Suspension type workpiece air cooling device

A hanging workpiece and air-cooling device technology, which is applied in the field of metal heat treatment equipment, can solve the problems of inconvenience and difficulty in increasing the cooling speed, and achieve the effects of increasing the cooling speed, preventing pressure drop and uneven pressure, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

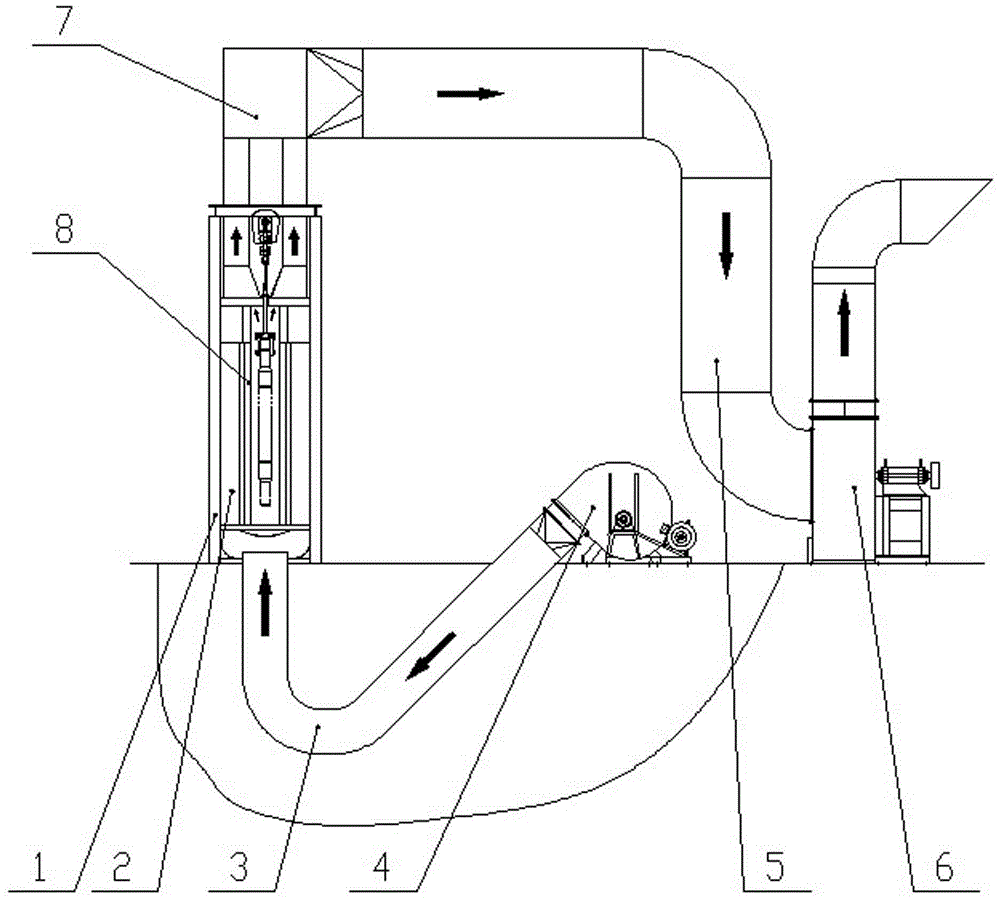

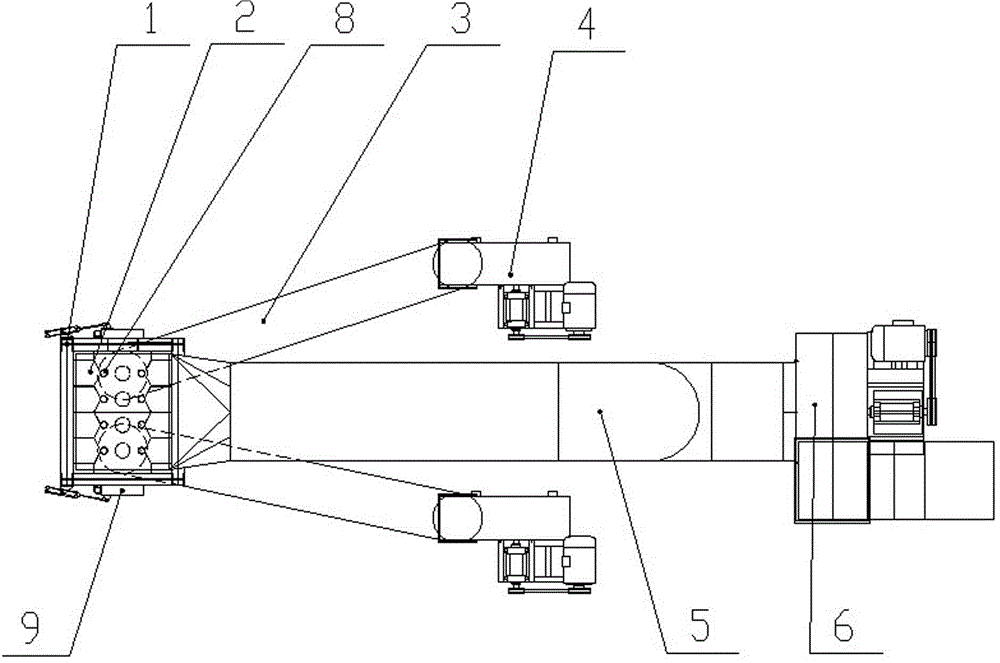

[0015] The specific embodiment of the present invention will be described with reference to the accompanying drawings.

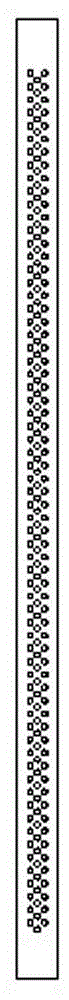

[0016] As shown in the accompanying drawings, the suspended workpiece air cooling device includes a cooling chamber 1, which is in the shape of a vertical rectangular box and is welded with high-quality steel and steel plates. The front and back of the cooling chamber 1 are equipped with workpiece inlets and outlets and equipped with workpiece inlets and outlets 9 respectively. Each workpiece inlet and outlet 9 is equipped with a pneumatic or hydraulic drive device to realize the opening and closing of the workpieces inlet and outlet. The elongated blowing boxes 2 with the upper end closed are installed vertically inside the cooling chamber 1, arranged in pairs left and right, as in the embodiment of the drawings, the blowing boxes 2 arranged in pairs left and right are arranged in multiple pairs in the cooling chamber 1. The relative inner side of each blow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com