Method for cooling steel pipe

A cooling method and steel pipe technology, applied in furnaces, heat treatment equipment, quenching devices, etc., to achieve excellent performance, low cost, and uniform cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation of the present invention will be further described below in conjunction with the examples and drawings, and the present invention is not limited to the scope of the examples.

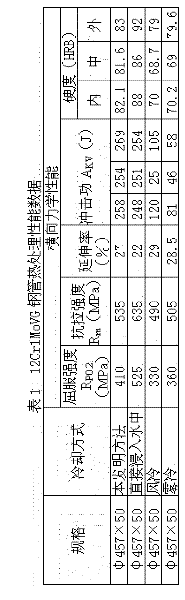

[0023] EXAMPLE 12Cr1MoVG steel pipe with a specification of φ457×50 was subjected to normalizing heat treatment.

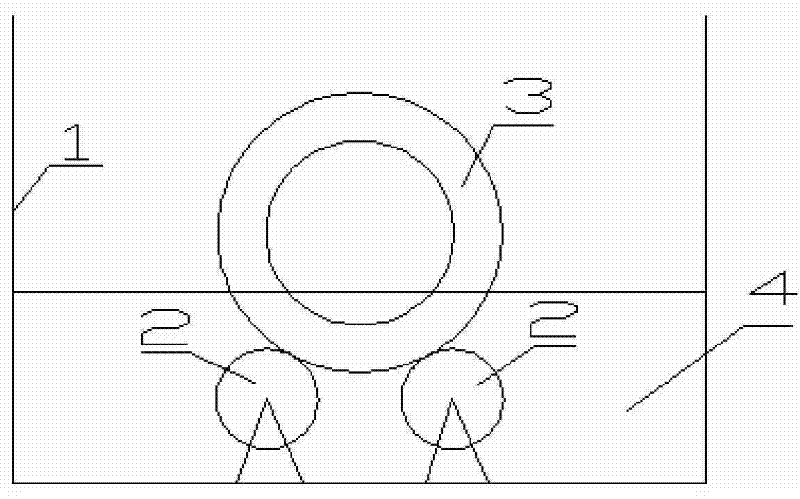

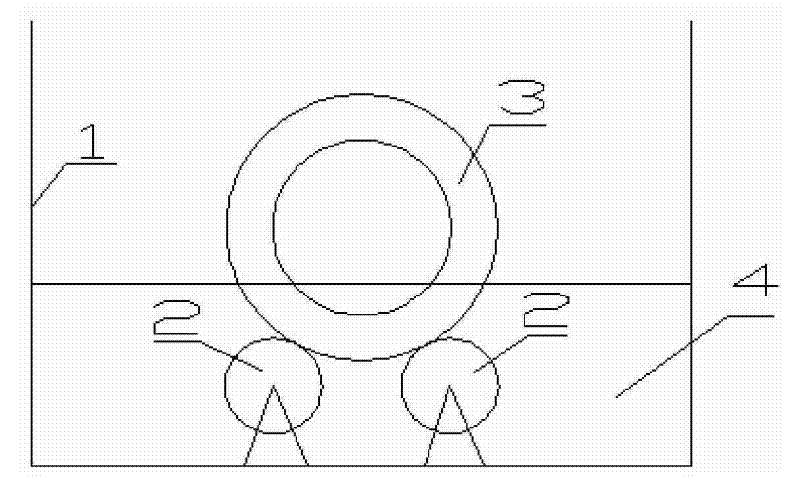

[0024] Before the heat treatment, the water in the cooling tank 1 is emptied (see the structural diagram of the equipment used) figure 1 ). After the steel pipe 3 is normalized and heated out of the furnace, the steel pipe 3 is hoisted into the cooling tank 1 and placed on the roller 2. The roller 2 is driven by the motor to rotate, and the rotating roller 2 drives the steel pipe to rotate, and water is injected into the cooling tank 1. The water surface rises, and when the water touches the outer surface of the steel pipe 3, the steel pipe 3 starts to cool from the outer surface; The inner and outer surfaces can be cooled evenly at the same time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com