Paperboard rounder

A spheronizing machine and cardboard technology, applied in the field of spheronizing machine, to achieve the effect of easy handling and storage, less spare parts and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below by means of specific embodiments:

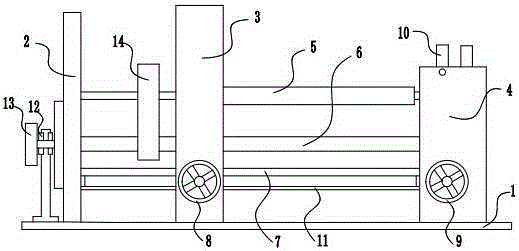

[0021] The reference signs in the drawings of the description include: base 1, left bracket 2, middle bracket 3, right bracket 4, upper pressure roller 5, lower pressure roller 6, adjustment roller 7, first distance adjustment wheel 8, second distance adjustment wheel Wheel 9, handle 10, side roller 11, reducer 12, belt 13, gear 14.

[0022] Such as figure 1 As shown, the cardboard rounding machine includes a base 1 and a frame and a motor arranged on the base 1 . Base 1 is welded with channel steel and steel plate, and frame is cast iron. The frame includes a left bracket 2, a middle bracket 3 and a right bracket 4 which are bolted to the base 1 in sequence from left to right; an upper pressure roller 5, a lower pressure roller 6 and an adjustment roller are arranged between the left bracket 2 and the right bracket 4 . The lower pressing roller 6 passes through the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com