Production process of ultrathin special-shaped aluminum alloy extruded section and product

A technology for aluminum alloy profiles and extruded profiles, which is applied in the production process and product field of ultra-thin special-shaped aluminum alloy extruded profiles, can solve the problems affecting quenching quality and size, and achieve the effects of ensuring size, reducing waves and good quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Alloy components and their contents are: Si: 0.47%; Fe: 0.15%; Cu: 0.02%; Mn: 0.05%; Mg: 0.45%; Cr: 0.02%; Zn: 0.02%; Ti: 0.05%; :margin.

[0027] (1) Preheating: the preheating temperature of the mold is 490°C, the preheating temperature of the ingot is 500°C, and the preheating temperature of the extrusion cylinder is 455°C;

[0028] (2) extrusion molding: extruding the ingot, controlling the extrusion coefficient to be 55.6, and the extrusion speed to be 2.0m / min;

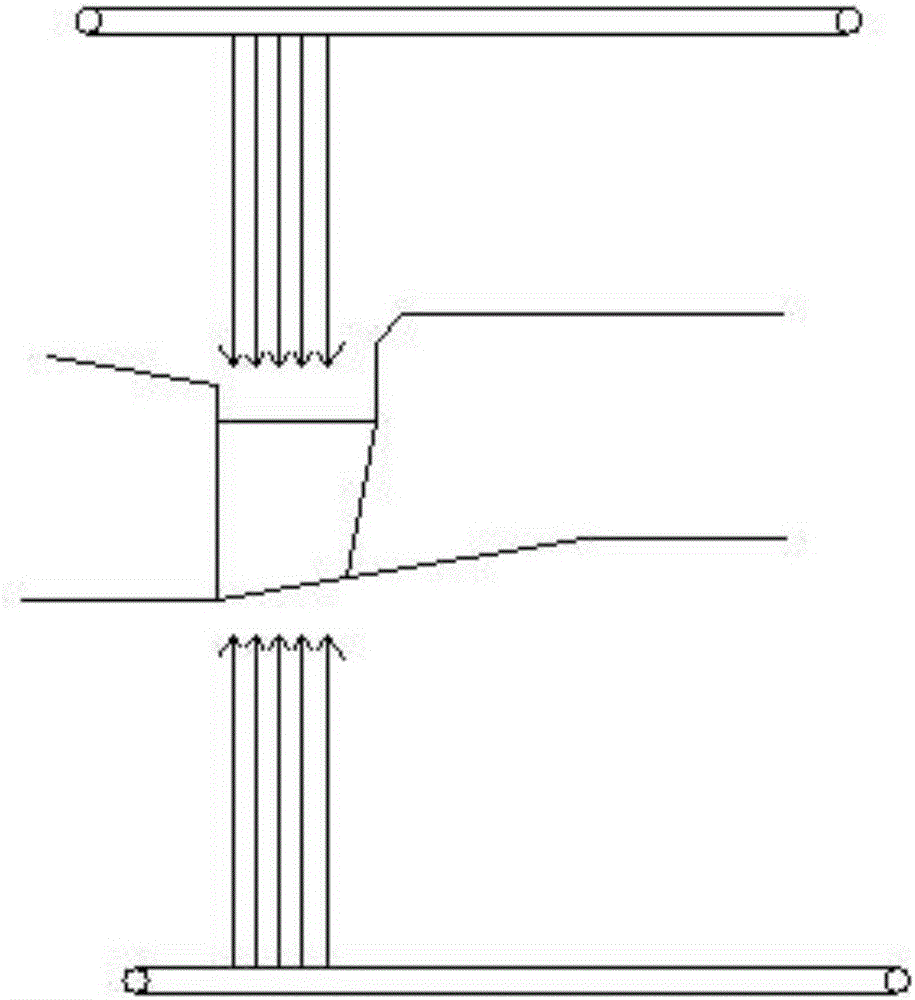

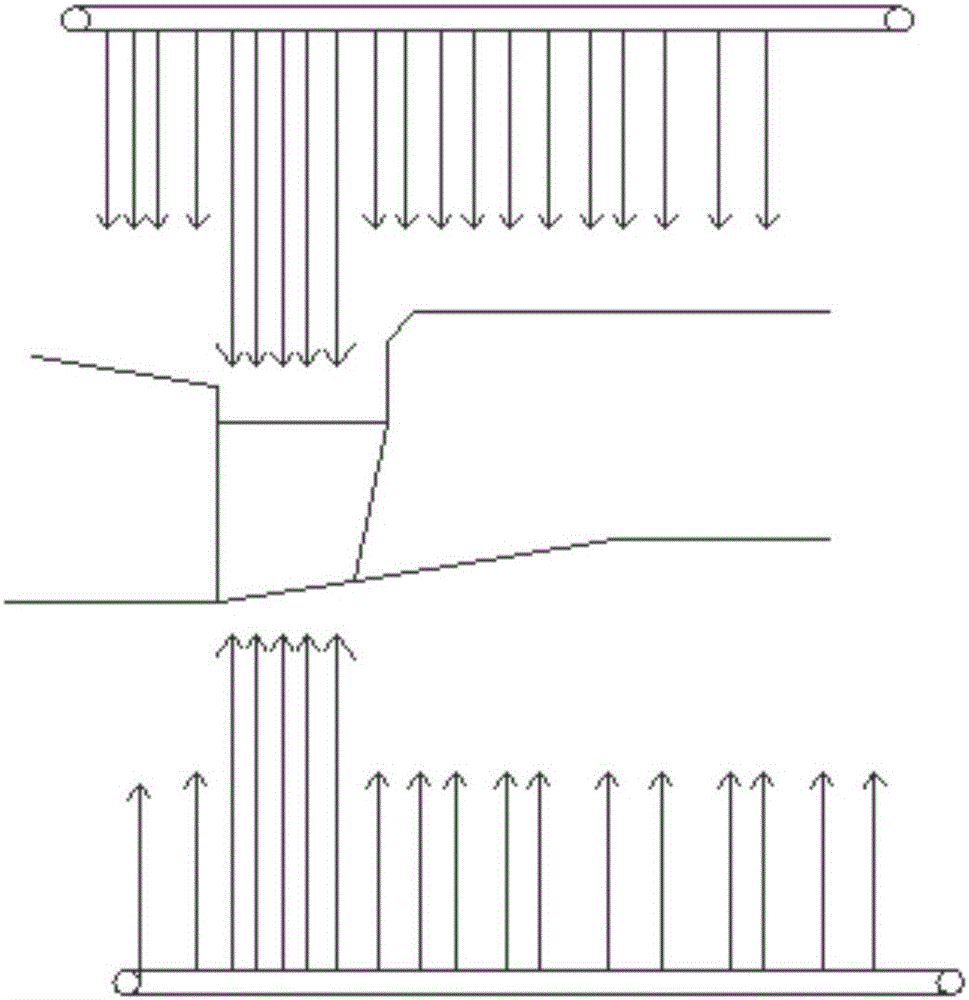

[0029] (3) Quenching treatment: the extruded aluminum alloy profile is first carried out on-line water mist treatment to shape the special-shaped area on the aluminum alloy profile at the outlet of the extrusion cylinder, such as figure 1 As shown, and then the overall online water mist treatment of aluminum alloy profiles, such as figure 2 As shown, and the temperature of the aluminum alloy profile is reduced to 18°C;

[0030] (4) Stretch straightening, traction straightening by traction leveler, elo...

Embodiment 2

[0034] Alloy components and their contents are: Si: 0.52%; Fe: 0.20%; Cu: 0.02%; Mn: 0.05%; Mg: 0.50%; Cr: 0.02%; Zn: 0.02%; Ti: 0.05%; :margin.

[0035] (1) Preheating: the preheating temperature of the mold is 510°C, the preheating temperature of the ingot is 520°C, and the preheating temperature of the extrusion cylinder is 460°C;

[0036] (2) extrusion molding: the ingot is extruded, the extrusion coefficient is controlled to be 55.6, and the extrusion speed is 2.3m / min;

[0037] (3) Quenching treatment: the extruded aluminum alloy profile is first carried out on-line water mist treatment to shape the special-shaped area on the aluminum alloy profile at the outlet of the extrusion cylinder, such as figure 1 As shown, and then the overall online water mist treatment of aluminum alloy profiles, such as figure 2 Shown, and make the aluminum alloy profile temperature drop to 30 ℃;

[0038] (4) Stretch straightening, traction straightening by traction leveler, stretch rate ...

Embodiment 3

[0042] Alloy components and their contents are: Si: 0.52%; Fe: 0.20%; Cu: 0.02%; Mn: 0.05%; Mg: 0.50%; Cr: 0.02%; Zn): 0.02%; Ti): 0.05% ; Al: margin.

[0043] (1) Preheating: the preheating temperature of the mold is 510°C, the preheating temperature of the ingot is 520°C, and the preheating temperature of the extrusion cylinder is 460°C;

[0044] (2) extrusion molding: the ingot is extruded, the extrusion coefficient is controlled to be 55.6, and the extrusion speed is 2.5m / min;

[0045] (3) Quenching treatment: the extruded aluminum alloy profile is first carried out on-line water mist treatment to shape the special-shaped area on the aluminum alloy profile at the outlet of the extrusion cylinder, such as figure 1 As shown, and then the overall online water mist treatment of aluminum alloy profiles, such as figure 2 As shown, and the temperature of the aluminum alloy profile is reduced to 35°C;

[0046] (4) Stretch straightening, traction straightening by traction level...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com