Crucible for the growth of silicon crystal and process for the growth of silicon crystal

A technology for growing silicon crystals and growing crystals, which is applied in crystal growth, single crystal growth, single crystal growth, etc., and can solve problems such as weakening the production capacity of excellent products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

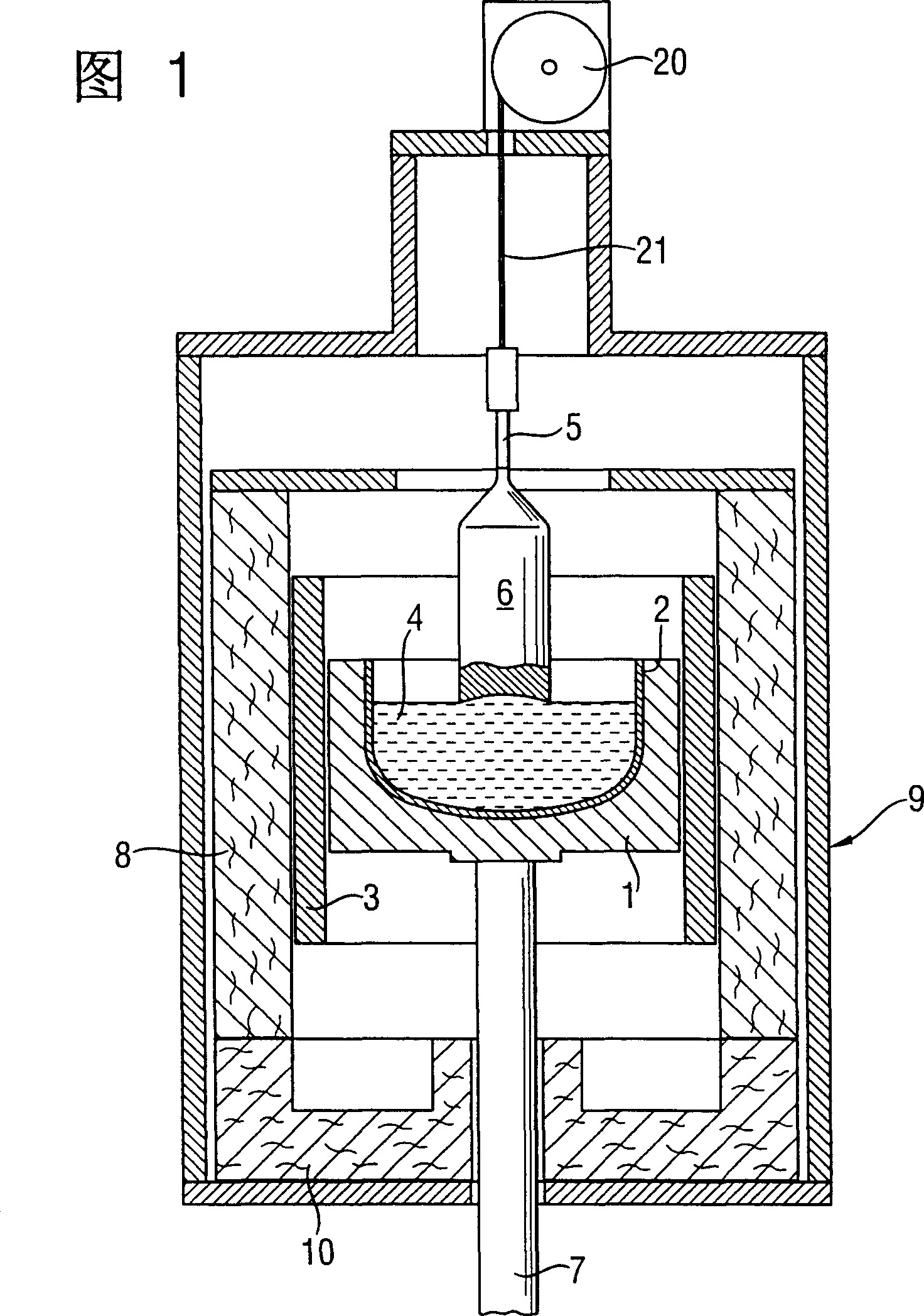

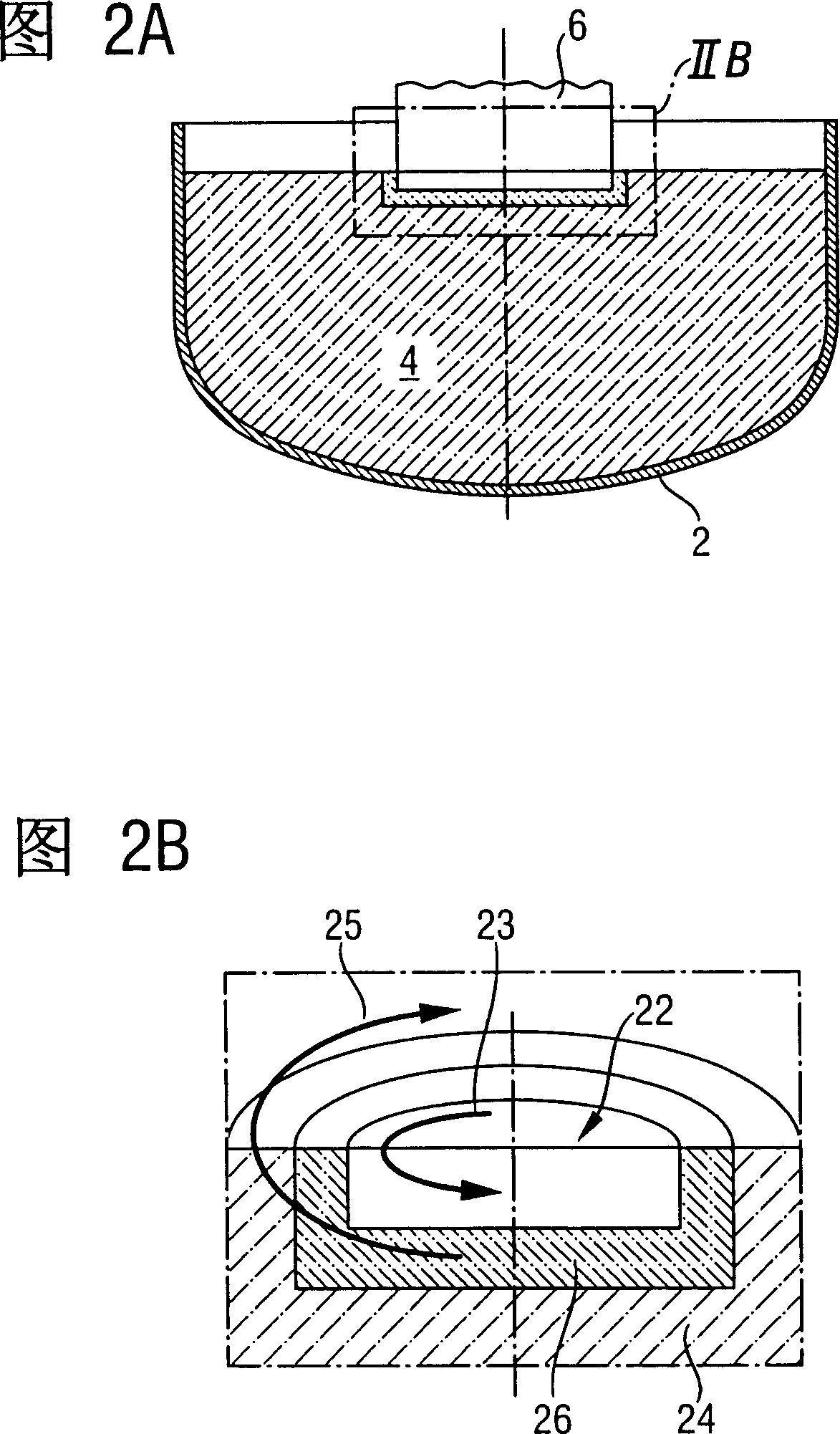

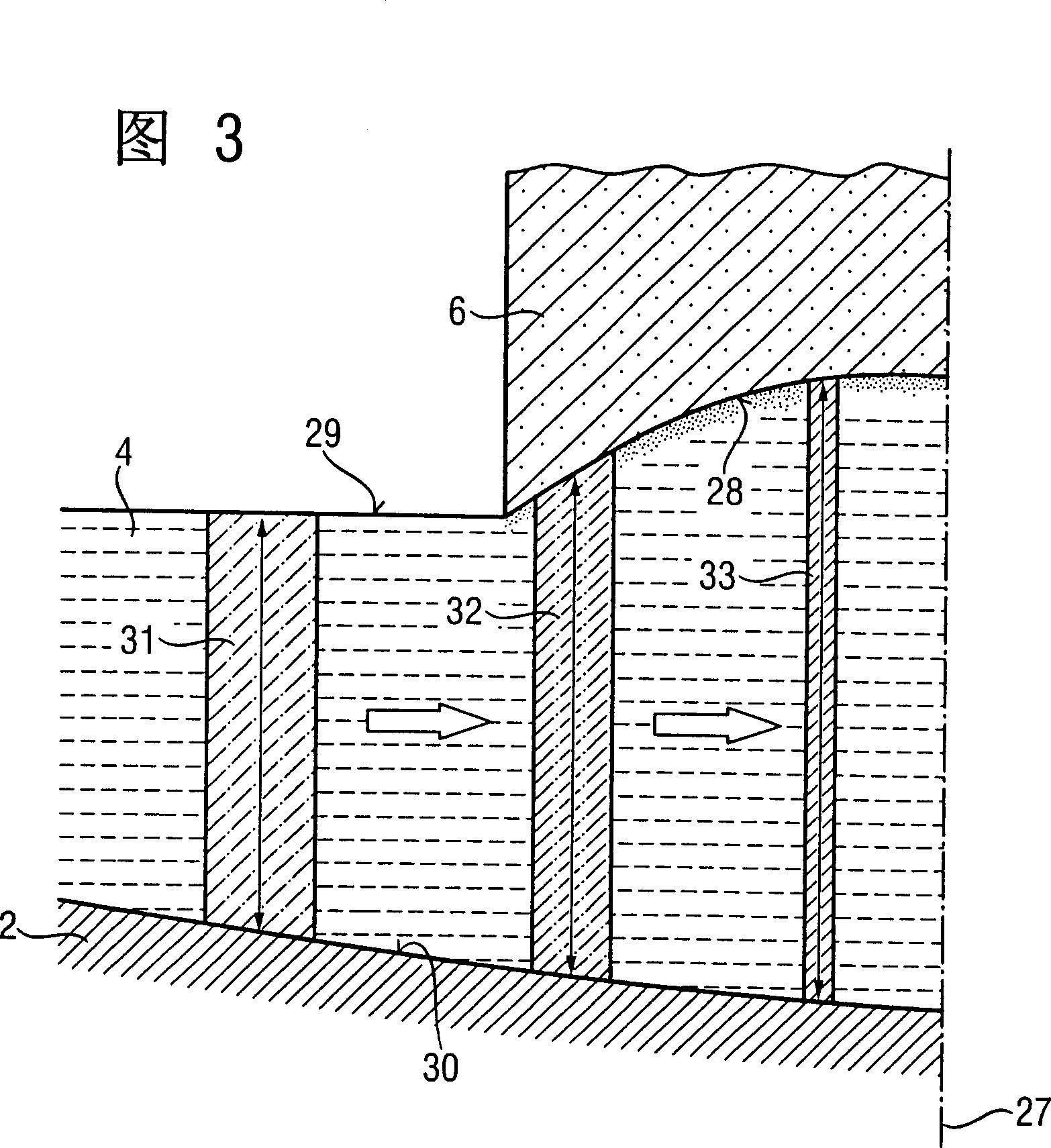

[0078] Referring now to the accompanying drawings, the present invention will be further described in the following embodiments.

[0079] Figure 7 shows the cross-sectional profile of a typical crucible made of quartz with a 350mm diameter used to manufacture state-of-the-art silicon crystals. The crucible consists of a vertically extending cylindrical outer wall with an inner diameter of 350 mm and a spherical bottom portion with a radius of 350 mm, which are inscribed by an arcuate wall with a radius of 70 mm.

[0080] Fig. 8 shows, when using this crucible to grow a crystal having a diameter of 100mm, along with the profile of the growth interface and the profile of the bottom of the crucible during the growth of the regularly shaped part of the crystal, in the range from the position of the outer wall of the crucible to the position of the central axis The change in the vertical length of the molten liquid layer on the cross-section.

[0081] In Fig. 8, the height is in m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com