Multiple precursor concentric delivery showerhead

a showerhead and precursor technology, applied in the direction of chemically reactive gases, crystal growth processes, coatings, etc., can solve the break-down of precursor materials, and special problems of precursor material deposition on the hot surfa

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

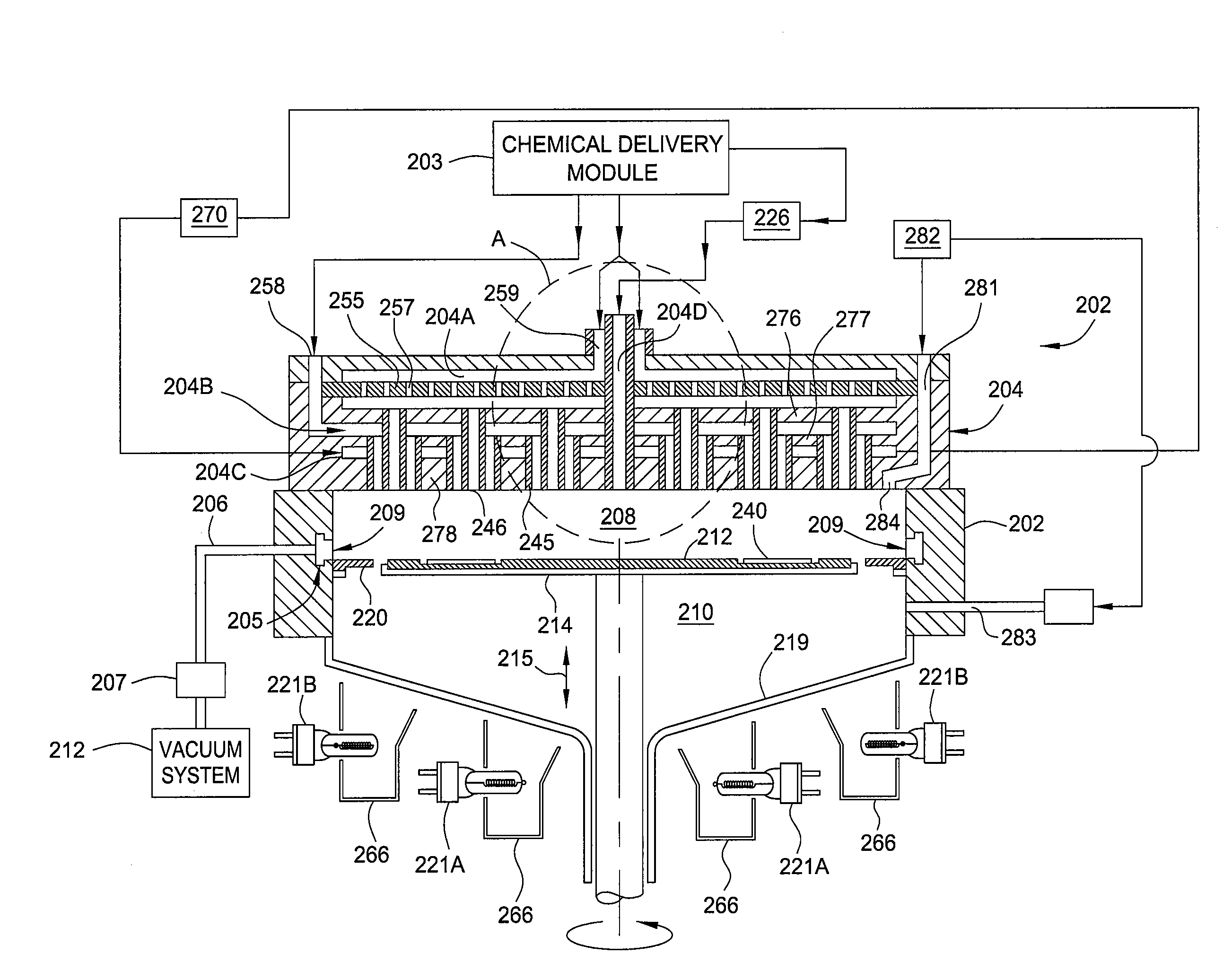

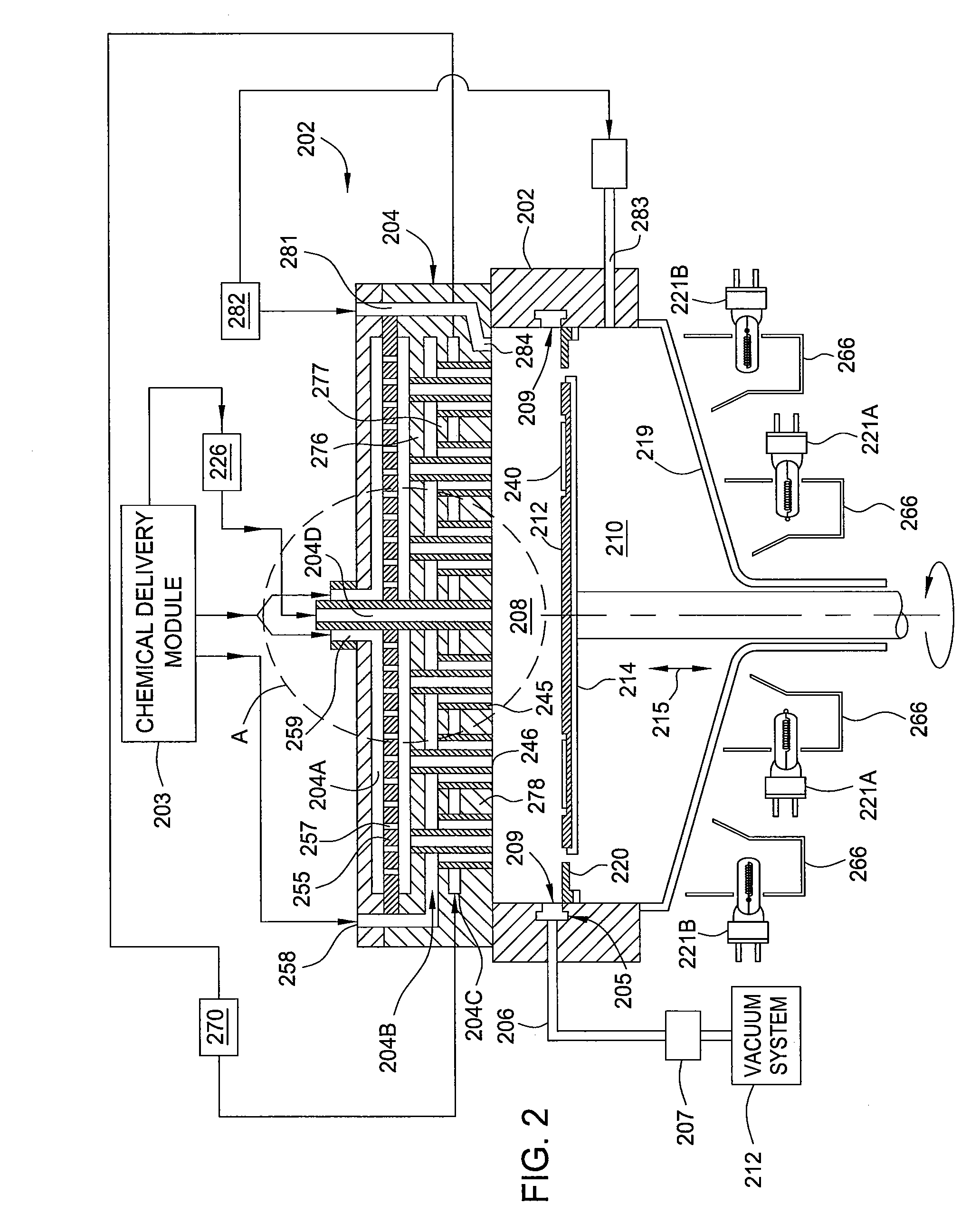

[0021]Embodiments of the present invention generally provide a method and apparatus that may be utilized for deposition of Group III-nitride films using MOCVD and / or HVPE hardware. In one embodiment, the apparatus a processing chamber that includes a showerhead with separate inlets and channels for delivering separate processing gases into a processing volume of the chamber without mixing the gases prior to entering the processing volume. In one embodiment, a plurality of concentric tube assemblies are disposed within the showerhead to separately deliver a first gas from a first gas channel and a second gas from a second gas channel into the processing volume of the chamber. In one embodiment, the showerhead further includes a cooling channel through which the plurality of concentric tube assemblies is disposed.

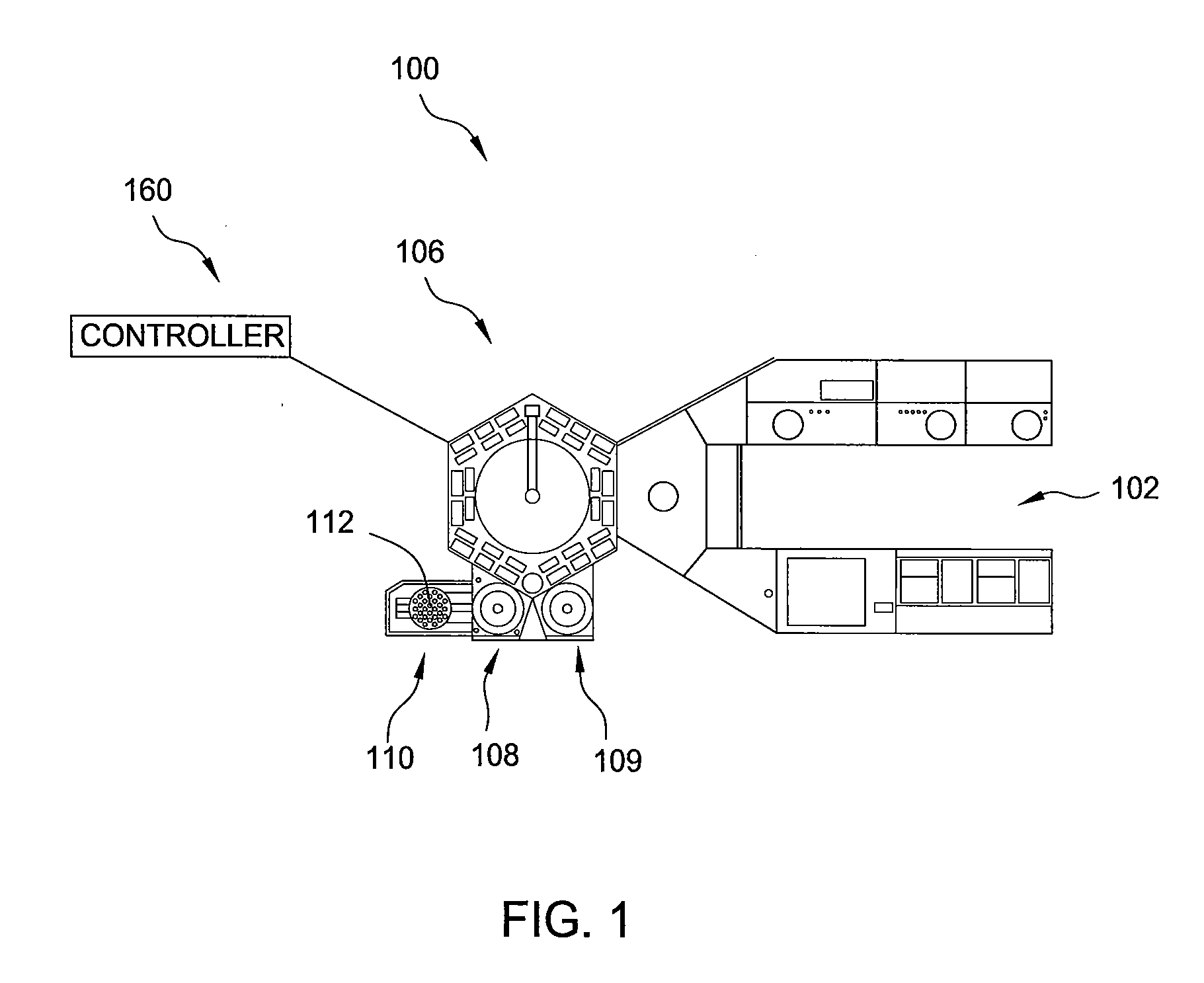

[0022]FIG. 1 is a schematic plan view illustrating one embodiment of a processing system 100 that comprises the one or more MOCVD chambers 102 for fabricating compound nitrid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com