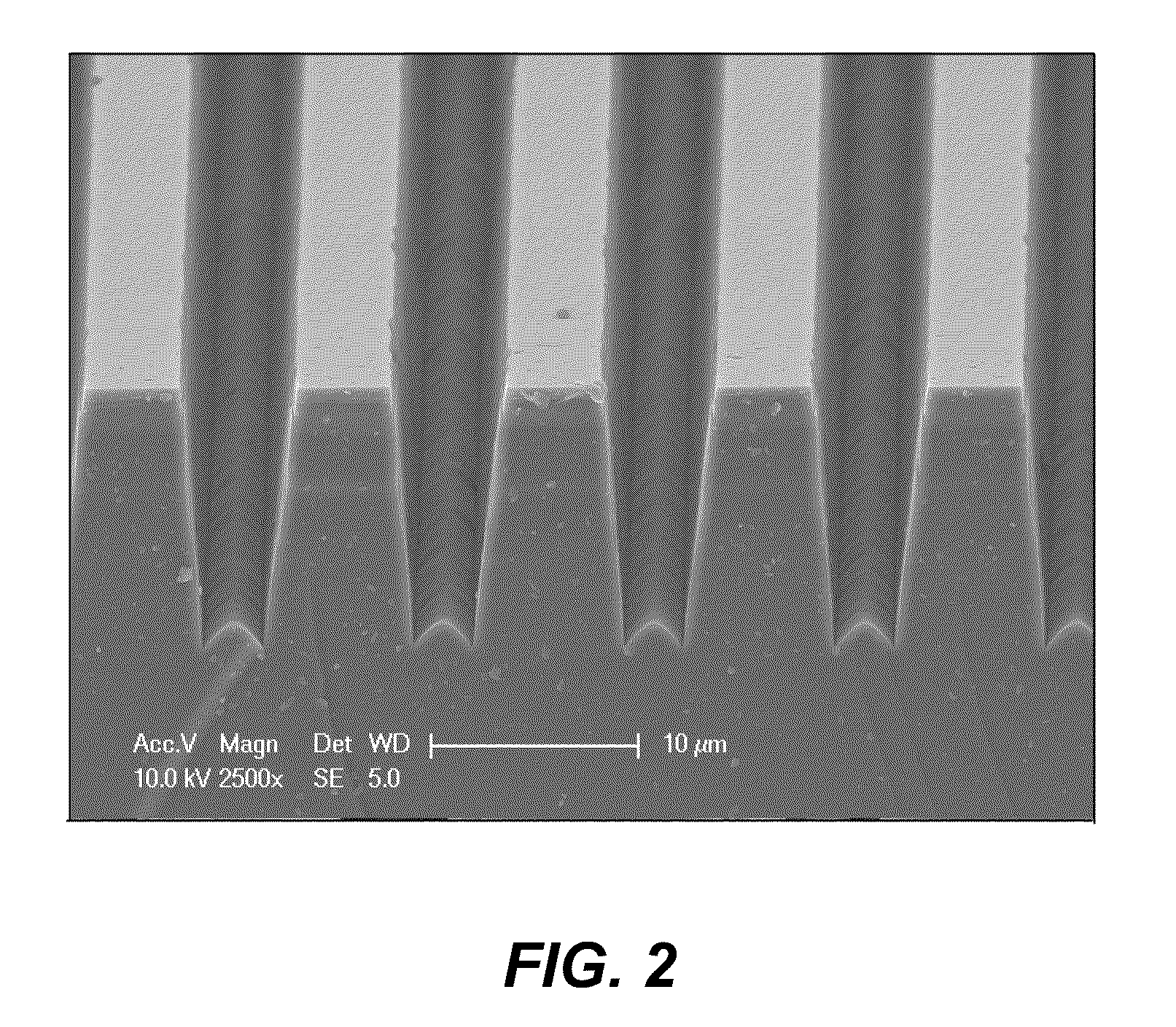

Method of forming a group iii-nitride crystalline film on a patterned substrate by hydride vapor phase epitaxy (HVPE)

ActiveUS20110012109A1Quality improvementSemiconductor/solid-state device manufacturingChemical vapor deposition coatingCrystal orientationPatterned substrate

A method of depositing a high quality low defect single crystalline Group III-Nitride film. A patterned substrate having a plurality of features with inclined sidewalls separated by spaces is provided. A Group III-Nitride film is deposited by a hydride vapor phase epitaxy (HVPE) process over the patterned substrate. The HVPE deposition process forms a Group III-Nitride film having a first crystal orientation in the spaces between features and a second different crystal orientation on the inclined sidewalls. The first crystal orientation in the spaces subsequently overgrows the second crystal orientation on the sidewalls and in the process turns over and terminates treading dislocations formed in the first crystal orientation.

Owner:APPLIED MATERIALS INC

Multi-gas centrally cooled showerhead design

InactiveUS20160136660A1Polycrystalline material growthLiquid surface applicatorsProcess regionEngineering

A method and apparatus for chemical vapor deposition and / or hydride vapor phase epitaxial deposition are provided. The apparatus generally include a lower bottom plate and an upper bottom plate defining a first plenum. The upper bottom plate and a mid-plate positioned above the upper bottom plate define a heat exchanging channel. The mid-plate and a top plate positioned above the mid-plate define a second plenum. A plurality of gas conduits extend from the second plenum through the heat exchanging channel and the first plenum. The method generally includes flowing a first gas through a first plenum into a processing region, and flowing a second gas through a second plenum into a processing region. A heat exchanging fluid is introduced to a heat exchanging channel disposed between the first plenum and the second plenum. The first gas and the second gas are then reacted to form a film on a substrate.

Owner:APPLIED MATERIALS INC

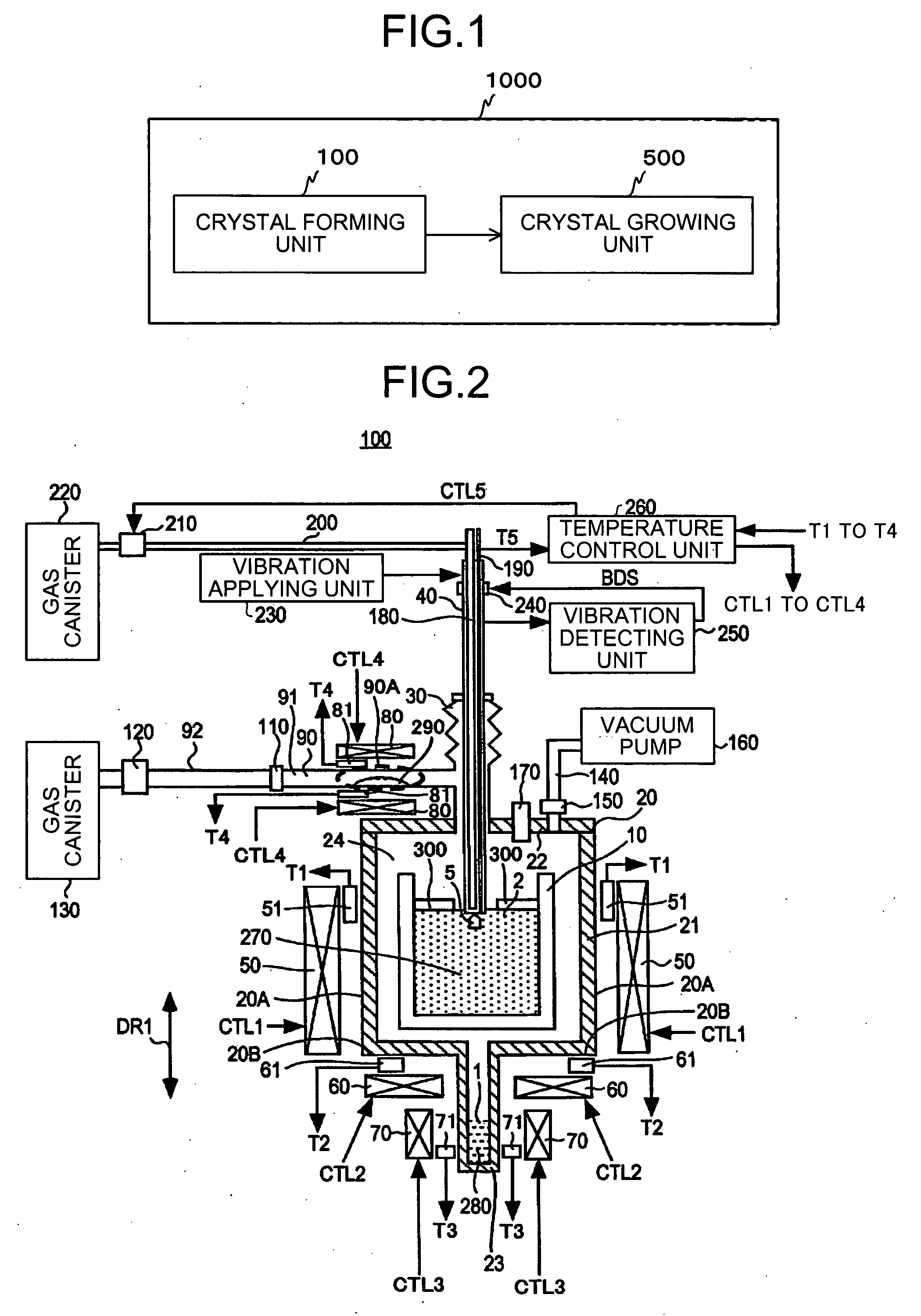

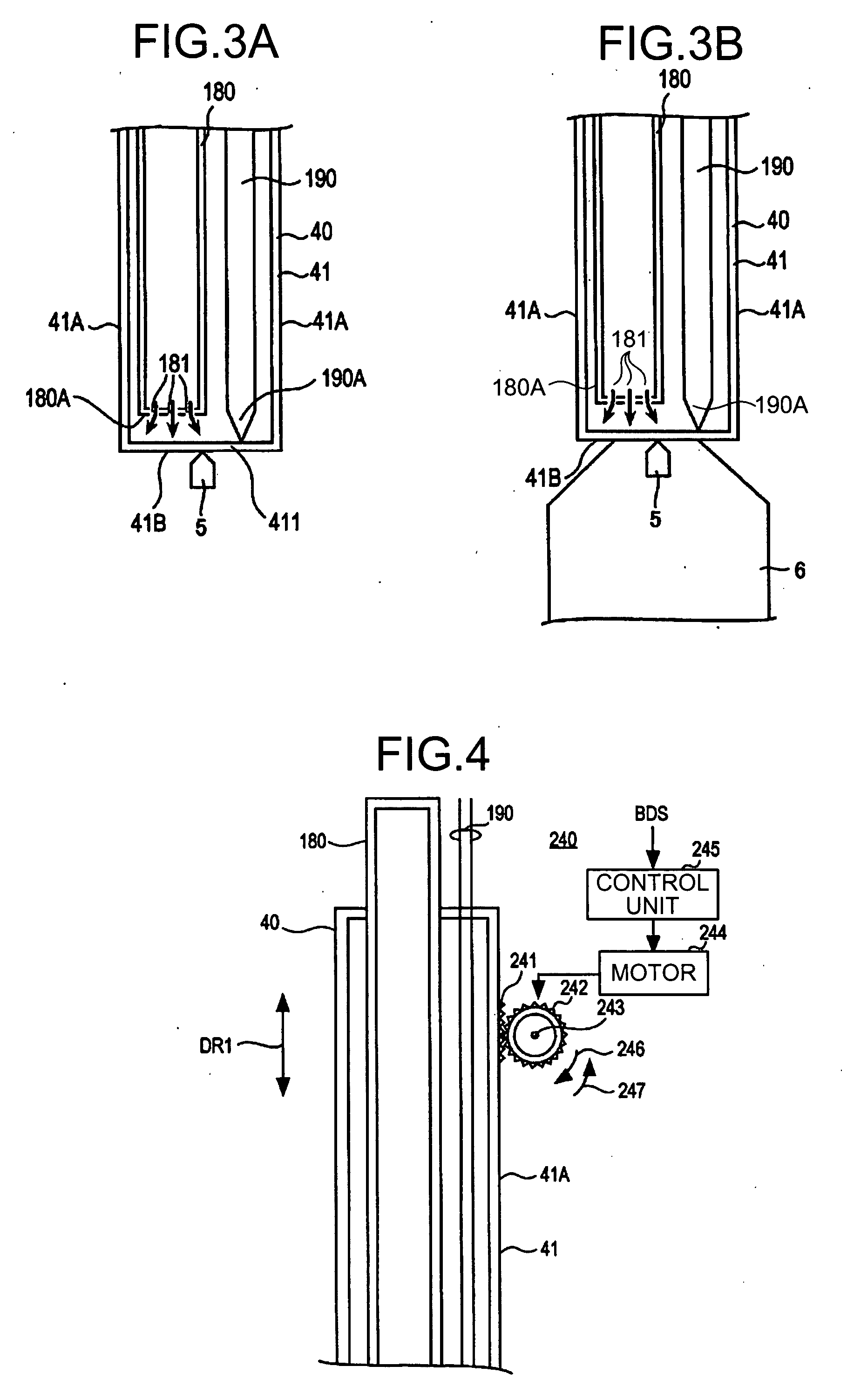

Crystal producing apparatus, crystal producing method, substrate producing method, gallium nitride crystal, and gallium nitride substrate

InactiveUS20080081015A1Solve problemsAfter-treatment apparatusPolycrystalline material growthGallium nitrideVapor phase

A crystal producing apparatus includes a crystal forming unit and a crystal growing unit. The crystal forming unit forms a first gallium nitride (GaN) crystal by supplying nitride gas into melt mixture containing metal sodium (Na) and metal gallium (Ga). The first GaN crystal is sliced and polished to form GaN wafers. The crystal growing unit grows a second GaN crystal on a substrate formed by using a GaN wafer, by the hydride vapor phase epitaxy method, thus producing a bulked GaN crystal.

Owner:RICOH KK

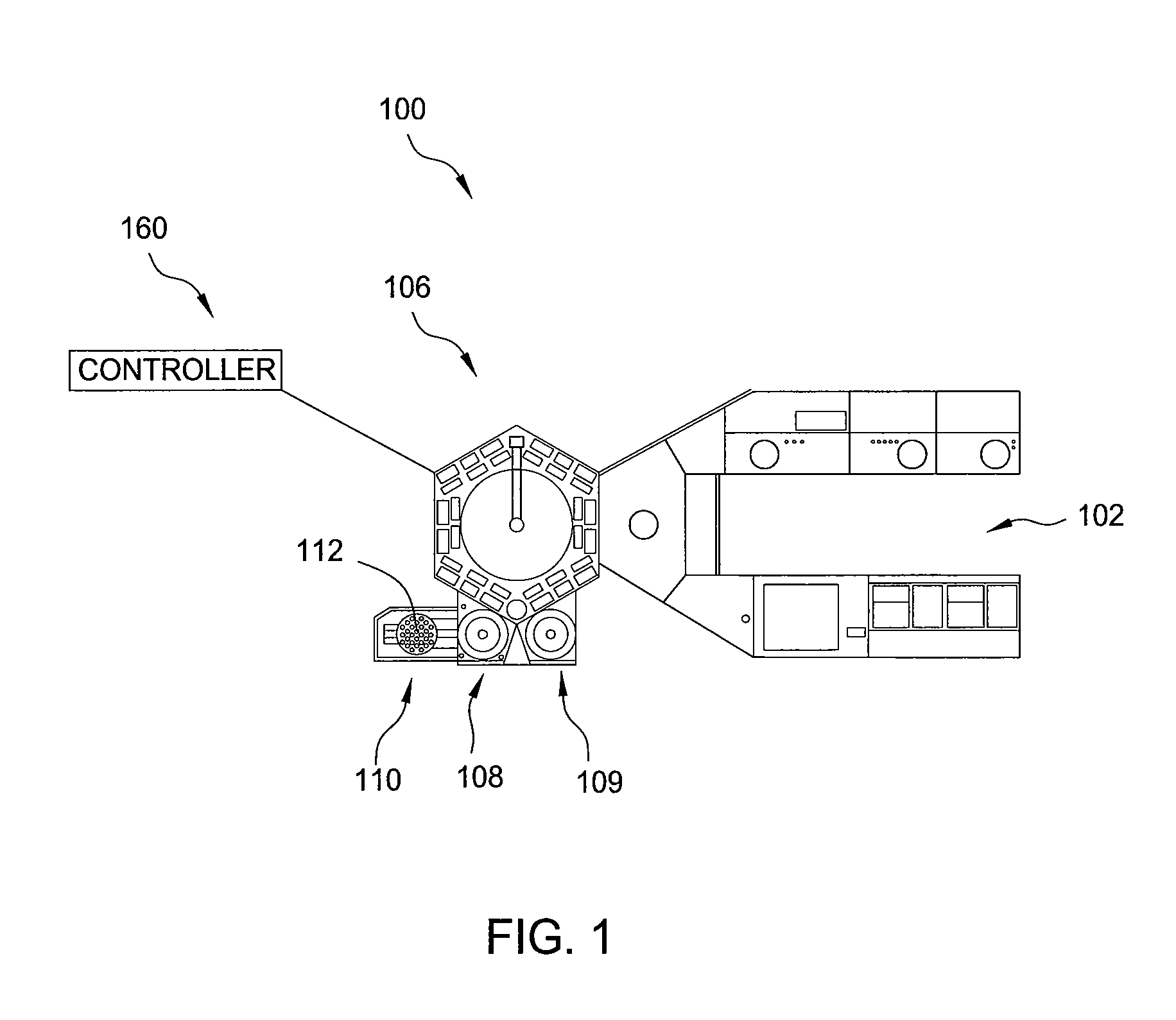

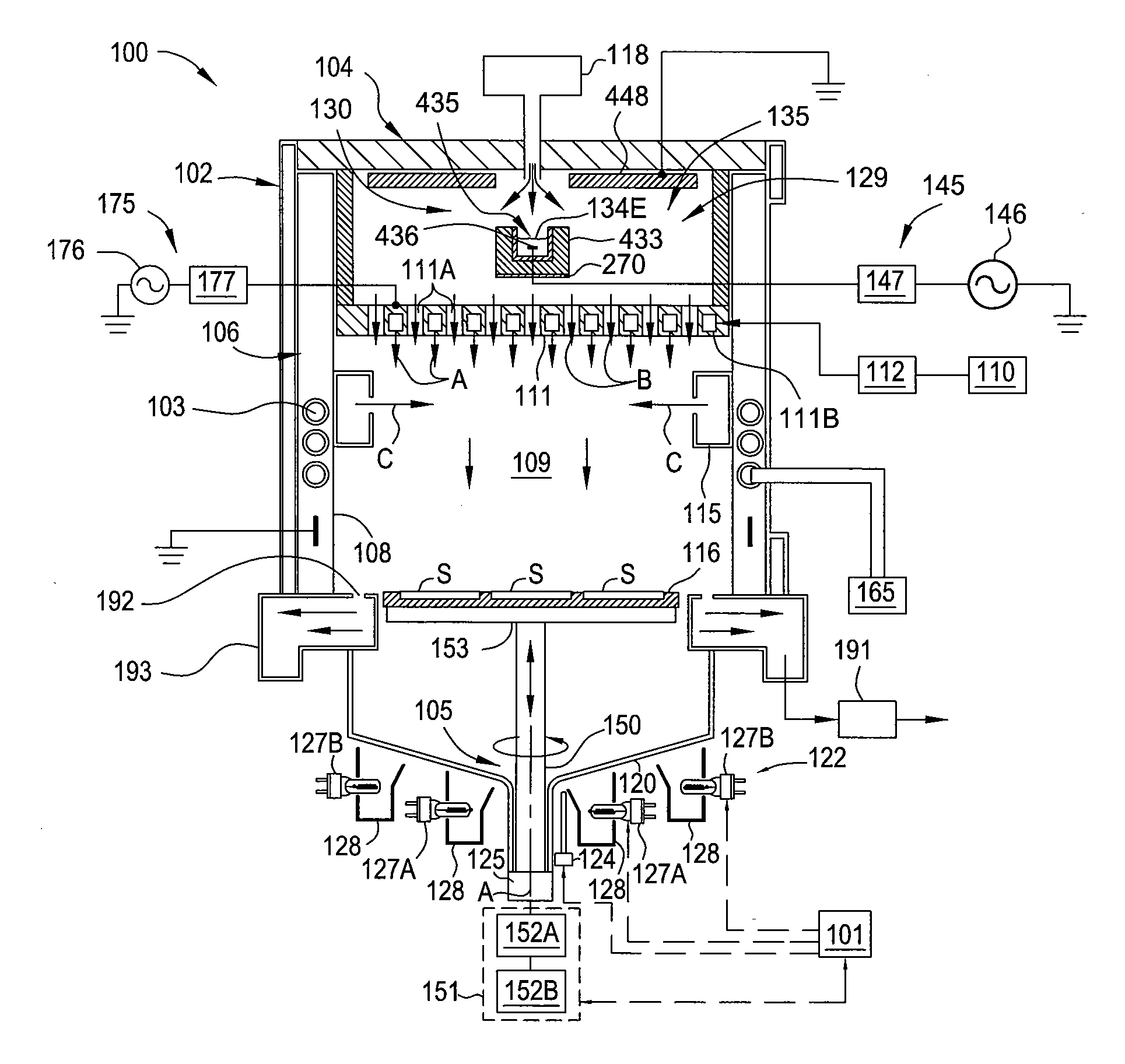

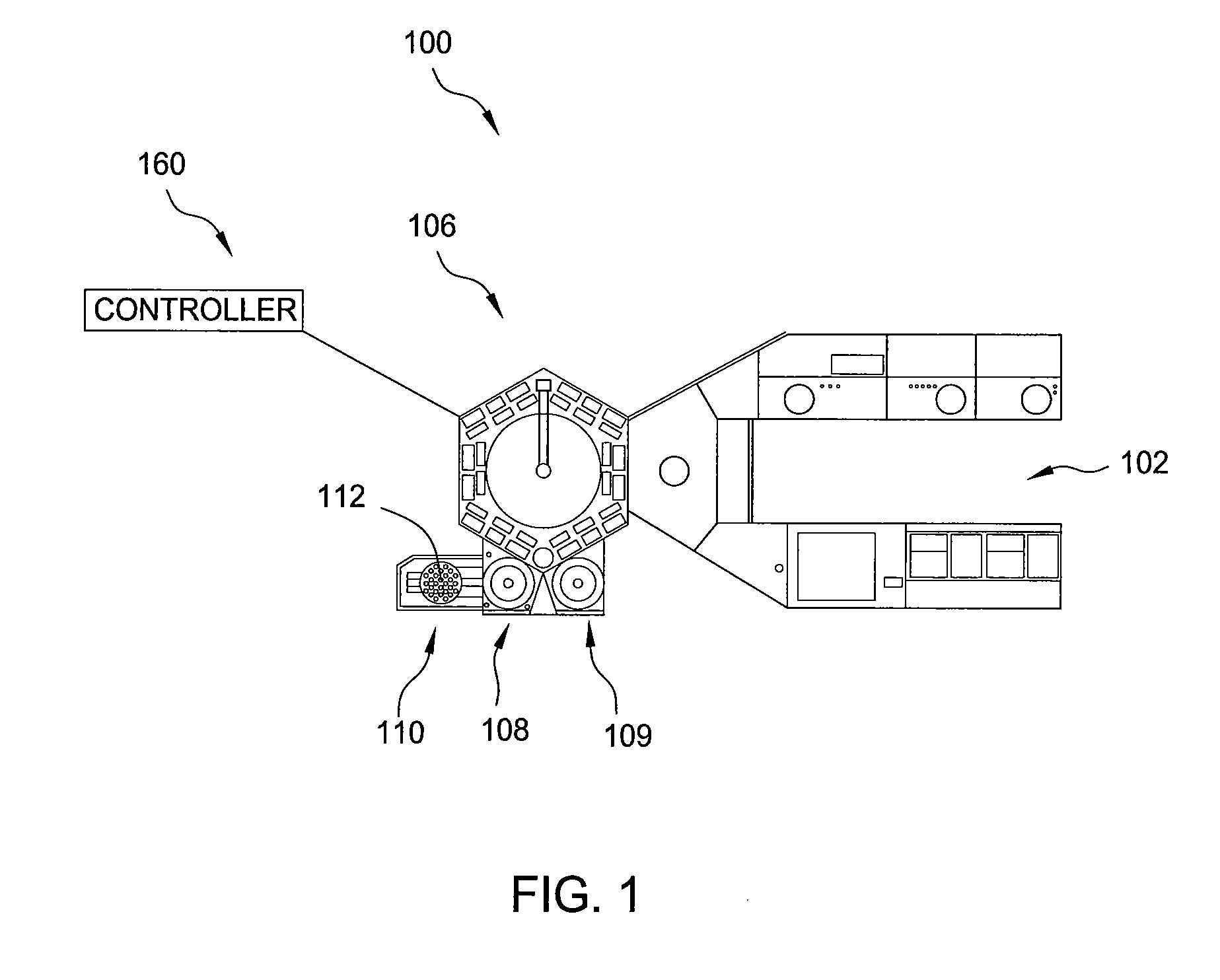

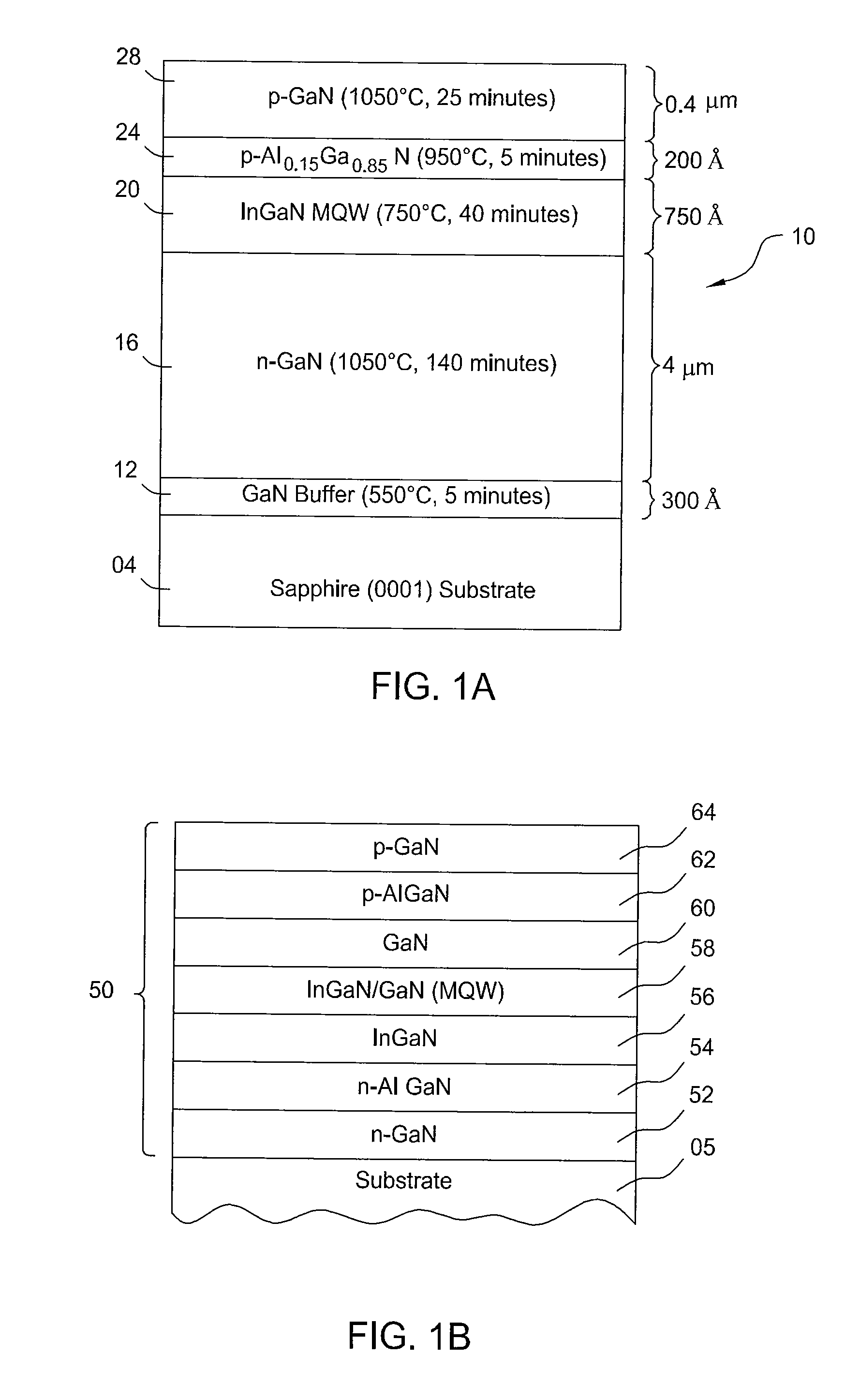

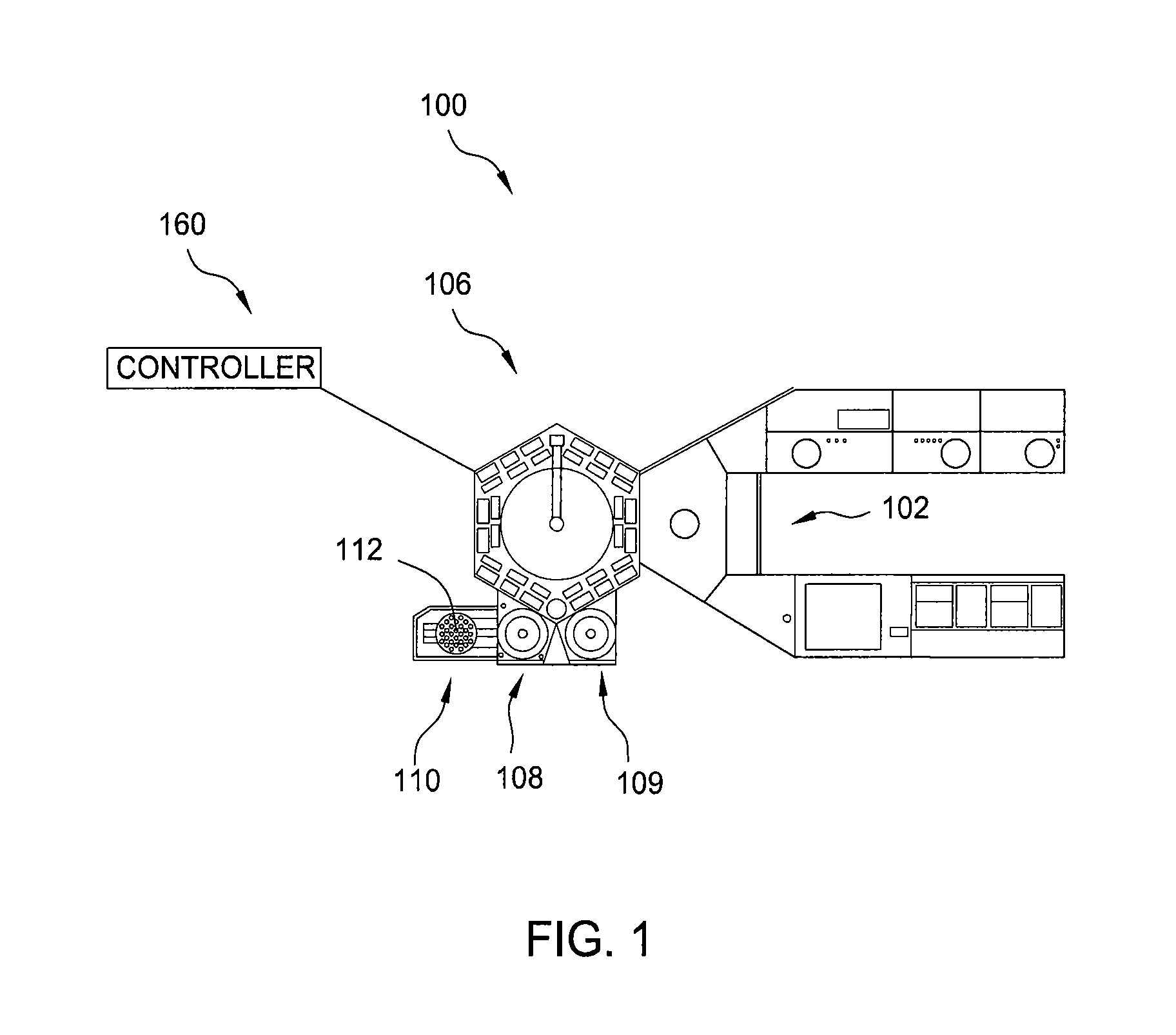

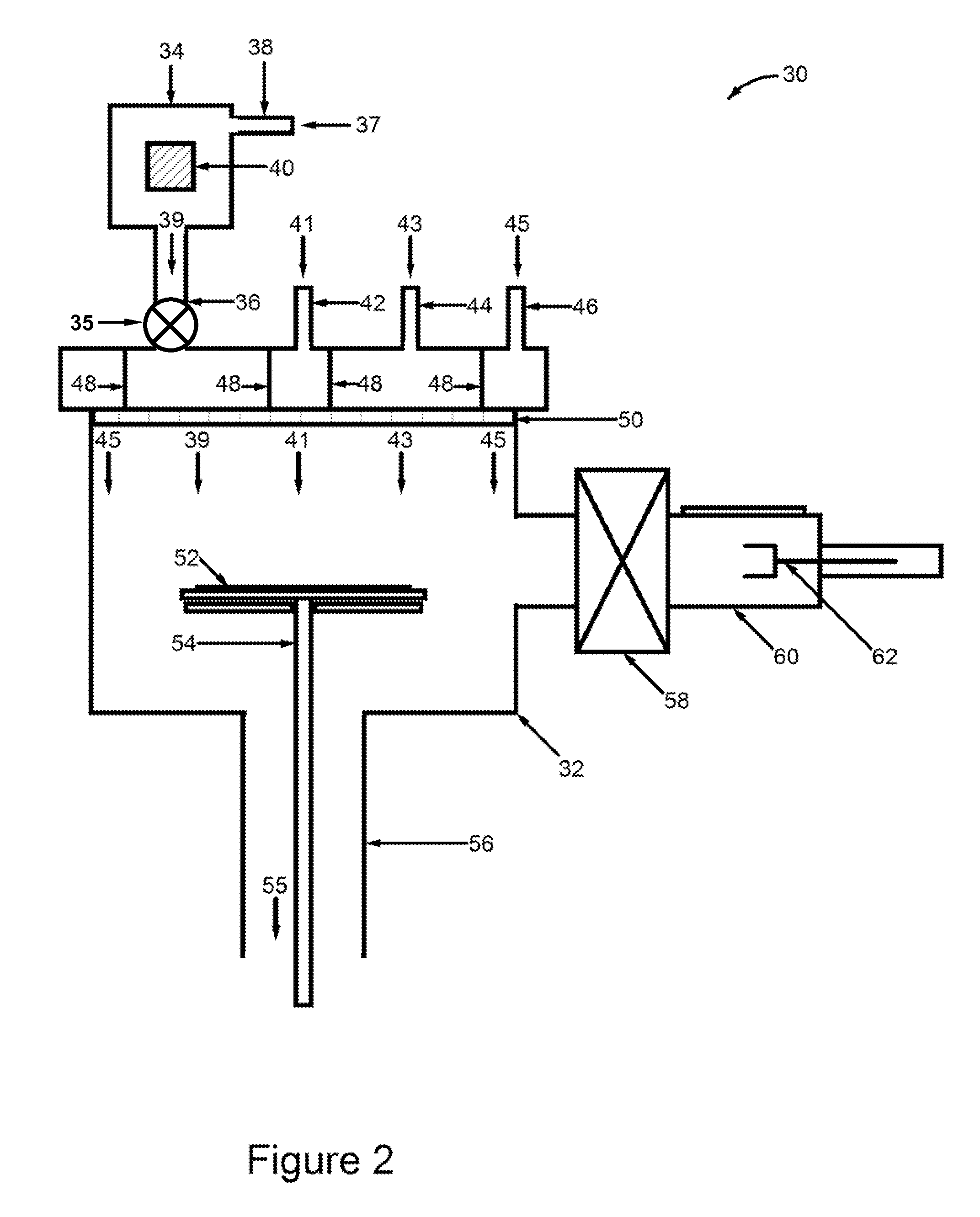

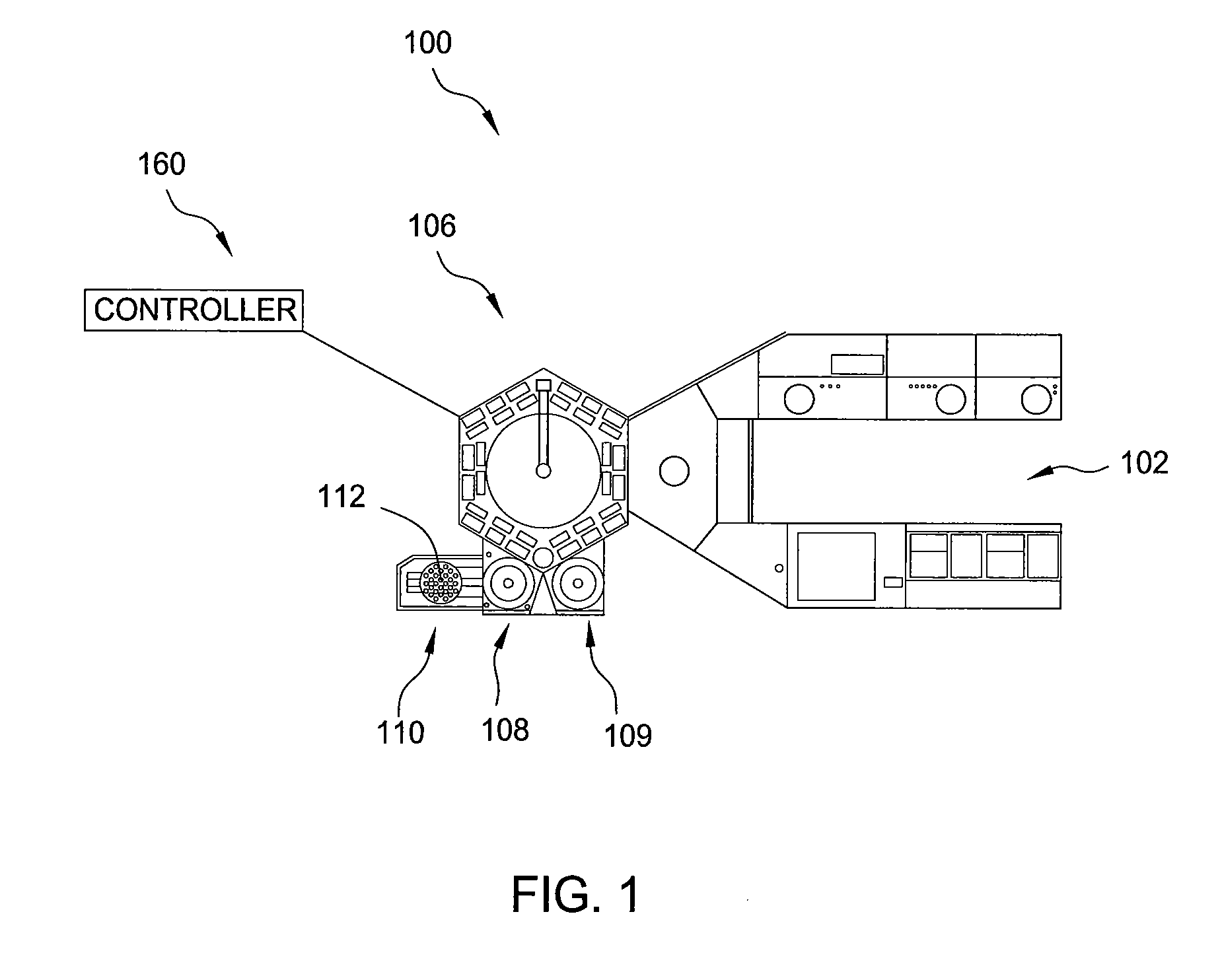

Cluster tool for leds

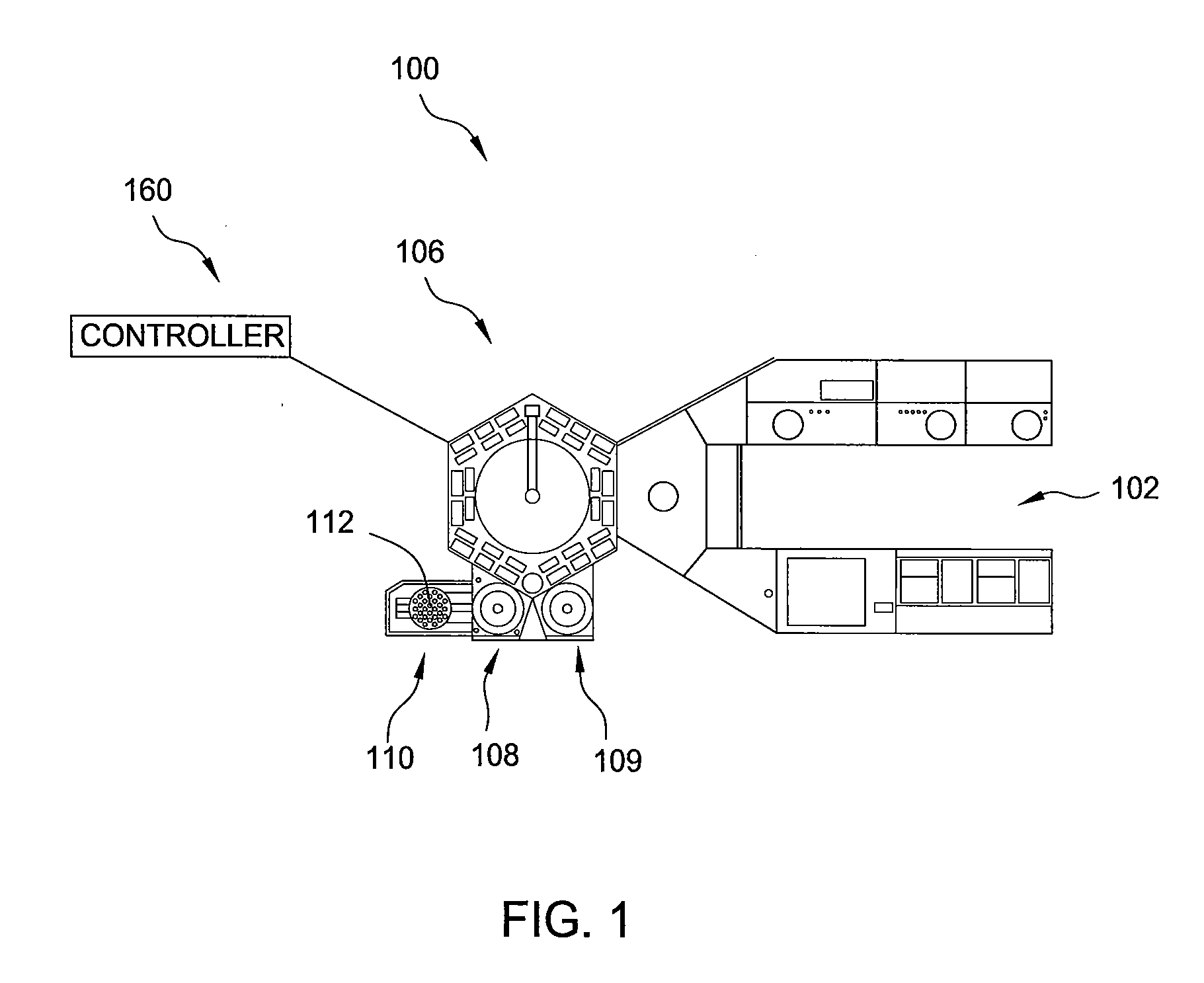

ActiveUS20100261340A1Polycrystalline material growthSemiconductor/solid-state device manufacturingNitrogenChemical vapor deposition

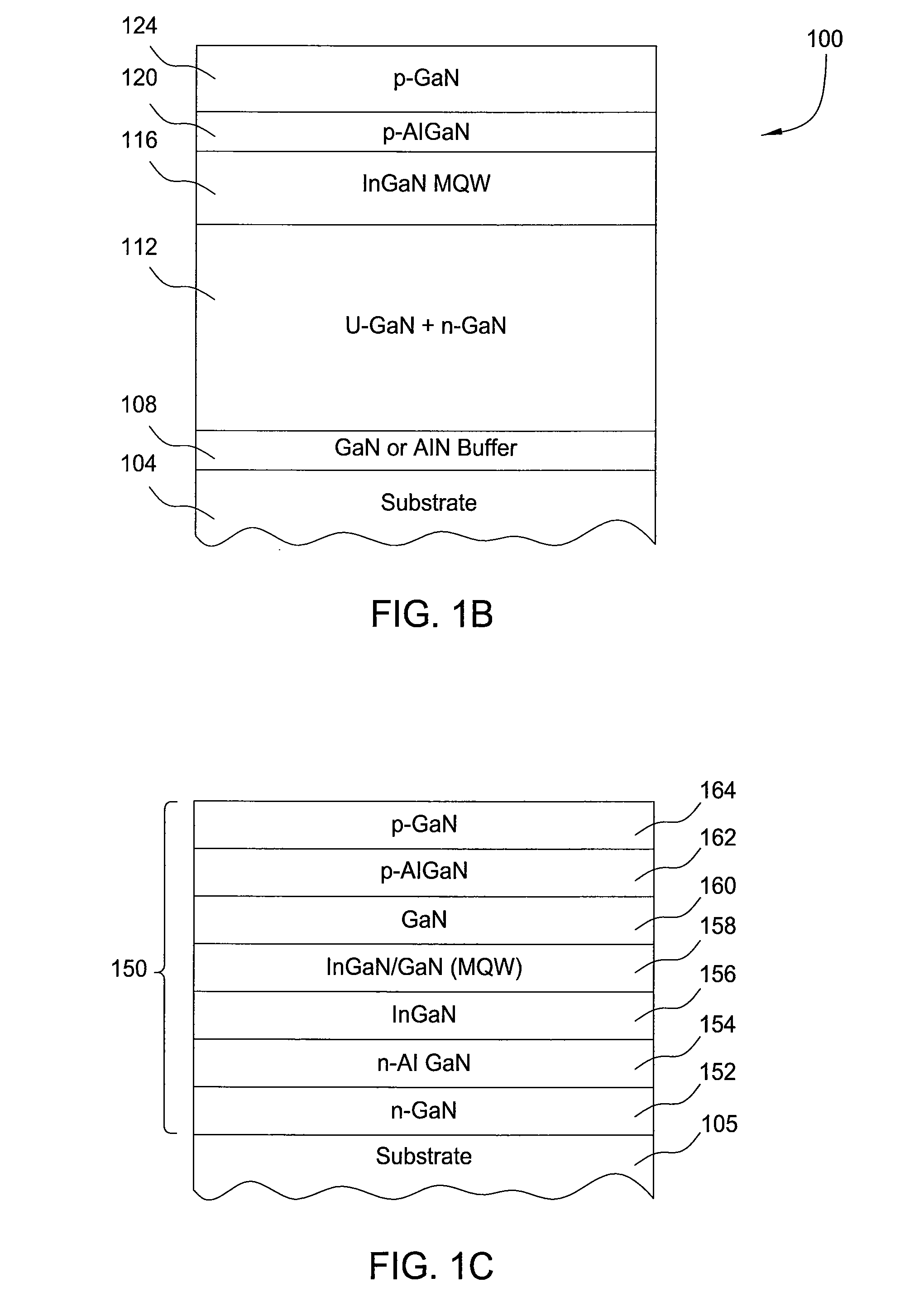

The present invention generally provides apparatus and methods for forming LED structures. One embodiment of the present invention provides a method for fabricating a compound nitride structure comprising forming a first layer comprising a first group-III element and nitrogen on substrates in a first processing chamber by a hydride vapor phase epitaxial (HVPE) process or a metal organic chemical vapor deposition (MOCVD) process, forming a second layer comprising a second group-III element and nitrogen over the first layer in a second processing chamber by a MOCVD process, and forming a third layer comprising a third group-III element and nitrogen over the second layer by a MOCVD process.

Owner:APPLIED MATERIALS INC

Showerhead assembly with gas injection distribution devices

ActiveUS20110256315A1Spray nozzlesSemiconductor/solid-state device manufacturingChemical vapor depositionVapor phase

A method and apparatus that may be utilized for chemical vapor deposition and / or hydride vapor phase epitaxial (HVPE) deposition are provided. The apparatus includes a showerhead assembly with separate inlets and manifolds for delivering separate processing gases into a processing volume of the chamber without mixing the gases prior to entering the processing volume. The showerhead includes a plurality of gas distribution devices disposed within a plurality of gas inlets for injecting one of the processing gases into and distributing it across a manifold for uniform delivery into the processing volume of the chamber. Each of the gas distribution devices preferably has a nozzle configured to evenly distribute the processing gas flowing therethrough while minimizing recirculation of the processing gas within the manifold. As a result, improved deposition uniformity is achieved on a plurality of substrates positioned in the processing volume of the processing chamber.

Owner:APPLIED MATERIALS INC

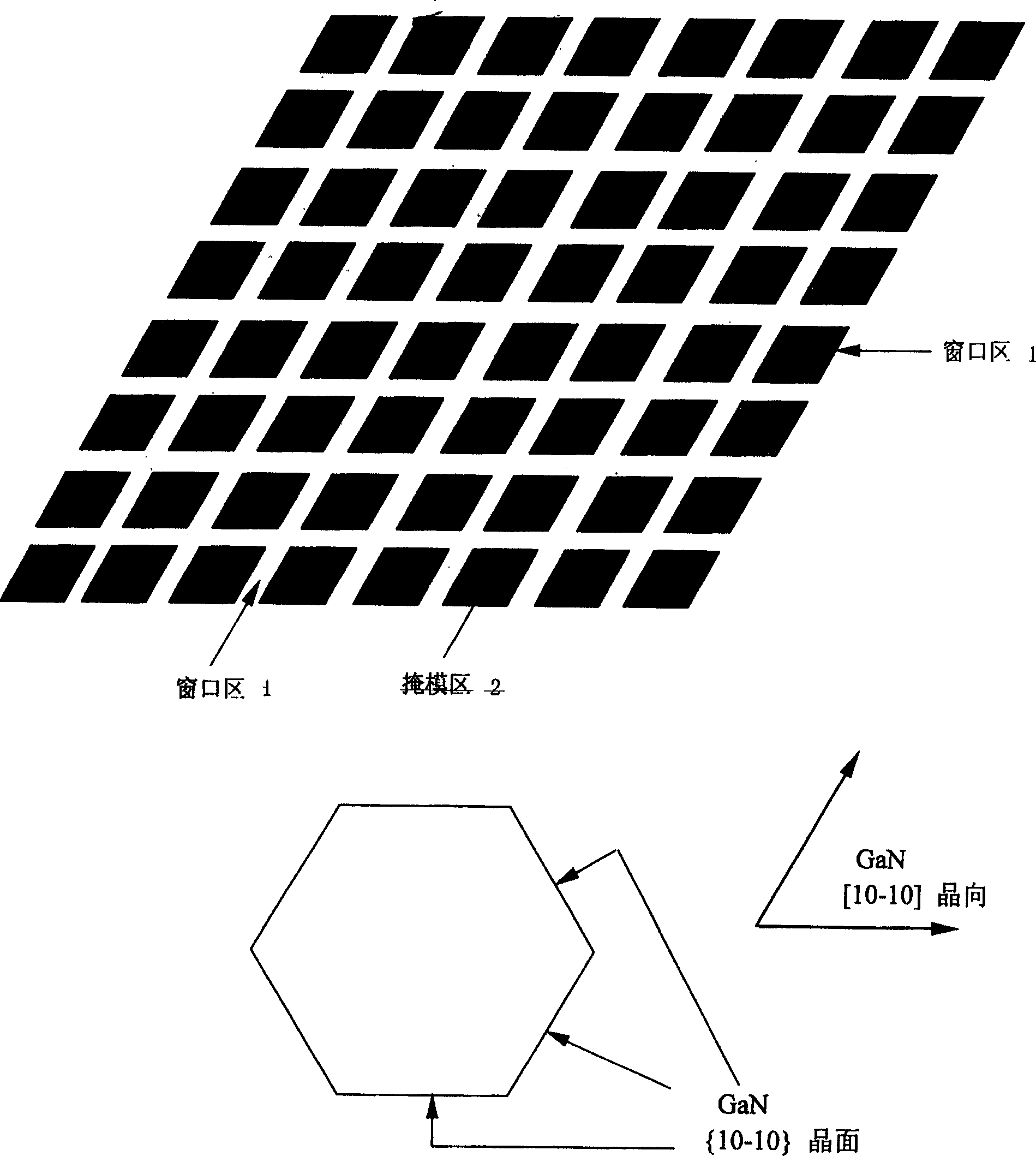

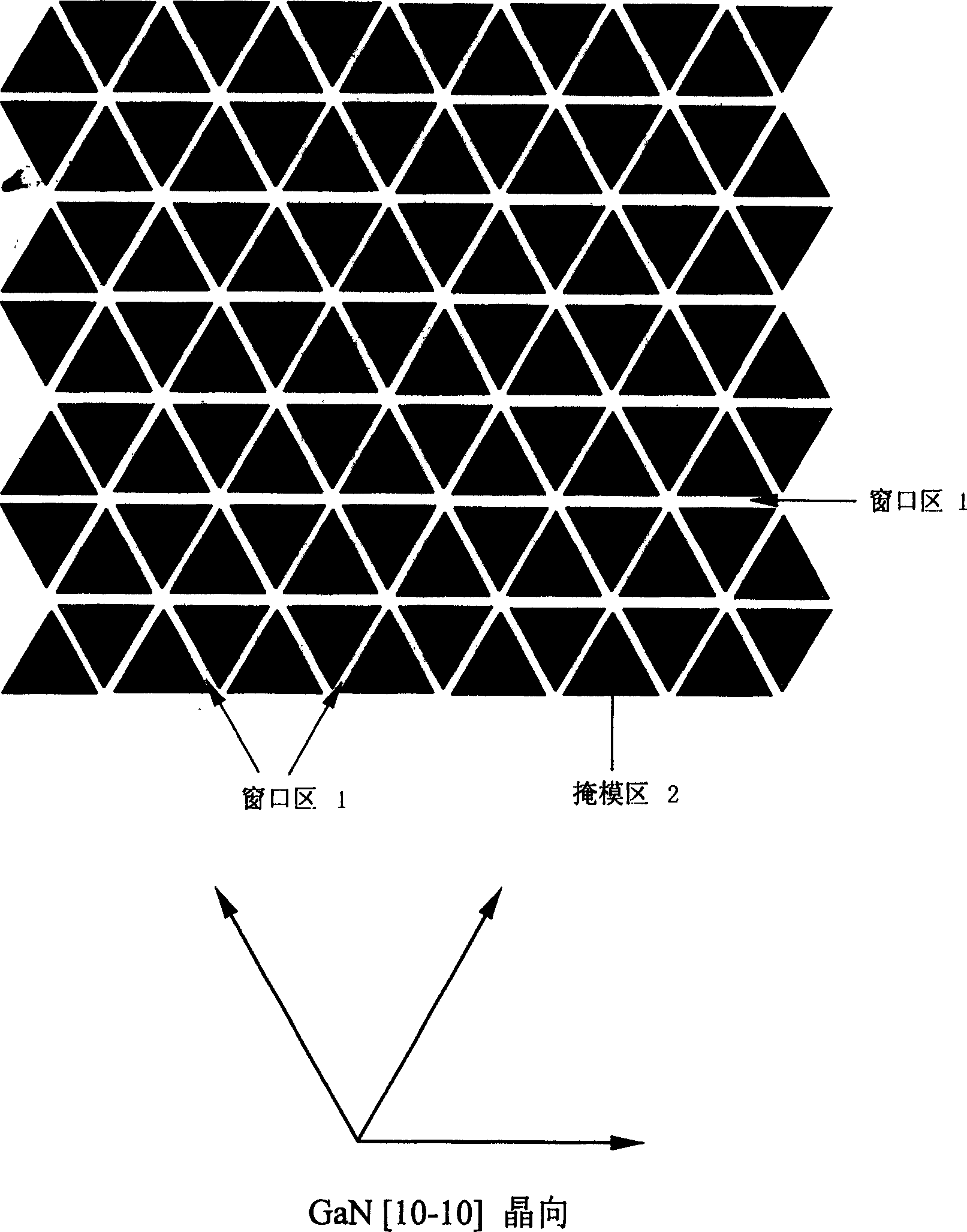

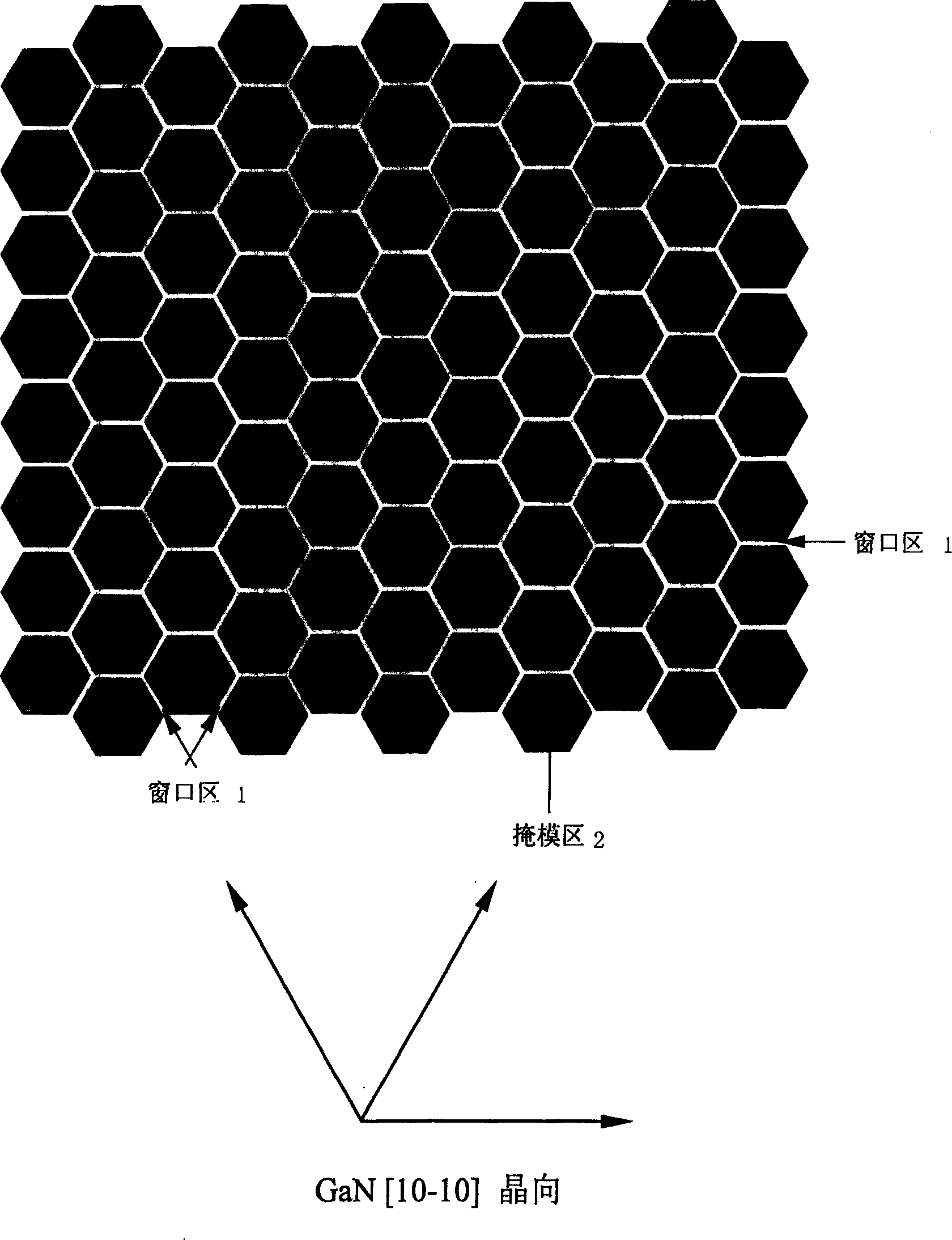

Horizontal epitaxial growth of gallium nitride and its compound semiconductor

InactiveCN1490844AOvercome MisorientationQuick mergeSemiconductor/solid-state device manufacturingGas phaseGallium nitride

The present invention provides a method for growing a lateral epitaxy of the gallium nitride and its compound semiconductors, comprising the following steps: growing an intrinsic gallium nitride on the ( 0001 ) crystal face of sapphire or the ( 111 ) of silicon or the ( 0001 ) of silicon carbide using the metal organic chemical vapor deposition or the molecule beam epitaxy or the hydride vapor epitaxy; then depositing on it a layer of silicon nitride or silicon dioxide or silicon nitride-oxide as the mask area; patterning the mask area using the photolithography and wet or dry etch techniques, the pattern of the mask area being designed into the pattern structure of the triangle or parallelogram or rhombus or hexagon with the included angles of 60 or 120 degrees or the combination of above shapes which are constituted of the [ 10 - 10 ] crystal direction of gallium nitride on the edge of the adjacent windows; and finally growing the secondary epitaxy, that is, lateral epitaxy of gallium nitride and its compound using the metal organic vapor deposition or the molecule beam epitaxy or the hydride vapor epitaxy.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

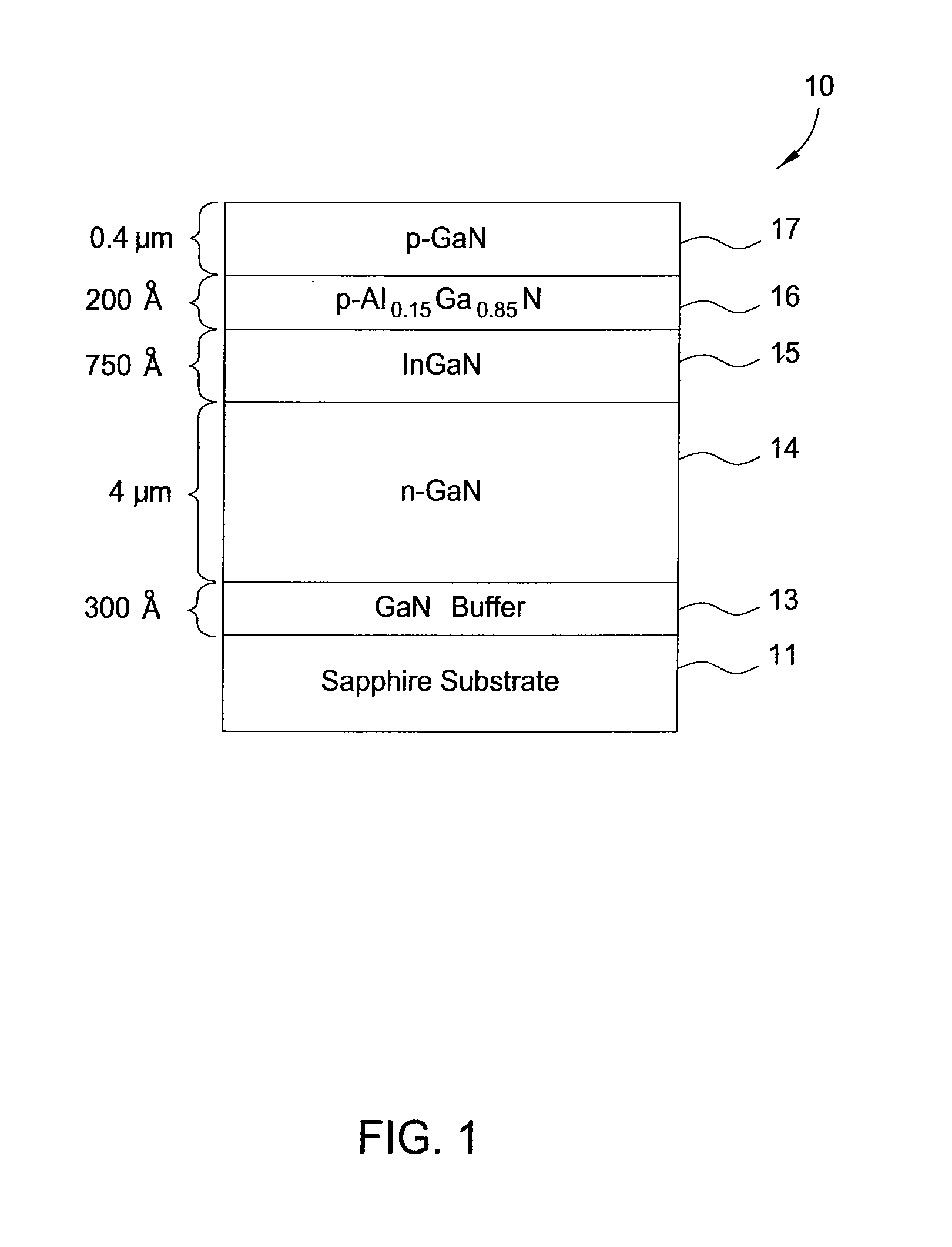

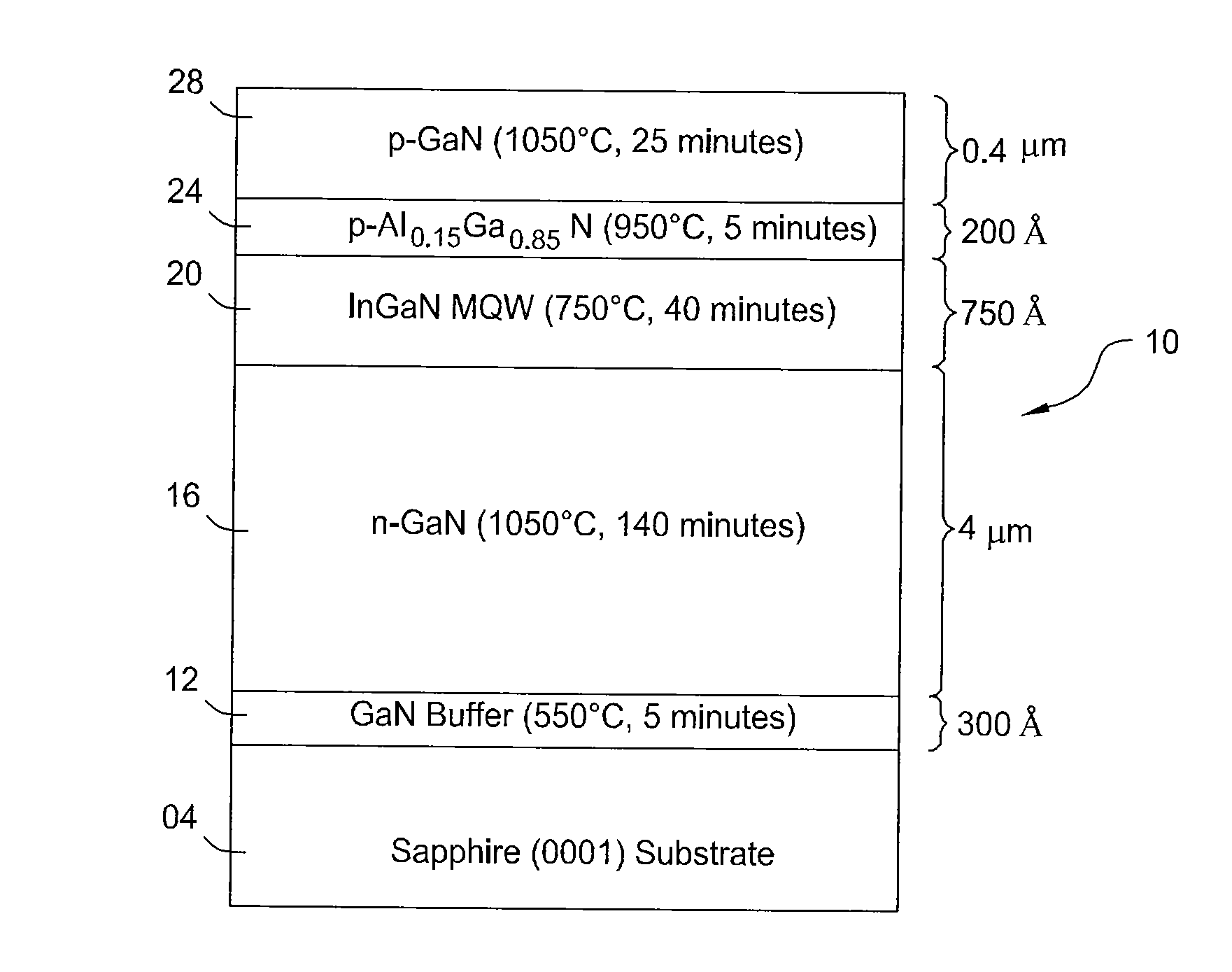

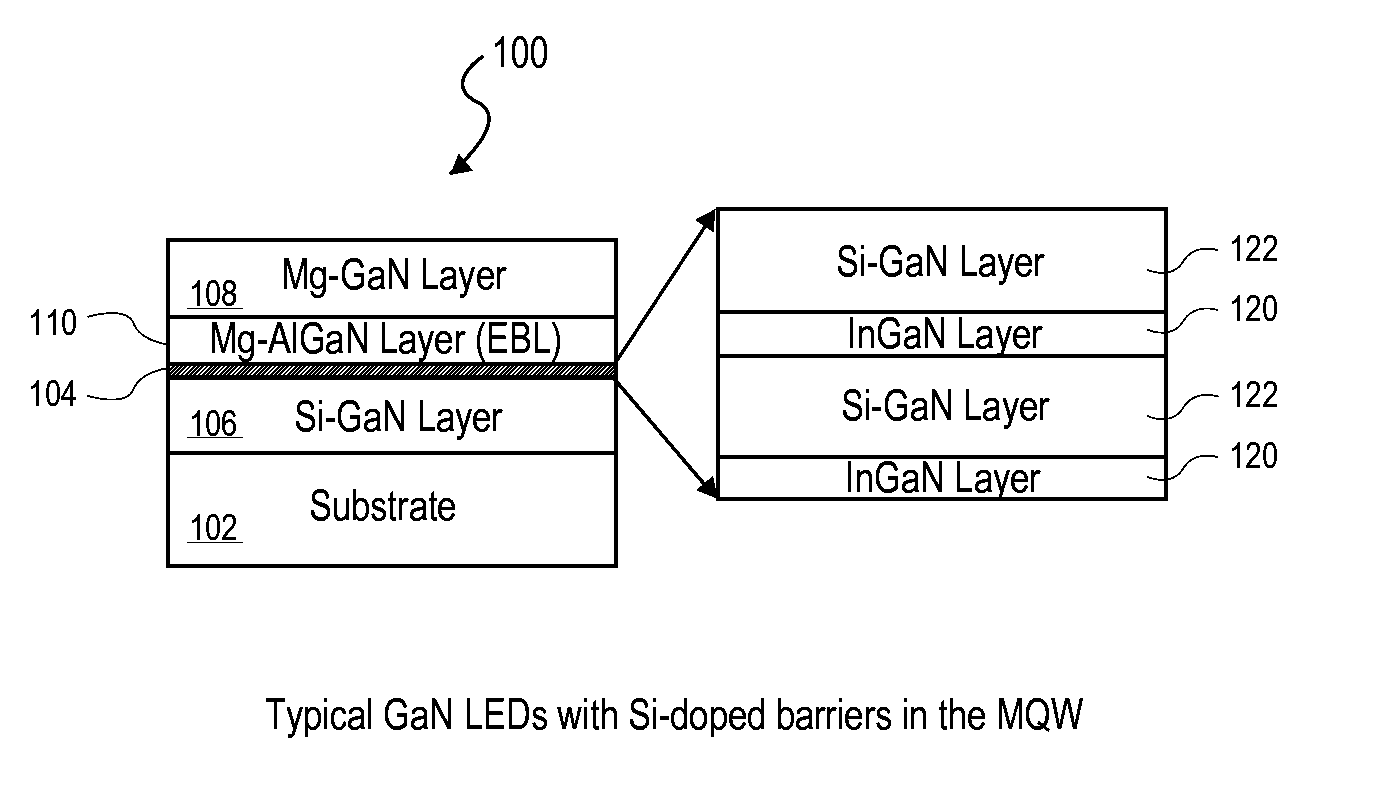

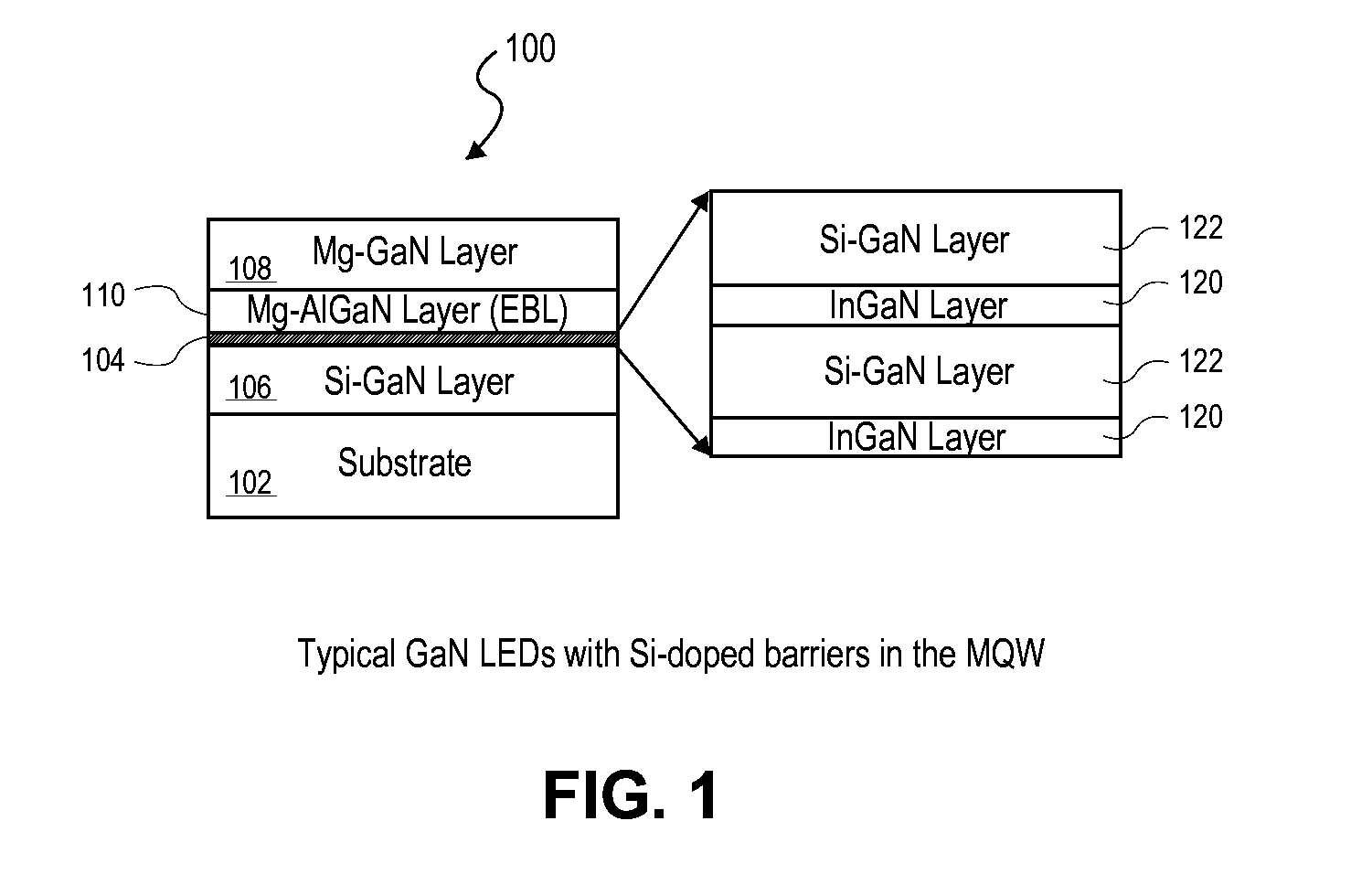

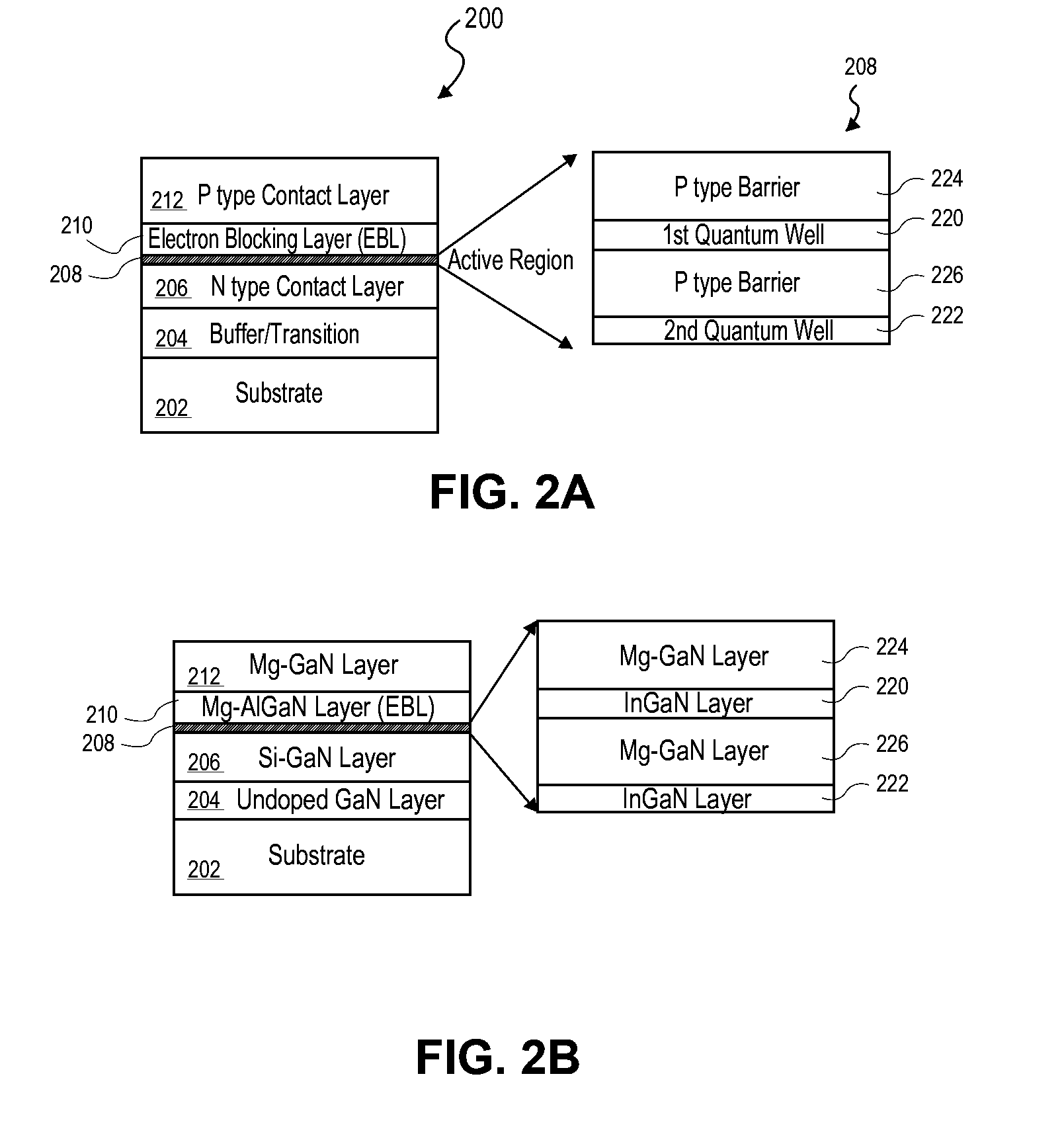

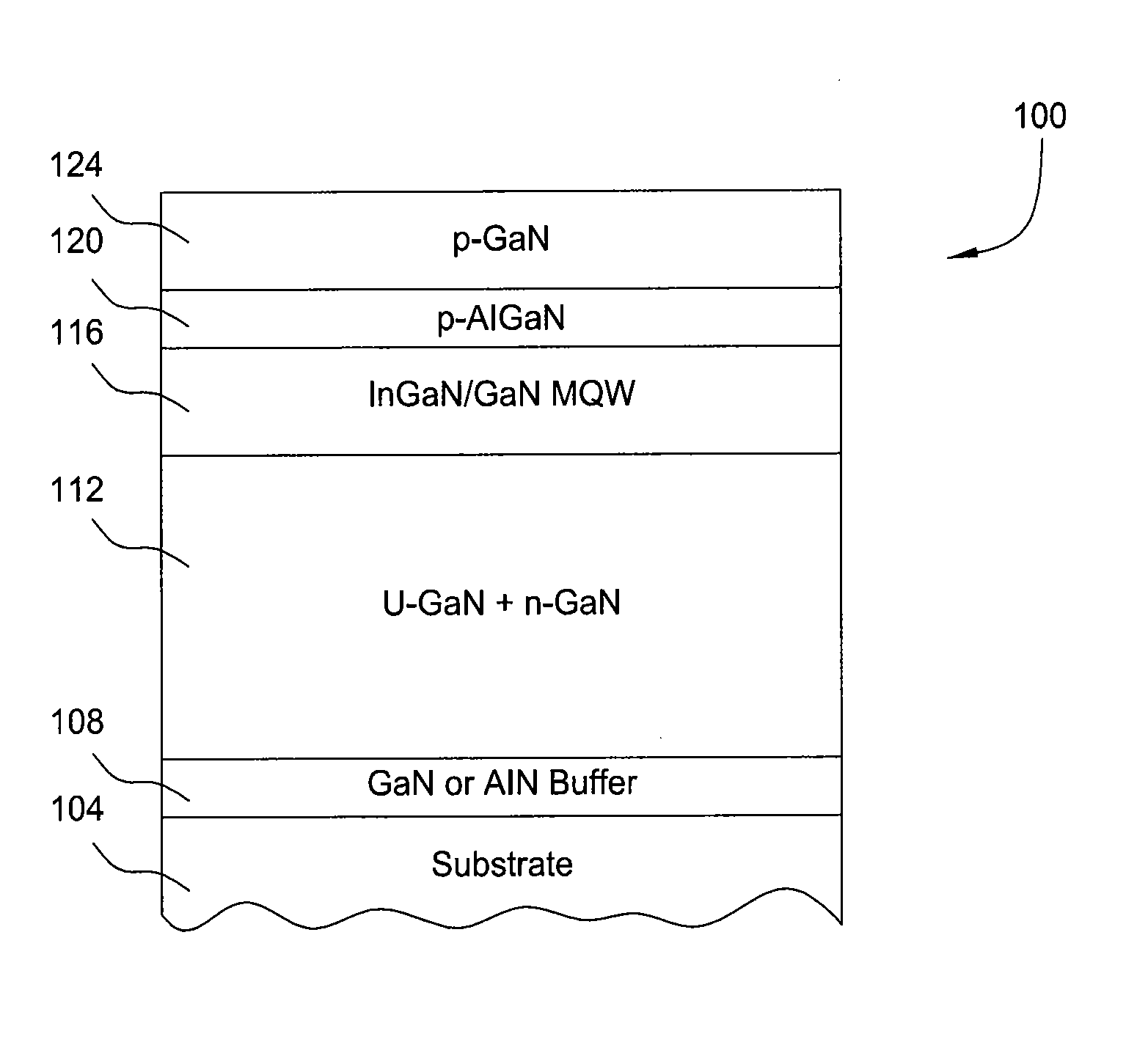

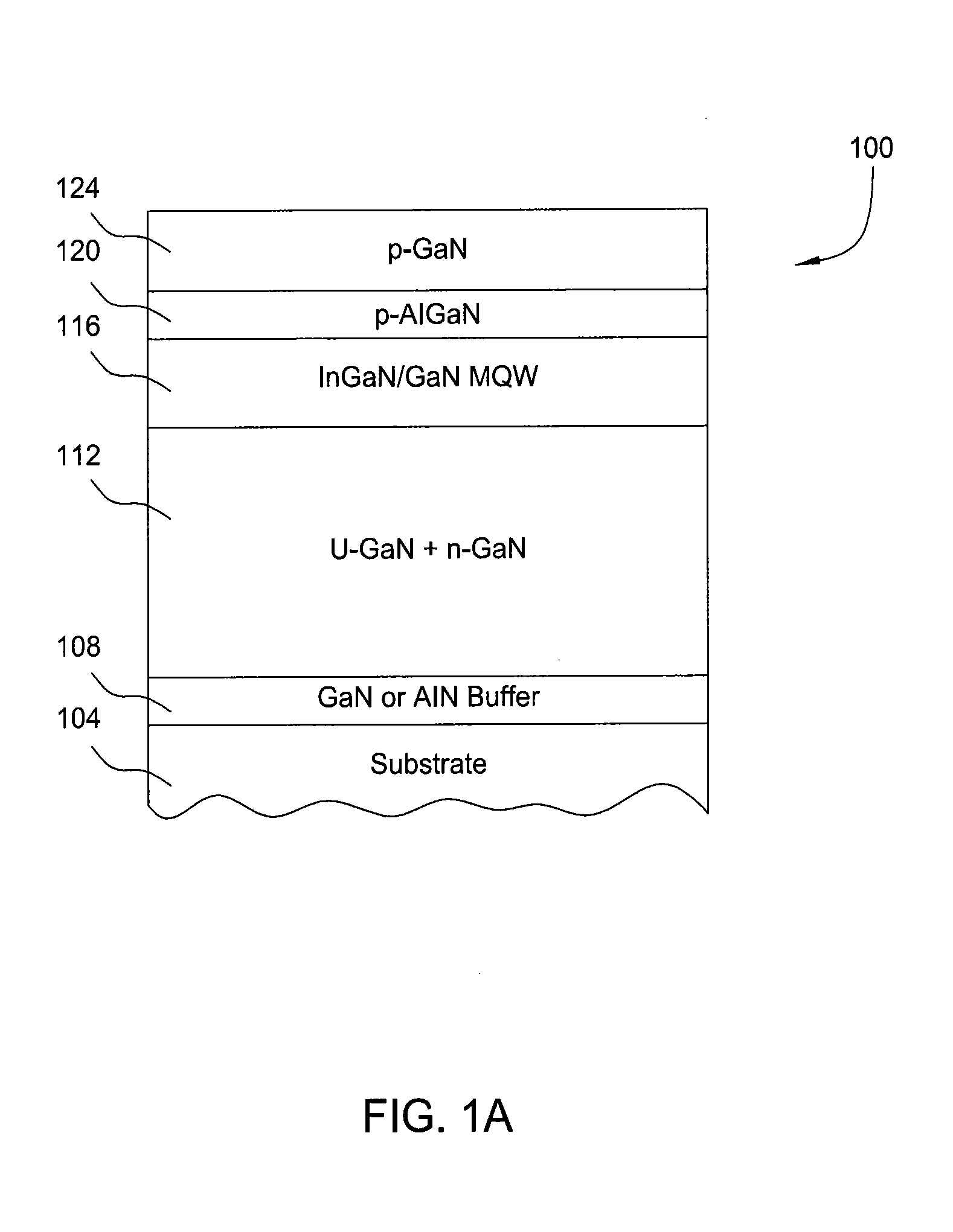

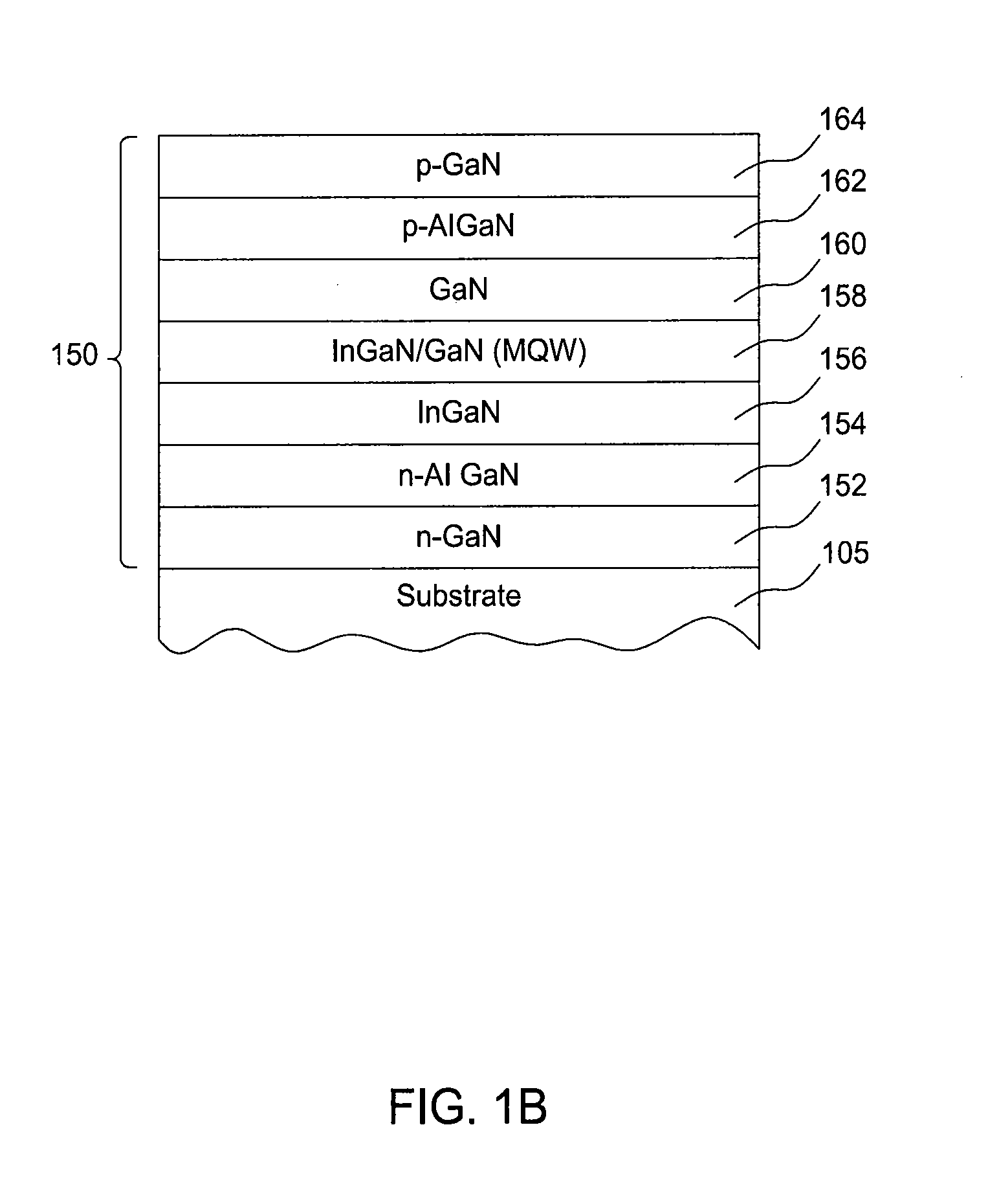

Light emitting diode with enhanced quantum efficiency and method of fabrication

InactiveUS20120235116A1Low costIncrease varietyPolycrystalline material growthConductive materialIndiumAlloy

One embodiment of a quantum well structure comprises an active region including active layers that comprise quantum wells and barrier layers wherein some or all of the active layers are p type doped. P type doping some or all of the active layers improves the quantum efficiency of III-V compound semiconductor light emitting diodes by locating the position of the P-N junction in the active region of the device thereby enabling the dominant radiative recombination to occur within the active region. In one embodiment, the quantum well structure is fabricated in a cluster tool having a hydride vapor phase epitaxial (HVPE) deposition chamber with a eutectic source alloy. In one embodiment, the indium gallium nitride (InGaN) layer and the magnesium doped gallium nitride (Mg—GaN) or magnesium doped aluminum gallium nitride (Mg—AlGaN) layer are grown in separate chambers by a cluster tool to avoid indium and magnesium cross contamination. Doping of group III-nitrides by hydride vapor phase epitaxy using group III-metal eutectics is also described. In one embodiment, a source is provided for HVPE deposition of a p-type or an n-type group III-nitride epitaxial film, the source including a liquid phase mechanical (eutectic) mixture with a group III species. In one embodiment, a method is provided for performing HVPE deposition of a p-type or an n-type group III-nitride epitaxial film, the method including using a liquid phase mechanical (eutectic) mixture with a group III species.

Owner:APPLIED MATERIALS INC

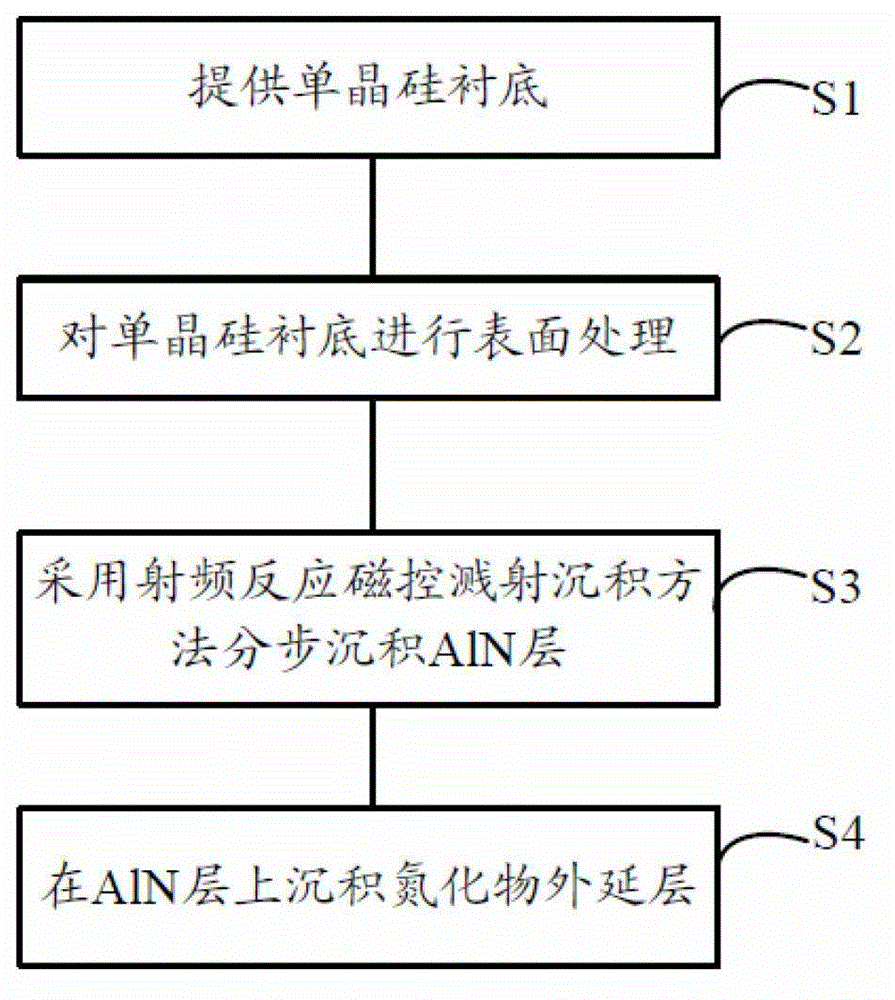

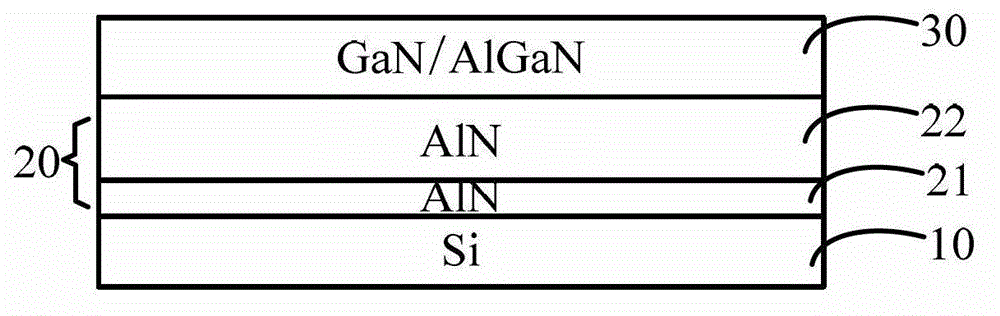

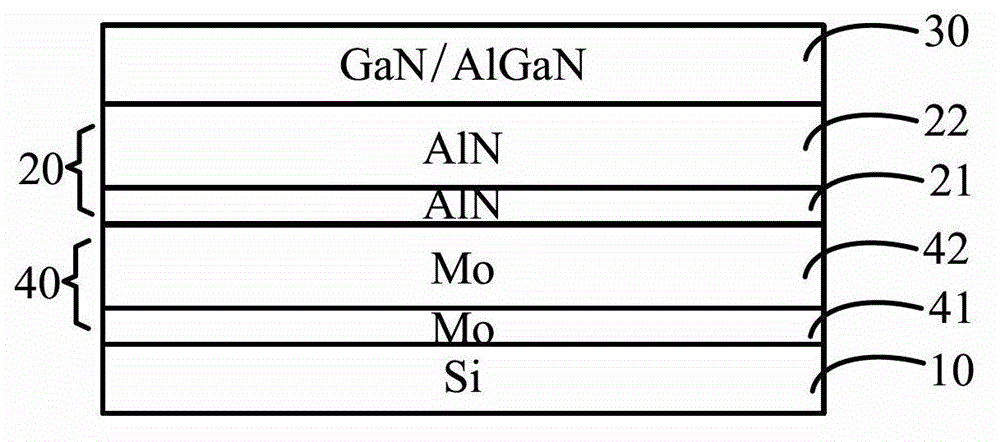

Growth method of compound semiconductor epitaxial layer on silicon substrate and device structure with epitaxial layer

ActiveCN103915537AImprove crystal qualityImprove performanceSemiconductor/solid-state device manufacturingSemiconductor devicesOrganometallic chemistryGas phase

The invention discloses a growth method of a compound semiconductor epitaxial layer on a silicon substrate and a device structure with the epitaxial layer. The method comprises the steps of providing a single-crystal silicon substrate, carrying out surface processing on the single-crystal silicon substrate, depositing an AlN layer step by step through a radio frequency magnetron sputtering deposition method on the single-crystal silicon substrate, and depositing an AlN layer, or a GaN layer or an AlGaN layer on the AlN layer through an organometallic chemistry vapor deposition method or a hydride vapor phase epitaxy method. The AlN layer comprises an AlN nucleating layer used for controlling AlN crystal orientation and an AlN buffering layer used for controlling AlN crystal stress, and the AlN buffering layer is thicker than the AlN nucleating layer. The method effectively avoids the cracking and dislocation phenomenon caused by thermal mismatching and lattice mismatching, improves the crystal quality of the epitaxial layer, and enhances device performance.

Owner:DEPOSITION EQUIP & APPL SHANGHAI LTD

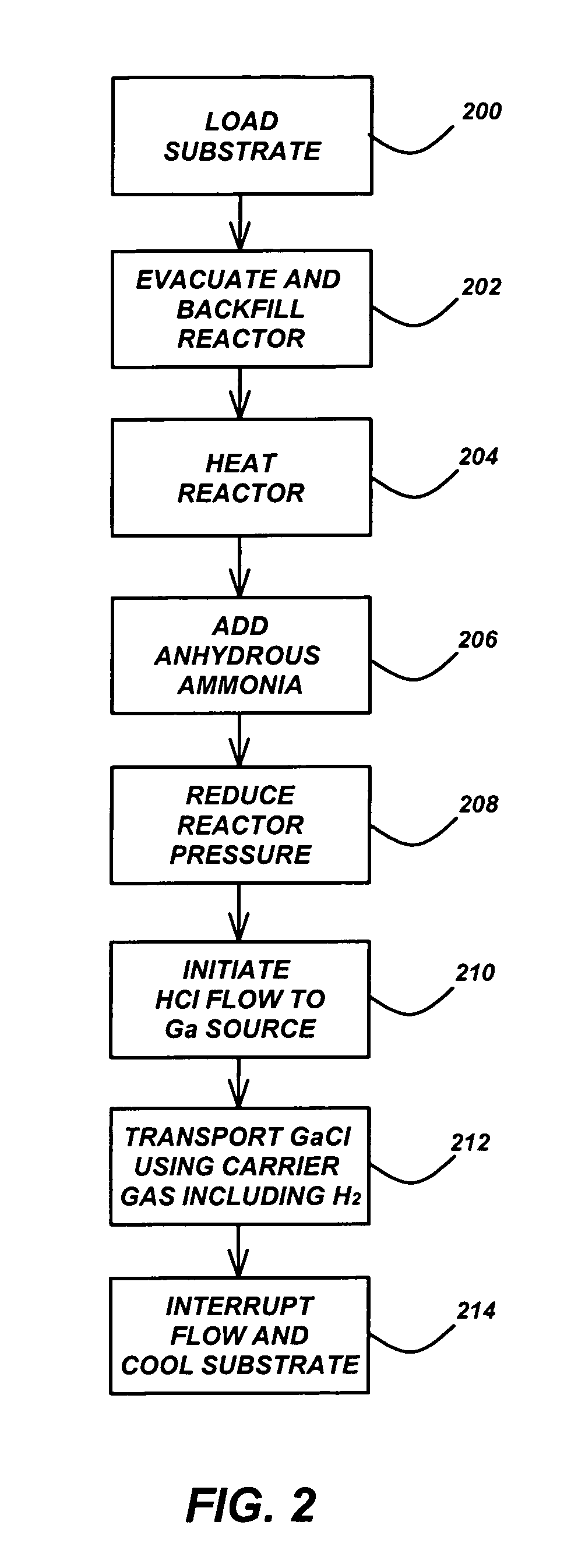

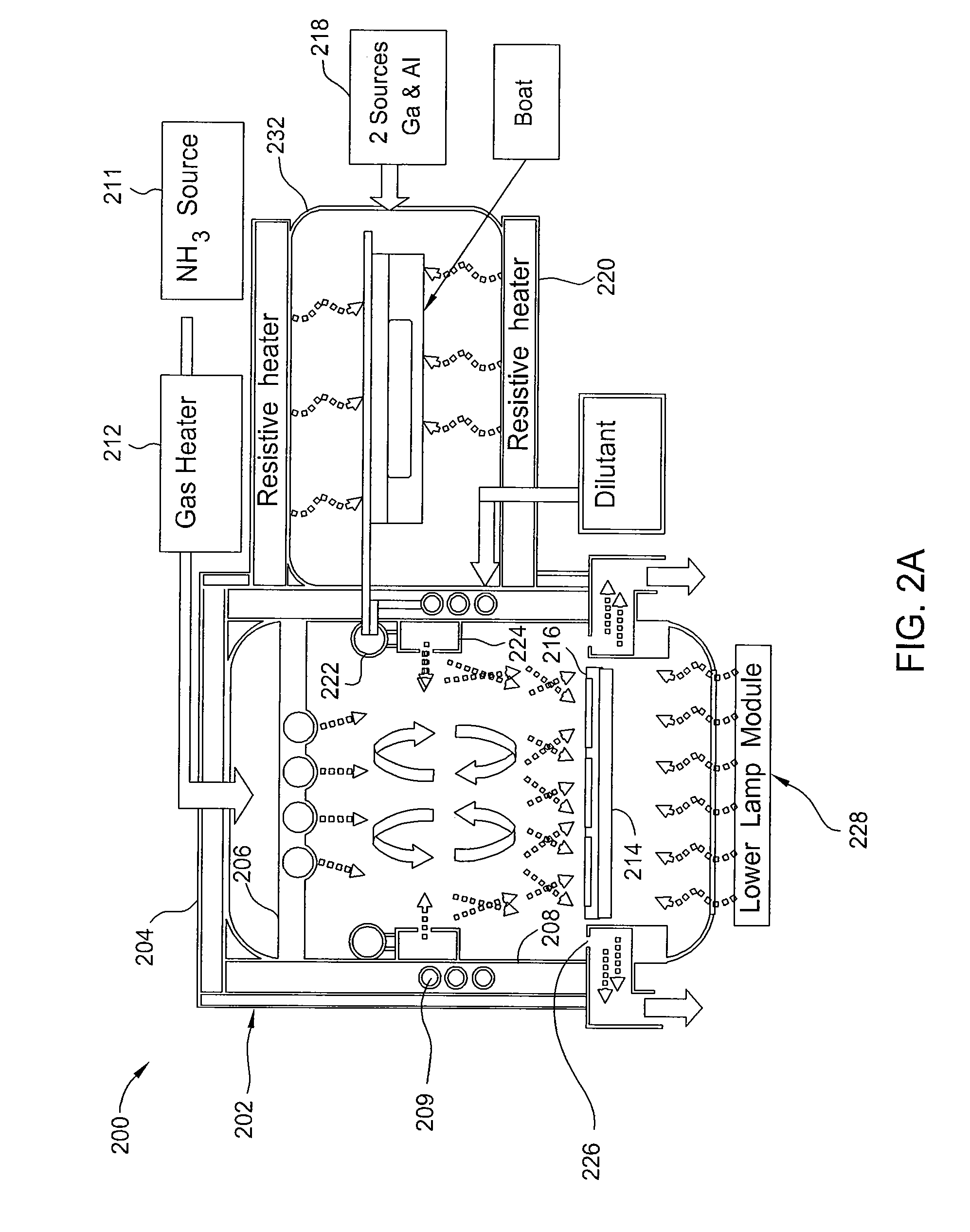

Modern hydride vapor-phase epitaxy system & methods

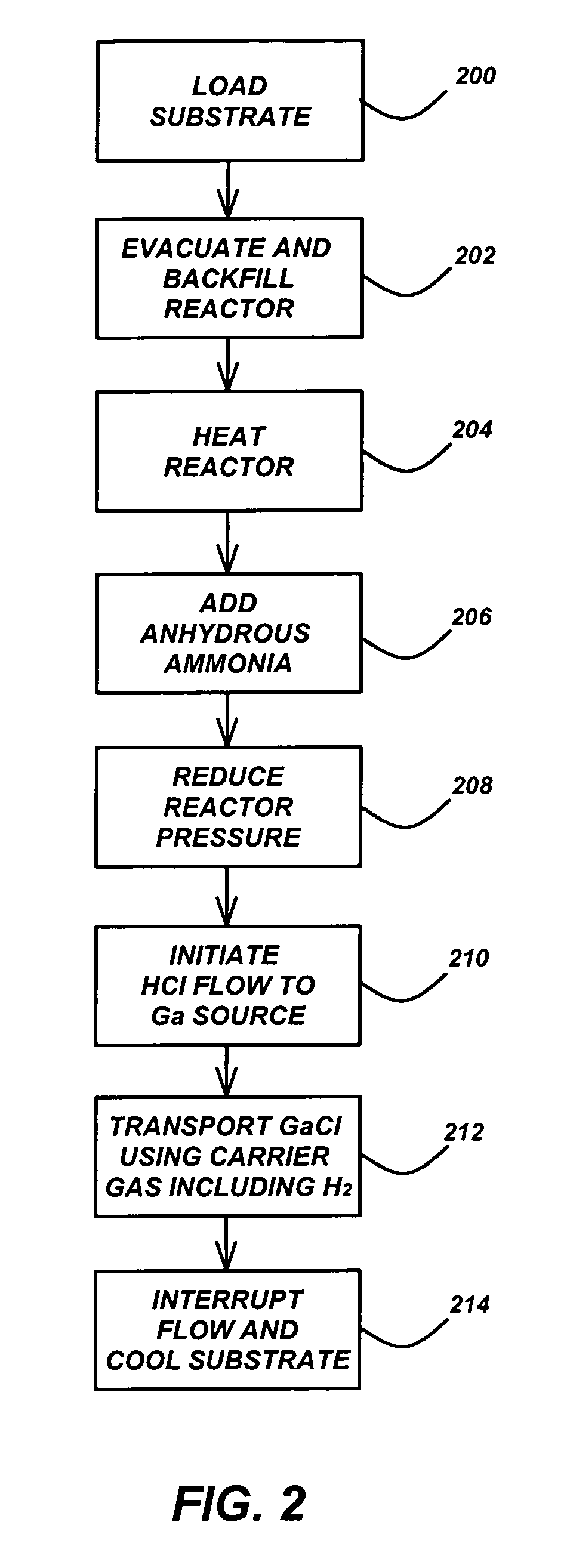

ActiveUS20110155049A1Uniform flow rateReduce distancePolycrystalline material growthFrom chemically reactive gasesChemical reactionSusceptor

Hydride vapor-phase deposition (HVPE) systems are disclosed. An HVPE hydride vapor-phase deposition system may include a reactant source chamber and a growth chamber containing a susceptor coupled to the reactant source chamber. The reactant source chamber may be configured to create a reactant gas through a chemical reaction between a solid or liquid precursor and a different precursor gas. The reactant source chamber can be configured to operate at a temperature T(M) significantly above room temperature. The reactant gas can be chemically unstable at or near room temperature. The susceptor is configured to receive a substrate and maintain the substrate at a substrate temperature T(S). The growth chamber includes walls can be configured to operate at a temperature T(C) such that T(M), T(S) are greater than T(C).

Owner:CBL TECH

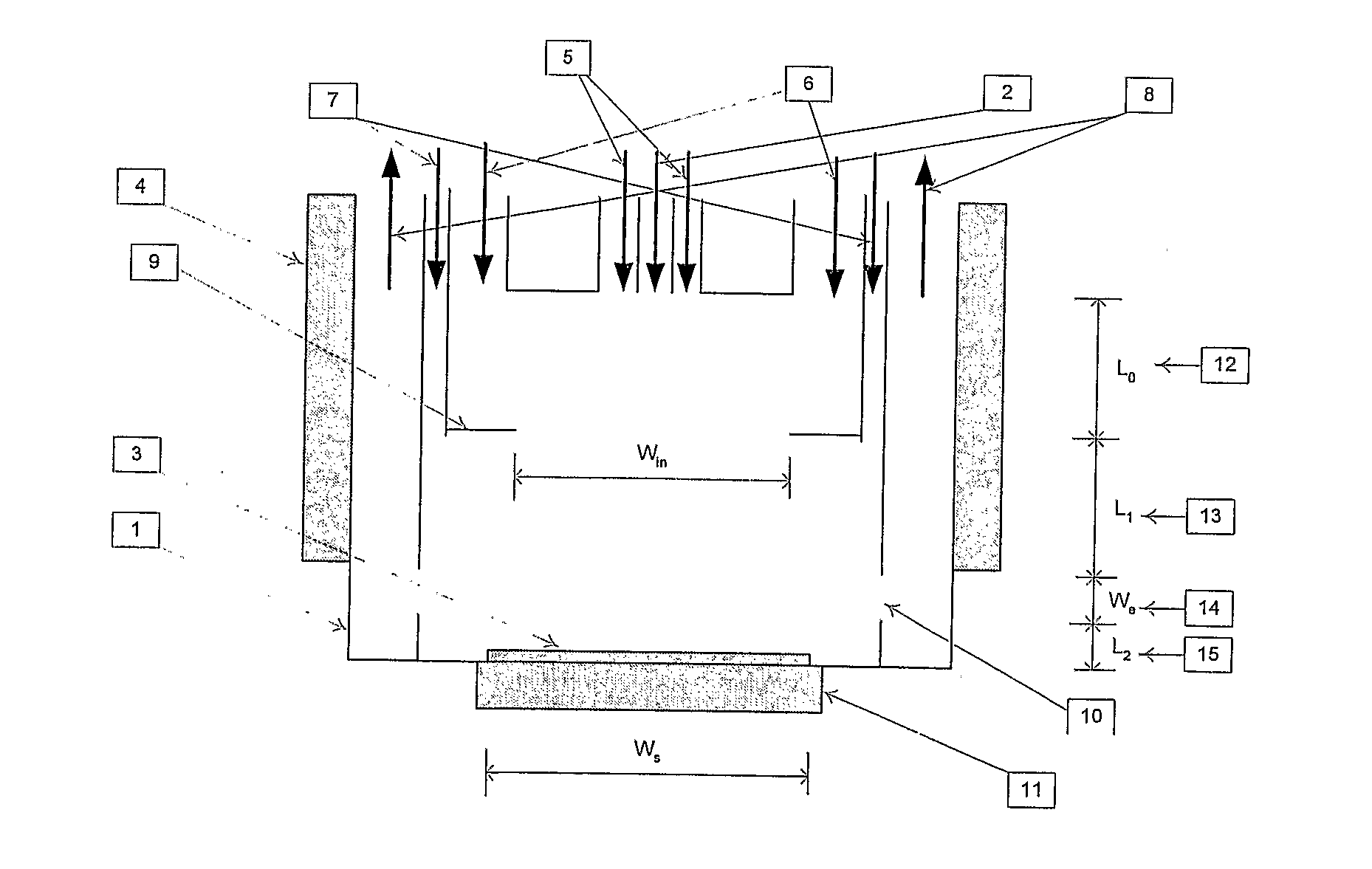

Deposition Technique for Producing High Quality Compound Semiconductor Materials

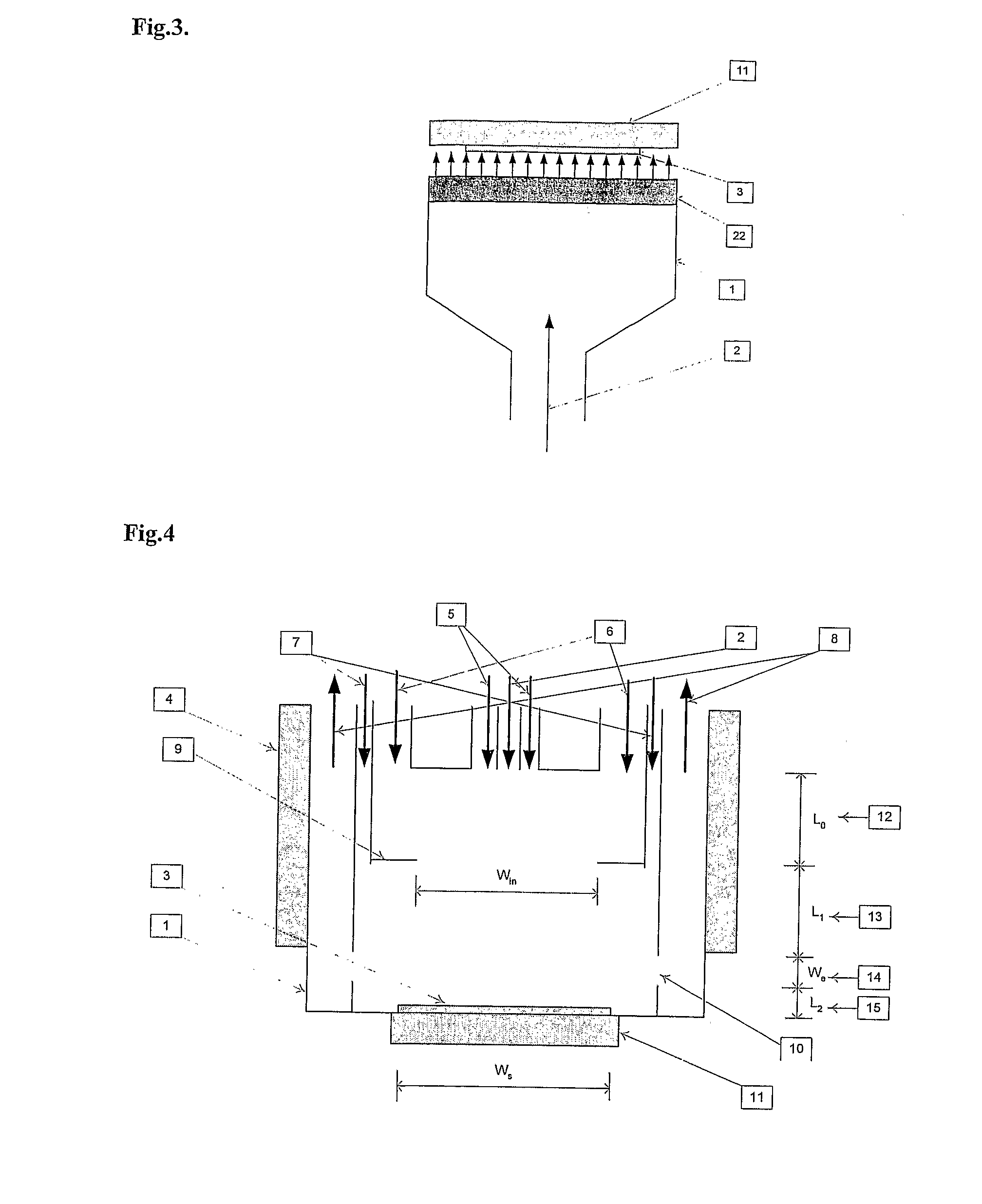

ActiveUS20080132040A1Reduce defect densityImprove uniformitySemiconductor/solid-state device manufacturingFrom chemically reactive gasesSemiconductor materialsShortest distance

Deposited layers are advantageously obtained by utilizing a specific hydride vapour phase epitaxy deposition procedure. In this procedure, a vertical growth cell structure with extended diffusion layer, a homogenising diaphragm, sidewall purging gases, anal independent gas and substrate heaters is used for the deposition of III-V and VI compound semiconductors. This gas flow is uniformly mixed through the extended diffusion layer and directed so that it contacts the full surface of the substrate to produce high quality and uniform films. Exemplary of such gas flow configurations are the positioning of a substrate at a distance from the gas outlets to allow the extended diffusion and a diaphragm placed in a short distance above the substrate to minimise the impact of the convection effect and to improve the uniformity. This symmetrical configuration allows easy scale up from a single wafer to multi-wafer system. This vertical configuration allows the quick switching between different reactive gas precursors so that time modulated growth and etch processes can be employed to further minimise the defects density of the deposited materials.

Owner:QUANTUM NIL LTD +1

Multichamber split processes for LED manufacturing

InactiveUS20110081771A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingVapor phaseChemical vapor deposition

Embodiments described herein generally relate to methods for forming Group III-V materials by metal-organic chemical vapor deposition (MOCVD) processes and / or hydride vapor phase epitaxial (HVPE) processes. In one embodiment, deposition of a group III1-N layer on a substrate is performed in a first chamber, deposition of a group III2-N layer on the substrate is performed in a second chamber, and deposition of a group III3-N layer on the substrate is performed in a chamber different from the chamber where the group III2-N layer is deposited. Between the group III2-N layer deposition and the group III3-N layer deposition, one or more surface treatment processes are performed on the substrate to reduce non-radiative recombination at the interface and improve overall electroluminescence of the produced structure.

Owner:APPLIED MATERIALS INC

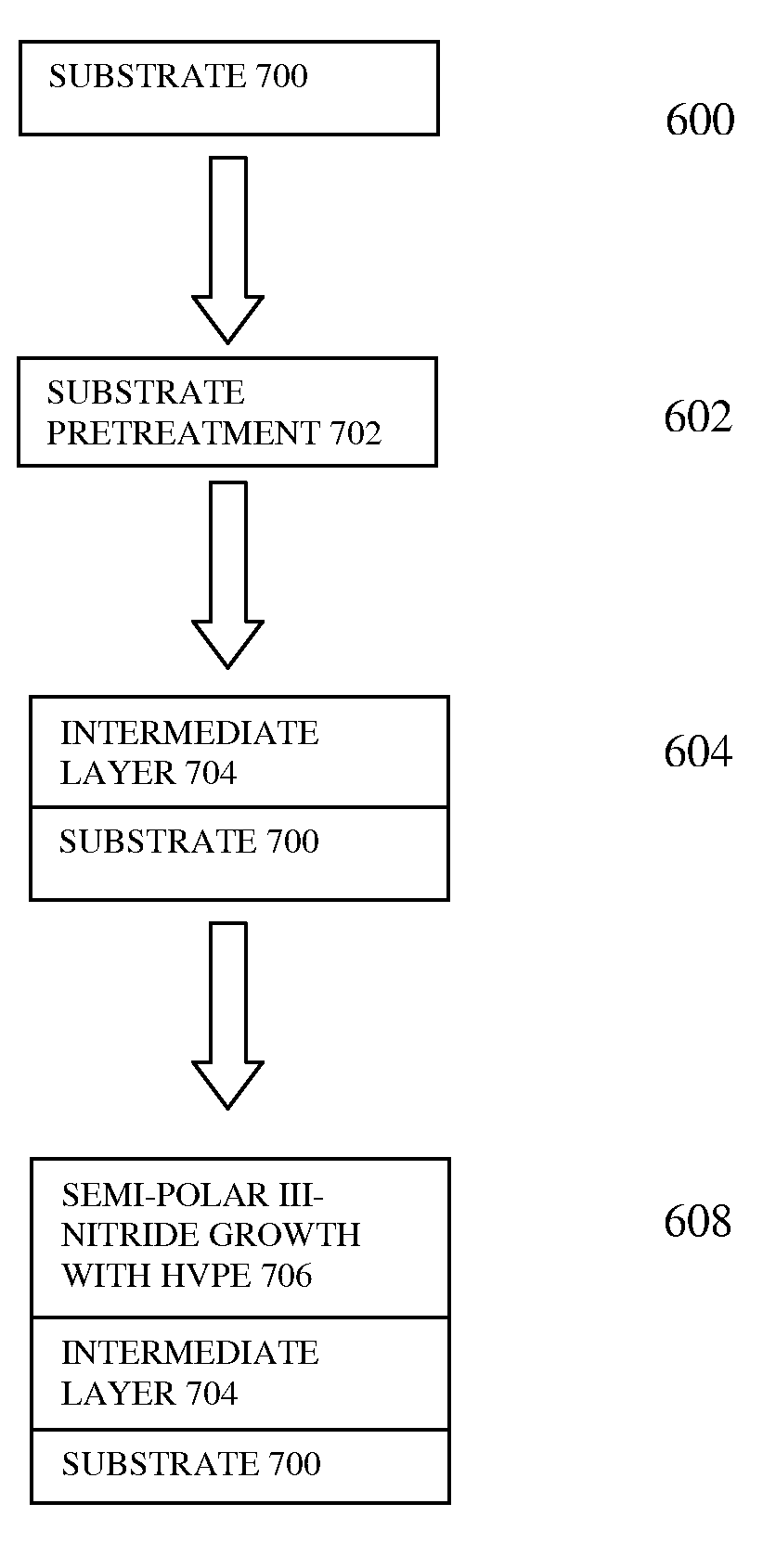

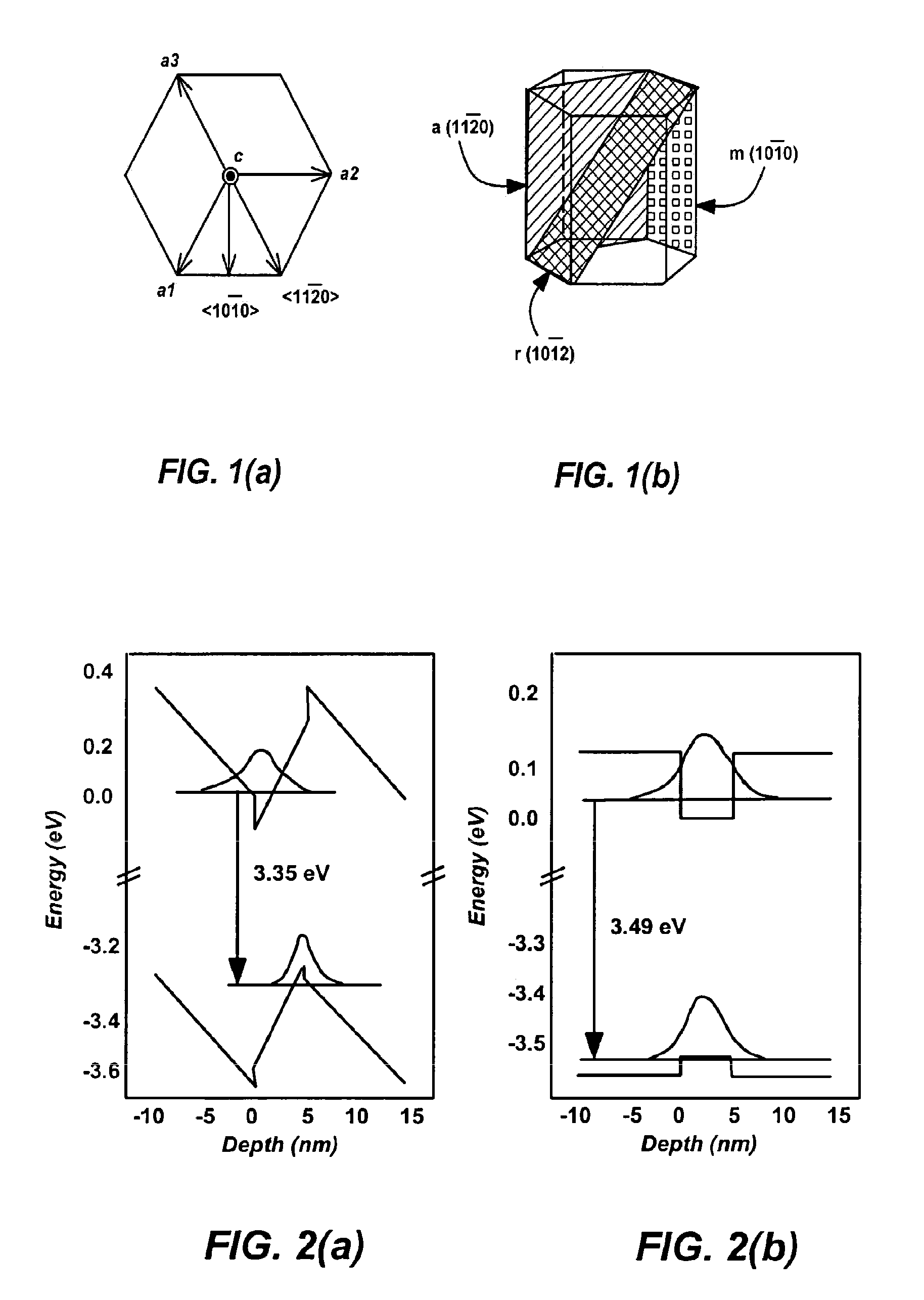

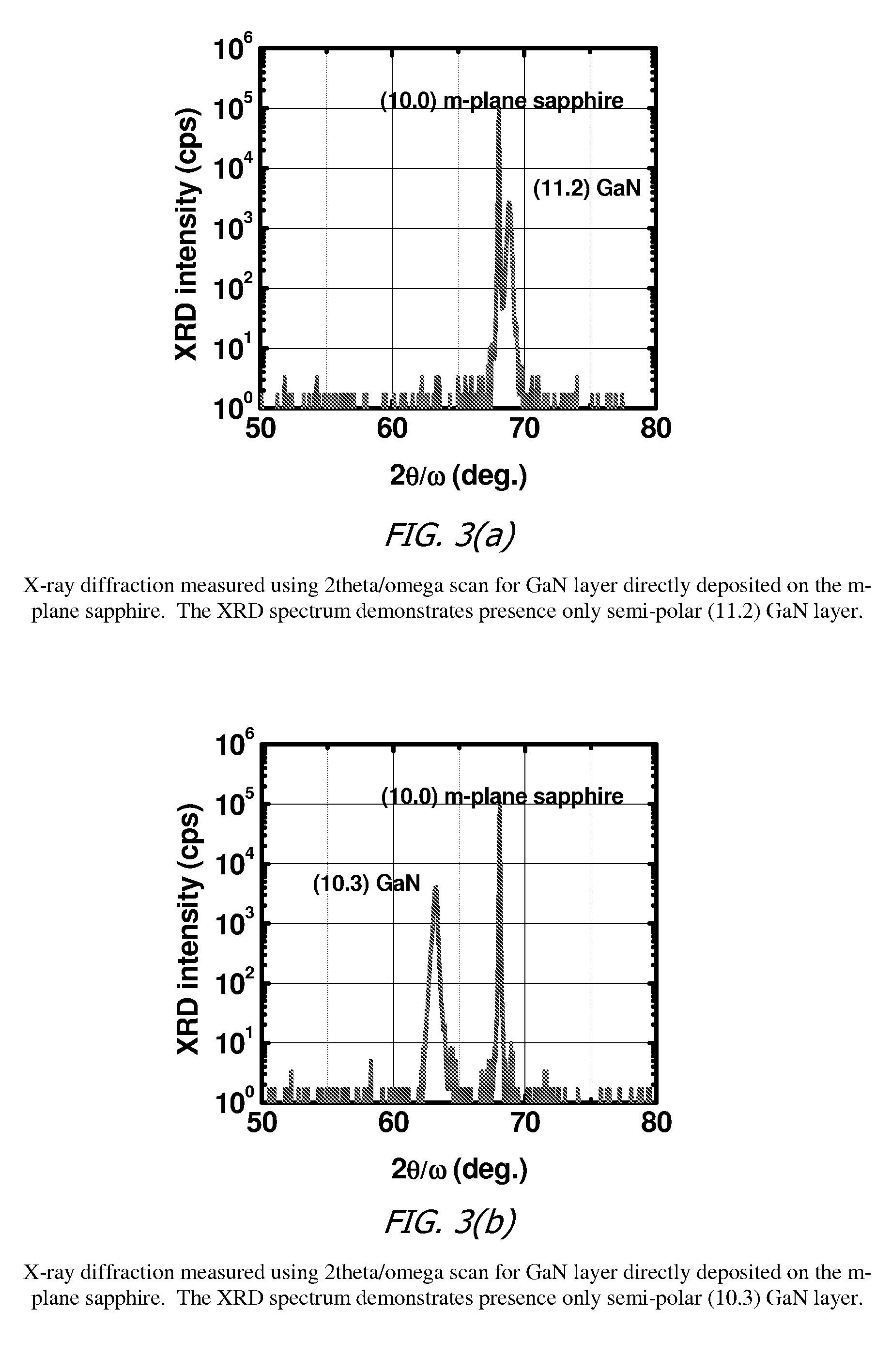

Growth of Planar Non-Polar M-Plane and Semi-Polar Gallium Nitride with Hydride Vapor Phase Epitaxy (HVPE)

ActiveUS20100012948A1Polycrystalline material growthSemiconductor/solid-state device manufacturingGallium nitrideVapor phase

A method of growing planar non-polar m-plane or semi-polar III-Nitride material, such as an m-plane gallium nitride (GaN) epitaxial layer, wherein the III-Nitride material is grown on a suitable substrate, such as an m-plane Sapphire substrate, using hydride vapor phase epitaxy (HVPE). The method includes in-situ pretreatment of the substrate at elevated temperatures in the ambient of ammonia and argon, growing an intermediate layer such as an aluminum nitride (AlN) or aluminum-gallium nitride (AlGaN) on the annealed substrate, and growing the non-polar m-plane III-Nitride epitaxial layer on the intermediate layer using HVPE.

Owner:OSTENDO TECH INC

Multiple precursor showerhead with by-pass ports

ActiveUS20110256645A1Simple methodLiquid surface applicatorsSemiconductor/solid-state device testing/measurementProcess engineeringChemical vapor deposition

Owner:APPLIED MATERIALS INC

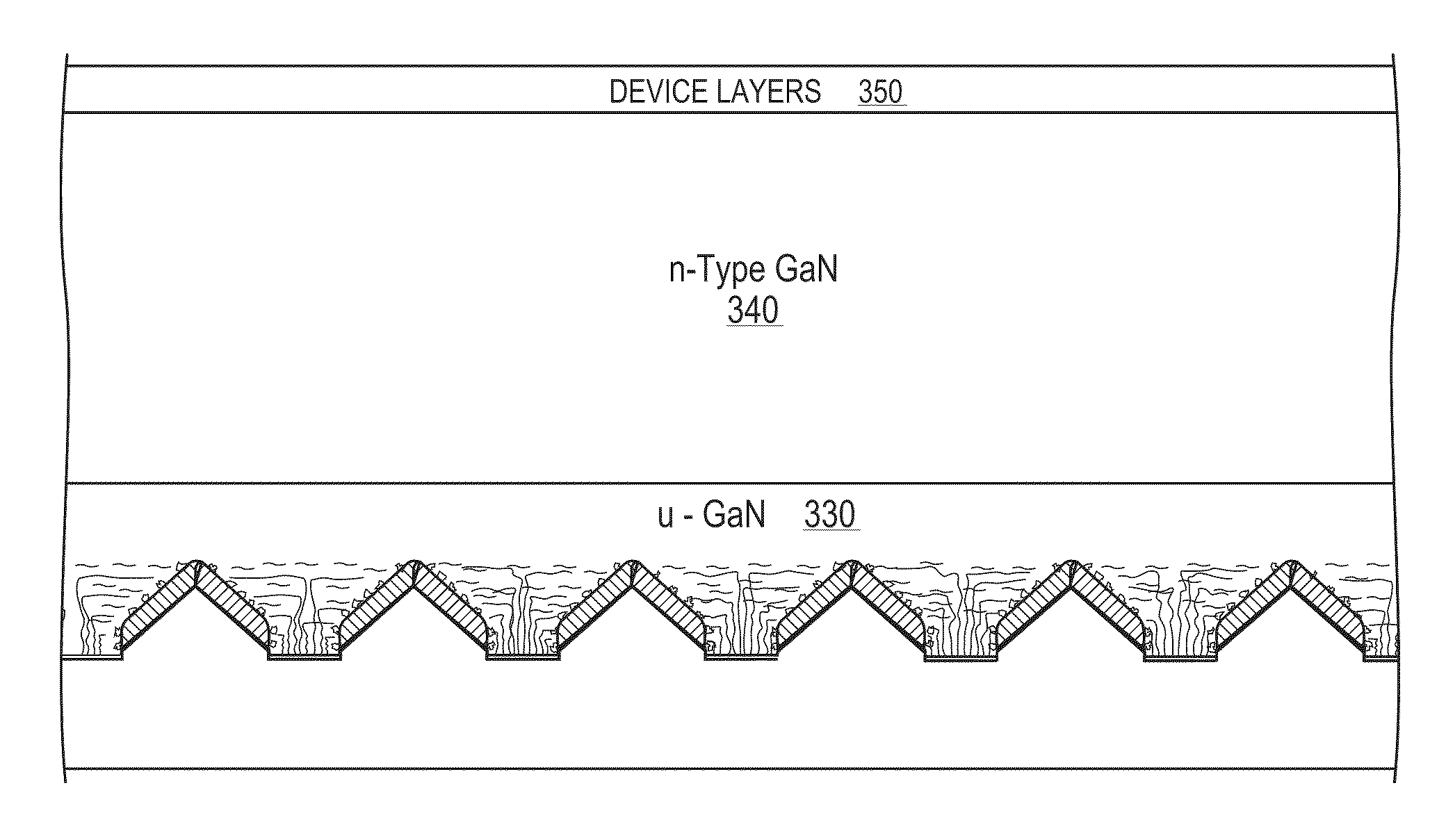

Growth and manufacture of reduced dislocation density and free-standing aluminum nitride films by hydride vapor phase epitaxy

InactiveUS20100065854A1Simple methodReduce defect densityPolycrystalline material growthSemiconductor/solid-state device manufacturingGrown filmVapor phase

A Group III-nitride semiconductor film containing aluminum, and methods for growing this film. A film is grown by patterning a substrate, and growing the Group III-nitride semi-conductor film containing aluminum on the substrate at a temperature designed to increase the mobility of aluminum atoms to increase a lateral growth rate of the Group III-nitride semiconductor film. The film optionally includes a substrate patterned with elevated stripes separated by trench regions, wherein the stripes have a height chosen to allow the Group III-nitride semiconductor film to coalesce prior to growth from the bottom of the trenches reaching the top of the stripes, the temperature being greater than 1075° C., the Group III-nitride semiconductor film being grown using hydride vapor phase epitaxy, the stripes being oriented along a (1-100) direction of the substrate or the growing film, and a dislocation density of the grown film being less than 107 cm−2.

Owner:JAPAN SCI & TECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com