Technique for oil quenching casting sphere made from high chrome alloy

A high-chromium alloy and casting ball technology, which is applied in the oil quenching process of the casting section and the field of high-chromium alloy casting balls, can solve the problems of spalling, restriction of wear resistance and service life, and easy occurrence of out-of-roundness, so as to achieve wear resistance and corrosion resistance Increased capacity, multiple economic benefits, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The invention mainly relates to the quenching treatment of φ6.5-φ130 high chromium alloy wear-resistant casting balls and casting segments in oil medium. Its implementation process is as follows:

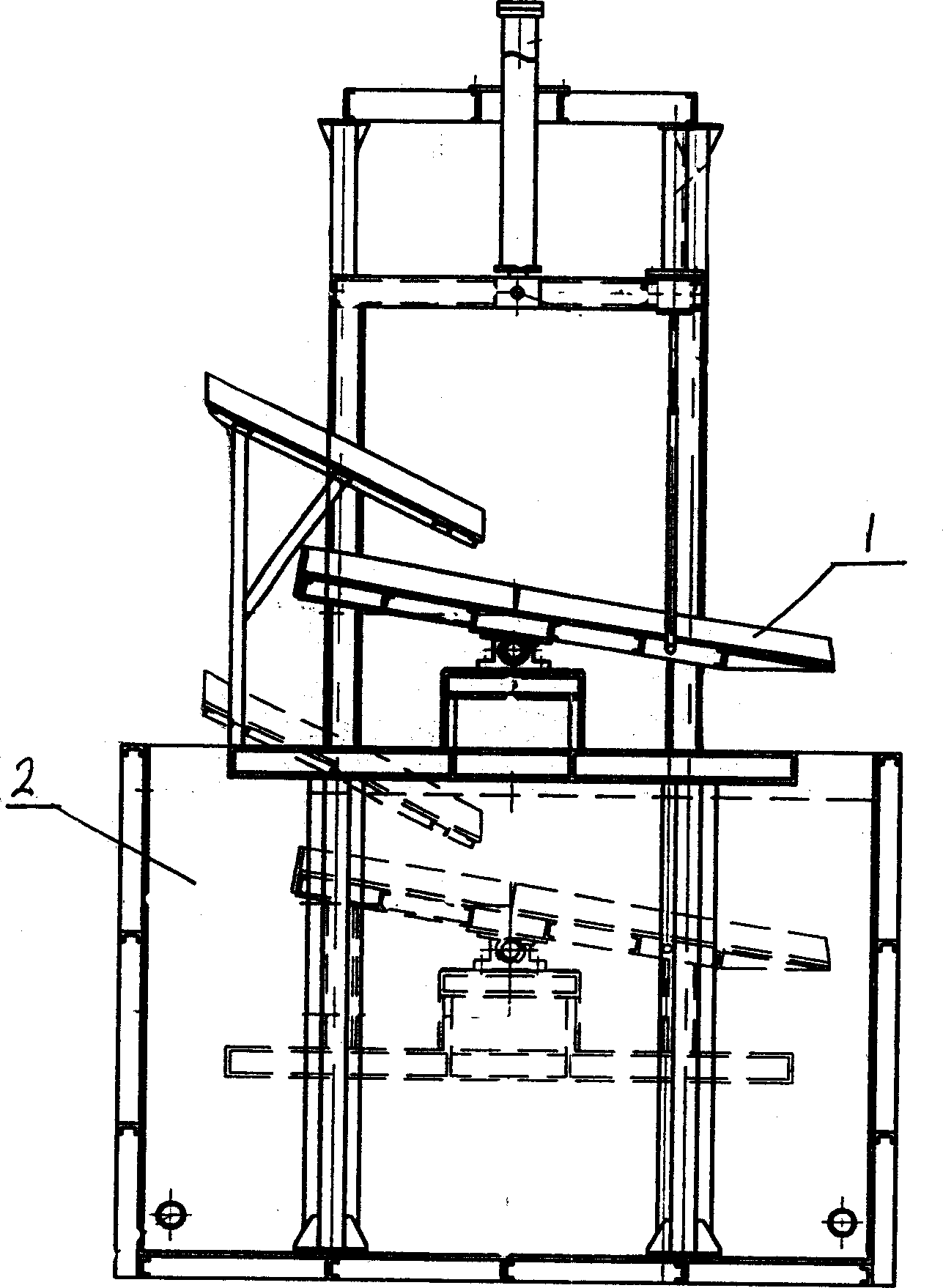

[0018] 1. High chromium alloy wear-resistant cast balls and cast segments are heated to the quenching temperature (920-1150°C) in a push rod type continuous heating furnace, and placed on the movable quenching cradle 1 after being released from the furnace (see attached figure), and made to Spread evenly.

[0019] 2. Start the cradle control mechanism to make the quenching cradle move back and forth up and down to ensure that the high chromium alloy wear-resistant casting balls and casting segments can roll freely on it.

[0020] 3. Immerse the movable quenching cradle in the oil pool 2 (see the attached picture) to carry out oil cooling and quenching treatment on the high chromium alloy wear-resistant casting balls and casting segments. The quenching medium is No. 10 or No....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com