Plastic coating with lotus leaf effect and preparation method and application thereof

A technology of plastic coating and lotus leaf effect, applied in the direction of coating, can solve the problems of negative hydrophobicity on the surface of the paint film, hinder the escape of water vapor from the substrate, reduce absorption, etc., and achieve good anti-fouling ability and overall hydrophobic effect. Good, high adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1 Plastic coating with lotus leaf effect

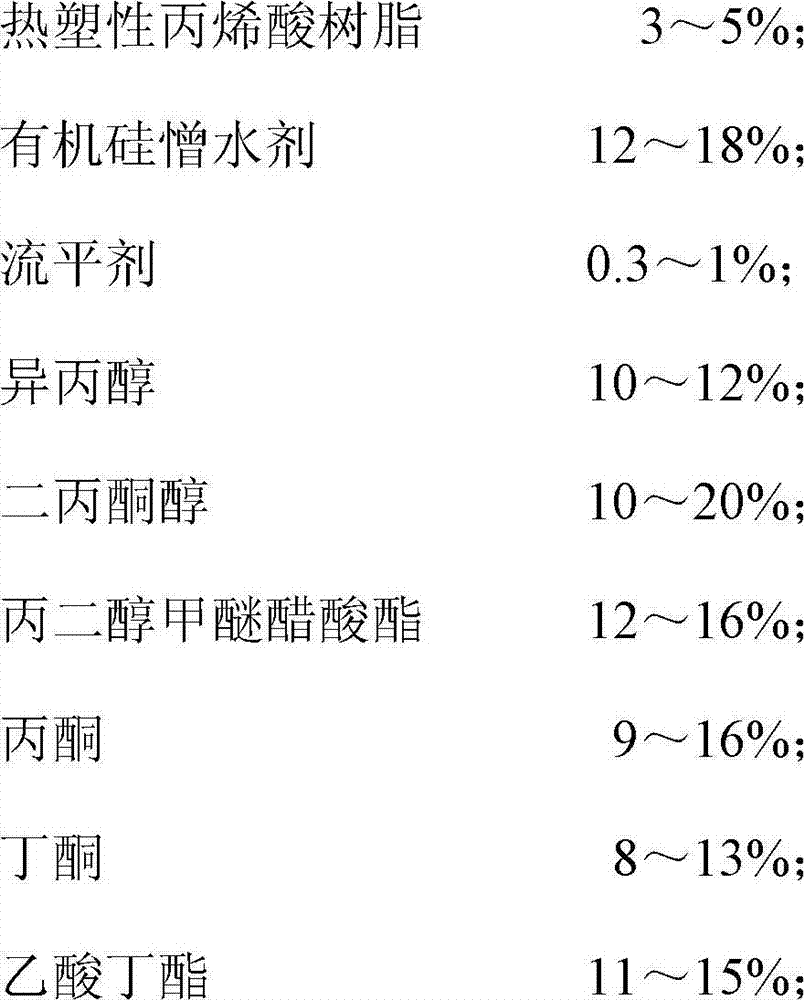

[0037] The plastic paint with lotus leaf effect of the present embodiment, its raw material formula is to be made up of each component of following mass percentage:

[0038] Acrylic resin 7%;

[0039] Silicone water repellent 14%;

[0040] Leveling agent 0.3~1%;

[0041] Isopropanol 10-12%;

[0042] Diacetone alcohol 10-20%;

[0043] Propylene glycol methyl ether acetate 12-16%;

[0044] Acetone 9-16%;

[0045] Butanone 8-13%;

[0046] Butyl acetate 11-15%.

[0047] The above-mentioned acrylic resin is BR-113 of Mitsubishi, Japan.

[0048] The plastic paint with lotus leaf effect of the present embodiment, its preparation method is as follows:

[0049] Weigh each component according to the above raw material formula, then mix each component evenly and disperse at high speed to a fineness of ≤25um, so as to prepare the required plastic coating with lotus leaf effect.

Embodiment 2

[0050] Example 2 Plastic coating with lotus leaf effect

[0051] The plastic paint with lotus leaf effect of the present embodiment, its raw material formula is to be made up of each component of following mass percentage:

[0052] Acrylic resin 5%;

[0053] Silicone water repellent 15%;

[0054] Leveling agent 0.3~1%;

[0055] Isopropanol 10-12%;

[0056] Diacetone alcohol 10-20%;

[0057] Propylene glycol methyl ether acetate 12-16%;

[0058] Acetone 9-16%;

[0059] Butanone 8-13%;

[0060] Butyl acetate 11-15%.

[0061] The above-mentioned acrylic resin is BR-113 of Mitsubishi, Japan.

[0062] The plastic paint with lotus leaf effect of the present embodiment, its preparation method is as follows:

[0063] Weigh each component according to the above raw material formula, then mix each component evenly and disperse at high speed to a fineness of ≤25um, so as to prepare the required plastic coating with lotus leaf effect.

Embodiment 3

[0064] Example 3 Plastic coating with lotus leaf effect

[0065] The plastic paint with lotus leaf effect of the present embodiment, its raw material formula is to be made up of each component of following mass percentage:

[0066] Acrylic resin 4%;

[0067] Silicone water repellent 16%;

[0068] Leveling agent 0.3~1%;

[0069] Isopropanol 10-12%;

[0070] Diacetone alcohol 10-20%;

[0071] Propylene glycol methyl ether acetate 12-16%;

[0072] Acetone 9-16%;

[0073] Butanone 8-13%;

[0074] Butyl acetate 11-15%.

[0075] The above-mentioned acrylic resin is BR-113 of Mitsubishi, Japan.

[0076] The plastic paint with lotus leaf effect of the present embodiment, its preparation method is as follows:

[0077] Weigh each component according to the above raw material formula, then mix each component evenly and disperse at high speed to a fineness of ≤25um, so as to prepare the required plastic coating with lotus leaf effect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com