[0002]

Titanium-nickel-based

shape memory alloy has always been a key researched functional alloy material at home and abroad. In recent years, international academic conferences have been held every year to discuss and exchange its research theoretical and principle results, organizational properties,

processing methods and production technologies. China's Northwest Institute of Nonferrous Metals, Shenyang Institute of

Metal Research, Chinese Academy of Sciences, Tianjin University and other institutions of higher learning and scientific research institutes have also conducted a large number of

theoretical research and production

process research, and have achieved many scientific research results and patented technologies.

Titanium-nickel-based memory In the application of alloys, it is widely used in

aerospace parts;

vascular stents and orthopedic implants in the medical field; industrial springs and pipeline connectors; thermostatic valves and spectacle frames in daily necessities. The application mainly uses its two functions: shape memory function and superelasticity, but its other function, high damping characteristics, is rarely studied and used at home and abroad, because the shape

memory performance and superelasticity of titanium-nickel-based alloys are determined by the composition In addition to the martensitic transformation point, it also depends on the heat treatment and cold deformation of the material. Conventional manufacturing can only mainly produce titanium-nickel-based alloy wires, tubes, plates and other simple geometric shape processing materials and products produced with them. Products and small parts such as nets, springs, sheets, etc., for parts with complex shapes that use the alloy's damping properties, the inconsistency in the

cooling rate of each part during heat treatment will cause uneven structure and performance, which will affect its application field; titanium-nickel-based

shape memory alloy The reason why it has the ability to recover from deformation is because of the thermoelastic martensitic phase transformation that occurs inside the material during the deformation process. There are two phases in the shape memory alloy: the high-temperature phase

austenite phase, the low-temperature phase

martensite phase, and the

martensite phase. Phase transformation is not only caused by temperature, but also by stress. This stress-induced martensitic transformation is called stress-induced martensitic transformation, and the phase transformation temperature has a

linear relationship with stress. Elasticity (pseudo-elasticity) means that when the shape memory alloy undergoes a

large deformation under the high-temperature phase

austenite state, the

large deformation will be completely restored after the external force is removed, but the stress-strain curve is not linear during the deformation process. Dissipative energy is generated. The high damping characteristics of titanium-nickel-based memory alloys are due to the

internal friction of the alloy material. As an energy dissipation coefficient of the material, the

internal friction becomes an important parameter for designing structural materials like other mechanical properties of the material. , the high damping performance of shape memory alloys is mainly due to the

hysteresis of interfacial movement. )-based titanium-

nickel alloy, adding 2% - 5%

copper instead of nickel atoms, its

corrosion resistance, fatigue performance and high damping performance are very good, not long ago German scientists discovered its extremely high fatigue performance,

spray coating Smart

new materials can be made on other metals. The high damping properties of titanium-nickel alloys are of great significance for shock absorption and

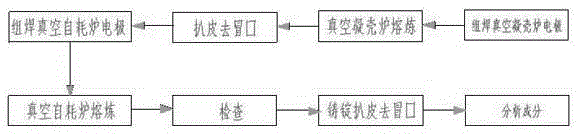

noise reduction for military, ship, and civilian blades and paddles. However, the chemical properties of titanium-nickel memory alloys The composition requirements are very strict, and the content of low-interstitial impurities is extremely low. In addition to the strict requirements on raw materials, the melting method of the alloy has a great influence on its performance. Most of the melting at home and abroad adopts

vacuum induction furnace and water-cooled

copper crucible vacuum induction furnace to melt the alloy. , due to the high

chemical activity of the alloy, the

crucible material of the

vacuum induction furnace is polluted during the melting process, so the control of O, N.H is very difficult and the stability is poor. This is the reason why this type of alloy has been unstable in China, while the water-cooled

copper Although the

crucible vacuum

induction furnace can solve this problem, due to its

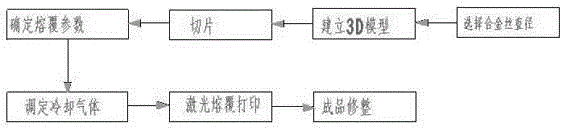

limited capacity, it cannot produce large ingots and cast large parts. It is impossible to manufacture propellers of hundreds of kilograms or even several tons for ships. For general additive manufacturing (3D printing), it is very difficult to produce uniform titanium-

nickel alloy powder with accurate composition and low

impurity content, and the existing process methods cannot produce

powder components and properties that can reach functional parts. 3D printing requirements, so no reports have been seen at home and abroad

Login to View More

Login to View More  Login to View More

Login to View More