Automatic quenching oil tank

A quenching oil tank, automatic technology, applied in the direction of quenching device, furnace type, furnace, etc., can solve the problems of unfavorable automatic quenching of leaf spring, strong mechanical plasticity, irregular arrangement position, etc., to reduce quenching labor intensity, improve quenching efficiency, The effect of improving quenching quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to facilitate the understanding of the technical content of the present invention, the technical solutions thereof will be further described below in conjunction with the accompanying drawings.

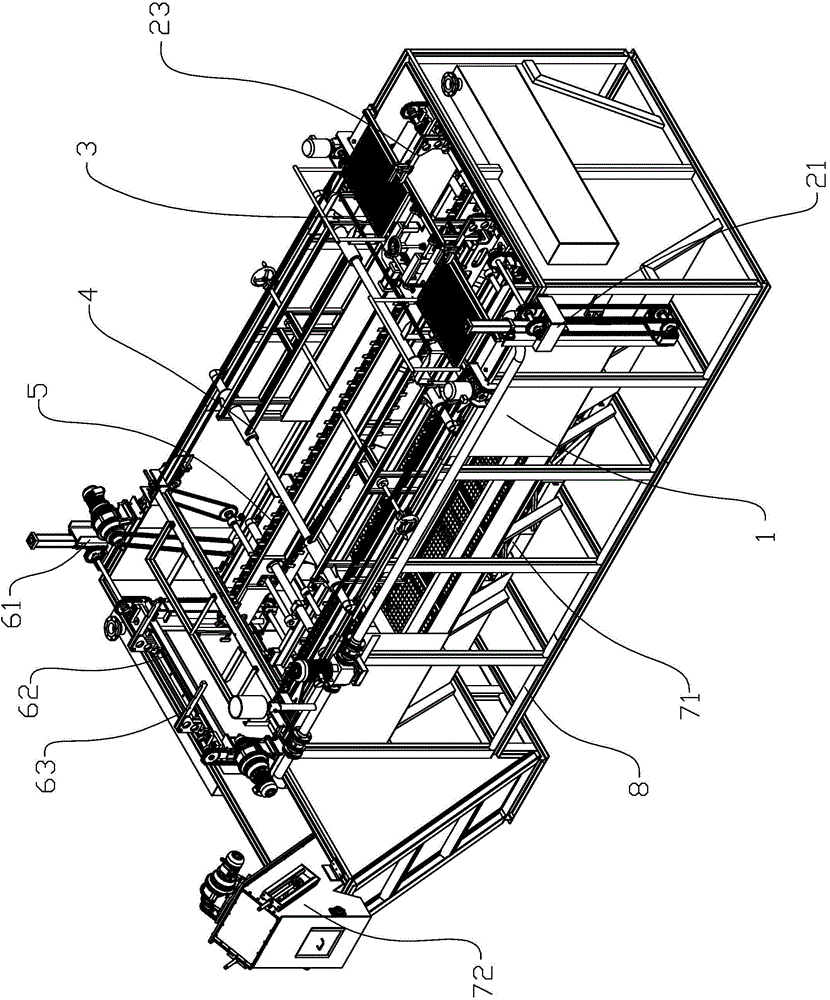

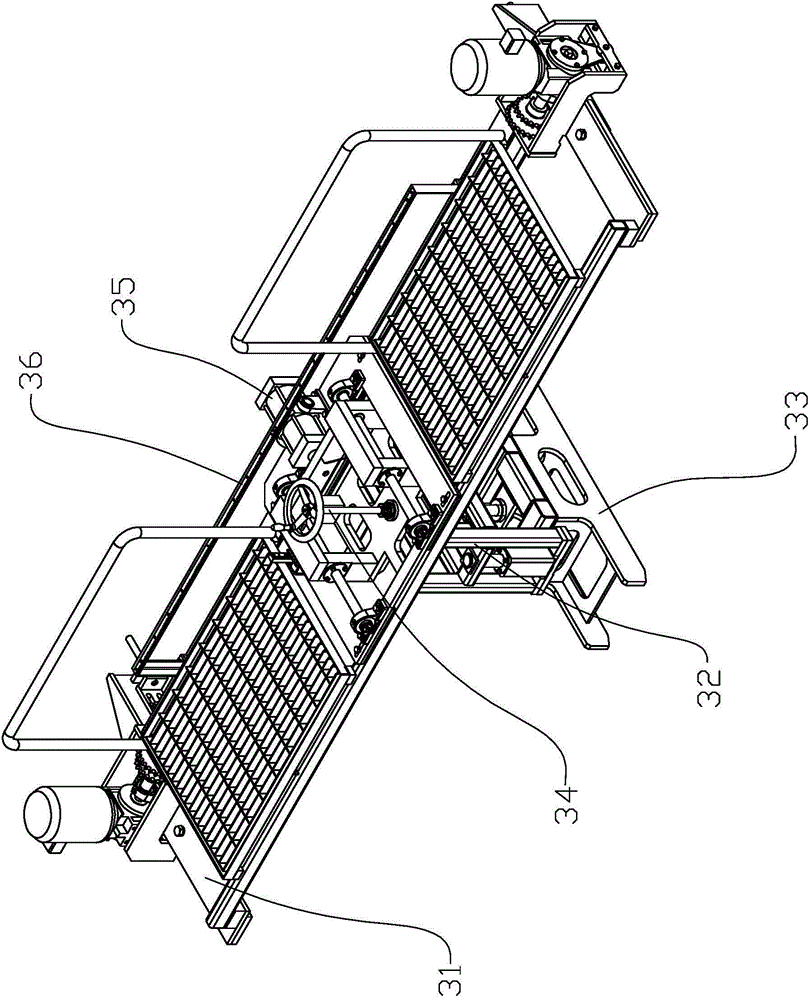

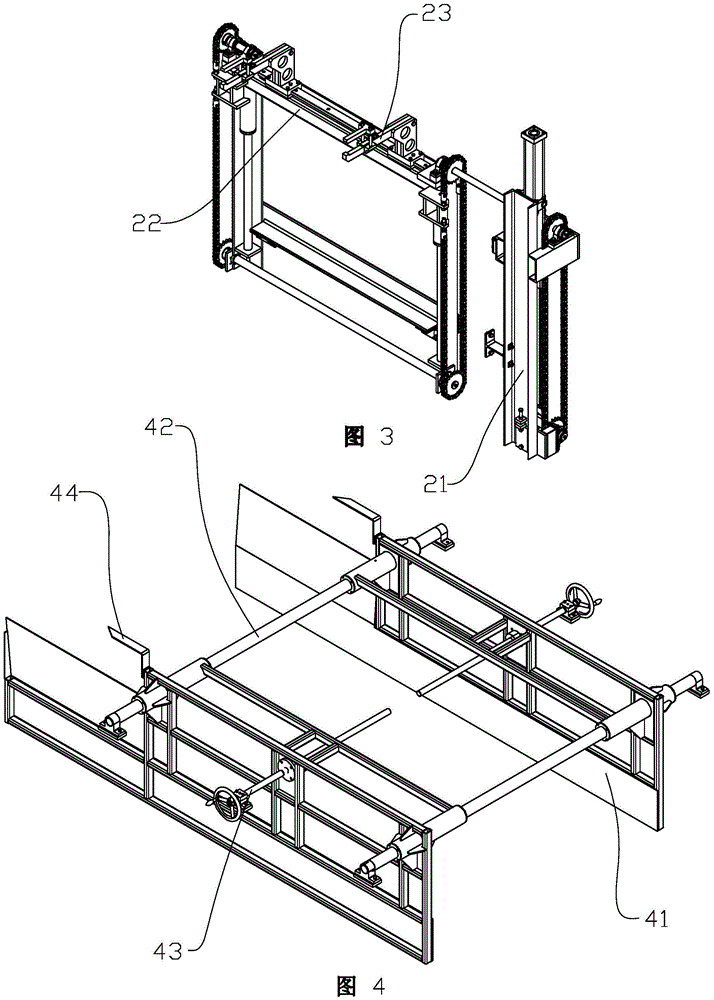

[0018] Such as Figure 1 to Figure 4 The shown automatic quenching oil tank includes a feeding device, a discharging device, an anti-skid machine 3, a material retaining frame 4, a quenching conveyor chain 5, a slag scraper 71 placed under the quenching conveyor chain 5, and an oxide skin slag elevator 72 and forced circulation cooling system. Described feeding device comprises feed lifter 21, feed lifting frame 22 and feeding manipulator 23, similarly, described discharging device comprises material discharging lifter 61, material discharging lifting frame 62 and material discharging manipulator 63, and feeds, The elevator in the discharge device is the same as the cooperation form of the lifting frame, and both are structures that realize the lifting drive through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com