Flame tube air inlet method of solid oxide fuel cell system and combustion chamber of solid oxide fuel cell system

A technology of fuel cell system and solid oxide, applied in solid electrolyte fuel cells, gas fuel burners, fuel cell additives, etc., can solve the problems of limited service life, poor shock resistance and vibration resistance, expensive catalysts, etc., and achieve improved Stability, improved uniformity, effect of improved uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

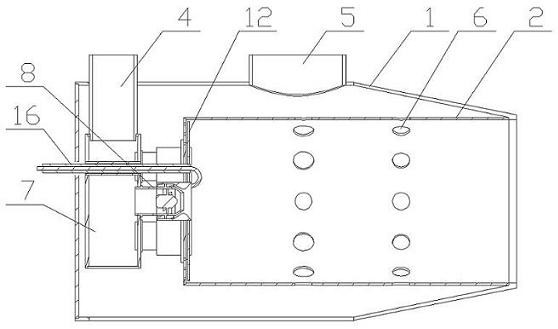

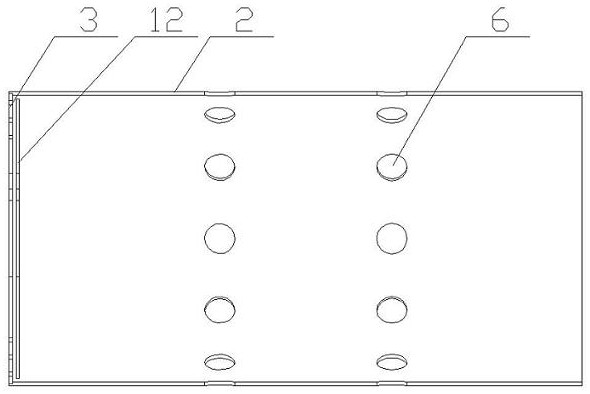

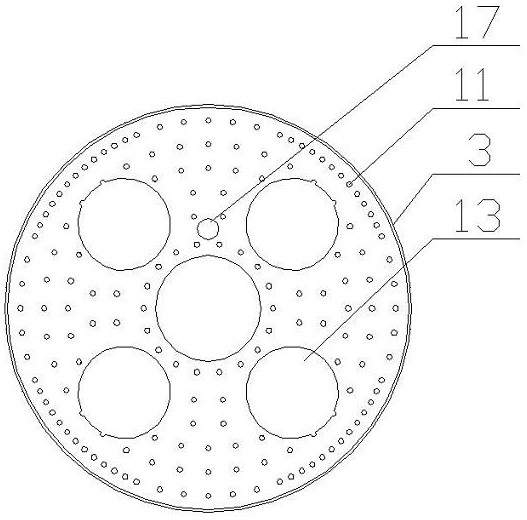

[0043] The invention discloses a flame cylinder intake method of a solid oxide fuel cell system (SOFC system). The anode tail gas of the electric stack enters the flame cylinder from the head of the flame cylinder in a swirling manner, and the cathode tail gas of the electric stack enters the flame in the following manner cylinder:

[0044] 1) Enter the flame tube from the side wall through holes distributed on the side wall of the flame tube;

[0045] 2) Enter the flame tube through the end wall through holes distributed on the head end wall of the flame tube;

[0046] and

[0047] 3) Enter the flame tube from the head of the flame tube by swirling flow.

[0048] The cathode tail gas entering the flame cylinder in a swirling manner wraps the anode tail gas entering the flame cylinder in a swirling manner along the air intake direction.

[0049] The side wall through-holes distributed on the side wall of the flame tube are preferably divided into several groups, and the qua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com