steam mixer

A mixer and steam technology, applied in fluid mixers, mixers, mixing methods, etc., can solve problems such as energy waste, and achieve the effects of simple manufacturing, high heat exchange efficiency, and uniform fluid temperature distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

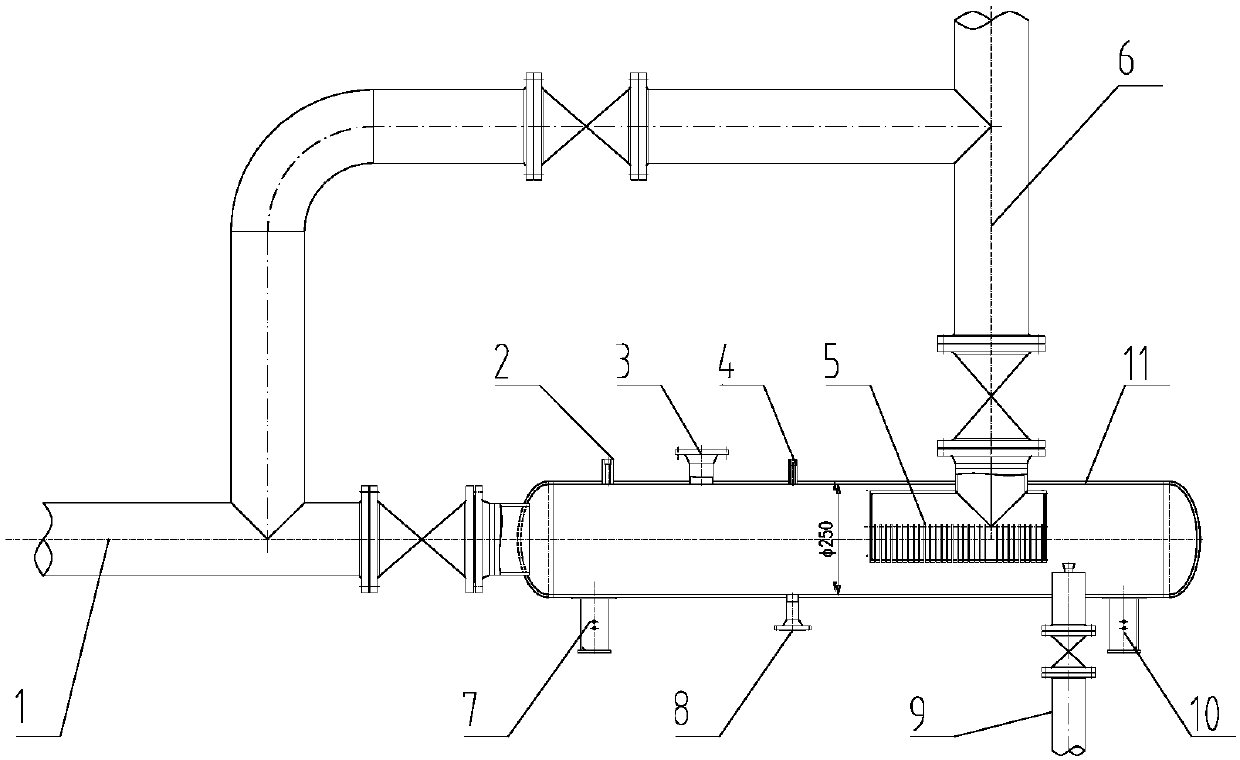

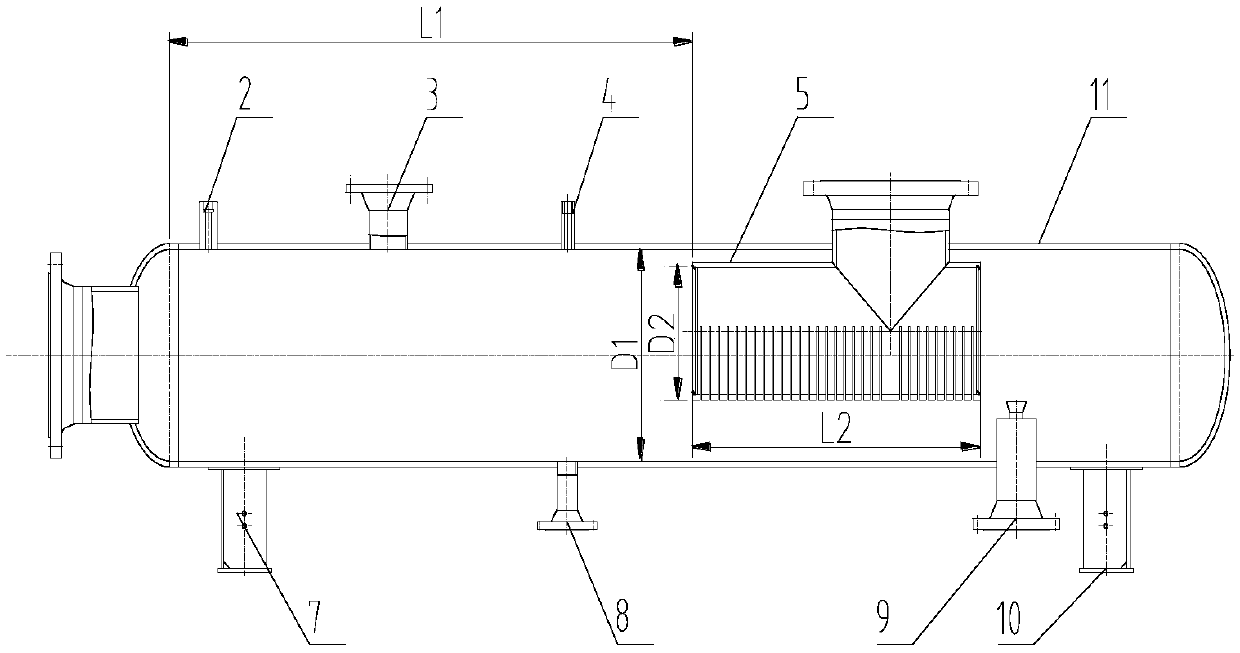

[0030] Such as figure 1 with figure 2 As shown, the steam mixer includes a heater housing 11, the top of one end of the heater housing 11 is connected to the main steam pipe 6 through a flow regulating valve, and the other end of the heater housing 11 is connected to the mixed steam pipe through a gate valve or a shut-off valve. 1 connection, the main steam pipe 6 is connected to the mixed steam pipe 1 through a gate valve or a shut-off valve, and the bottom of the heater housing 11 opposite to the entrance of the main steam pipe 6 is connected to the heating steam pipe 9 through a flow regulating valve, and the main steam pipe 6 is directed to Extending inside the heater housing 11 are a connection pipe 15 and a main steam distribution pipe 5 arranged in sequence. The main steam distribution pipe 5 is evenly distributed along the axial direction of the heater housing 11, and the air flow is parallel to the radial direction of the heater housing 11. The heating steam pipe 9 ...

Embodiment 2

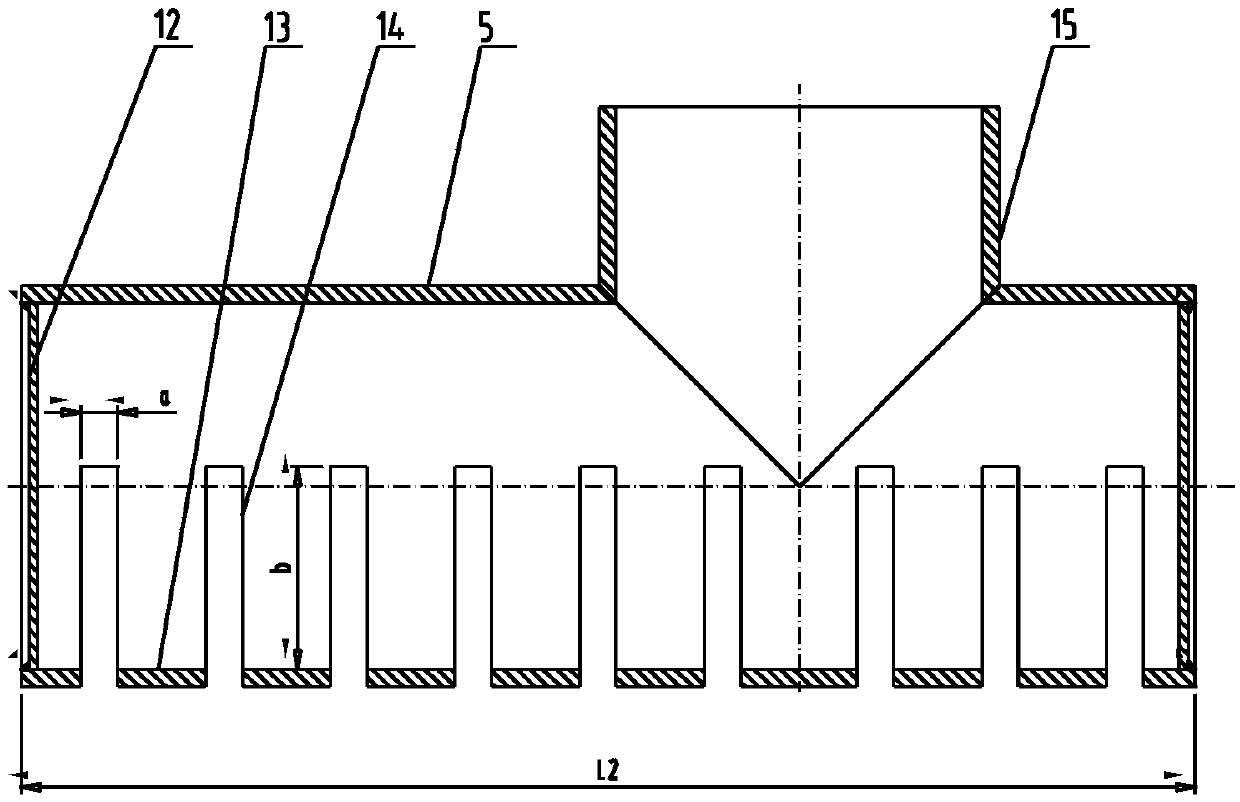

[0033] On the basis of Example 1, different from Example 1, such as image 3As shown in the steam mixer, the main steam distribution pipe 5 is horizontally arranged as a cylindrical pipe along the central axis of the heater shell, the end of the main steam distribution pipe 5 is sealed by a blocking plate a12, and the bottom of the main steam distribution pipe 5 is opened There are circular steam holes 13, and there are elongated steam holes 14 equally spaced between adjacent circular steam holes 13. The elongated steam holes 14 are distributed from the bottom of the main steam distribution pipe 5 to the main steam distribution pipe. The central axis of the piping 5 is recessed and extended.

[0034] Open the circular steam hole 13 when the steam volume is relatively small, the diameter of the circular steam hole 13 is not more than 15mm, and open the strip steam hole 14 when the steam volume is relatively large, the width a of the strip steam hole 14 is Not greater than 10mm...

Embodiment 3

[0036] On the basis of Example 1, different from Example 1, such as Figure 4 , Figure 5 , Image 6 , Figure 7 with Figure 8 As shown in the steam mixer, the combined nozzle includes a spiral nozzle 16, a central nozzle 17 and a sleeve 19, and the central nozzle 17 is sleeved inside the spiral nozzle 16 along the central axis of the spiral nozzle 16, and the central nozzle 17 and the spiral nozzle 16 The bottom of the nozzle is sealed by the blocking plate b18, and the sleeve 19 is sleeved on the outside of the spiral nozzle 16.

[0037] The casing 19 is provided with a hollow cylindrical cavity, and the upper and lower ends of the hollow cylindrical cavity are all set as retracted ports. The internal thread provided on the inner wall of the upper port of the casing 19 and the external thread on the outer wall of the spiral nozzle 16 are assembled and matched. A protruding U-shaped clamp is provided on the outer wall, and the U-shaped clamp engages with the upper end su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com