Method for decreasing occurrence rate of transverse cracks of boiler water walls

A technology of transverse cracks and water-cooled walls, applied in boiler water pipes, combustion methods, combustion chambers, etc., can solve problems such as unbalanced water-cooled wall temperature field, unit shutdown, large fluctuation range, etc., to reduce the occurrence area and probability, parameters Reasonable control and smooth temperature distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

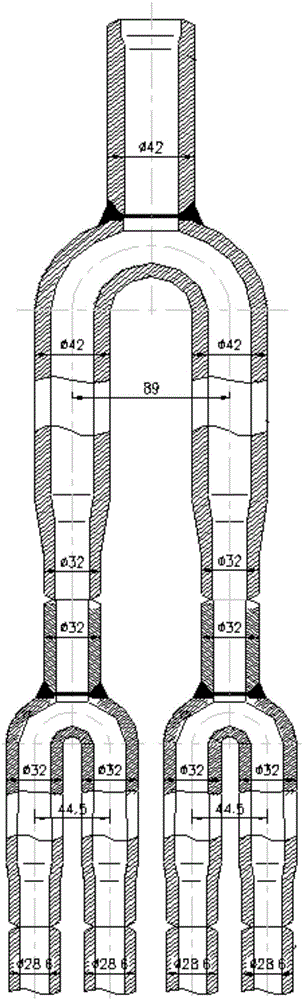

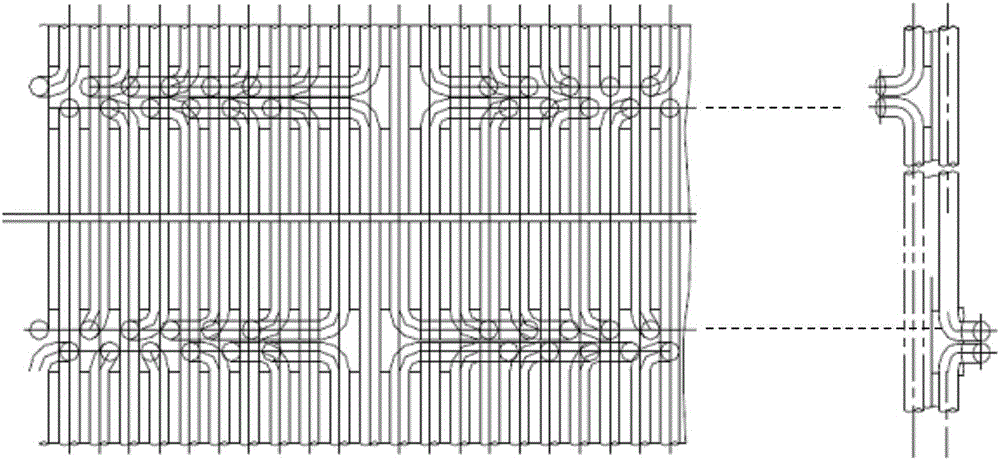

[0037] Hereinafter, taking the water wall of the HG-2000 / 26.15-YM3 boiler as an example, the method for reducing transverse cracks in the water wall of the boiler described in the present invention is described.

[0038] According to the analysis of the causes of cracks in the water-cooled wall, the running state of the water-cooled wall is monitored in the present invention. Through the analysis of the running wall temperature data of the water-cooled wall, it is found that the metal of the water-cooled wall has irregular short-term overheating and large-scale temperature fluctuations during operation, and both Both phenomena occurred almost simultaneously.

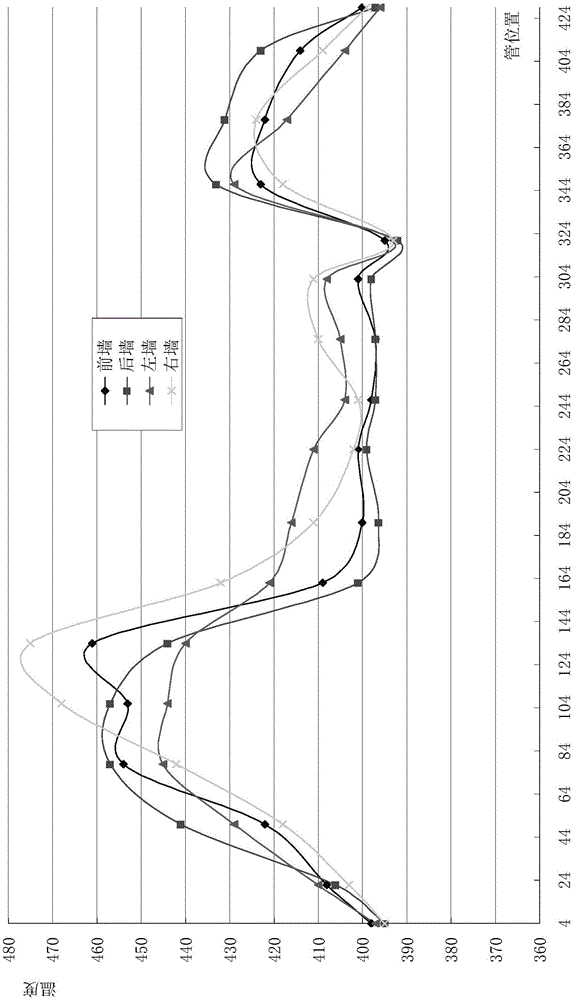

[0039] figure 2 The curve shown is a specific example for analyzing the thermal deviation of the water-cooled wall after temperature monitoring. The temperature of the water-cooled wall on the front, rear, left, and right walls all presents a "double-peak" state distribution: in this example, the 50th of each wall of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com