Method and equipment for preparing semisolid fused mass of ferrous material

A technology for iron and steel materials and a preparation device is applied in the field of preparation of semi-solid melts of iron and steel materials, and can solve the problems of high manufacturing cost and inconvenience in popularization and application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in conjunction with accompanying drawings.

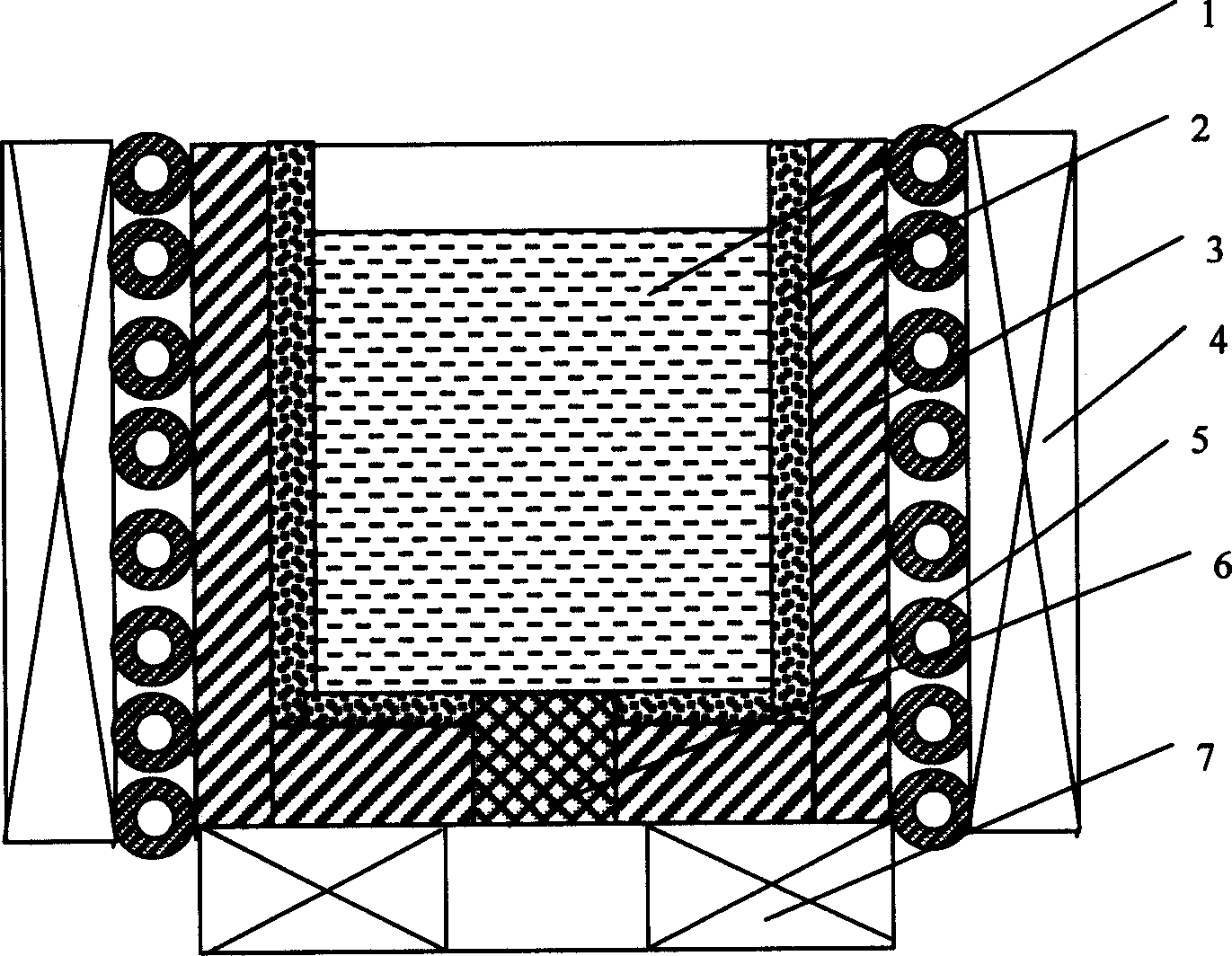

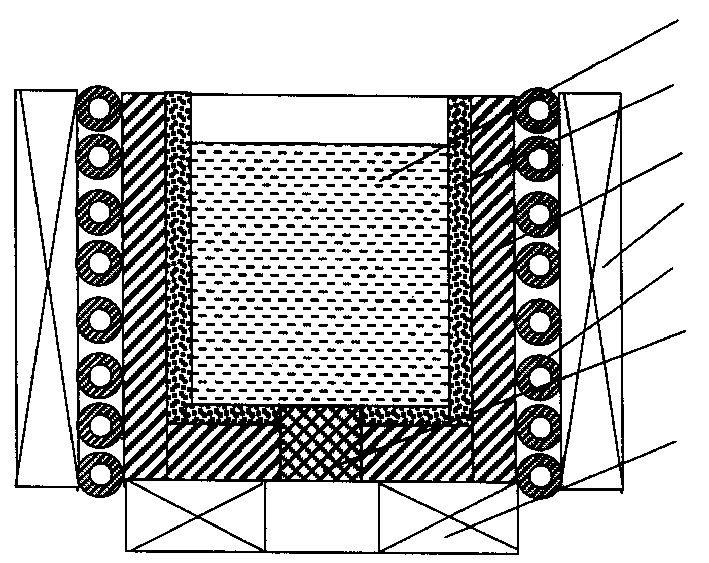

[0028] The preparation device of semi-solid melt of iron and steel materials such as figure 1 . The device includes: a special container for holding a molten steel material 1, a temperature regulating device 5 installed outside the special container, an agitator 4 and a vibrator 7 at the bottom.

[0029] The steel material melt 1 is placed in a special container, and the stirrer 4 and the vibrator 7 respectively or simultaneously generate a stirring force field and a vibration force field to move the melt 1, and promote the freeing and freeing of the crystals formed on the inner wall of the special container crystal spheroidization. The temperature regulating device 5 installed outside the special container regulates the cooling rate of the melt 1 and the temperature gradient inside the melt to suppress the growth of dendrites. Open the sprue plug 6, and pour the qualified se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com