Sheet jelly steaming supporting device

A technology of vermicelli and cooking box, which is applied in the field of food processing, can solve the problems of adhesion and superimposed poor taste, and achieve the effects of preventing vermicelli from sticking, good cooking effect and good vermicelli texture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

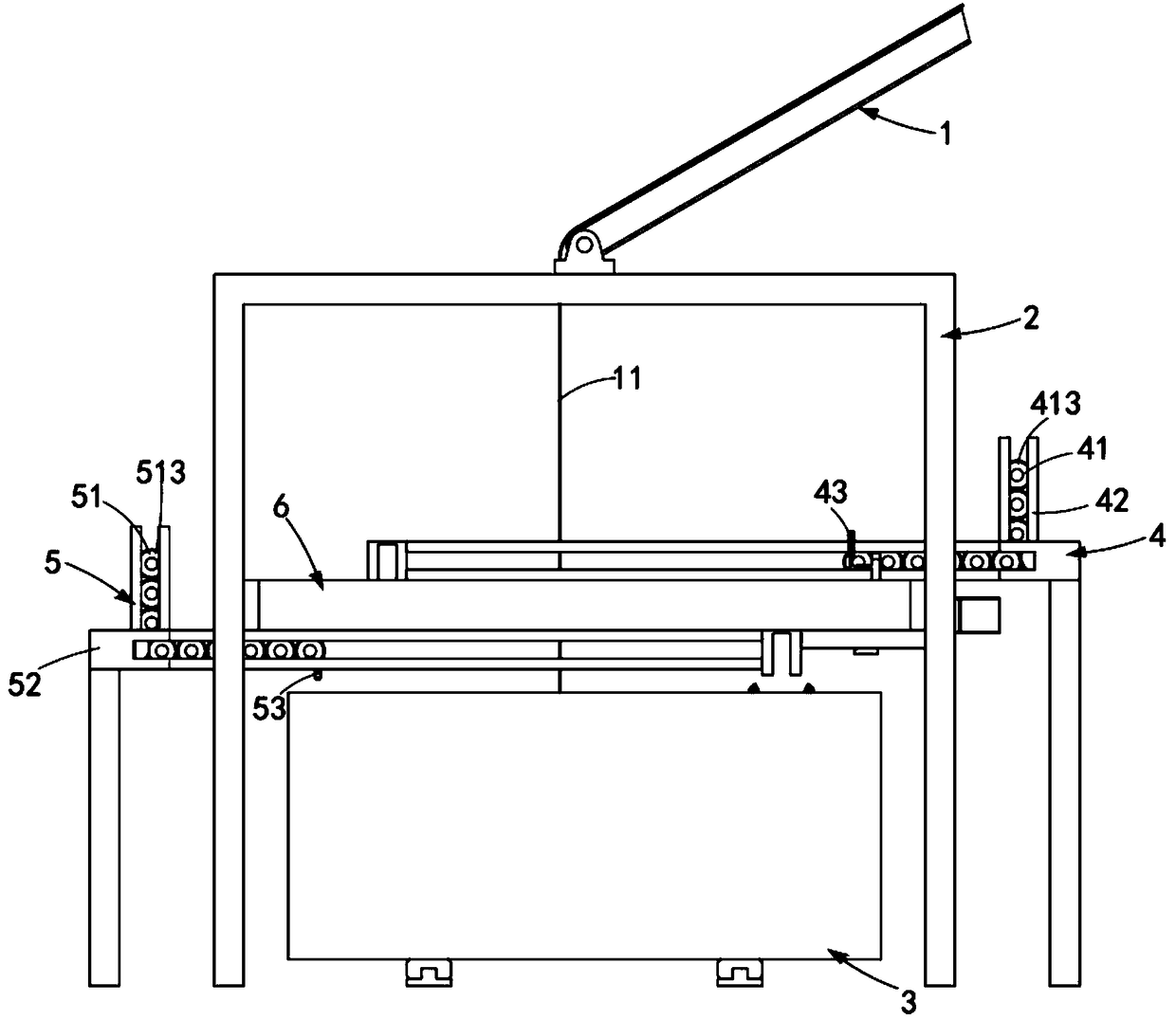

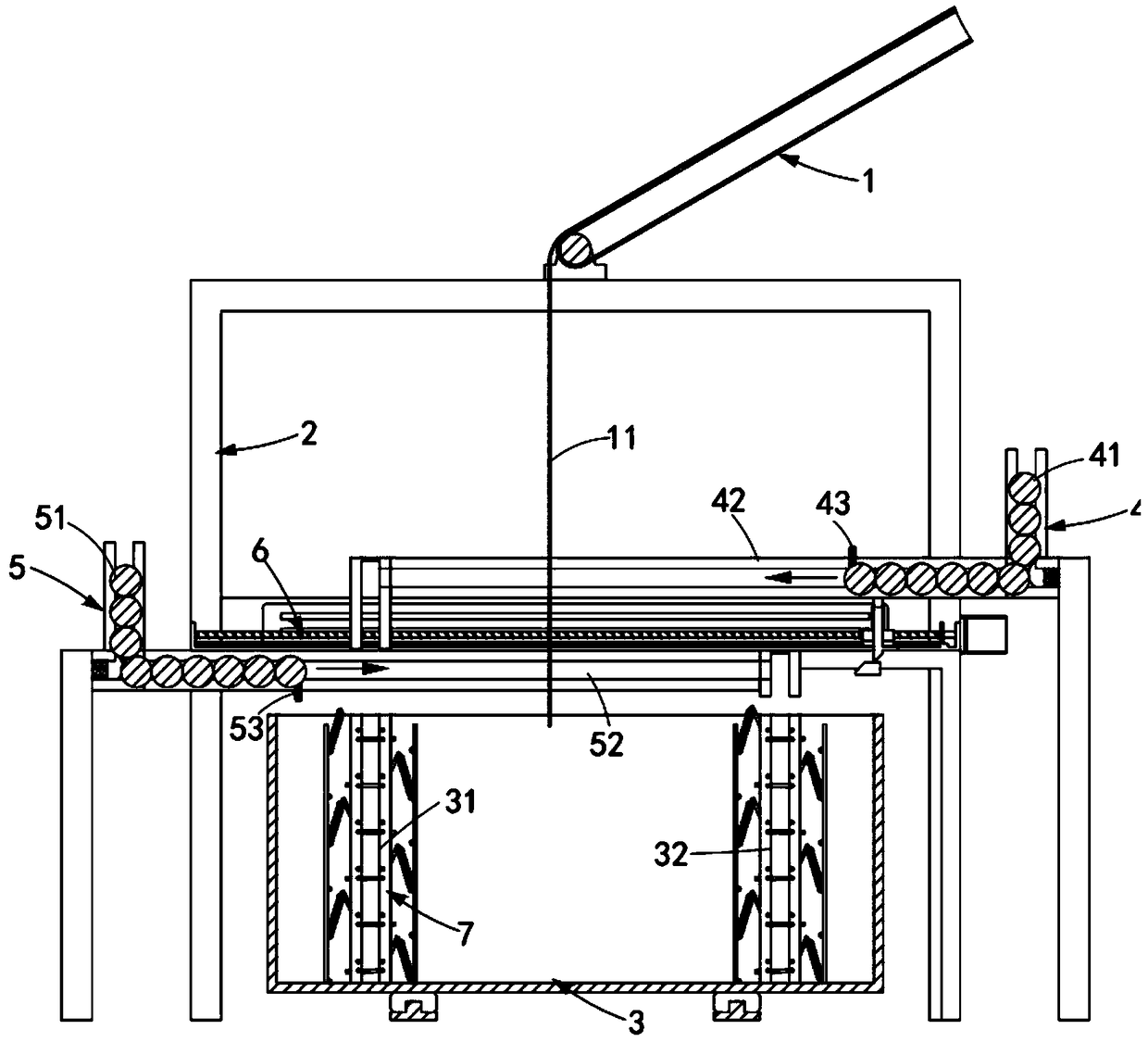

[0051] Such as figure 1 and figure 2 Shown, a kind of vermicelli steaming and supporting material device comprises vermicelli conveyor belt 1, and it is erected on the top of frame 2, and its bottom is provided with movable cooking box 3, and cooking box 3 is used for steaming vermicelli slowly, and also include:

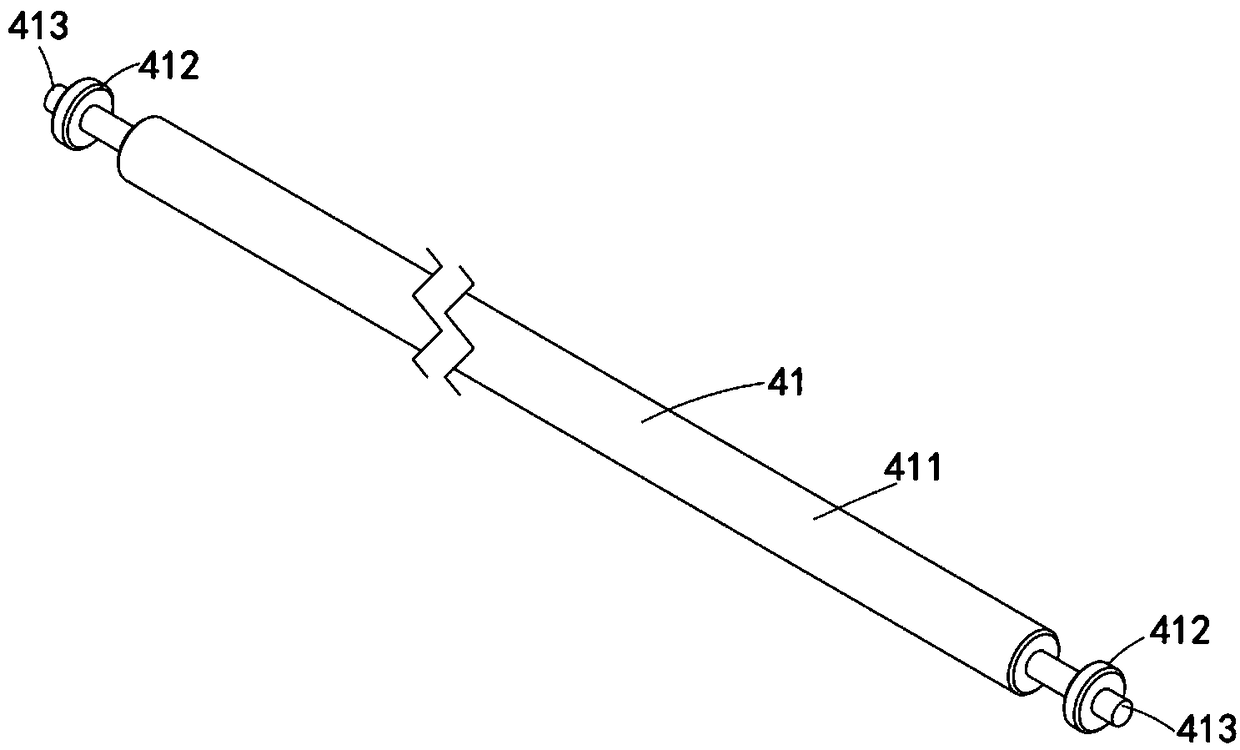

[0052] The first support mechanism 4, the first support mechanism 4 is fixedly arranged below the powder skin conveyor belt 1, it is installed on the frame 2, and it outputs the first support rollers 41 one by one, the first The support roller 41 is used to support the vermicelli 11 output vertically by the vermicelli conveyor belt 1;

[0053] The second support mechanism 5, the second support mechanism 5 is arranged below the powder skin conveyor belt 1, it is located below the first support mechanism 4, and it is installed on the frame 2, The second supporting mechanism 5 outputs second supporting rollers 51 opposite to the output direction of the first suppor...

Embodiment 2

[0075] Figure 10 It is a structural schematic diagram of Embodiment 2 of a vermicelli steaming and supporting device of the present invention; as Figure 10 As shown, the parts that are the same as or corresponding to the first embodiment adopt the corresponding reference numerals of the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The second embodiment is similar to the first embodiment. figure 1 The difference of the shown embodiment one is:

[0076] Such as Figure 10 and Figure 11 As shown, a noodle steaming and supporting device, the cooking box 3 is symmetrically provided with a first receiving groove 31 for receiving the output of the first supporting roller 41, and a receiving groove for receiving the output of the second supporting roller 51. The second receiving groove 32, and the outer sides of the first receiving groove 31 and the second receiving groove 32 are provided with a spacing mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com