Decontamination of mocvd chamber using nh3 purge after in-situ cleaning

a technology of in-situ cleaning and mocvd chamber, which is applied in the direction of coatings, chemical vapor deposition coatings, solid-state devices, etc., can solve the problems of affecting process reproducibility and uniformity, process cumbersomeness, and process conditions that dri

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

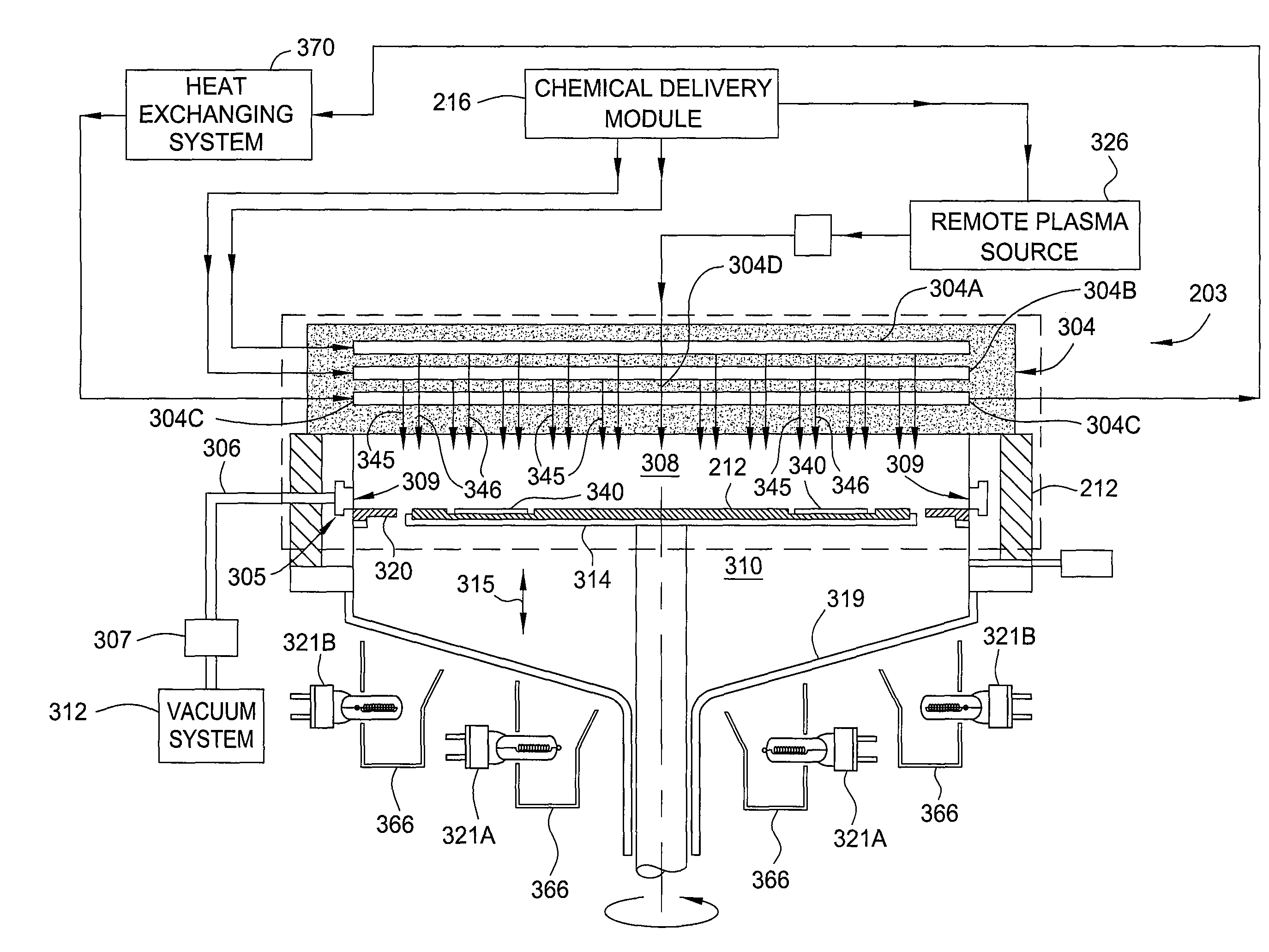

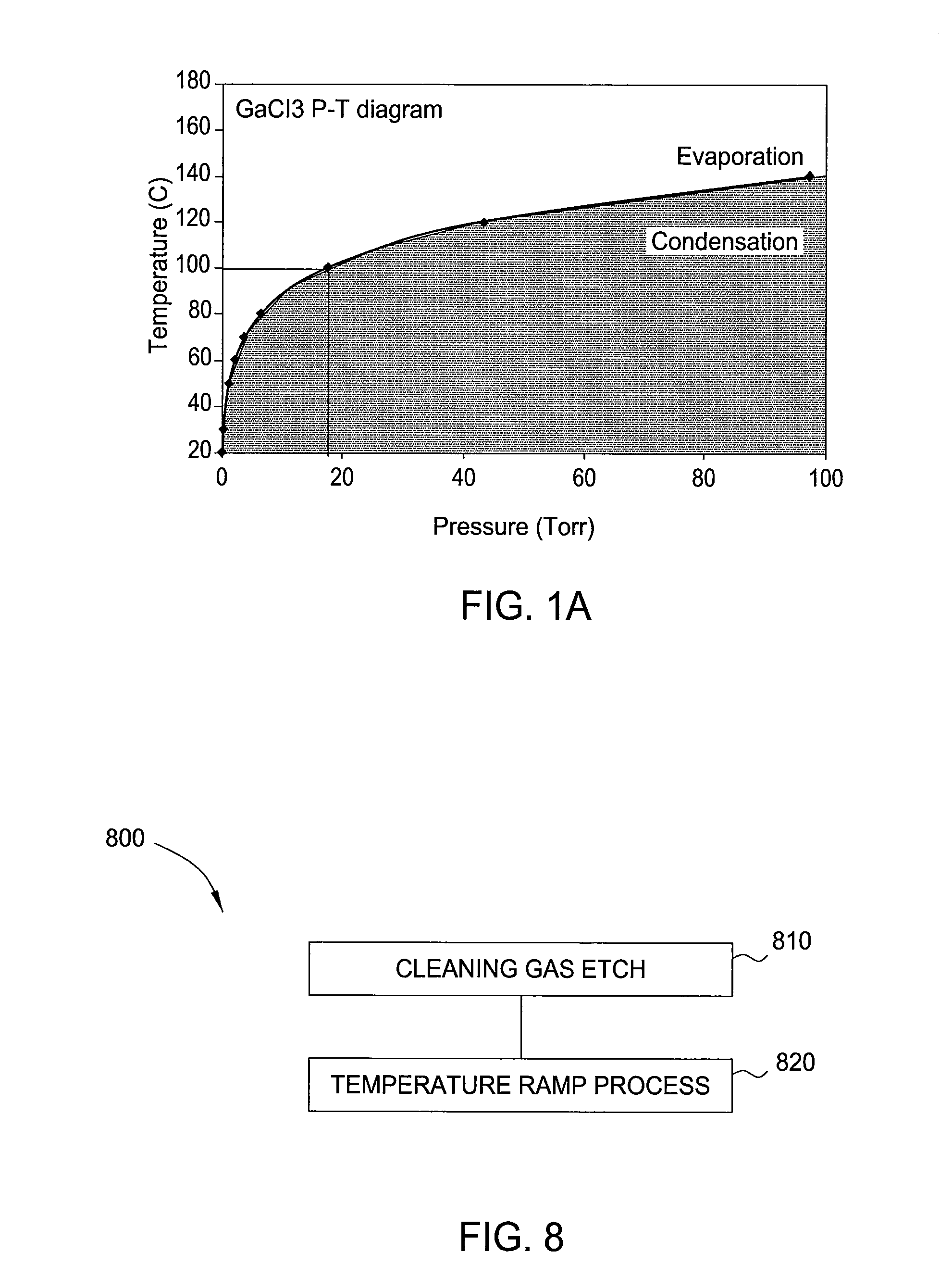

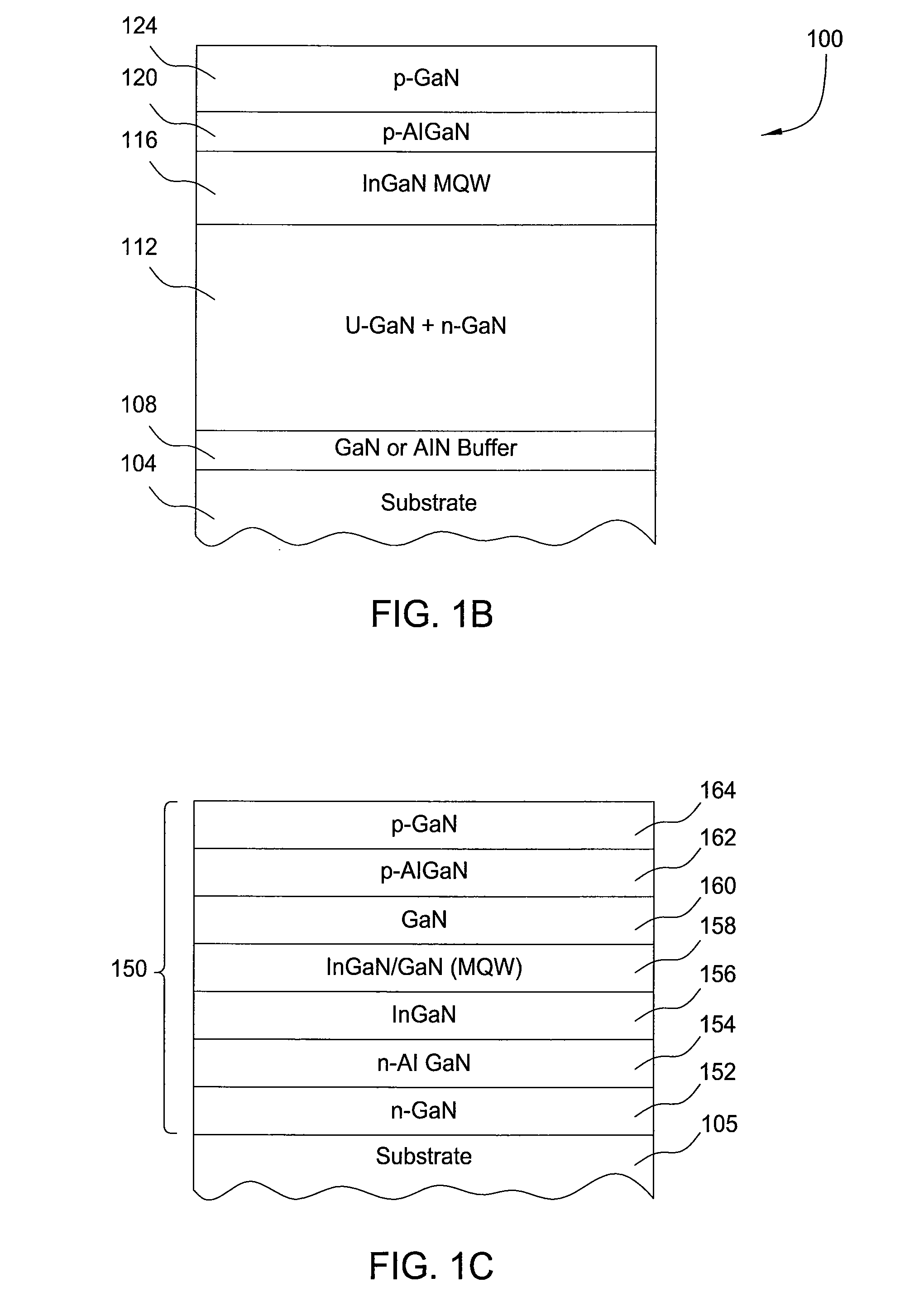

[0028]Embodiments described herein provide improved methods and apparatus for chamber cleaning which may be performed in-situ to remove unwanted deposition build-up off the interior surfaces of a substrate processing chamber thus reducing particle contamination while maintaining system uptime. In one embodiment, the chamber cleaning process is performed by pulsing a halogen containing gas, such as chlorine containing cleaning gas, into the substrate processing chamber to convert the unwanted deposition, such as gallium coating, on the surfaces of the chamber and the chamber components into a gaseous form, such as GaCl3, which may then be removed from the chamber.

[0029]As previously discussed, the growth of high temperature GaN by MOCVD or HVPE often results in severe parasitic deposition on chamber parts especially the showerhead. This parasitic deposition causes particles and flaking inside the chamber, resulting in drift of the process conditions, and most importantly affecting th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| time | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com