Method for preparing high-bonding-strength carbide coating on diamond surface by using thermal plasma

A thermal plasma, bonding strength technology, applied in metal material coating process, coating, melting spray plating, etc., can solve the problems of low bonding strength, difficult thickness, uneven and dense carbide coating, etc., to achieve airflow velocity Low, small gradient, single and pure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

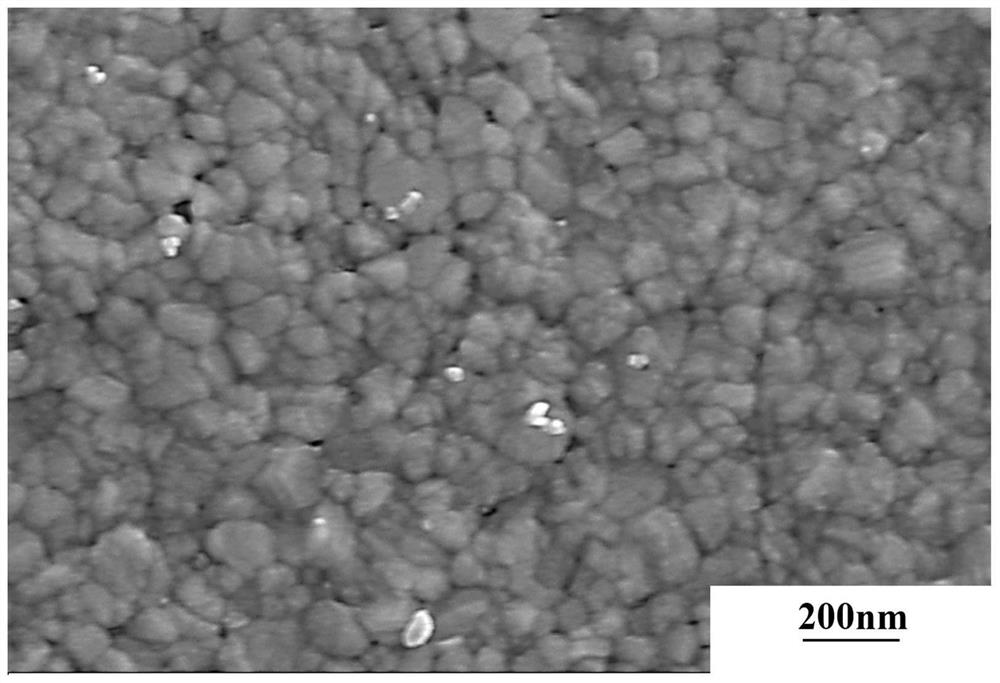

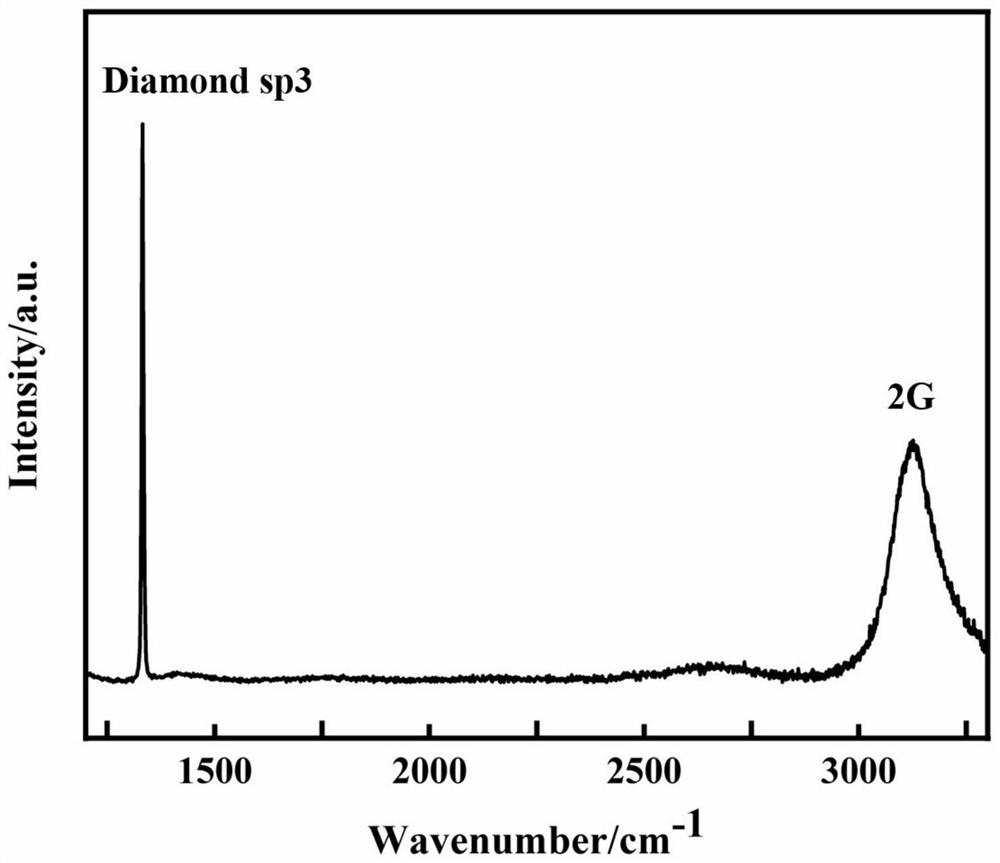

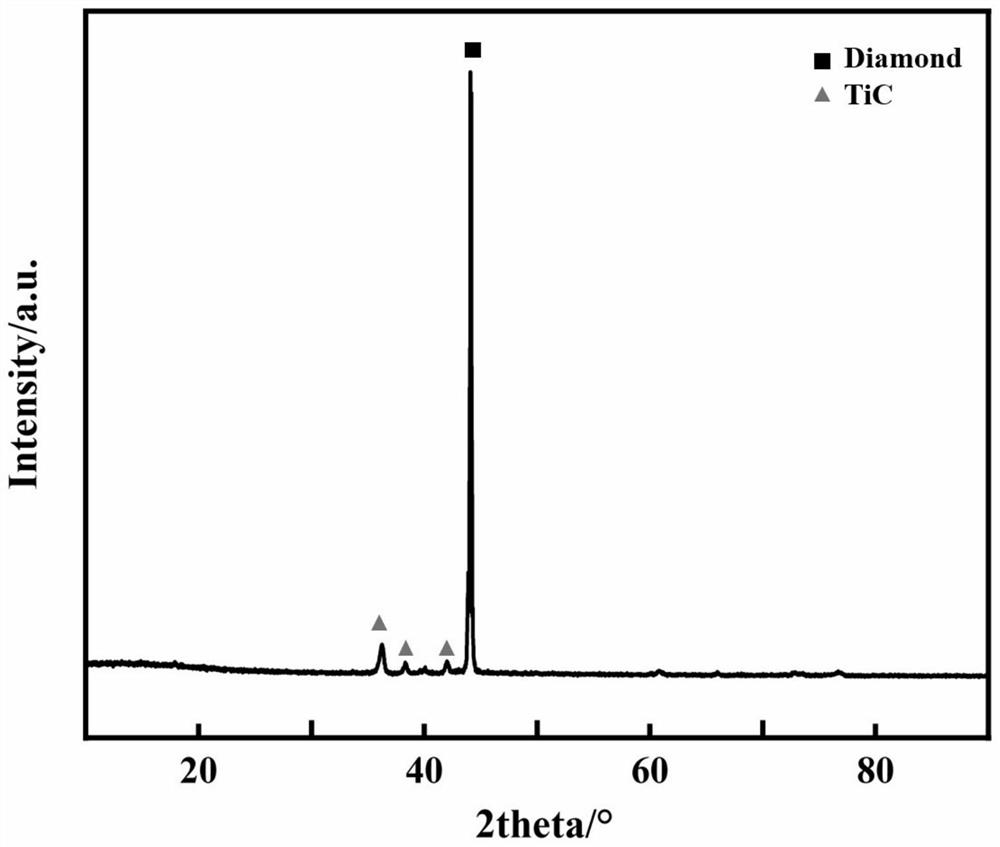

[0030] Specific embodiment one: the method of this embodiment utilizes thermal plasma to prepare carbide coating with high binding strength on the diamond surface according to the following steps:

[0031] 1. Weighing:

[0032] Weigh a certain quality of diamond powder with a metal coating;

[0033] The metal coating described in step 1 is a kind of in W, Ti, Cr, Mo;

[0034] Second, cleaning and drying:

[0035] The diamond powder is placed in deionized water, ultrasonically cleaned by an ultrasonic machine, and then dried in a vacuum drying oven;

[0036] Among them, the purpose of ultrasonic cleaning is to fully clean the diamond surface, remove the oil stain on the diamond surface and the impurities adsorbed in the air; the purpose of vacuum drying is to remove the oxygen and water vapor adsorbed on the diamond surface, and avoid side reactions to generate impurities during subsequent processing;

[0037] 3. The diamond powder obtained in step 2 is delivered to a therma...

specific Embodiment approach 2

[0051] Embodiment 2: This embodiment is different from Embodiment 1 in that: the thickness of the metal coating in Step 1 is 50-300 nm.

specific Embodiment approach 3

[0052] Embodiment 3: This embodiment is different from Embodiment 1 or Embodiment 2 in that: the particle size of the diamond powder in step 1 is 100-500 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com