Vertical multi-stage coaxial impact crushing sorting unit

A technology of impact crushing and sorting device, which is applied in the direction of solid separation, separation of solids from solids by air flow, and grain treatment, etc. and other problems, to achieve the effect of simple equipment structure, few spare parts and wide adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

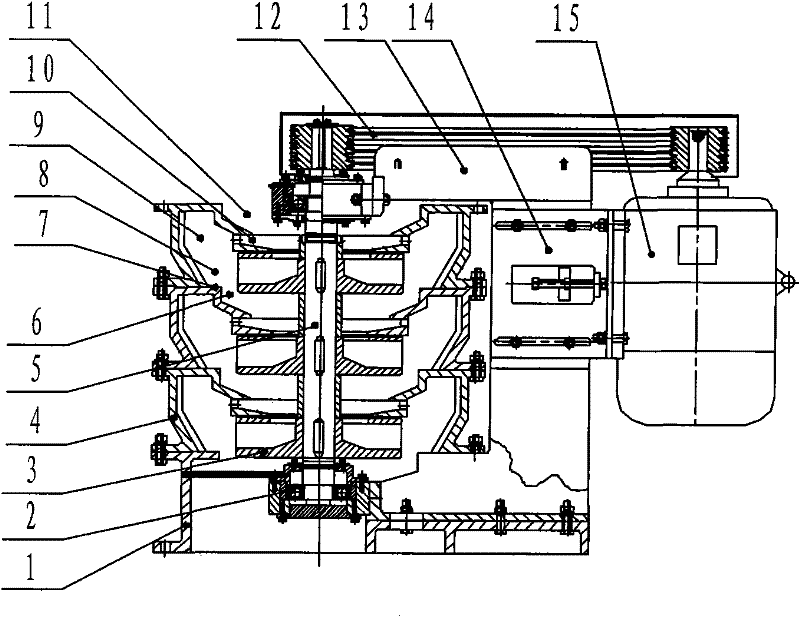

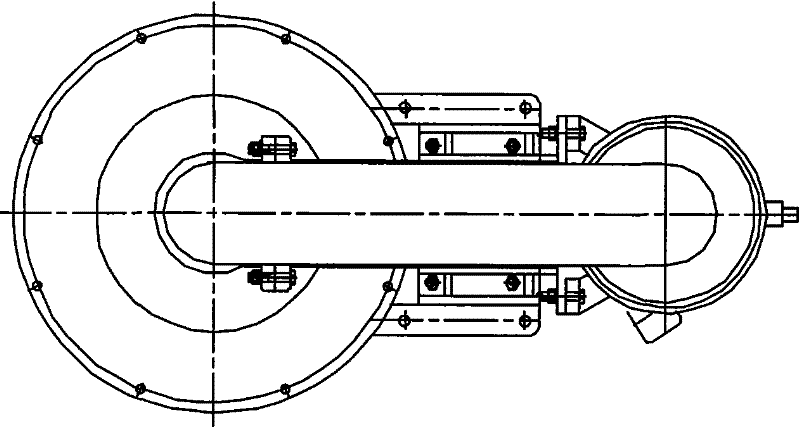

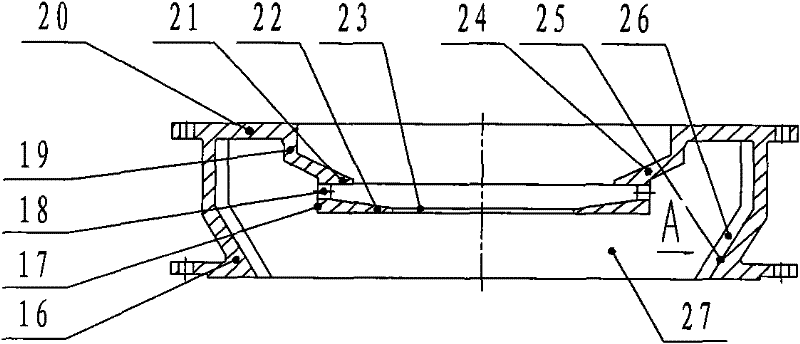

[0023] Combine below Figure 1 to Figure 7 The present invention is described in detail:

[0024] Such as figure 1 and figure 2 , the vertical multi-stage coaxial impact crushing and sorting device is composed of a motor 15 installed on the motor base 14 and a belt transmission mechanism 12 to form a power system, which drives the vertical main shaft 5 installed on the bracket 13 through the bearing assembly 2, along the vertical The main shaft 5 is equipped with one or more impact crushing and sorting mechanisms from top to bottom. Among the multiple crushing and sorting mechanisms, two adjacent crushing and sorting mechanisms are closely connected end to end. The feed port of the next stage of crushing and sorting mechanism, the feed port of the first stage of crushing and sorting mechanism is the feed port 11 of the whole equipment, and the discharge port of the last stage of crushing and sorting mechanism corresponds to the trough of base 1 A plurality of crushing and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com