Tunnel steel pipe quenching device and quenching method thereof

A quenching equipment and tunnel-type technology, which is applied in the direction of quenching devices, heat treatment equipment, furnaces, etc., can solve problems affecting the quenching quality of steel pipes, and achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

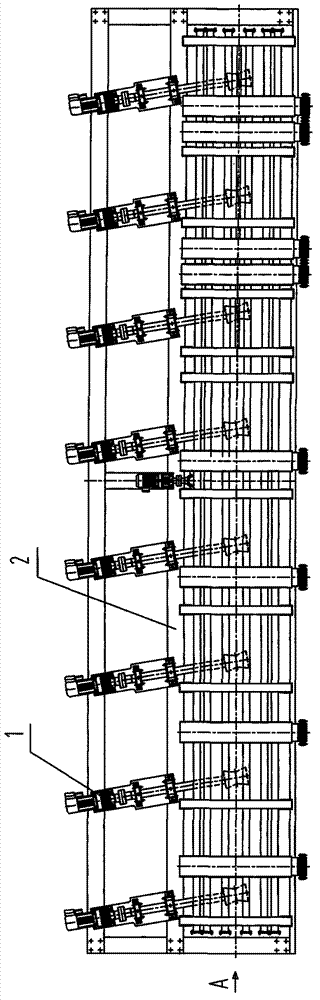

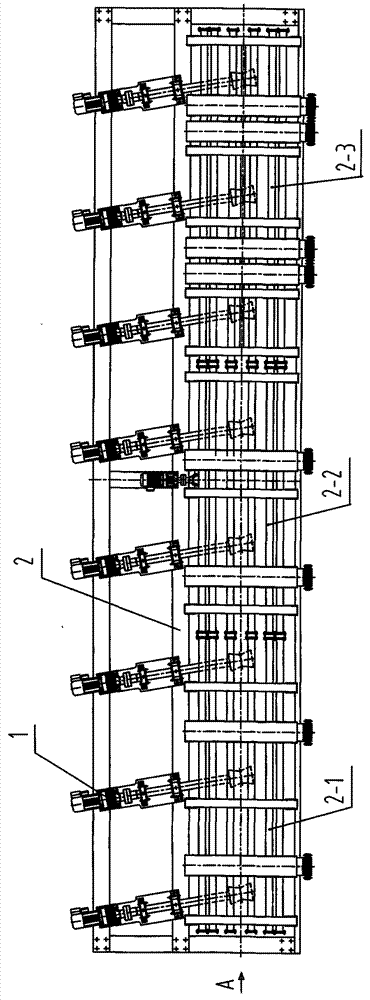

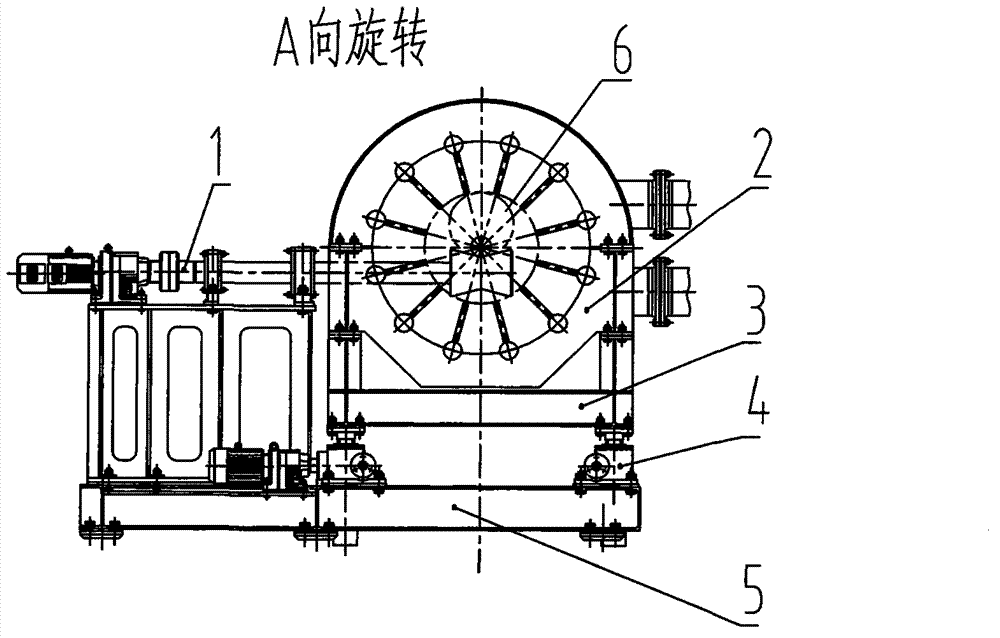

[0019] Such as image 3 , 4 Shown: a tunnel-type steel pipe quenching equipment, including: a roller table device 1 at an angle of 10° to the tunnel axis, a quenching tunnel 2 installed on a tunnel support 3, and the tunnel support 3 is connected with a lifting device 4 and is formed by Driven by the lifting device 4, the roller table device 1, the lifting device 4 are installed on the base 5 together with the tunnel support 3 and the quenching tunnel 2, and the inside of the quenching tunnel 2 is provided with a ring-shaped nozzle pipe connected to the external water pump of the tunnel; The quenching area of tunnel 2 is composed of the rapid cooling zone 2-1 with densely arranged annular nozzles, the slower cooling zone 2-2 with annular nozzles, and the slow cooling zone 2-3 with gas-water mixing nozzles, which are independently controlled , the three independently controlled units are: the densely packed annular nozzle quenching unit directly connected to the tunnel exter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com