Lipstick tube extrusion cooling device

A technology of cooling device and lipstick tube, which is applied in the field of cooling, can solve problems such as inability to achieve instant cooling, and achieve the effects of diversified cooling methods, high work efficiency, and accelerated cooling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

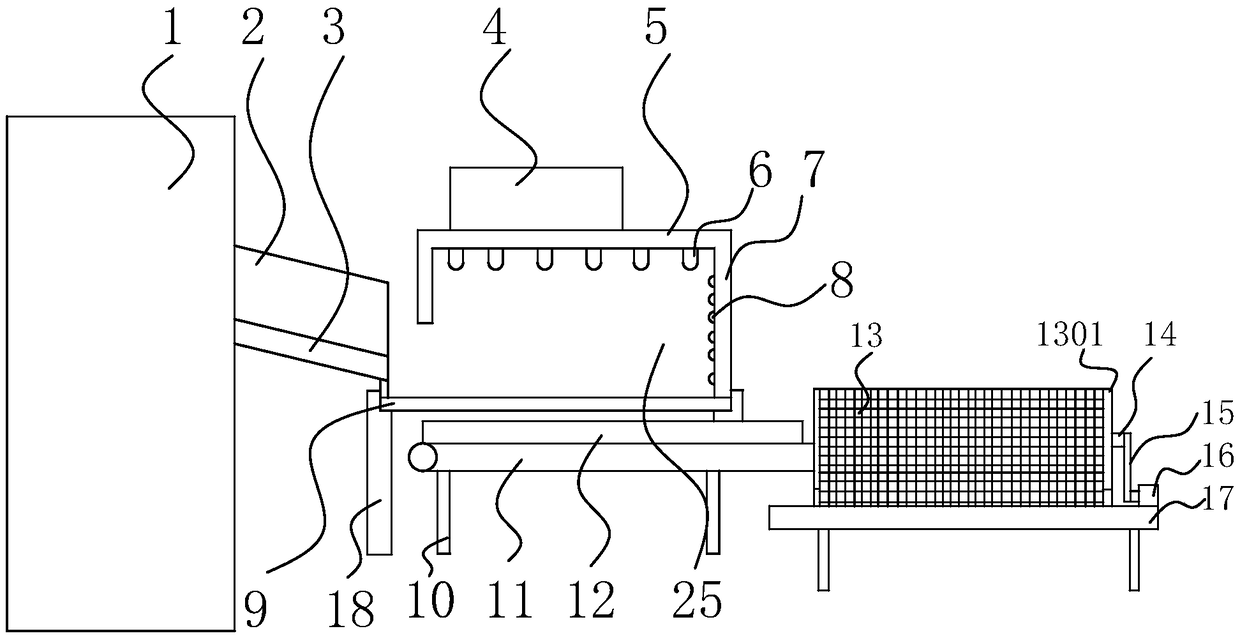

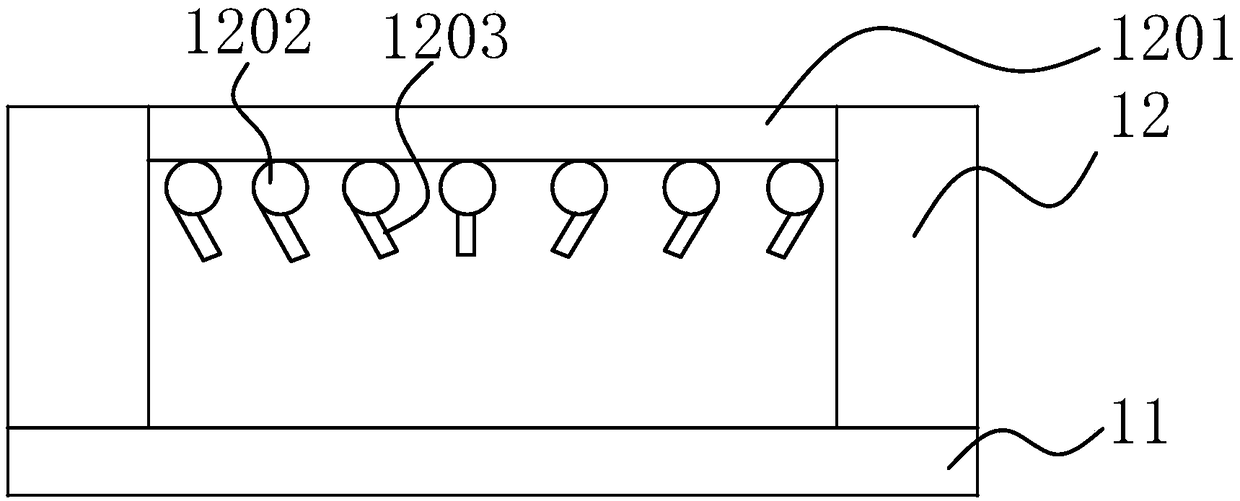

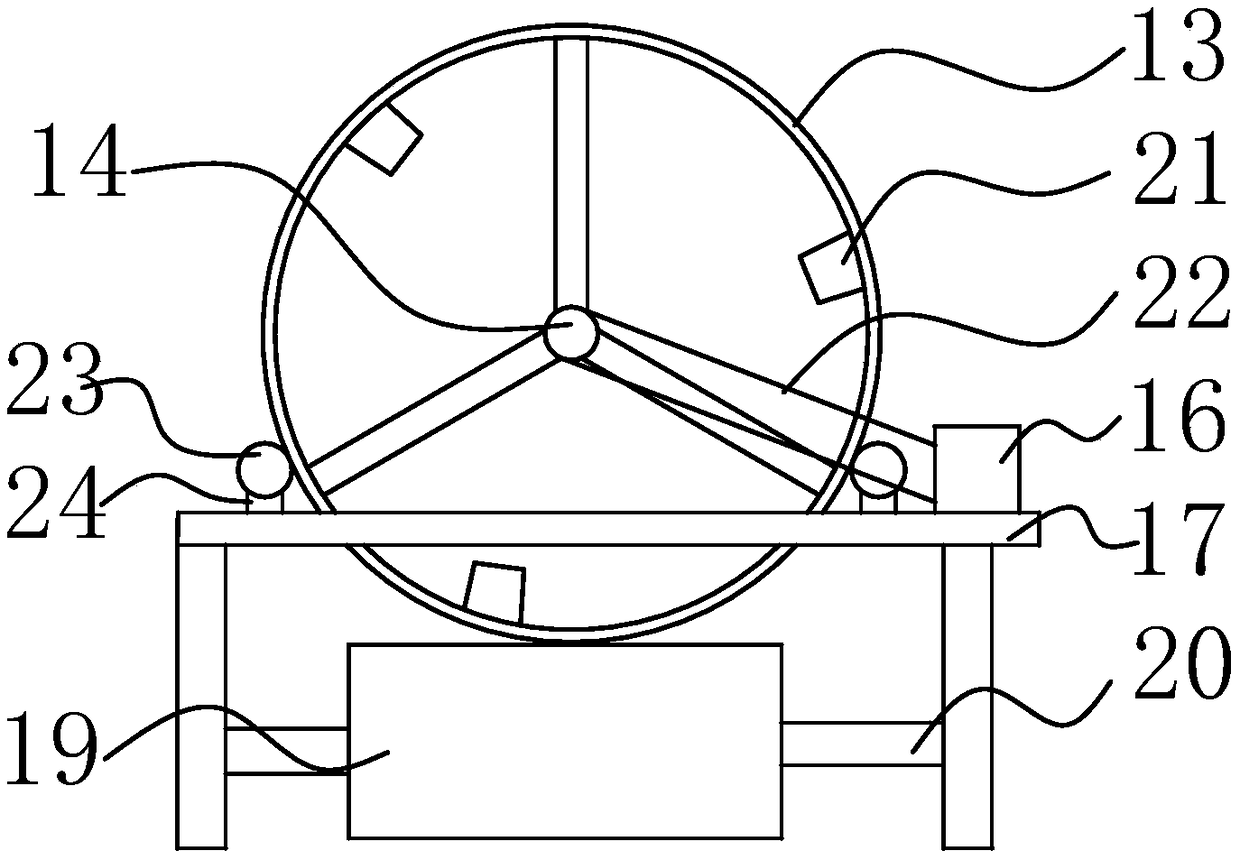

[0023] Such as figure 1 , figure 2 , image 3 Shown, a kind of lipstick tube extrudes cooling device, comprises the atomizing device that is arranged on the extruder 1 outlet end, is arranged on the air-drying device and the discharge device that are arranged on the lower end of the atomizing device, is characterized in that: the outlet end of extruder 1 The discharge plate 3 is arranged obliquely, and side plates 2 are provided on both sides of the discharge plate 3. The atomization device includes a longitudinal conveyor belt 9 arranged at the bottom of the discharge plate 3, a support 18 supporting the longitudinal conveyor belt 9, and The top plate 5 at the upper end, the two sides of the longitudinal conveyor belt 9 are relatively vertically provided with a support plate 7, the support plate 7 is provided with an opening on one side of the discharge plate 3, and the inner side of the support plate 7 away from the discharge plate 3 is evenly provided with a sponge block ...

Embodiment 2

[0028] Such as figure 1 , figure 2 , image 3 Shown, a kind of lipstick tube extrudes cooling device, comprises the atomizing device that is arranged on the extruder 1 outlet end, is arranged on the air-drying device and the discharge device that are arranged on the lower end of the atomizing device, is characterized in that: the outlet end of extruder 1 The discharge plate 3 is arranged obliquely, and side plates 2 are provided on both sides of the discharge plate 3. The atomization device includes a longitudinal conveyor belt 9 arranged at the bottom of the discharge plate 3, a support 18 supporting the longitudinal conveyor belt 9, and The top plate 5 at the upper end, the two sides of the longitudinal conveyor belt 9 are relatively vertically provided with a support plate 7, the support plate 7 is provided with an opening on one side of the discharge plate 3, and the inner side of the support plate 7 away from the discharge plate 3 is evenly provided with a sponge block ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com