Automotive interior energy-storage fluorescent paint and preparation method thereof

A fluorescent coating and automotive interior technology, applied in the coating field, can solve problems such as poor adhesion and rough appearance, and achieve the effects of promoting adhesion, enhancing solubility, and reducing surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

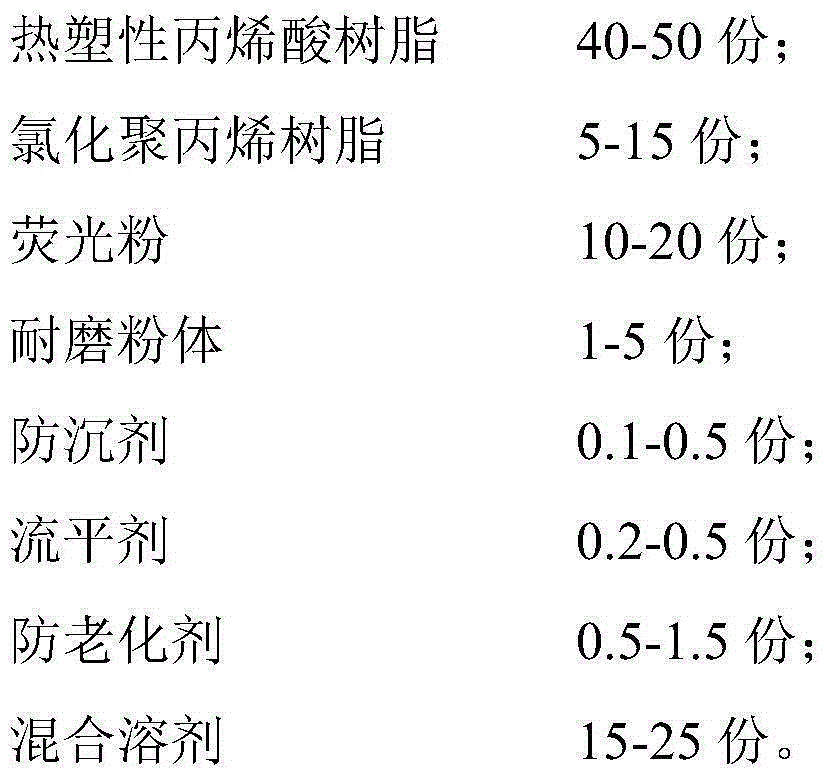

Embodiment 1

[0040] A method for preparing an energy-storing fluorescent paint for automobile interior decoration, the method comprising the following process steps:

[0041]

[0042]

[0043] Put butyl ester, methylcyclohexane, LR-7697, DX-526P, AEROSIL200, TF1778 into the container in order, stir at a slow speed of 100-300r / pm for 10min, then put it on a horizontal grinder, and adjust the fineness Grind ≤20um, add BYK306, Tinuvin770, SinloihiFA-41, stir slowly at 100-300r / pm for 20min. Get energy-storing fluorescent coatings for automotive interiors

[0044] Apply the above components to ABS, Polypropylene and Nylon.

[0045] The performance results of fluorescent coatings are shown in Table 1.

[0046] Table 1 Performance results of fluorescent coatings

[0047]

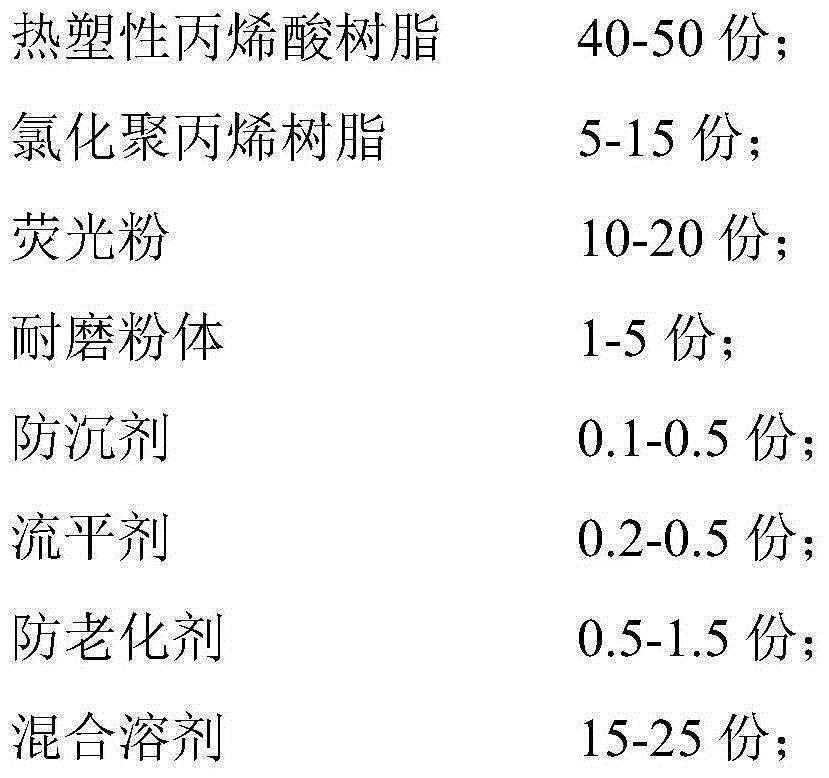

Embodiment 2

[0049] A method for preparing an energy-storing fluorescent paint for automobile interior decoration, the method comprising the following process steps:

[0050]

[0051]

[0052] Put butyl ester, methylcyclohexane, LR-7651, DX-526P, AEROSIL200, TF1778 into the container in sequence, stir at a slow speed of 100~300r / pm for 10min, then put it on a horizontal grinder, and adjust the fineness Grind ≤20um, add BYK306, Tinuvin770, SinloihiFA-41, stir slowly at 100-300r / pm for 20min. Get energy-storing fluorescent coatings for automotive interiors

[0053] Apply the above components to ABS, Polypropylene and Nylon.

[0054] The performance results of fluorescent coatings are shown in Table 2.

[0055] Table 2 Performance results of fluorescent coatings

[0056]

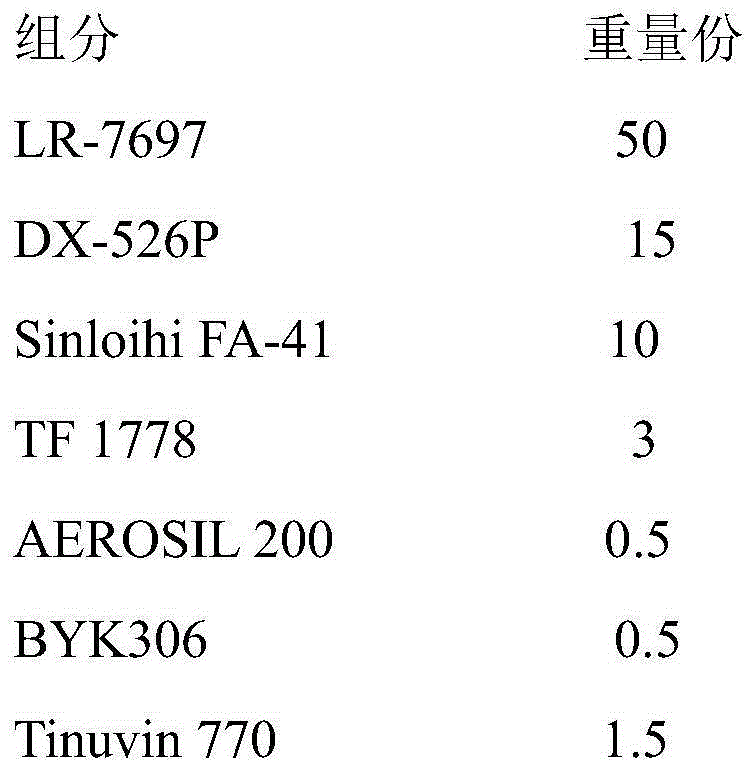

Embodiment 3

[0058] The energy-storing fluorescent paint for interior decoration of automobiles in this embodiment comprises the following components and contents in parts by weight:

[0059]

[0060] Among them, the acid value of the thermoplastic acrylic resin is 7-8mgKOH / g, the solid content is 35-47%, and the chlorine content of the chlorinated polypropylene resin is 26-27%.

[0061] The average particle size of the phosphor is 3.5-4.5 μm, and the softening point is ≥130° C. The acid value of the wear-resistant powder is less than 1mgKOH / g, and the hardness is 2 under the standard of ASTM D1321. The wear-resistant powder is graded micronized polytetrafluoroethylene modified polyethylene wax. Anti-settling agents include fumed silica. The leveling agent includes one or more of polydimethylsiloxane, polyether polyester modified organosiloxane, alkyl modified organosiloxane or terminal group modified organosilicon. Antiaging agents include hindered amine light stabilizers. The mixe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com