A recovery method of platinum crucible for relaxation ferroelectric single crystal growth

A relaxor ferroelectric single crystal and platinum crucible technology is applied in the field of recycling platinum crucibles for relaxor ferroelectric single crystal growth, and can solve problems such as leaky crucibles for single crystal growth, inability to clean crystal impurities, and decrease in platinum purity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

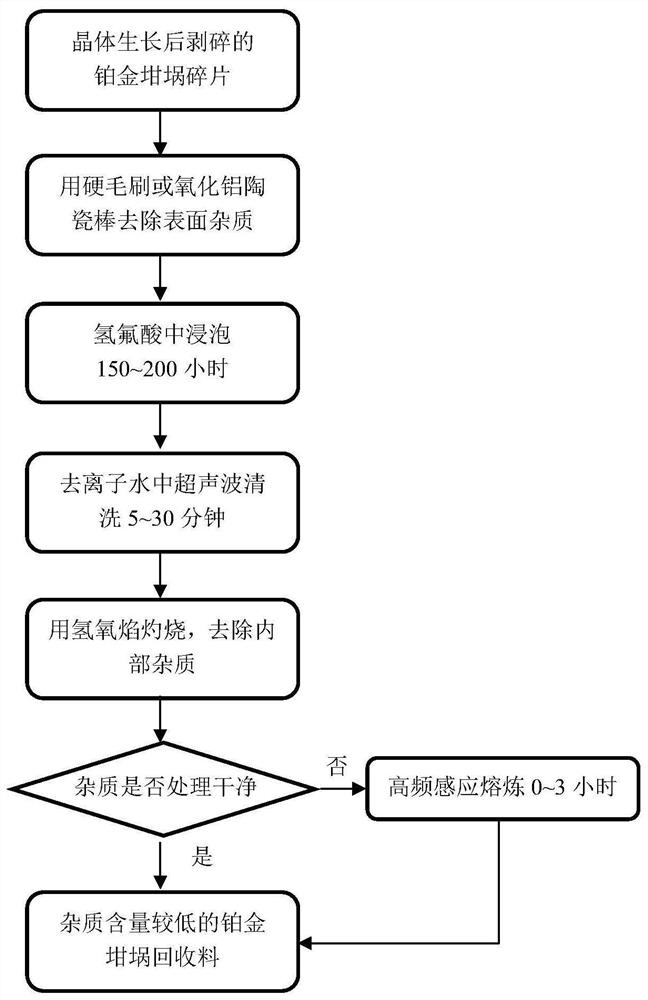

Method used

Image

Examples

Embodiment 1

[0030] Recycling of platinum crucibles without corroded leaky crucibles:

[0031] (1) Flatten the platinum crucible fragments and cut them into long strips with basically the same length. Use a hard brush to wipe the surface of the platinum crucible fragments in deionized water, and try to remove the impurities stuck on the surface. If there are hard single crystal impurities, you can use an alumina ceramic rod to gently poke them off. For those that cannot be removed must not be forcibly removed to prevent loss of platinum. After cleaning, rinse again with deionized water and dry.

[0032] (2) Soak the platinum crucible fragments cleaned in step (1) in a 1:1 hydrofluoric acid solution for 150 hours. During the soaking process, the platinum crucible fragments should be turned every 24 hours to ensure the acid bubble effect. After soaking, use a hard brush to clean impurities, and then use deionized water to ultrasonically clean, specifically: room temperature, frequency 40KH...

Embodiment 2

[0037] For recovery of platinum crucibles with slightly corroded leaky crucibles:

[0038](1) Flatten the platinum crucible fragments and cut them into long strips with basically the same length. Use a hard brush to wipe the surface of the platinum crucible fragments in deionized water, and try to remove the impurities stuck on the surface. If there are hard single crystal impurities, you can use an alumina ceramic rod to gently poke them off. For those that cannot be removed must not be forcibly removed to prevent loss of platinum. After cleaning, rinse again with deionized water and dry;

[0039] (2) Soak the platinum crucible fragments cleaned in step (1) in a 1:1 hydrofluoric acid solution for 180 hours. During the soaking process, the platinum crucible fragments should be turned every 24 hours to ensure the acid bubble effect. After soaking, use a hard brush to clean impurities, and then use deionized water to ultrasonically clean, specifically: room temperature, freque...

Embodiment 3

[0045] For recovery of platinum crucibles with severely corroded leaky crucibles:

[0046] (1) Flatten the platinum crucible fragments and cut them into long strips with basically the same length. Use a hard brush to wipe the surface of the platinum crucible fragments in deionized water, and try to remove the impurities stuck on the surface. If there are hard single crystal impurities, you can use an alumina ceramic rod to gently poke them off. For those that cannot be removed must not be forcibly removed to prevent loss of platinum. After cleaning, rinse again with deionized water and dry.

[0047] (2) Soak the platinum crucible fragments cleaned in step (1) in a 1:1 hydrofluoric acid solution for 200 hours. During the soaking process, the platinum crucible fragments should be turned every 24 hours to ensure the acid bubble effect. After soaking, use a hard brush to clean impurities, and then use deionized water to ultrasonically clean, specifically: room temperature, frequ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com