An automatic feeding mechanism used for quenching of shaft type workpieces

A shaft workpiece, automatic feeding technology, applied in the direction of quenching device, furnace type, manufacturing tools, etc., can solve the problems affecting the mechanical properties of the motor mandrel, affecting the straightness of the motor mandrel, and the damage to the structure of the motor mandrel, so as to avoid Minor bending deformation, high level of automation, and the effect of improving quenching quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

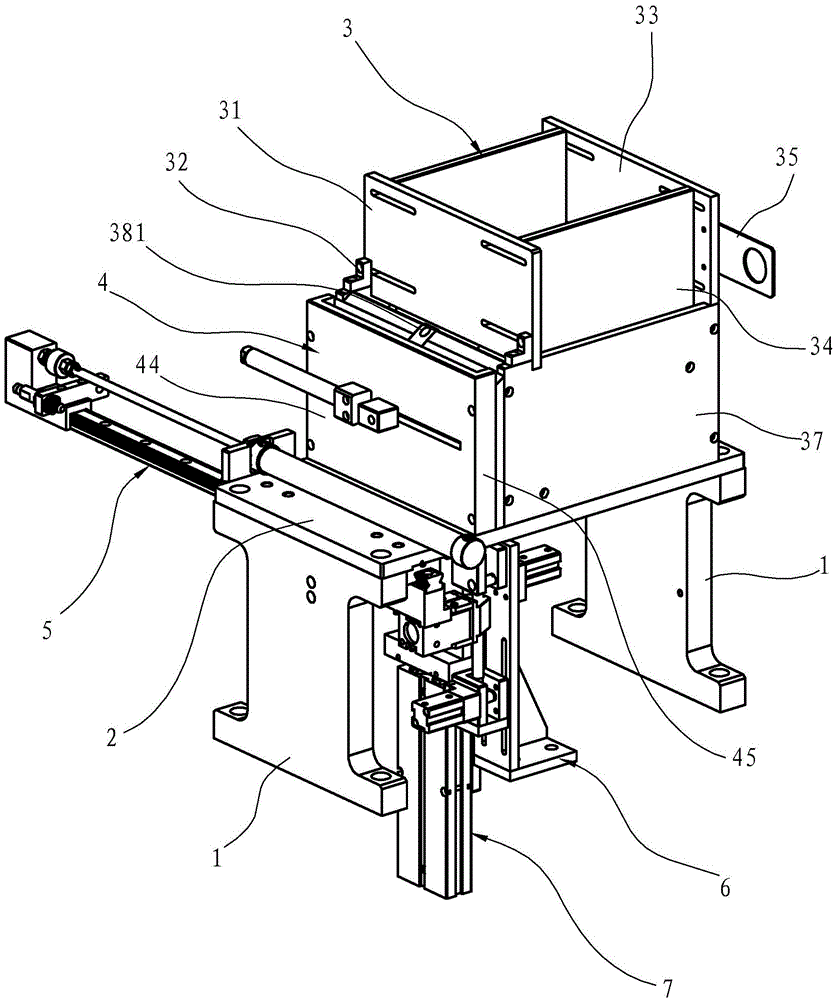

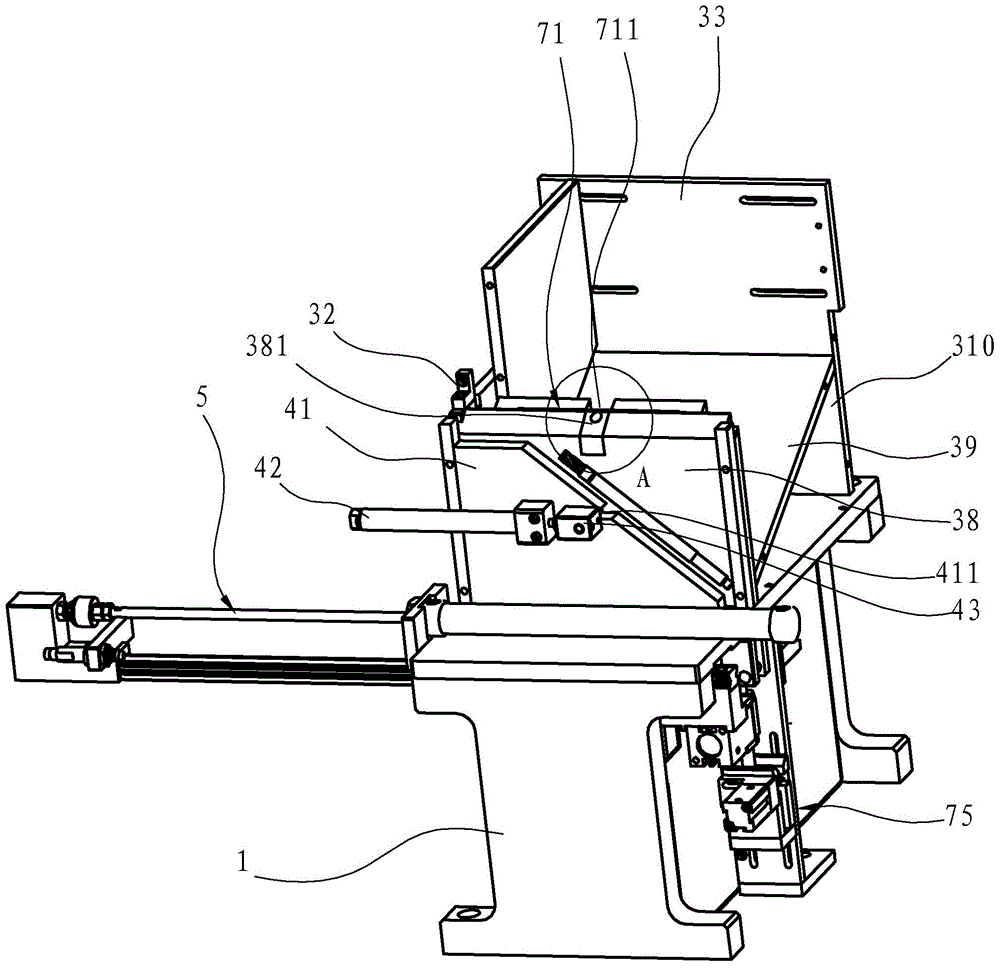

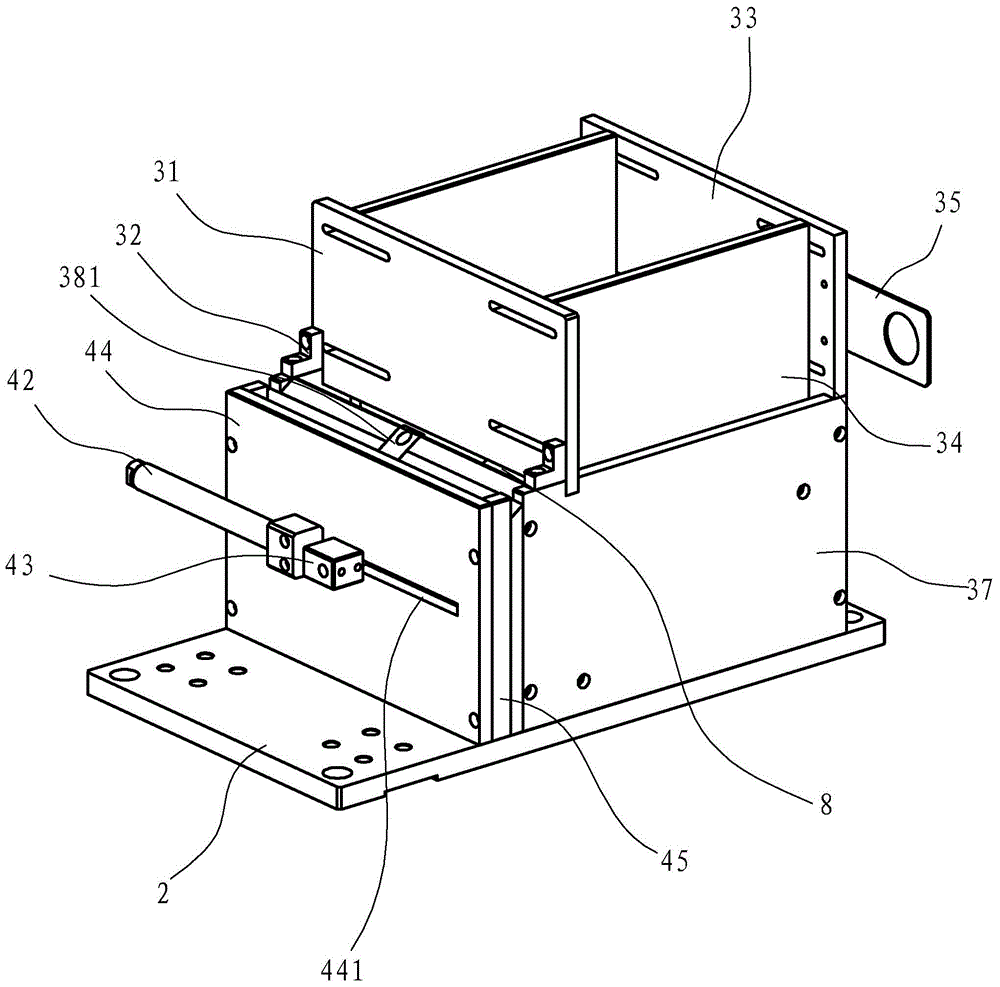

[0025] Such as Figures 1 to 7 As shown, the present invention discloses an automatic feeding mechanism for quenching shaft workpieces, including two vertical plates 1 oppositely arranged in an upright state, a flat plate 2 erected on the vertical plates 1, and a flat plate 2 arranged on the flat plate 2 so that The discharge box 3 placed horizontally for the shaft workpiece, the whole material box 4 arranged adjacent to the discharge box 3, and the feeding assembly for moving the shaft workpiece to the bottom of the air claw, the feeding assembly adopts the feeding slide rail assembly 5, of course A relatively simple structure may also be adopted.

[0026] Wherein, discharge box 3 upper openings comprise left and right side panels 37, front panel 38 and rear panel 310, the upper end face of this front panel 38 is the inclined surface incline...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com