Heating method during quenching of large supporting roller

A heating method and backup roll technology, applied in the direction of heat treatment furnace, furnace type, heat treatment equipment, etc., can solve problems such as difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

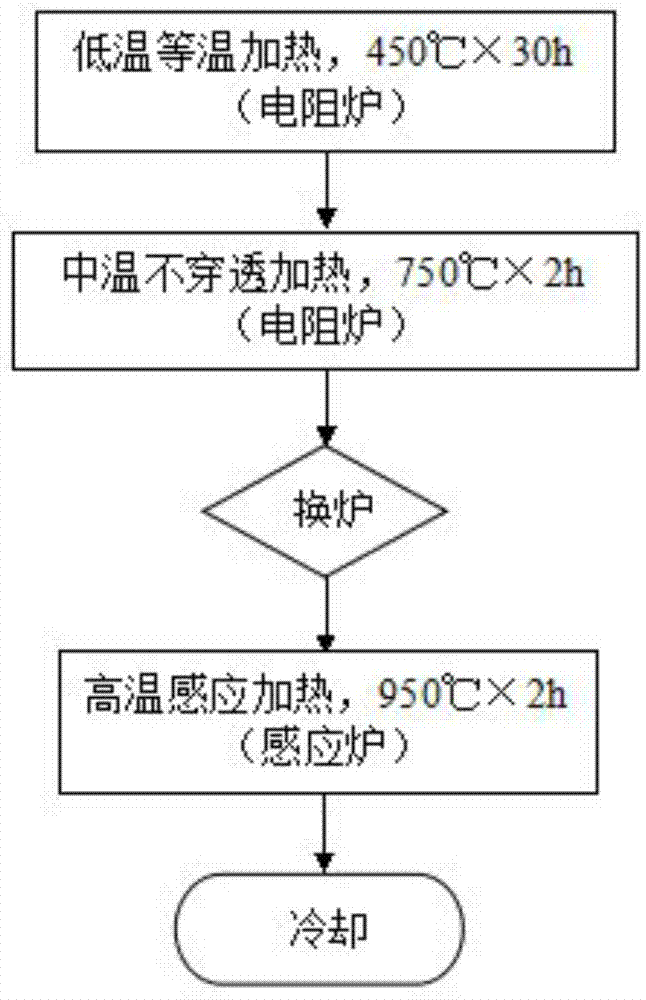

[0035] A heating method during quenching of a large backup roll, which includes the following stages:

[0036] (I) Low-temperature isothermal heating: carried out in a resistance furnace, and kept at a constant temperature of 450°C for 30h;

[0037] (II) Non-penetrating heating at medium temperature: Carry out in a resistance furnace to raise the surface temperature of the roll body to 750°C and keep it at a constant temperature for 2 hours. It is necessary to take heat insulation or even local cooling measures for the roll shafts at both ends of the roll;

[0038] (III) High-temperature induction heating: Carry out in a high-temperature induction heating furnace to raise the surface temperature of the roll body to 950°C and keep it at a constant temperature for 2 hours.

[0039] After the heating is completed, the subsequent cooling and quenching of the roll can be carried out in the spray quenching equipment as soon as possible.

[0040] see image 3 .

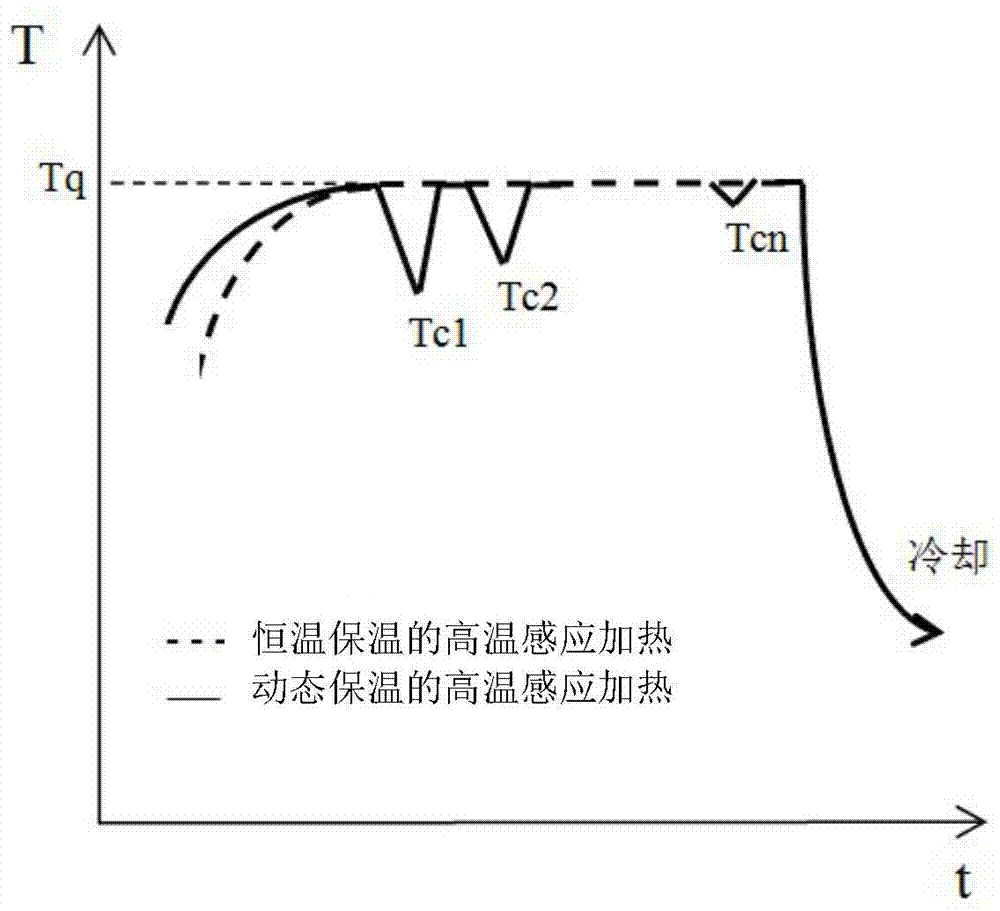

[0041] Stage (III...

Embodiment 2

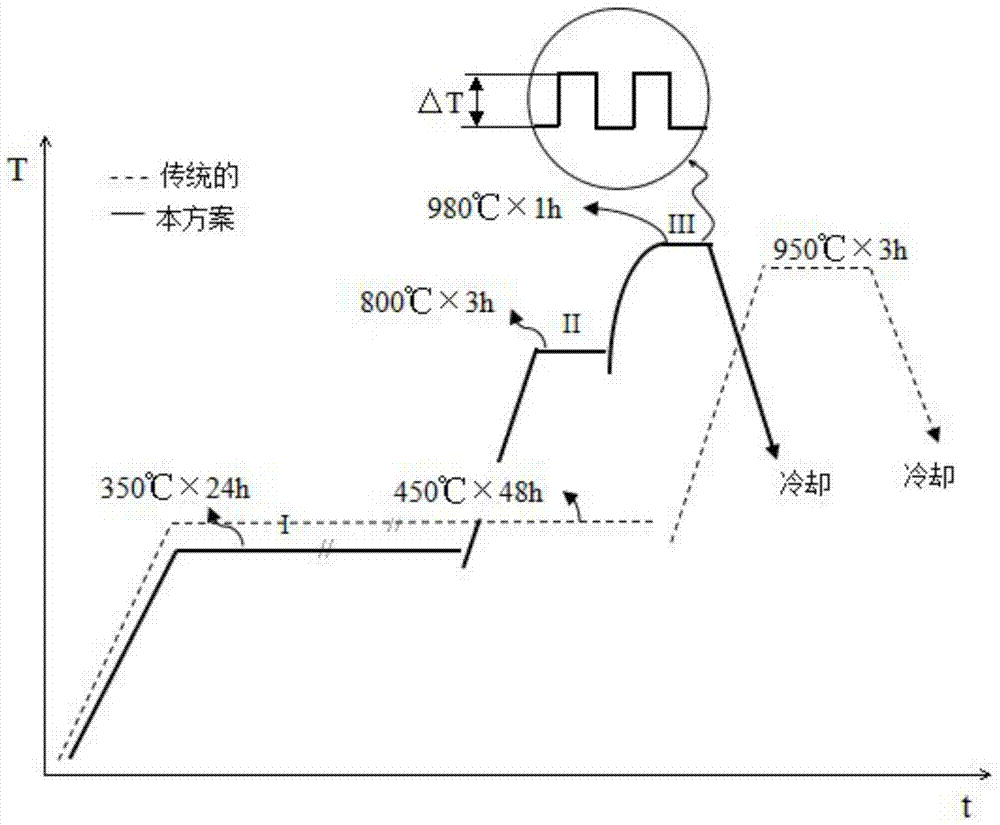

[0043] A heating method during quenching of a large backup roll, which includes the following stages:

[0044] (I) Low-temperature isothermal heating: carried out in a resistance furnace, and kept at a constant temperature of 350°C for 24h;

[0045] (II) Non-penetrating heating at medium temperature: carried out in a differential temperature furnace to raise the surface temperature of the roll body to 800°C and keep it at a constant temperature for 3 hours, without heat insulation protection for the roll shaft;

[0046] (III) High-temperature induction heating: Carry out in a high-temperature induction heating furnace to raise the surface temperature of the roll body to 950°C and keep it at a constant temperature for 1 hour.

[0047] see Figure 4 .

[0048] Stage (III) The final heating depth is increased to 125mm, and the temperature difference between inside and outside is reduced to ≤75°C.

Embodiment 3

[0050] Heating is carried out according to the method described in Example 2, and the high temperature induction heating described in stage (III) in Example 2 is replaced with the following steps:

[0051] (1) In the high-temperature induction heating furnace, the roller surface is heated to 980°C and kept for 10 minutes, then cooled to 930°C, △T1=50°C;

[0052] (2) Heating to raise the surface temperature of the roll body to 980°C for 10 minutes, then cooling to 940°C, △T2=40°C;

[0053] (3) Heating to raise the surface temperature of the roll body to 980°C for 10 minutes, then cooling to 950°C, △T3=30°C;

[0054] (4) Heating to raise the surface temperature of the roll body to 980°C for 10 minutes, then cooling to 960°C, △T4=20°C;

[0055] (5) Heating to raise the surface temperature of the roll body to 980°C for 10 minutes, then cooling to 970°C, △T5=10°C;

[0056] (6) Heating to raise the surface temperature of the roll body to 980°C for 10 minutes.

[0057] see Figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com