Method for drying automobile glass printing ink

A technology for automotive glass and ink, applied in the post-processing of printing, general parts of printing machinery, printing and other directions, can solve the problems of affecting the viscosity of silver paste, decrease in printing quality, increase the number of screen cleanings, etc., and reduce the labor intensity of workers. , The effect of reducing cost investment and reducing the number of times of cleaning the net

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

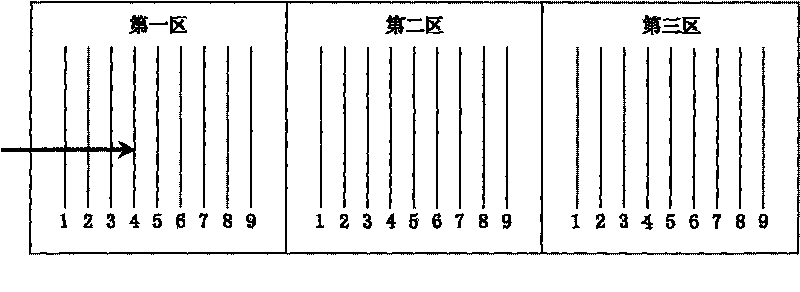

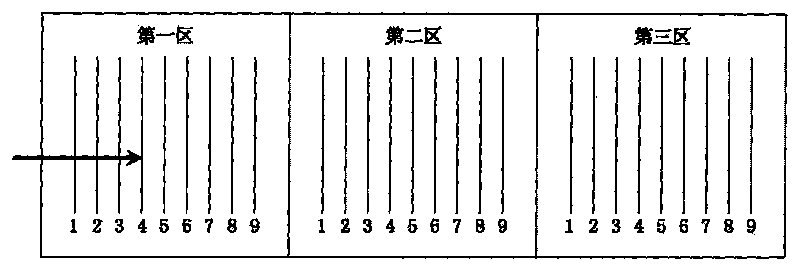

[0011] An application of new drying technology for automotive glass ink. The production process is as follows: After the glass is printed in the direction of the arrow, it flows into the dryer through the assembly line. The heating section of the dryer is divided into three areas, and each area is heated by different infrared rays. Tube distribution mode, the glass passes through the drying area, and the heat of the heating tube pair radiates to the ink, causing it to heat up rapidly and evaporate the water. Due to the increase in temperature, it can also play a pre-sintering effect. After the glass passes through the drying area, the surface The temperature can be reduced rapidly to meet the design requirements

[0012] Such as figure 1 As shown, the three zones of the dryer heating section are designed as:

[0013] 1. Ink drying is divide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com