Natural gas dehumidifying device

A natural gas and straight pipe technology, applied in the field of pipeline-type conical annular flow channel subsonic natural gas dehumidifiers, can solve the problems of complicated structure and operation of the expander unit, and achieve the effect of eliminating adverse effects and reducing processing difficulty and cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

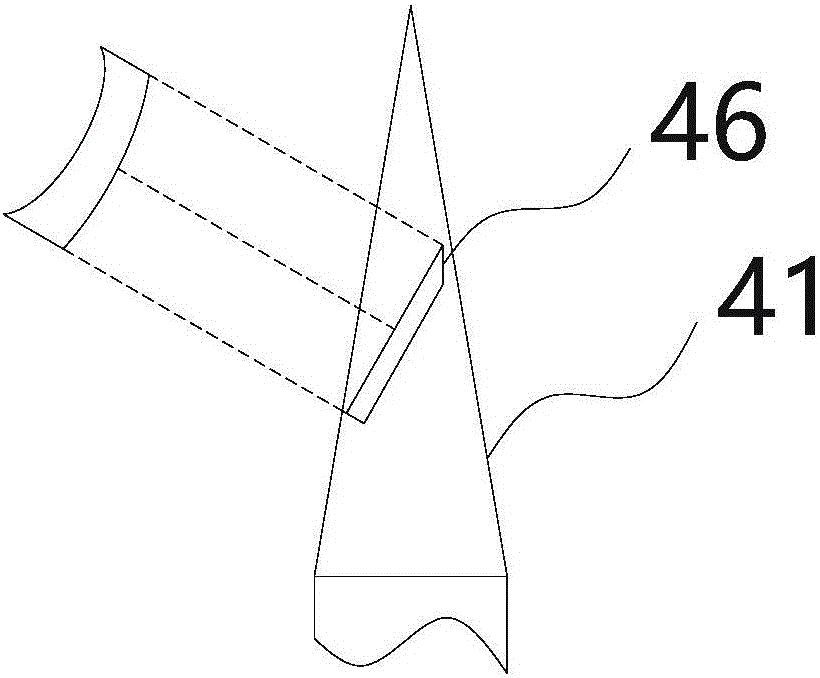

Embodiment 1

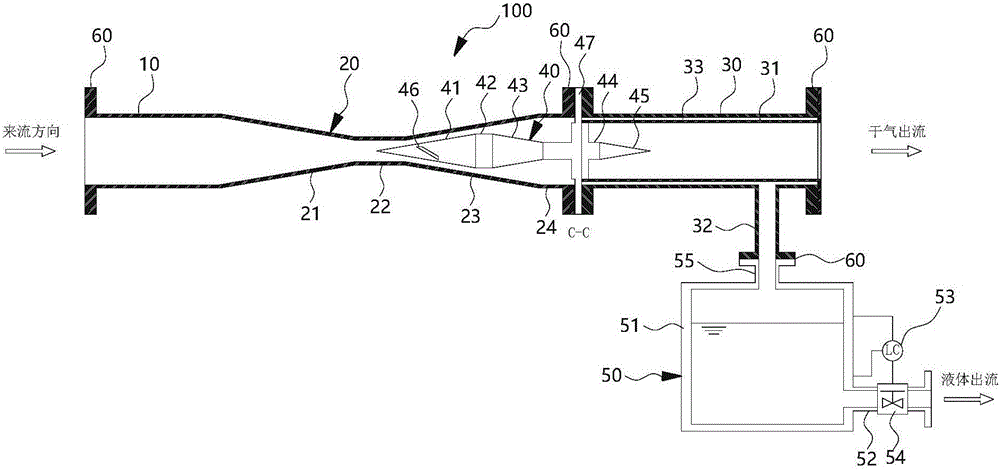

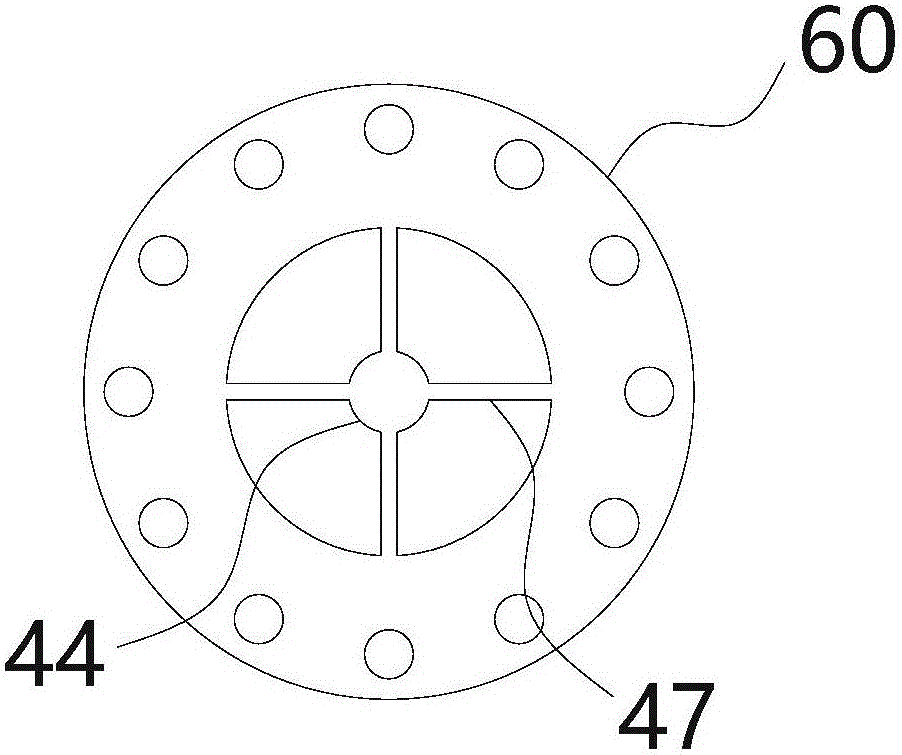

[0050] Taking a natural gas pipeline with a diameter of 150mm as an example, the total length of this natural gas dehumidifier is 1575mm, and four flange ports are used. One DN150 main air inlet is connected to the natural gas transmission channel by a straight pipe inlet section, and one DN150 is used to connect the rectifier section and straight pipe output section, a DN150 gas outlet is connected by the straight pipe output section and the natural gas transmission channel, and a DN50 is used for the outlet of the liquid discharge pipe.

Embodiment 2

[0052] The natural gas dehumidification device should be installed horizontally close to the wellhead or at the beginning of the gathering and transportation pipeline after the gas production pipes are assembled. The flange connection can replace a section of the delivery pipeline, and the installation is simple and convenient; the outlet of the liquid collection container is transported to the liquid storage tank through the infusion pipeline for further processing.

Embodiment 3

[0054] The on-site natural gas pipeline pressure is 3MPa, the gas temperature is 30 degrees Celsius, the actual measured pressure drop loss is about 20%, and the free liquid components can be separated by more than 95% after being treated by the natural gas dehumidification device, eliminating the liquid components in the pipeline transportation process Hazard of hydrate formation, freezing, clogging at elbows.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com