A kind of semiconductor packaging structure and preparation method thereof

A packaging structure and semiconductor technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor/solid-state device components, etc., can solve problems such as pad stripping, hidden dangers in semiconductor chip performance, and reduce semiconductor chip packaging yield, etc., to achieve The effect of avoiding pad peeling and good mechanical characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

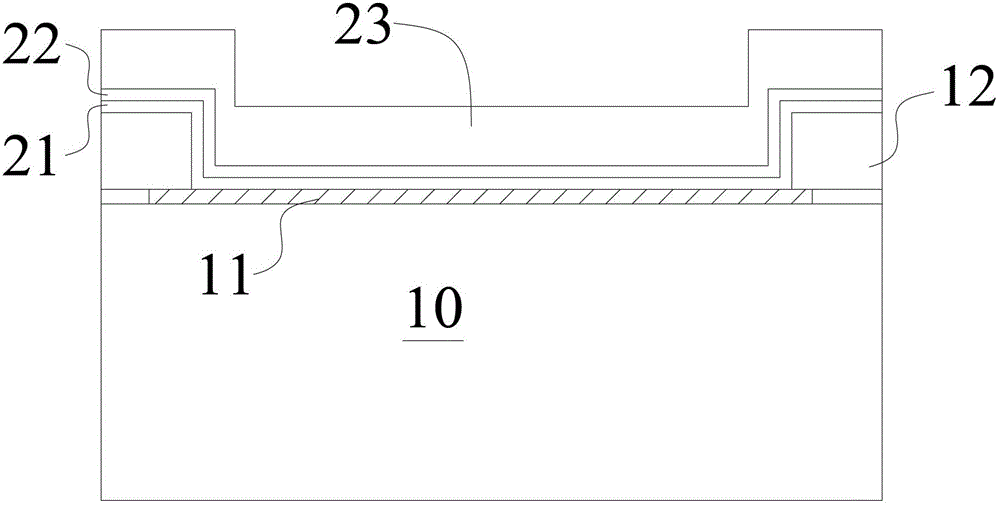

[0044] refer to Figure 1 to Figure 5 As shown, the specific process of the preparation method of a semiconductor package structure provided by the present invention includes:

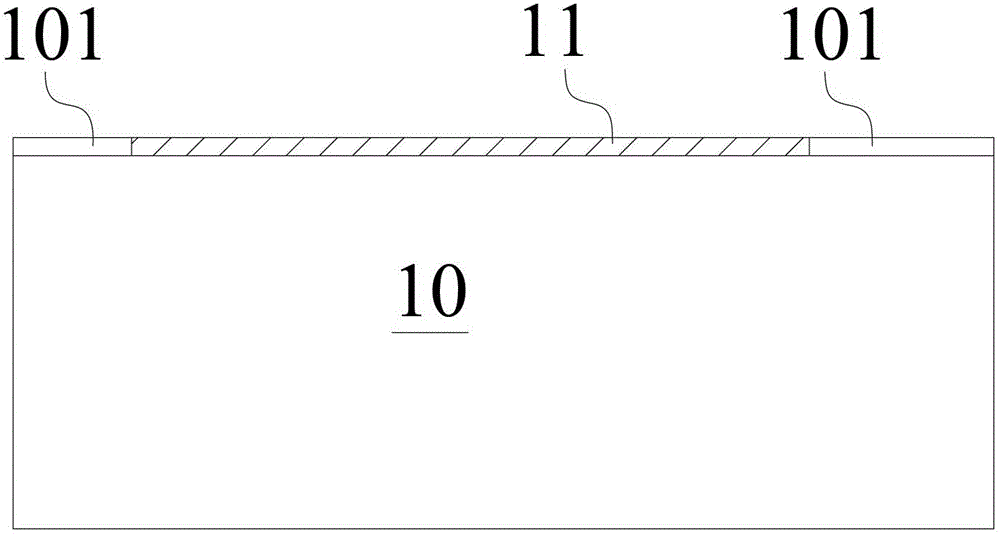

[0045] combined reference figure 1 As shown, a semiconductor substrate 10 is provided. The semiconductor substrate 10 has completed the front-end process in the semiconductor manufacturing process and has formed effective devices, which are collectively referred to as the semiconductor substrate 10 herein. A copper interconnection layer 11 and a dielectric 101 around the copper interconnection layer 11 are formed on the semiconductor substrate 10 . The process for forming the copper interconnection layer is the Dua-Damascene technology, which will not be repeated here.

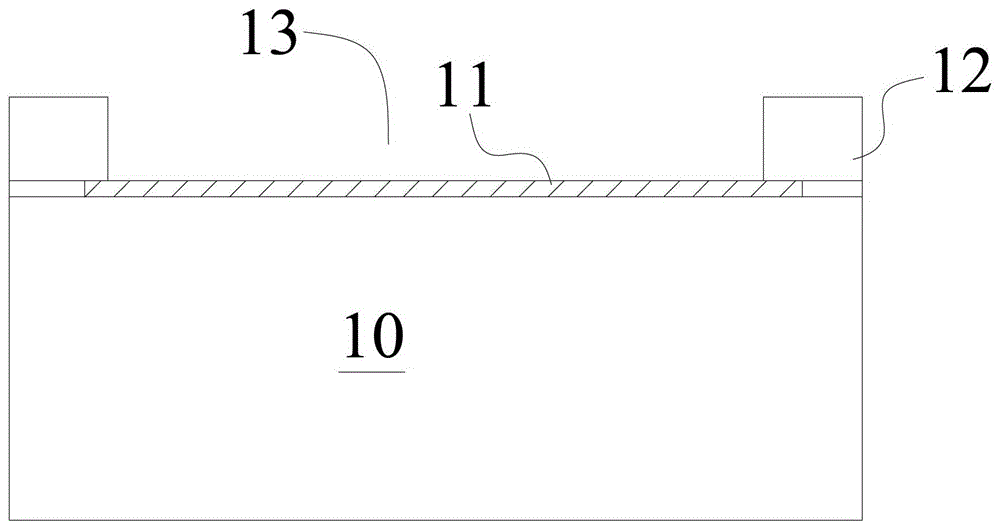

[0046] combined reference figure 2 As shown, thereafter, a passivation layer 12 is deposited on the copper interconnection layer 11 to cover the copper interconnection layer 11; the passivation layer 12 is patterned to form an ope...

Embodiment 2

[0058] The technical scheme of this embodiment and embodiment 1 is roughly the same, in conjunction with reference Image 6 , the difference is only that: in the process of preparing the semiconductor package structure in the above-mentioned embodiment 1, after the Ti layer 21 is formed, a TiN layer 24 is deposited on the Ti layer 21 by PVD method. Then the TaN layer 22 is deposited on the TiN layer 24 to form a metal shielding layer with a three-layer stacked structure.

[0059] combined reference Figure 7 with Figure 8 As shown, after the aluminum layer 23 is formed on the TaN layer 22, the aluminum layer 23 is patterned, and the parts on both sides of the aluminum layer 23 are removed by a dry etching process to expose the passivation layer 12, An auxiliary passivation layer 14 is deposited on the passivation layer 12 , and the auxiliary passivation layer 14 is patterned to form an opening 15 exposing the aluminum layer 23 .

[0060] At this time, in the semiconductor ...

Embodiment 3

[0064] This embodiment is roughly the same as the technical solutions of the above-mentioned embodiment 1 and embodiment 2, combined with reference image 3 , Image 6 as well as Figure 9 ~ Figure 11 , the difference being that, in the above image 3 or Image 6After the pad layer 23 is deposited, one or more auxiliary metal shielding layers are deposited on the pad layer 23, and another pad layer 33 is deposited on the one or more auxiliary metal shielding layers. . Afterwards, similar to the above-mentioned process of patterning the pad layer 23, the pad layer 33 is patterned, and the pad layer 33 and the auxiliary metal shields below the pad layer 33 are etched through an etching process. layer and the two sides of the metal shielding layer in a multilayer stacked structure until the passivation layer 12 is exposed. An auxiliary passivation layer 16 is deposited on the pad layer 33 and the passivation layer 12, and the auxiliary passivation layer 16 is patterned to fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com