Novel optical mold

An optical and mold technology, applied in the field of new optical molds, can solve problems such as affecting work efficiency, difficult to guarantee accuracy, and difficult to form, and achieve the effects of reducing material consumption, high precision, and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

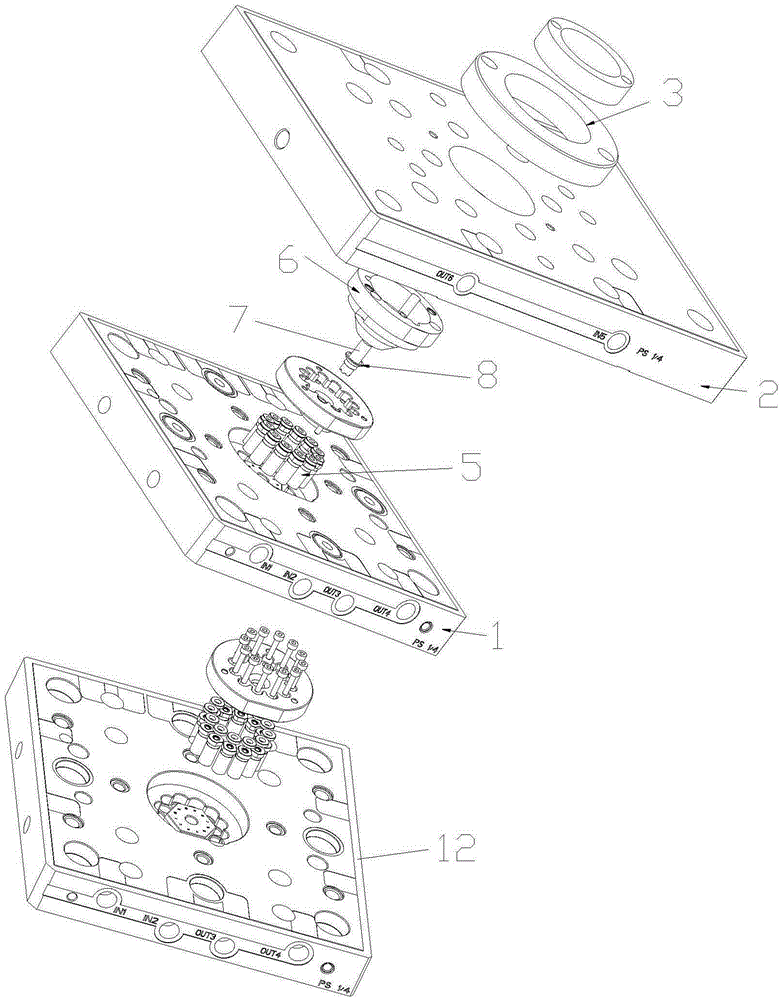

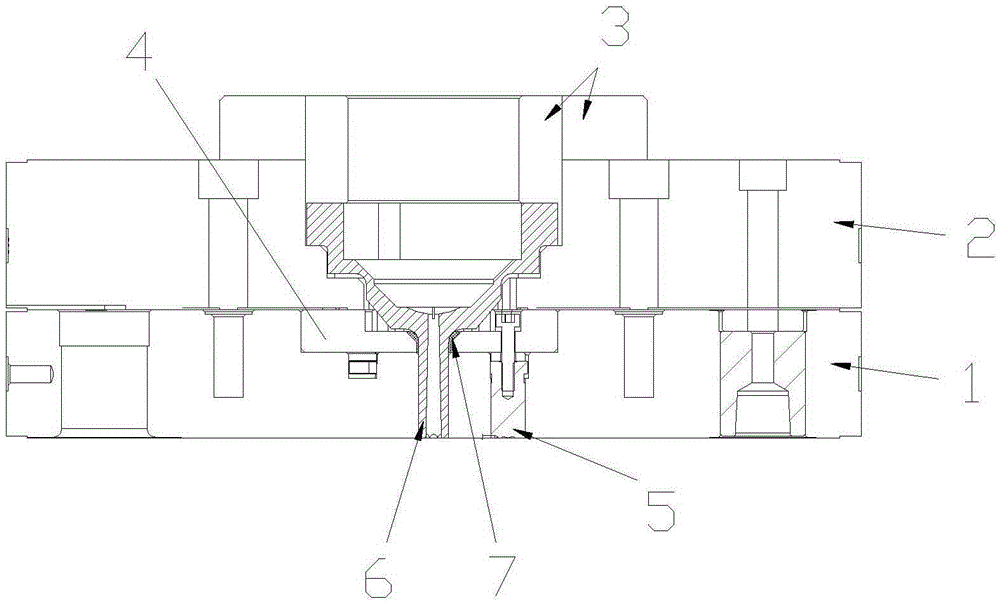

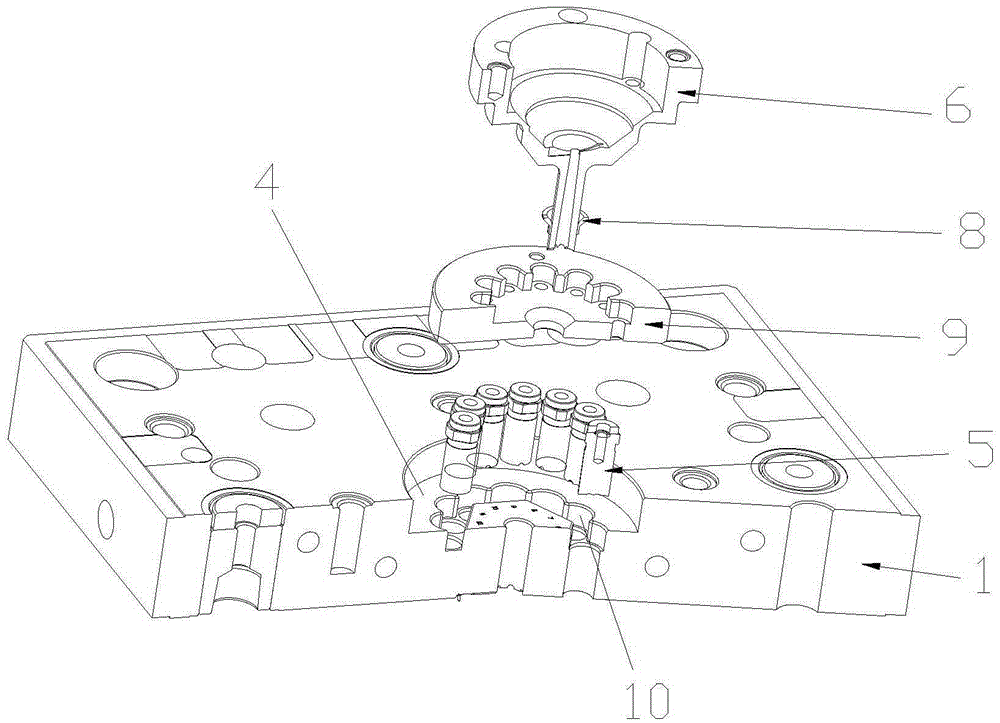

[0018] like Figure 1-Figure 4 As shown, a new type of optical mold includes a female template 1 and a male template 12. The female template 1 and the male template 12 are installed and fixed through the fixing plate 2 and the positioning ring 3. The bottom of the center of the female template 1 and the male template 12 is provided with Groove 4, spacer 9 is arranged in described hole groove 4, mold cavity 10 is respectively arranged in female template 1 and male template 12 below described hole groove 4, and described female template 1 and male template 12 are provided with A mold core 5, a filling nozzle 6 is arranged inside the master template 1 .

[0019] The mold core 5 is adapted to the mold cavity 10 .

[0020] The mold core 5 is compatible with the spacer 9 .

[0021] A glue channel 7 is arranged below the filling nozzle 6 .

[0022] A cooling sleeve 8 is provided outside the glue channel 7 .

[0023] When in use, the filling nozzle 6 is in contact with the nozzle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com