Sliding-vane rotor engine

A vane rotor and engine technology, applied in combustion engines, machines/engines, internal combustion piston engines, etc., can solve the problems of experimental use, large vibration and noise, and structural asymmetry, and achieve light weight, low vibration, and structure. symmetrical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

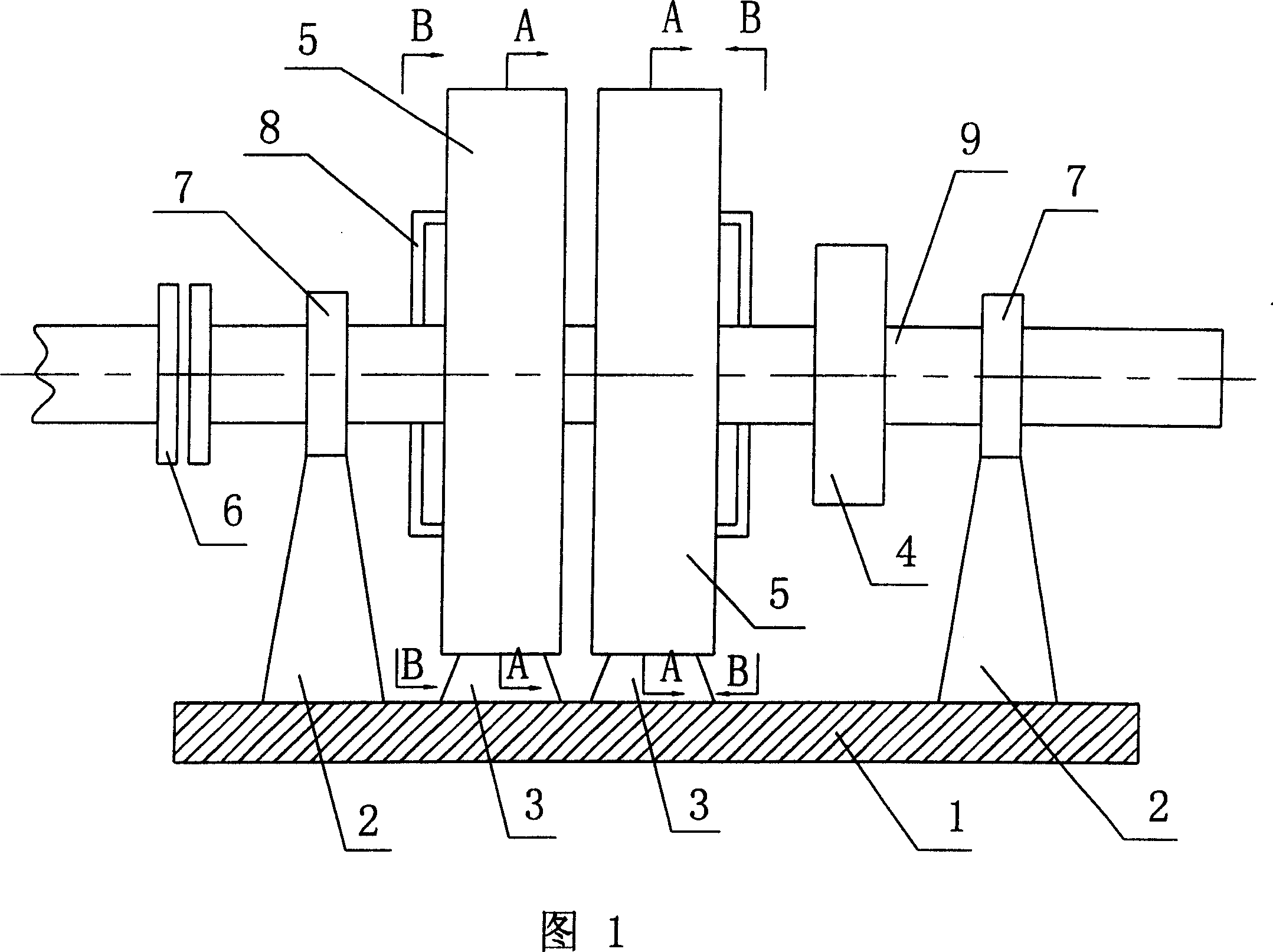

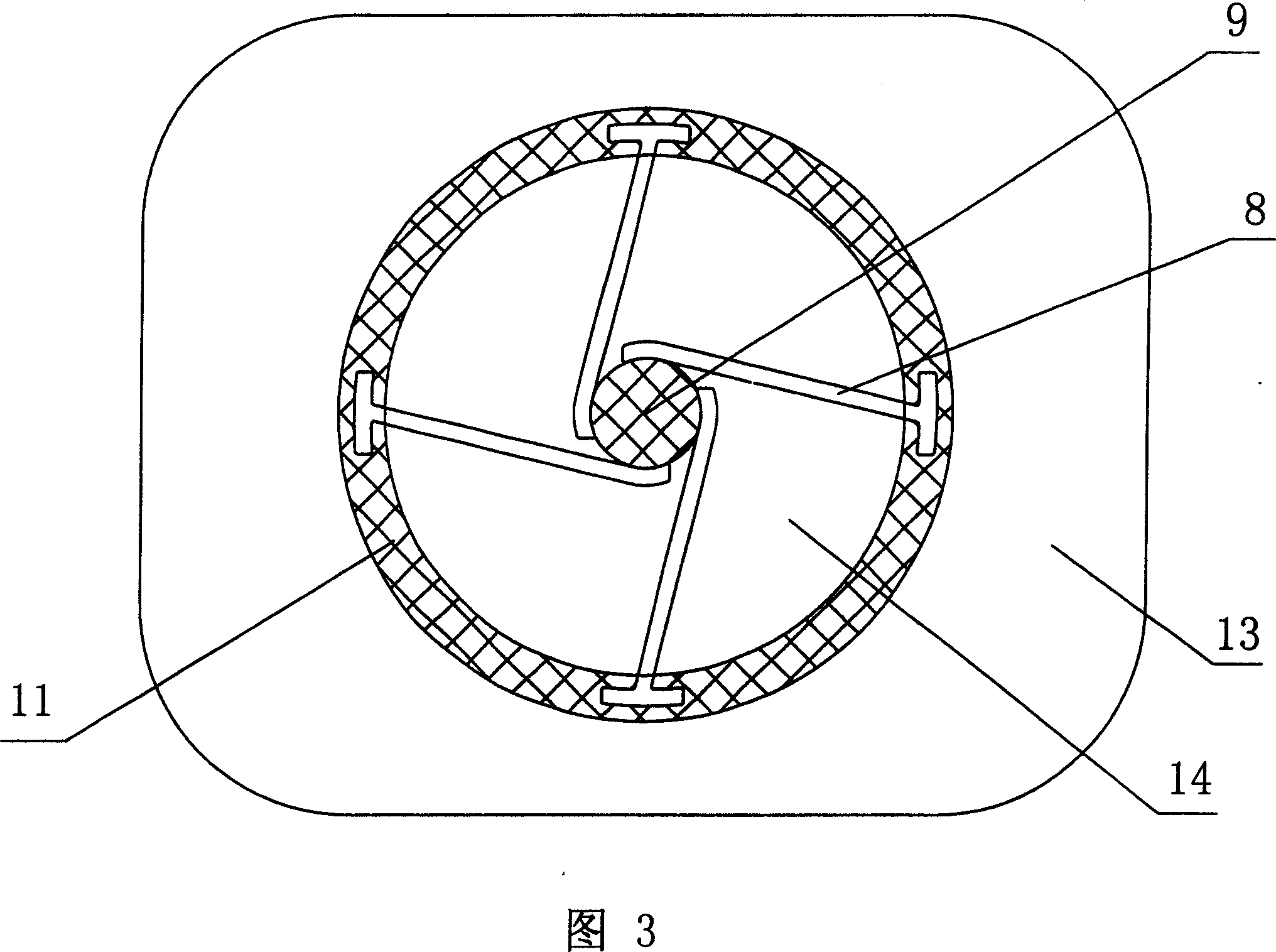

[0017] Referring to Figures 1, 2, and 3, the G·W engine is mounted on the bearing seat 2 of the machine base 1 through the bearing 7 with the rotating shaft 9, and the rotating shaft 9 is mounted on the rotating cylinder 5 supported by the cylinder block 3 and the starter motor. 4. One end of the rotating shaft 9 is matched with the clutch 6, the core component of the G·W single engine is, and the two adjacent rotating cylinders 5 are a coaxial 9 combination. The two rotary cylinders 5 are a power cylinder and a compression cylinder with basically the same structure. The rotor 11 is connected with the rotating shaft 9 through the connecting rib 8, so that the rotor 11 and the shaft 9 are mutually driven to rotate synchronously. It is arranged outside the cylinder 5 side.

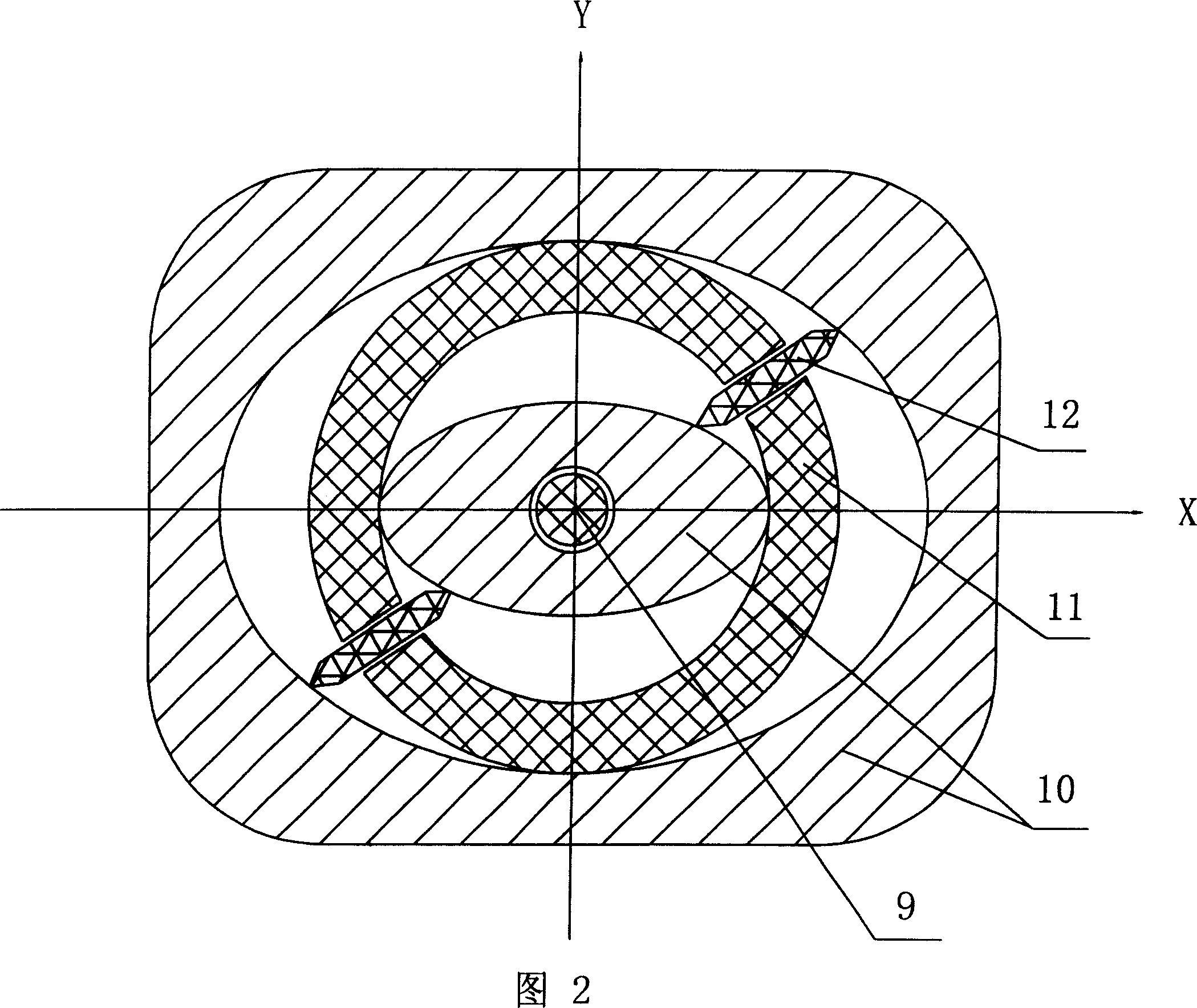

[0018] It can be seen from the sectional view of the A-A rotary cylinder and FIG. 4 that there is a nearly elliptical annular cavity between the inner and outer solids of the stator 10 of the rotary cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com