Micro-lens array headlamp for led automotive lighting

A technology for microlens arrays and automotive lighting, which is applied to components of lighting devices, cooling/heating devices of lighting devices, lighting devices, etc., can solve problems such as low utilization of light energy, improve service life, and ensure safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, but the implementation and protection of the present invention are not limited thereto.

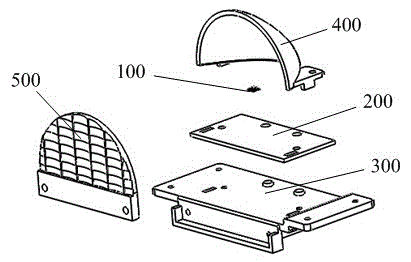

[0048] Such as figure 1 As shown, the microlens array headlamp for LED automotive lighting provided by the present invention is composed of LED chip 100, aluminum substrate 200, heat sink 300, parabolic reflector 400 and free-form surface microlens array 500. The LED chip is welded on the fixed position of the aluminum substrate, and the aluminum substrate, the parabolic reflector and the free-form surface microlens array are installed on the heat sink through corresponding assembly methods.

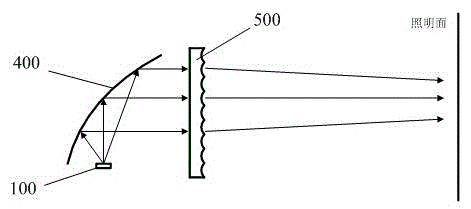

[0049] The light distribution principle of the microlens array type headlight for LED automobile lighting provided by the invention is as follows: figure 2 As shown, the headlight does not need a light barrier, and the optical system only includes the LED c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com