Automatic quenching device

A quenching device, automatic technology, applied in the direction of quenching device, furnace, furnace type, etc., can solve the problems of affecting the quenching quality of the hub, delaying the quenching time of the hub, increasing the operation and maintenance cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

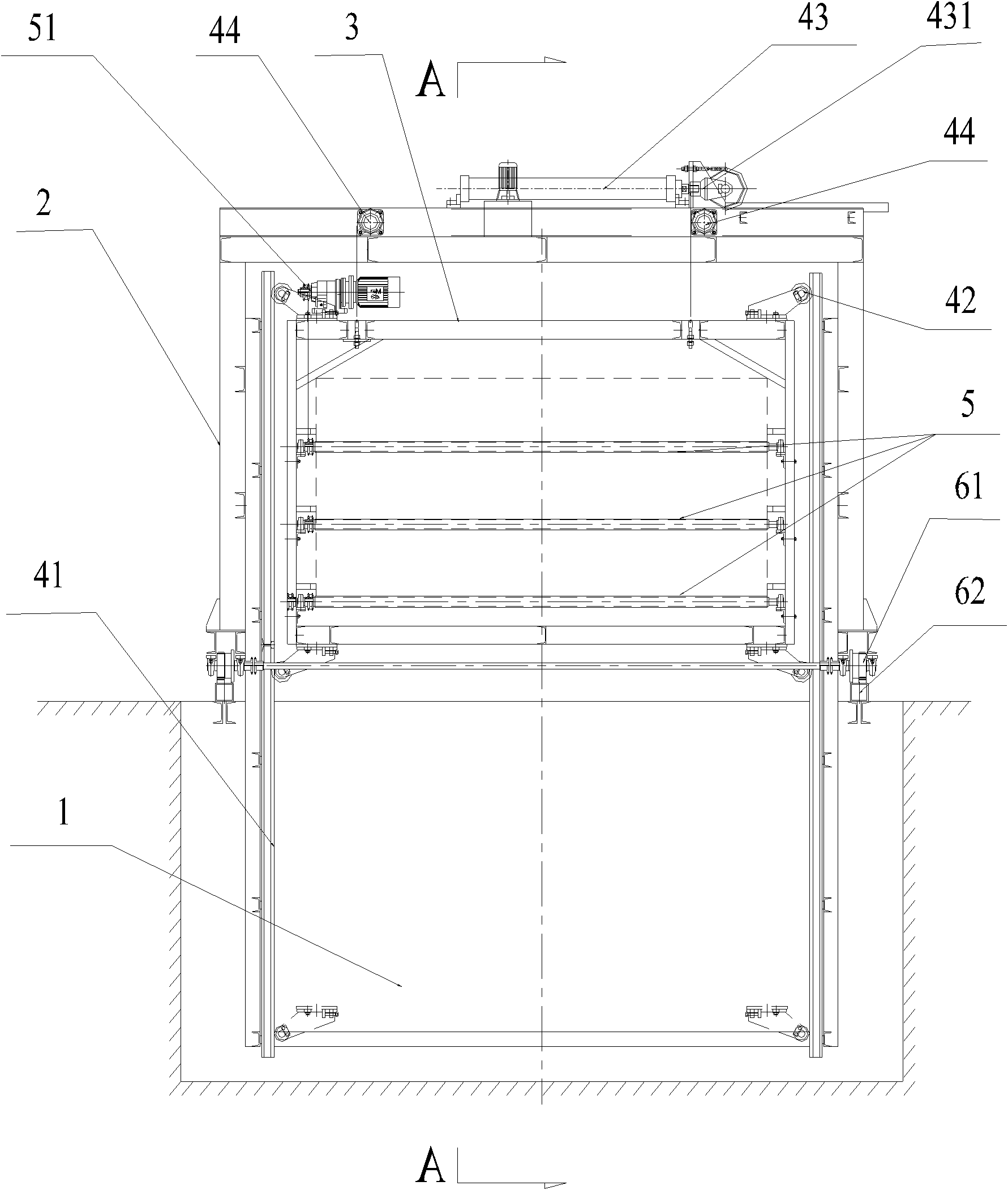

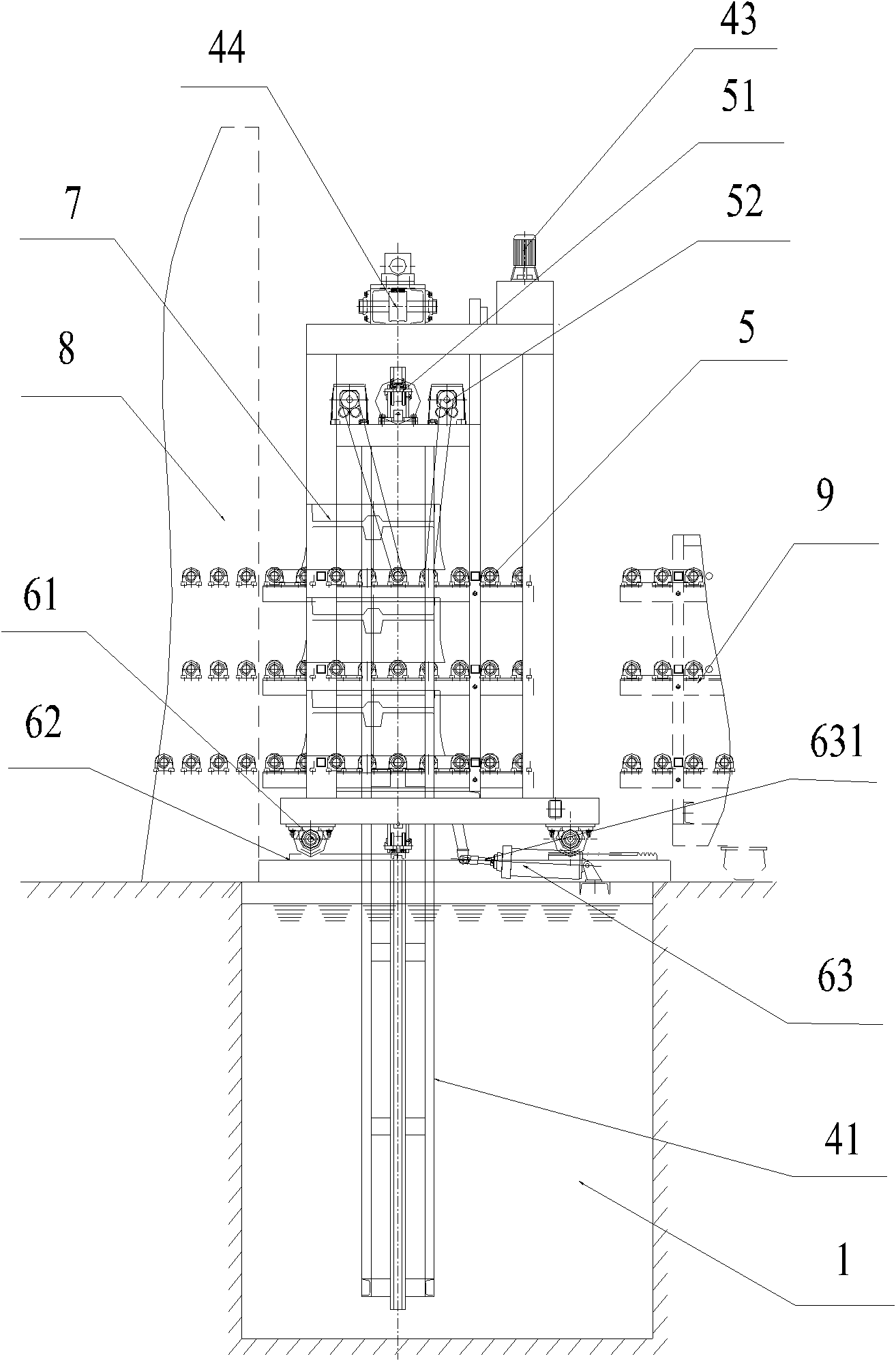

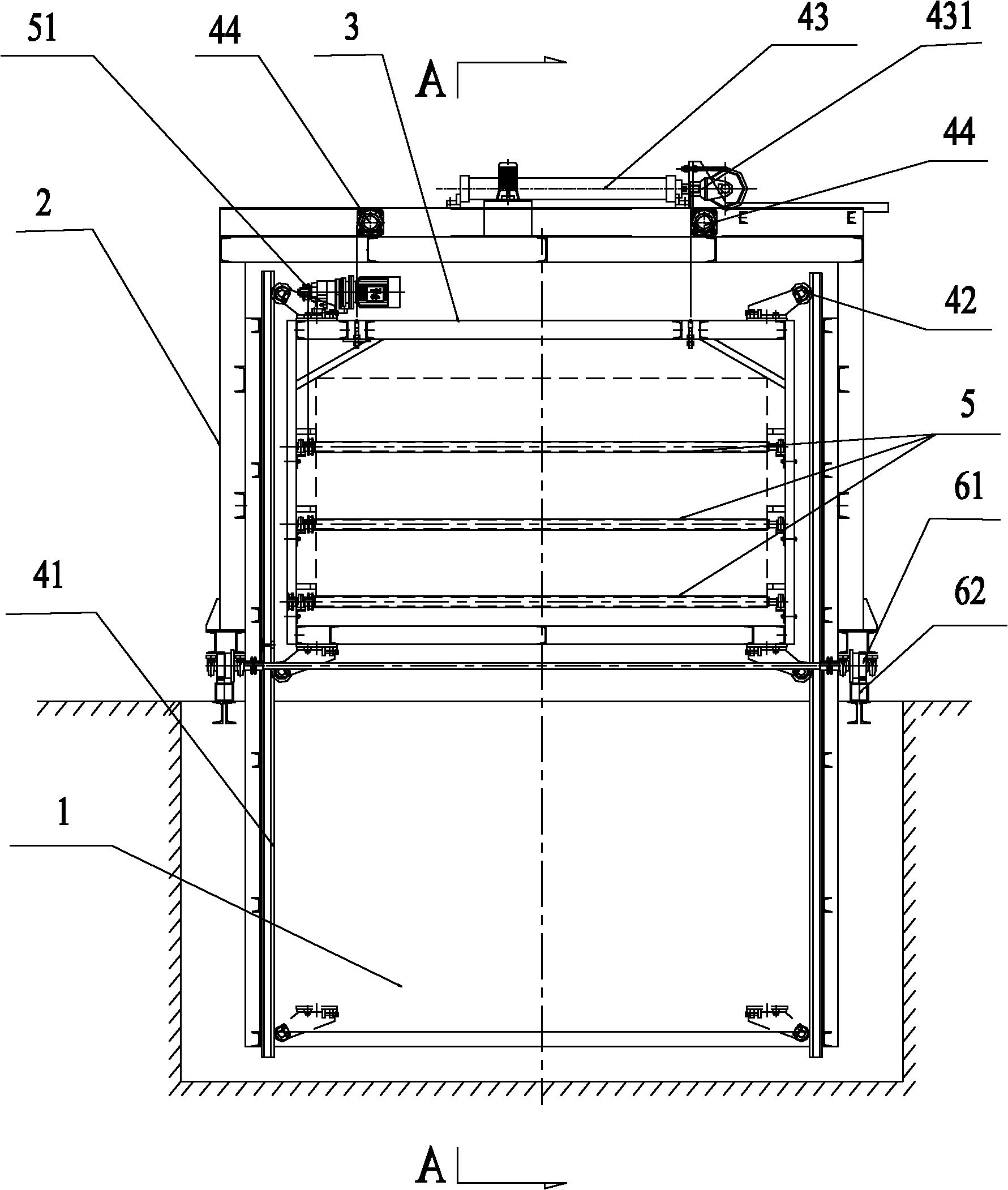

[0012] Such as Figure 1-2 The shown automatic quenching device includes a quenching tank 1, a support frame 2, a quenching frame 3, a lifting mechanism, a transmission roller 5 and a traveling mechanism, and the traveling mechanism is composed of a traveling wheel 61, a traveling guide rail 62 and a traveling driving cylinder 63. The support frame 2 is installed above the quenching tank 1, and the bottom corners are equipped with traveling wheels 61 in parallel, and the upper side of the quenching tank 1 is provided with a walking guide rail 62 corresponding to the traveling wheels 61; The cylinder piston 631 is connected with the bottom of the support frame 2 . The quenching frame 3 is located inside the supporting frame 2, and a lifting mechanism is provided between the quenching frame 3 and the supporting frame 2 to move the quenching frame 3 up and down. There are 2 pieces of 41, which are installed in parallel on the inner side of the support frame 2 and extend into the...

Embodiment 2

[0015] The difference from Embodiment 1 is that no walking mechanism is included, and the support frame 2 is installed above the quenching tank 1 . This device is close to the transmission frame 8 of the discharge port of the furnace body, and the hub 7 is directly transferred to the transfer roller 5, and the transfer roller 5 transfers the hub 7 to the quenching position. After the quenching time is over, the lifting mechanism will lift the quenching frame 3 above the liquid level of the quenching tank 1, and the transfer roller 5 will transfer the wheel hub 7 to the aging furnace drive frame 9 for the next process operation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com