Blending heat treatment intelligent control method of microwave oven

An intelligent control and oven technology, which is applied in the direction of temperature control using electric methods, can solve the problems of unsatisfactory microwave electric field distribution uniformity, poor heat treatment uniformity of materials, and long time consumption, so as to improve production efficiency and heat treatment quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0016] This embodiment is heat treatment of lithium battery diaphragm.

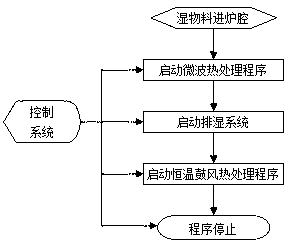

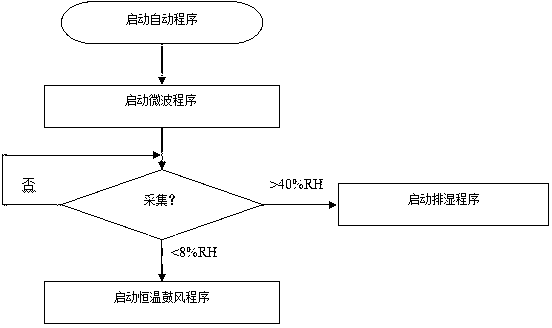

[0017] Heat treatment process: when wet materials enter the furnace cavity, the microwave heat treatment program is first started to dry the wet materials. When the ambient humidity in the furnace cavity is higher than 40%RH, the dehumidification system is started, and the water vapor is removed through the dehumidification system. When the ambient humidity is lower than 8%RH, the program automatically switches to the constant temperature blast heat treatment state, and runs for 10 hours under the constant temperature blast heat treatment state to complete drying and heat treatment. The entire heat treatment process is carried out under the control of the control system.

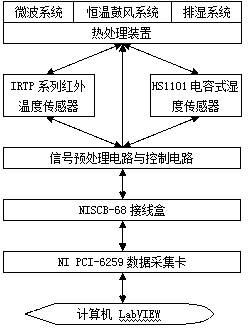

[0018] The industrial control technology adopted by the control system is labVIEW, which comprehensively utilizes the PC and the graphical virtual instrument development environment labVIEW to establish a flexible PC-based measur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com