New-type quick forming and processing technology of sheet jelly

A technology of molding processing and powder skin, which is applied in the field of food processing, can solve the problems of waste water and waste residue loss, and achieve the effects of saving water resources, fully wrapping, retaining and saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

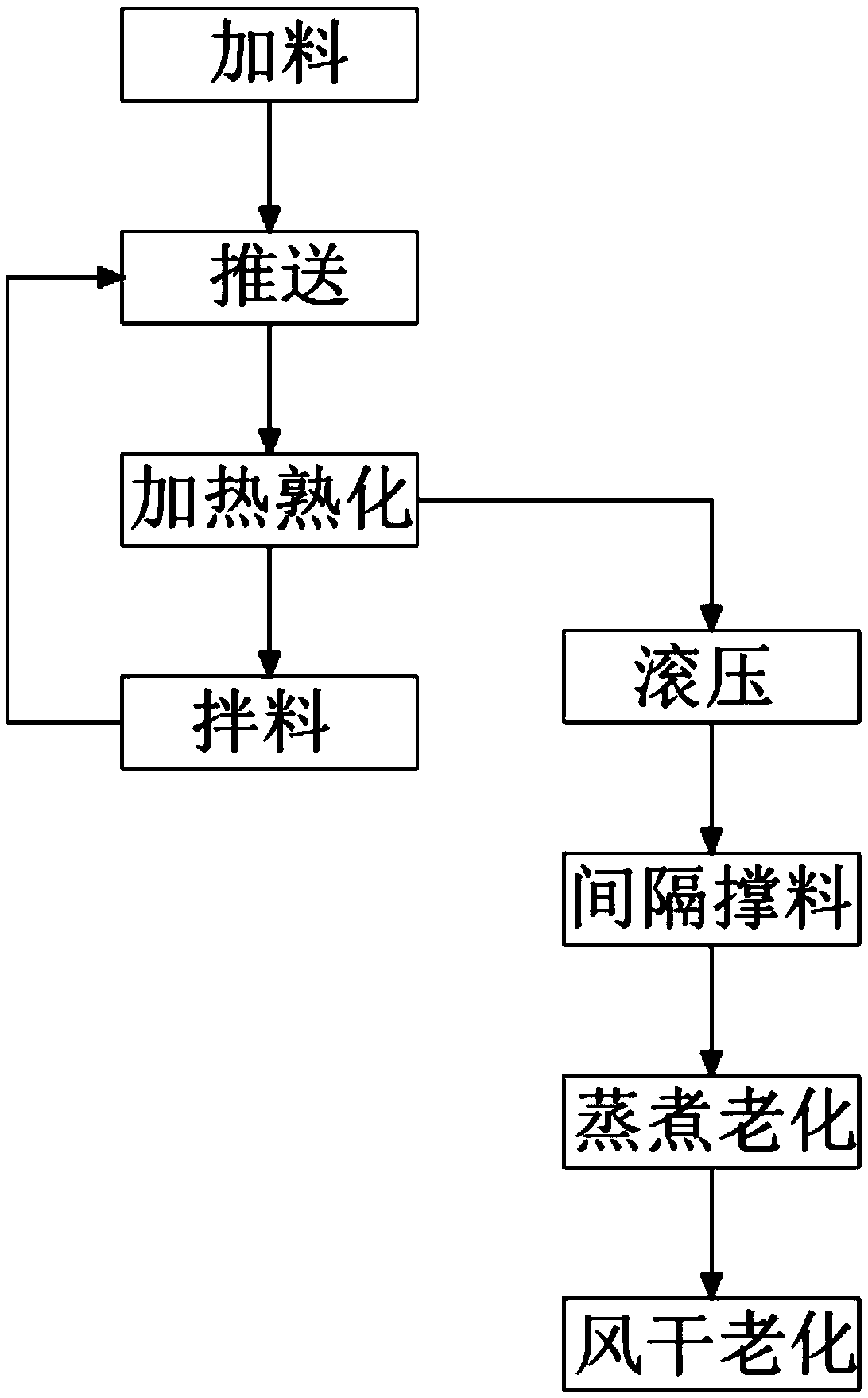

[0094] Such as figure 1 Shown, a kind of novel vermicelli rapid prototyping process is characterized in that, comprises:

[0095] Step 1, feeding, the sweet potato starch slurry that has been mixed with water in advance is automatically transported into the material box 2 through the delivery pipeline;

[0096] Step 2, pushing, transporting the sweet potato starch slurry that enters into the feed box 2, in the process that the feed box 2 is driven by the driving device 6 to reciprocate laterally along the frame 1, the pushing mechanism 31 moves along the vertical direction of the feed box 2 inner wall. Direction downwards squeezes and pushes the sweet potato starch slurry;

[0097] Step 3, heating and slaking, the sweet potato starch slurry pushed out from the feed box 2 by the pushing mechanism 31 is heated by the heating mechanism 32 arranged at the bottom of the feed box 2;

[0098] Step 4, mixing material, after push mechanism 31 finishes pushing sweet potato starch slur...

Embodiment 2

[0118] Referring to Example 1, a new type of rapid prototyping device for vermicelli according to Example 2 of the present invention is described.

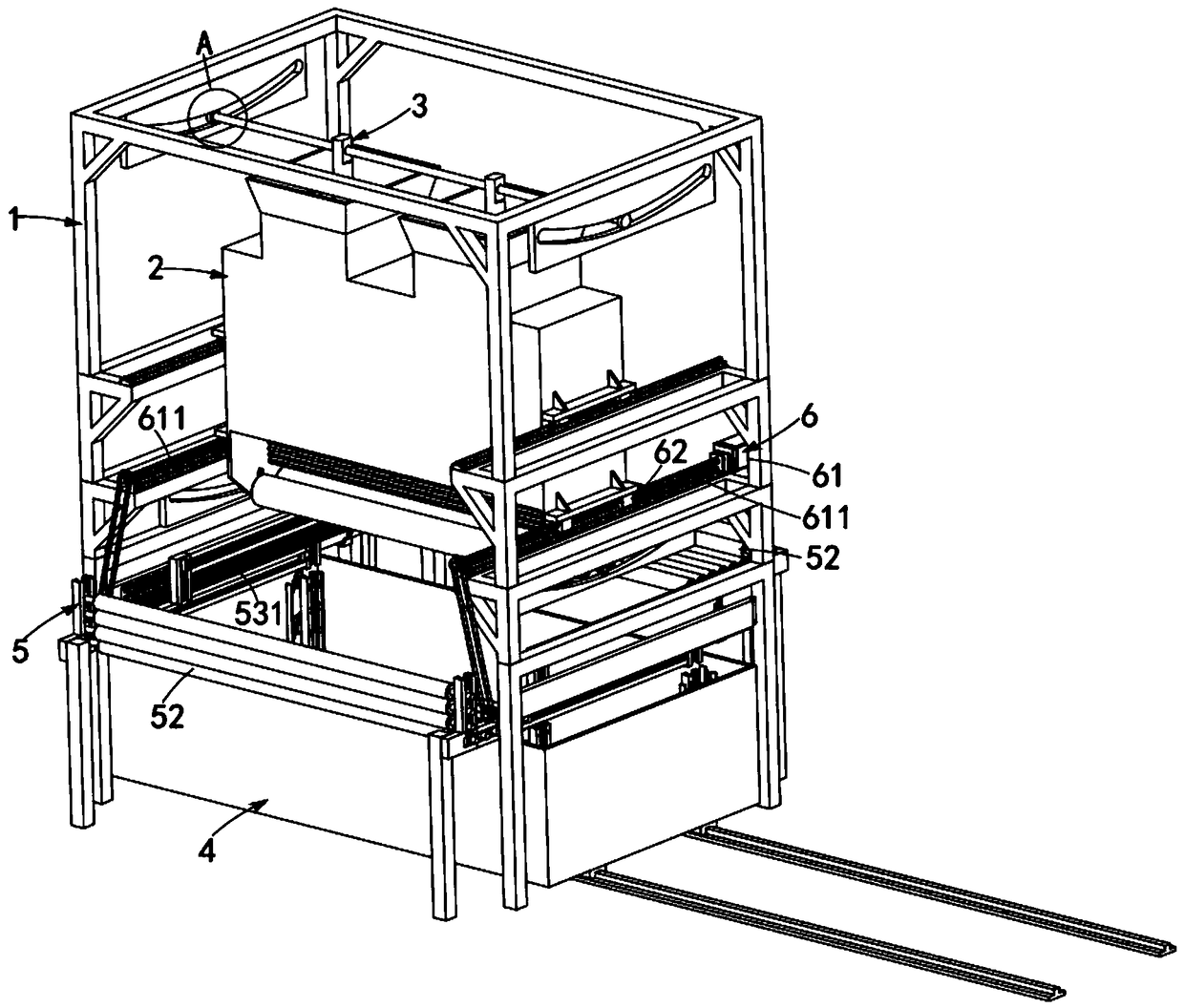

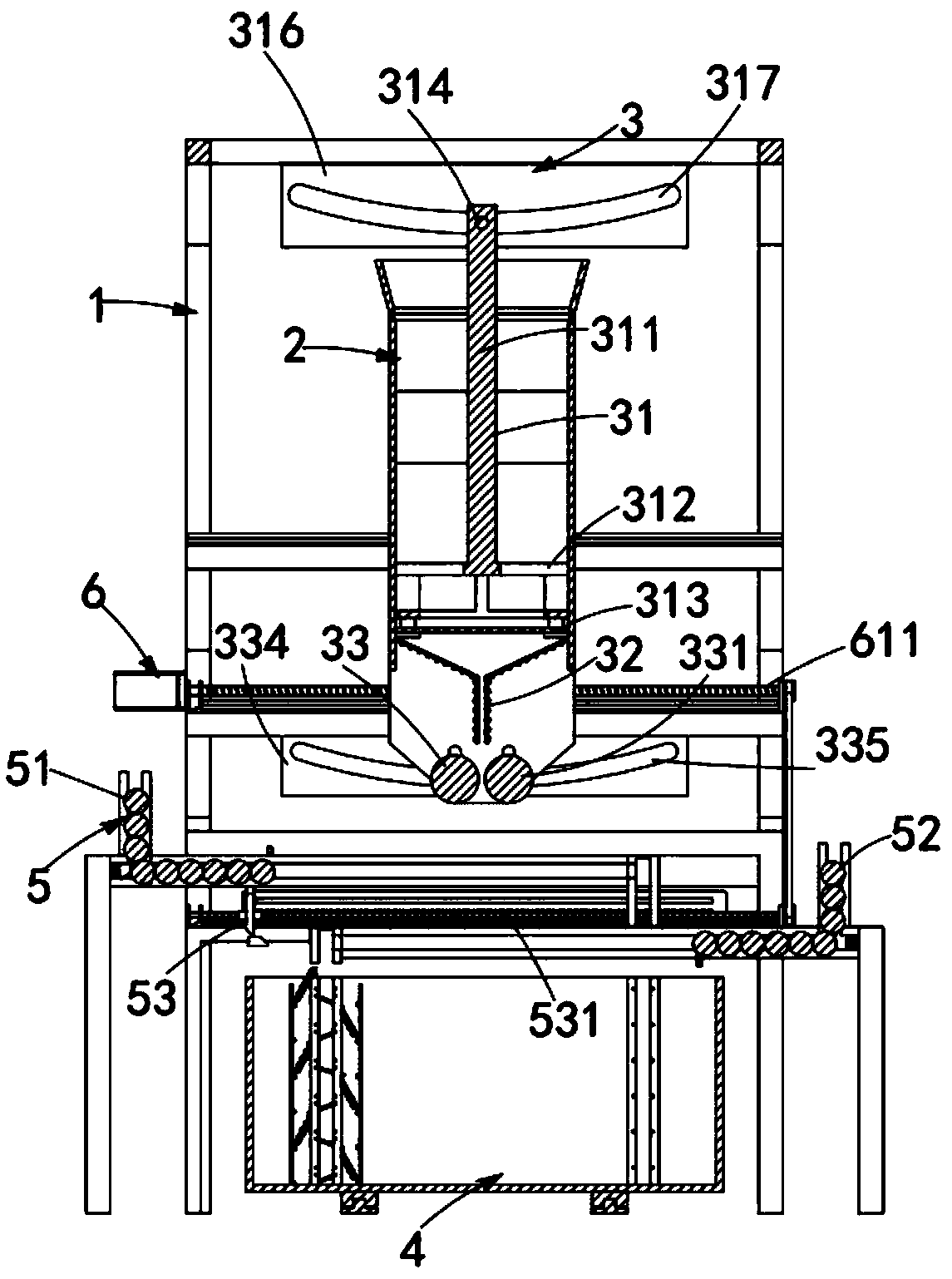

[0119] Such as figure 2 and image 3 As shown, a new type of rapid prototyping processing system for vermicelli, including frame 1, also includes:

[0120] Material box 2, said material box 2 comprises the upper part that is arranged on described frame 1, and its lateral reciprocating movement is set, and the slurry that produces vermicelli is contained in this material box 2, and the top of this material box 2 is provided with The feed port 20 is provided with a discharge port 21 at the bottom;

[0121] Forming device 3, the forming device 3 is arranged on the material box 2, which includes a push mechanism 31 vertically slidably arranged in the material box 2, and a heating mechanism 32 arranged on both sides of the discharge port 21 And the rolling mechanism 33 arranged below the discharge port 21, the pushing mechanism 31 ...

Embodiment approach

[0158] As a preferred implementation manner, the limiting mechanism 56 includes:

[0159] A fixing piece 561, the fixing piece 561 is arranged in a Z shape, and it is fixedly connected with the first track 54 or the second track 55; and

[0160] A limiting member 562, the limiting member 562 is vertically slidably arranged on the fixing member 561, and an elastic member 563 is arranged between the limiting member 562 and the fixing member 561, and the limiting member 562 is facing The ends of the first support roller 51 and the second support roller 52 are arranged in a slope shape.

[0161] It should be noted that the driving device 6 squeezes the limiting member 562 to compress the elastic member 563, and the limiting member 562 loses the position limiting of the first supporting roller 51 and the second supporting roller 52, so that the first supporting roller The material roller 51 and the second material roller 52 are output.

[0162] Among them, it is worth noting that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com