Reflow soldering machine

A technology of reflow soldering and tin machine, which is applied in the direction of welding equipment, auxiliary devices, electrical components, etc., can solve the problems that the cooling effect of the fan is difficult to achieve, the quality of component welding is affected, and the quality of solder joints is greatly affected, so that it is easy to move and Fixed, guaranteed cooling effect, effect with obvious cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

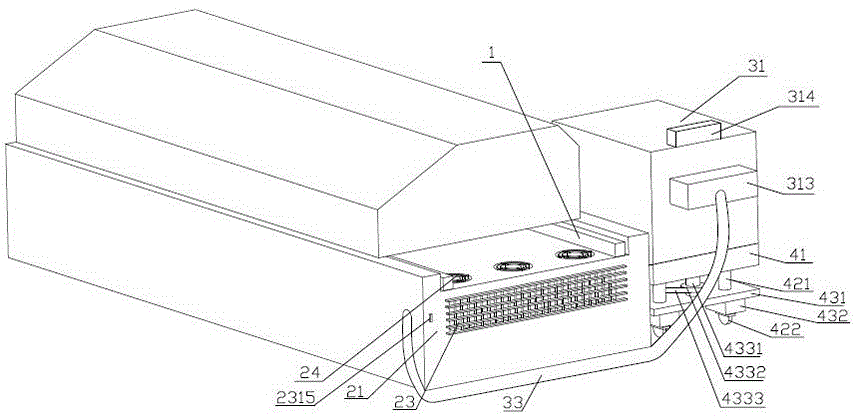

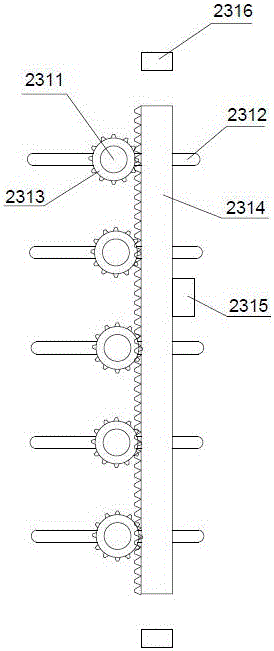

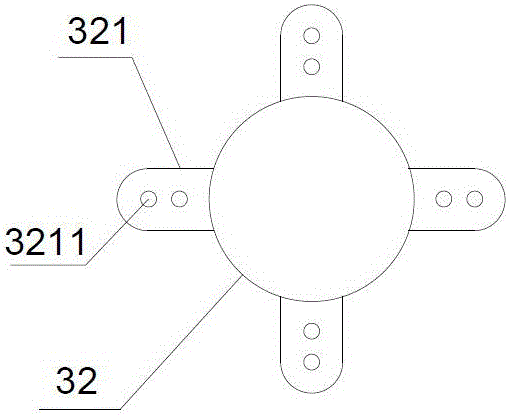

[0031] Such as Figure 1-5 As shown, the present invention includes a conveying track 1, an air cooling device arranged below the conveying track 1, and a water cooling mechanism connected to the air cooling device. Described air-cooling device comprises bellows 21, multiple fans, air inlet 23, air outlet 24, and described multiple fans are arranged at described air outlet 24 places, and described air inlet 23 is provided with flow adjustment device, and described flow adjustment The device includes a plurality of parallel turning shafts 2311, air regulating vanes 2312 arranged on the turning shafts 2311, a gear 2313 arranged at one end of the turning shafts 2311, a rack 2314 matching a plurality of said gears 2313, The rack 2314 is exposed to the toggle block 2315 outside the bellows, and the upper and lower sides of the rack 2314 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com