Patents

Literature

46results about How to "With anti-rust ability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chain lubricating oil composite agent and preparation method thereof

ActiveCN105176638AExcellent ultra-high temperature oxidation resistanceEasy to useLubricant compositionPolymer sciencePhenolic antioxidant

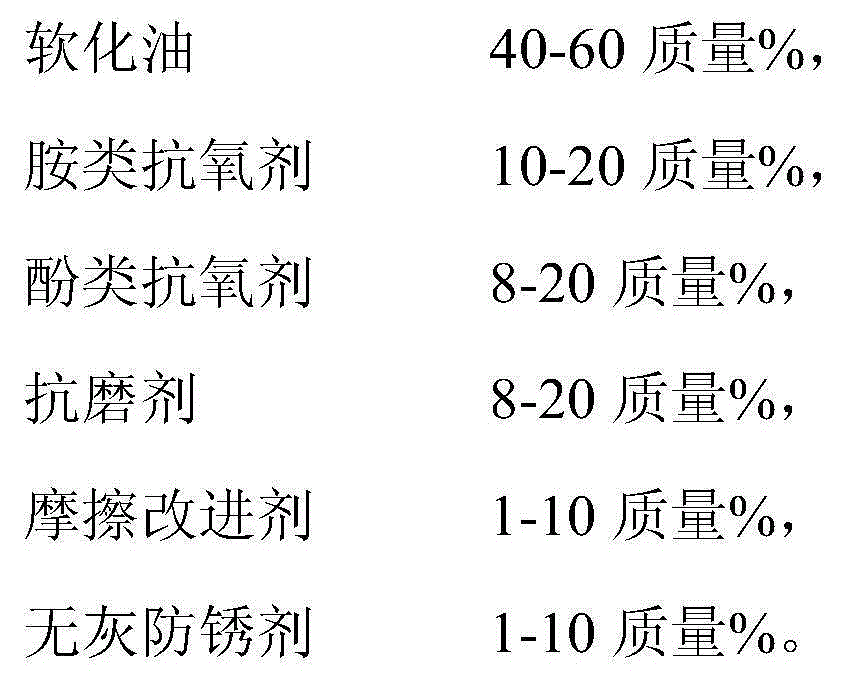

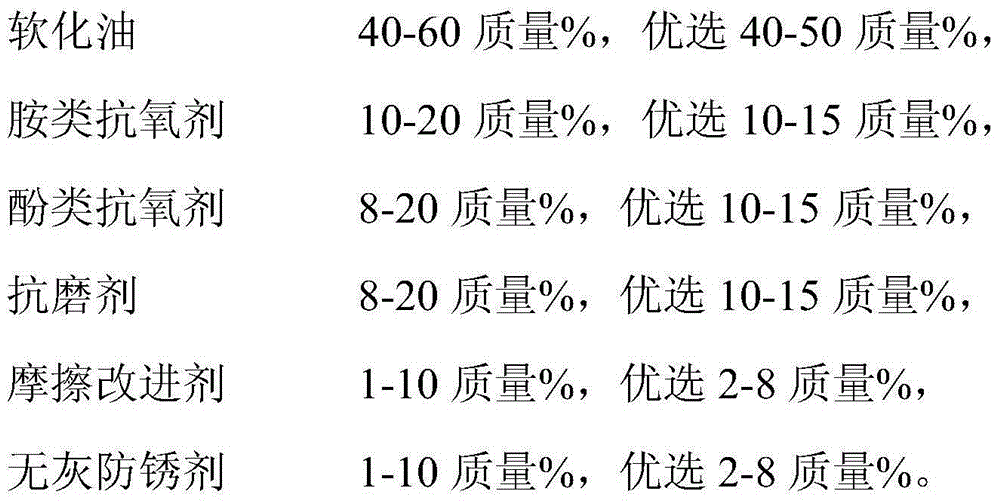

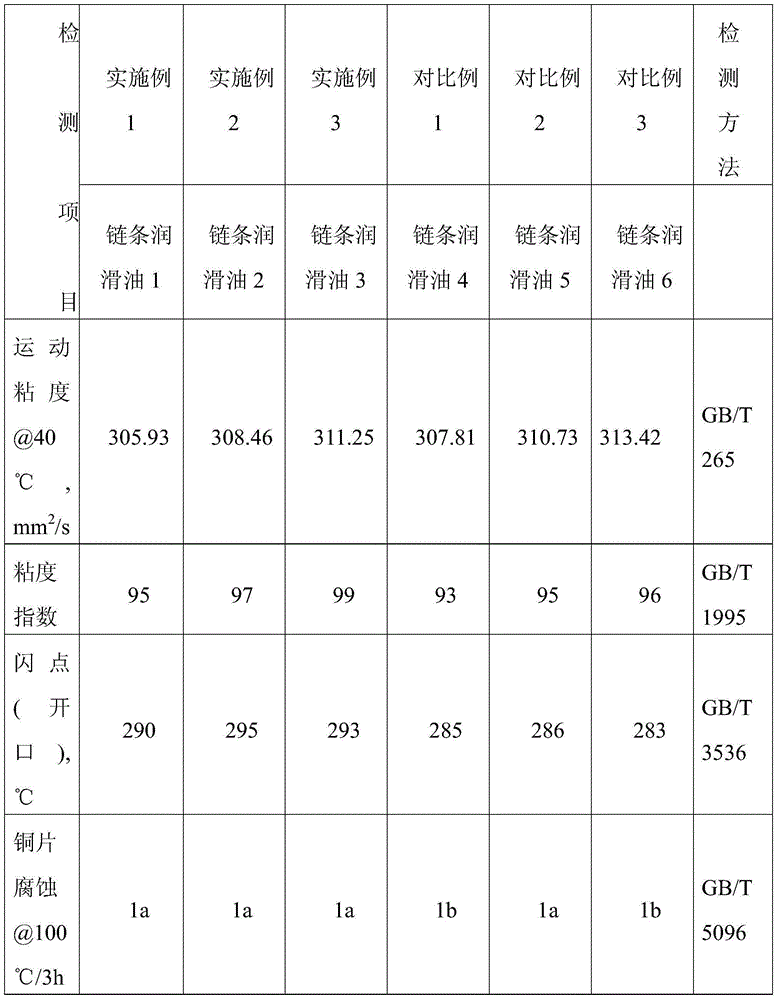

The invention relates to a chain lubricating oil composite agent and a preparation method thereof. The chain lubricating oil composite agent is characterized in that it comprises the following components by mass percentage: 40-60 mass% of softening oil; 10-20 mass% of an amine antioxidant; 8-20 mass% of a phenolic antioxidant; 8-20 mass% of an antiwear agent; 1-10 mass% of a friction improver; and 1-10 mass% of an ashless antirust agent. The high temperature chain lubricating oil prepared from the composite agent provided by the invention has superstrong oxidation resistance, wear resistance and corrosion resistance, so that the high temperature chain can acquire lower friction coefficient in work, safer and more reliable machine operation is ensured, the comprehensive performance is more excellent, and the antirust capability of the chain metal is further enhanced.

Owner:埃优诺特种新材料科技(山东)有限公司

Water-based metal-degreasing cleaning agent

The invention discloses a water-based metal-degreasing cleaning agent. The water-based metal-degreasing cleaning agent comprises the components in percent by weight: 10-30% of composite surface active agent, 5-10% of cleaning additive, 2-5% of corrosion inhibiting agent, 0.4-0.8% of hard-water resistant agent, 0.05-0.2% of defoaming agent and the balance of deionized water. By mass, the composite surface active agent is a mixture compounded by LAS (sodium alkyl benzene sulfonate), AEO-9 (Fatty alcohol polyoxyethylene ether) and TX-10 (alkylphenol ethoxylates) according to the mass ratio of 1:2:1; the corrosion inhibiting agent is a mixture compounded by benzotriazole (BTA) and benzimidazole (BIA) according to the mass ratio of 1:1; the cleaning additive is a mixture compounded by 4A zeolite, sodium metasilicate and sodium carbonate according to the mass ratio of 1:1:1; the defoaming agent is a polyether-modified organic silicon defoaming agent. The water-based metal-degreasing cleaning agent disclosed by the invention has the characteristics of low surface tension, fast defoaming, long foam-inhibiting time, low cost and less use amount and the like.

Owner:SUZHOU LOTTE CHEM TECH

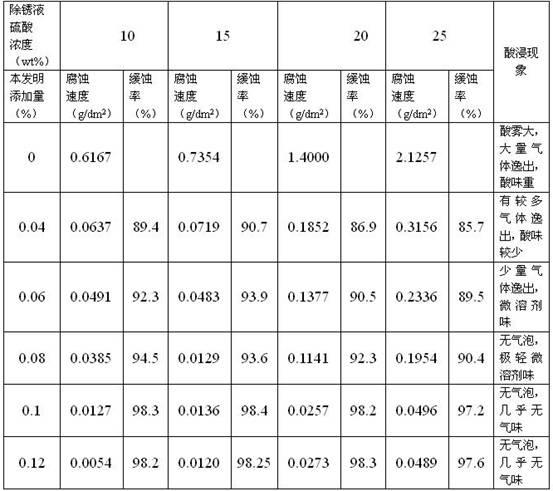

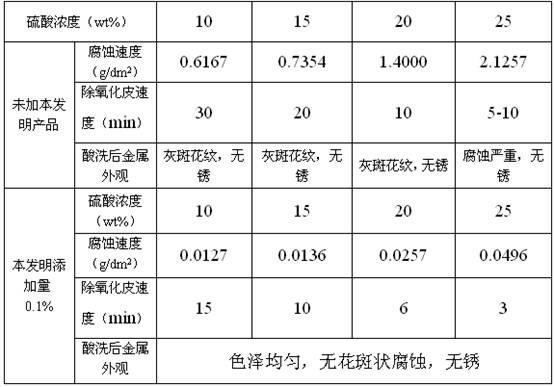

Sulfuric acid washing corrosion-retarding fog inhibitor and preparation method thereof

InactiveCN101851761AThe effect of suppressing acid mist is obviousThe effect of acid mist is obviousEthylenediamineGallic acid ester

The invention discloses a sulfuric acid washing corrosion-retarding fog inhibitor and a preparation method thereof. The sulfuric acid washing corrosion-retarding fog inhibitor comprises an inhibitor, a complexing agent and a wetting agent, wherein the inhibitor comprises di-o-tolyl-thiourea, o-toluidine, sulfonated protein and ethylene diamine tetraacetic acid; the complexing agent comprises sodium citrate, sodium tartrate, hydroxyacetic acid and gallic acid; and the wetting agent comprises sodium sulfonate, sodium carboxylate, L-548 and OP-10. The sulfuric acid washing corrosion-retarding fog inhibitor can retard the excessive corrosion of sulfuric acid to steel matrix, also can be used as an acid washing fog inhibitor, and has good stability at high temperature; and the capability of inhibiting acid fog can reach over 95 percent, the highest corrosion-retarding capability can reach over 98 percent, and the stability is no less than 5 hours.

Owner:NANFENG HOUSE KEEPING ELECTRIC APPLIANCES ZUNYI

Detergent

InactiveCN102108322ARestore surface finishRestore cleanlinessOrganic detergent compounding agentsAmpholytes/electroneutral surface-active compoundsActive componentSURFACTANT BLEND

The invention relates to the field of clearing, cleaning water scales and other stubborn scales. The invention discloses a detergent which comprises the following main active components in parts by weight: 1-5 parts of nonionic surfactant, 0.5-10 parts of anionic surfactant, 0.5-5 parts of ampholytic surfactant, 2-50 parts of methylsulfonic acid, 1-5 parts of hydroxy ethylidene di-phosphonic acid and 0.3-1.0 part of corrosion inhibitor. The detergent can effectively remove the water scales, rusty scales, tea scales, oil scales, dust scales and urine scales on daily life appliances of people, has the effects of removing the scales, cleaning, sterilizing, removing odor and the like, and can be used for hard surfaces of plastic, metal, stainless steel, porcelain and other products.

Owner:BEIJING REWARD HOME CARE CHEM

Cleaning agent for removing heavy dirt and greasy dirt

InactiveCN103710161AIncreased source of alkalinityLow viscosityNon-ionic surface-active compoundsOrganic detergent compounding agentsFiberCleansing Agents

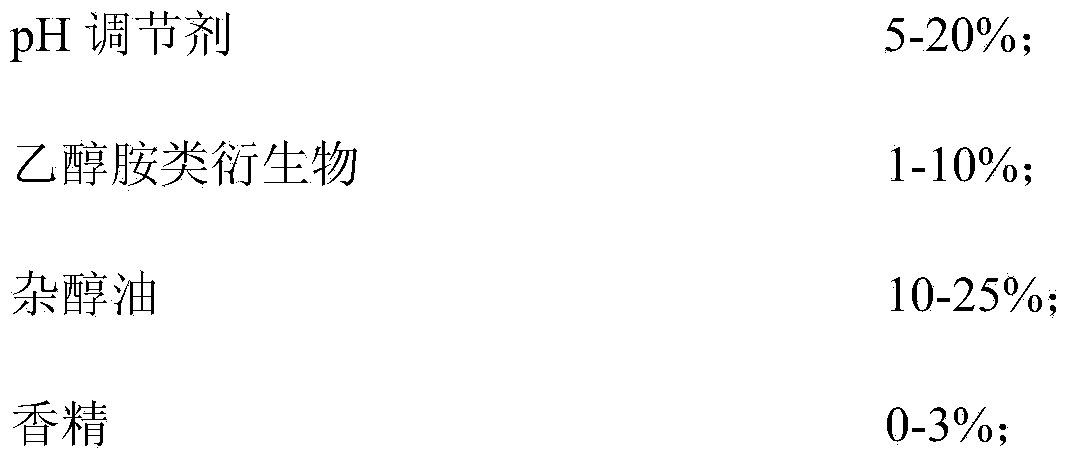

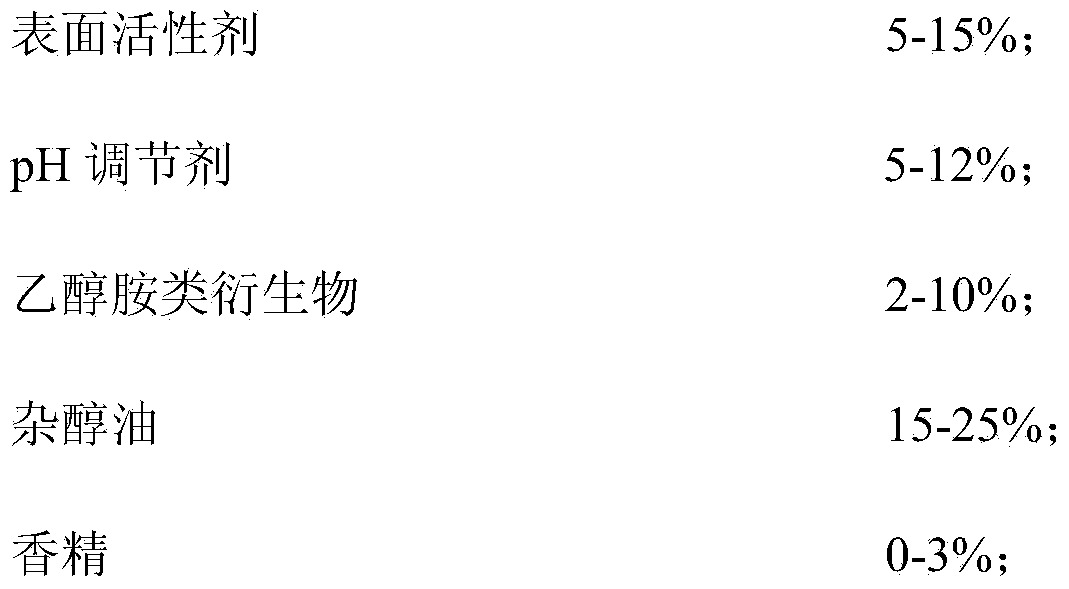

The invention discloses a cleaning agent for removing heavy dirt and greasy dirt. The cleaning agent comprises the following components in percentage by weight: 5%-30% of a surfactant, 5%-20% of a pH (Potential of Hydrogen) modifier, 1%-10% of ethanol amine derivatives, 10%-25% of fusel oil, 0-3% of essence and the balance of water, wherein the surfactant is selected from one or two of negative ion surfactants and nonionic surfactants; the fusel oil is a side product generated in a process for fermentation production of edible alcohol by using starch as a raw material. The cleaning agent disclosed by the invention can be used for effectively percolating into the heavy dirt and greasy dirt which are deposited on the surface of a hard material in a room temperature and a lower temperature; furthermore, with the adoption of the cleaning agent, the greasy dirt and the dirt can be prevented from being re-deposited. The cleaning agent does not pollute fibers, such as cotton, hemp and chemical fibers, and metal wires which are used for scrubbing, so that the fibers and the metal wires for scrubbing are easy to rinse and clean by the water.

Owner:SHANGHAI JIAO TONG UNIV

Efficient cleanser for aluminum products

The invention discloses an efficient cleanser for aluminum products. The efficient cleanser is prepared from, by weight, 10%-15% of EO-PO type surfactant, 3%-5% of EO-9, 3%-8% of polypropylene glycol, 0.5-1.5% of sodium gluconate, 15%-20% of anhydrous sodium carbonate, 2%-4% of sodium borate, 15%-20% of sodium metasilicate, 15%-20% of sodium hydroxide, 0.8%-1.2% of corrosion inhibitor, 0.5-1.5 parts of sulfated castor oil, 10-15 parts of ethyl alcohol and a proper amount of deionzed water. The efficient cleanser for the aluminum products is a water-based environment-friendly cleanser prepared from surfactant, special-effect auxiliaries, complexing agents, corrosion inhibitor and the like according to a special formula, and is suitable for being added to tap water or pure water to clean aluminum alloy metal materials; the good cleaning function is achieved on stamping oil, stretching oil, cutting liquid and other dirt, the use effect is good, degreasing capacity is high, production cost is low, no toxic or side effect exists, and the deoiling and degreasing range is wide. The efficient cleanser can be repeatedly used, is free of pollution and has rust preventing capacity.

Owner:ANHUI HUOSHAN LONGXIN METAL TECH CO LTD

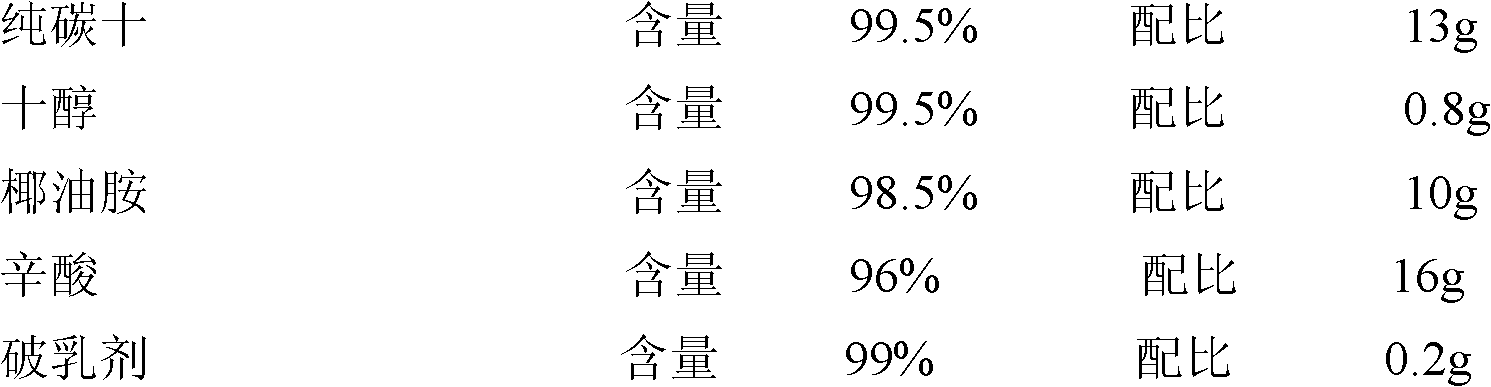

Environment-friendly type cleaning water cutting agent and preparation method thereof as well as displacer for same

ActiveCN102330106AThe mechanism of action is simple and scientificEasy to useLiquid displacementHydrocarbon solventsEmulsion

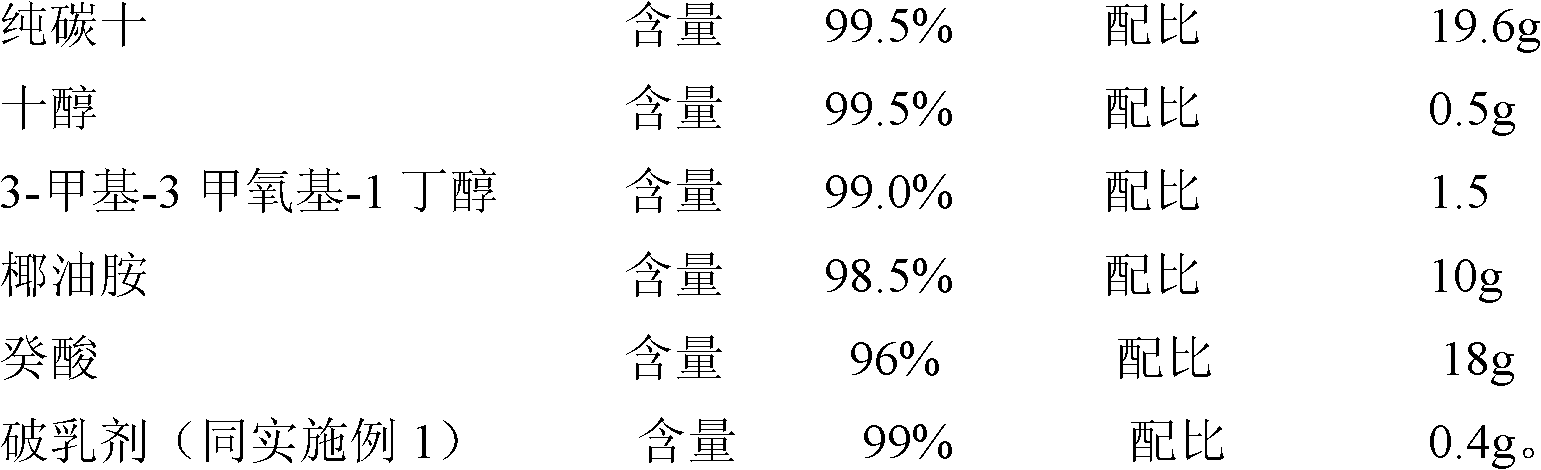

The invention relates to an environment-friendly type cleaning water cutting agent and a preparation method thereof as well as a displacer for the same. The environment-friendly type cleaning water cutting agent comprises the following components calculated according to weight percentage: 95-98 percent of solvent and 2-5 percent of displacer, wherein the displacer comprises the following components calculated according to weight percentage: 1-5 percent of alcohols solvents, 20-30 percent of filming amine, 30-40 percent of organic carboxylic acid, 0.3-0.8 percent of emulsion splitter and hydrocarbon solvent of which the amount is supplemented to 100 percent. The preparation method is realized by sequentially mixing various components. The environment-friendly type cleaning water cutting agent disclosed by the invention has strong cleaning function; more importantly, the environment-friendly type cleaning water cutting agent can be used for quickly removing water brought by a previous work procedure for cleaning parts; and the removed water is deposited at the bottom of a cleaning agent and is drained through the bottom of a rinse tank by using a pollution discharge mode, thus the service life of the cleaning agent is prolonged by over 3 months.

Owner:华阳新兴科技(天津)集团有限公司

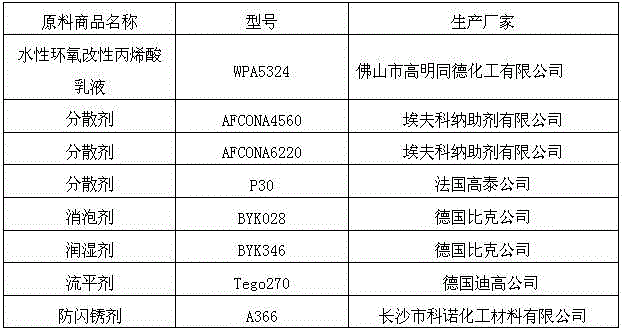

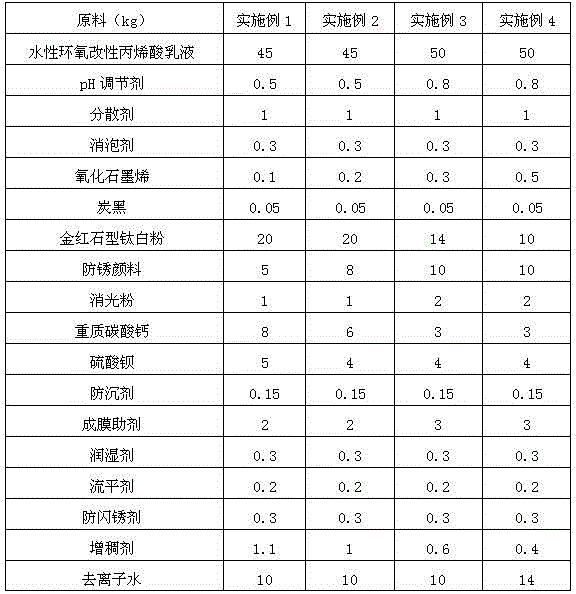

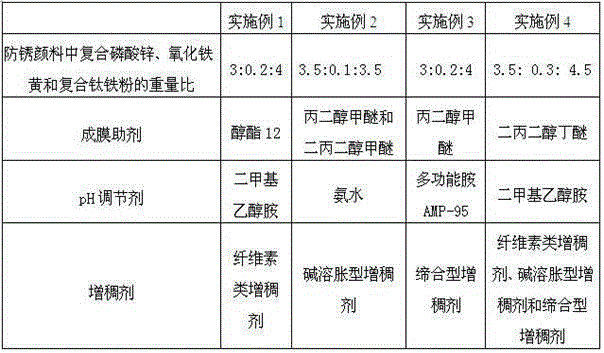

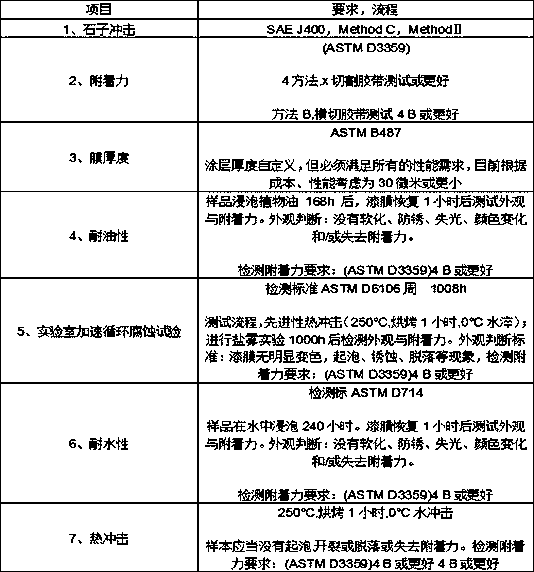

Acrylic water-based paint for motor shells and preparation method thereof

The invention discloses an acrylic water-based paint for motor shells and a preparation method thereof, relating to the technical field of metal water-based paints. The acrylic water-based paint for motor shells comprises the following raw materials in parts by weight: 45-50 parts of acrylic modified resin, 0.4-0.8 part of pH regulator, 0.6-1.5 part of dispersing agent, 0.3-0.5 part of defoaming agent, 0.01-0.5 part of graphene oxide, 0.05-3 parts of carbon black, 10-20 parts of rutile titanium white, 2-10 parts of antirust pigment, 0.5-4 parts of matting powder, 0.5-8 parts of ground calcium carbonate, 3-8 parts of barium sulfate, 0.05-0.15 part of anti-settling agent, 2-3 parts of film forming aid, 0.1-0.5 part of wetting agent, 0.1-0.5 part of leveling agent, 0.1-0.5 part of flash-rust inhibitor, 0.1-1.2 parts of thickener and 6-16 parts of deionized water. The water-based paint has the advantages of favorable antirust effect, quick air-drying, high adhesive force and high hardness; and by using water as the diluter, the water-based paint satisfies the environmental requirements, and is harmless to the human body.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

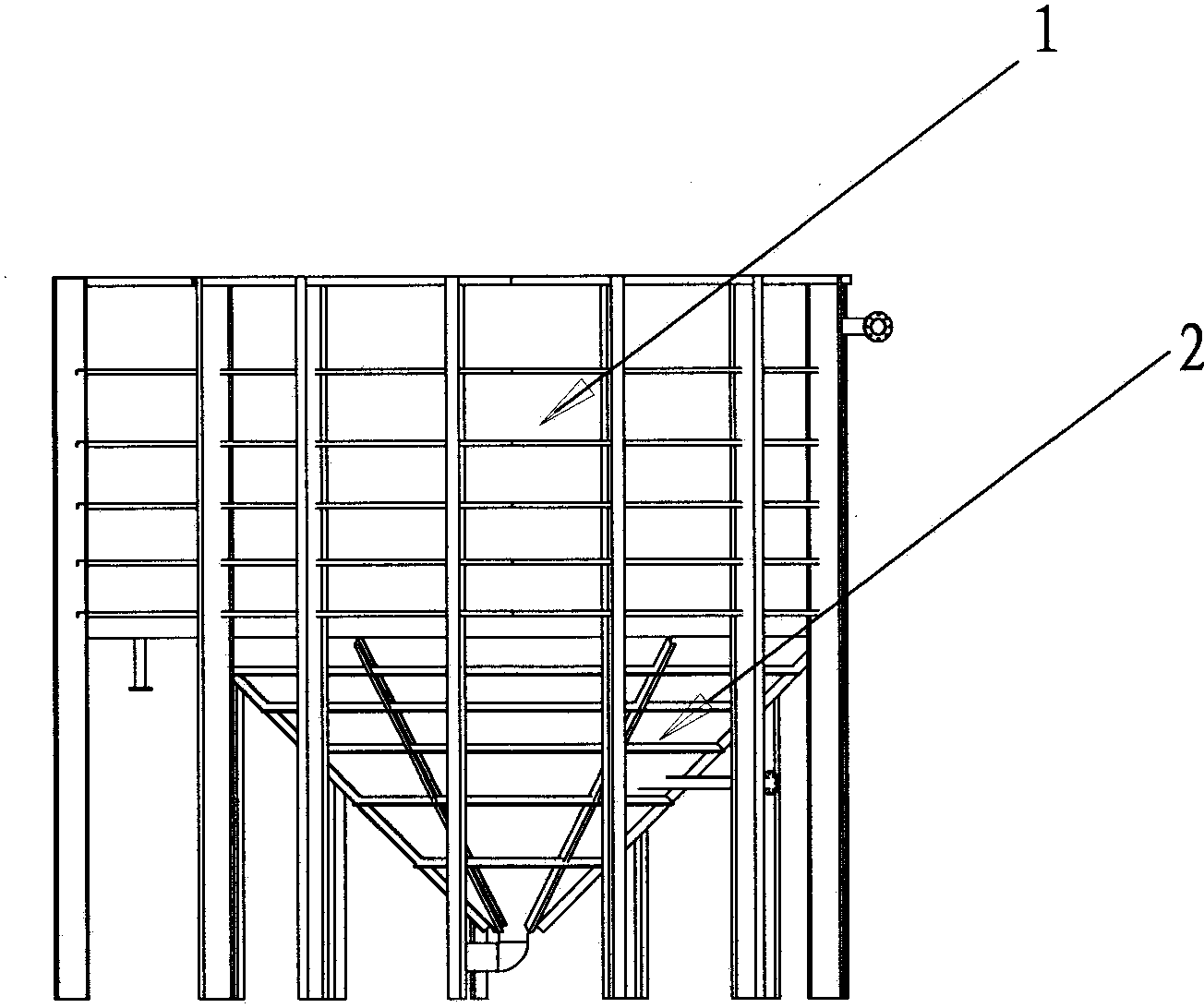

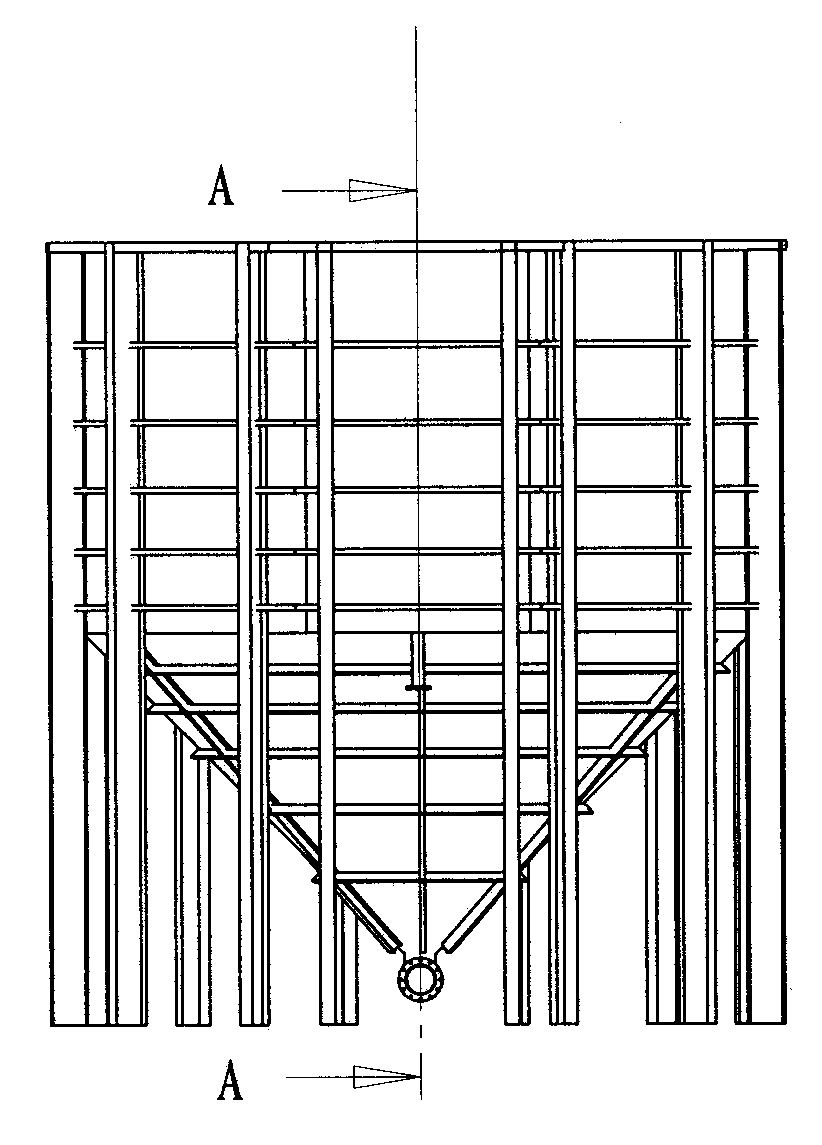

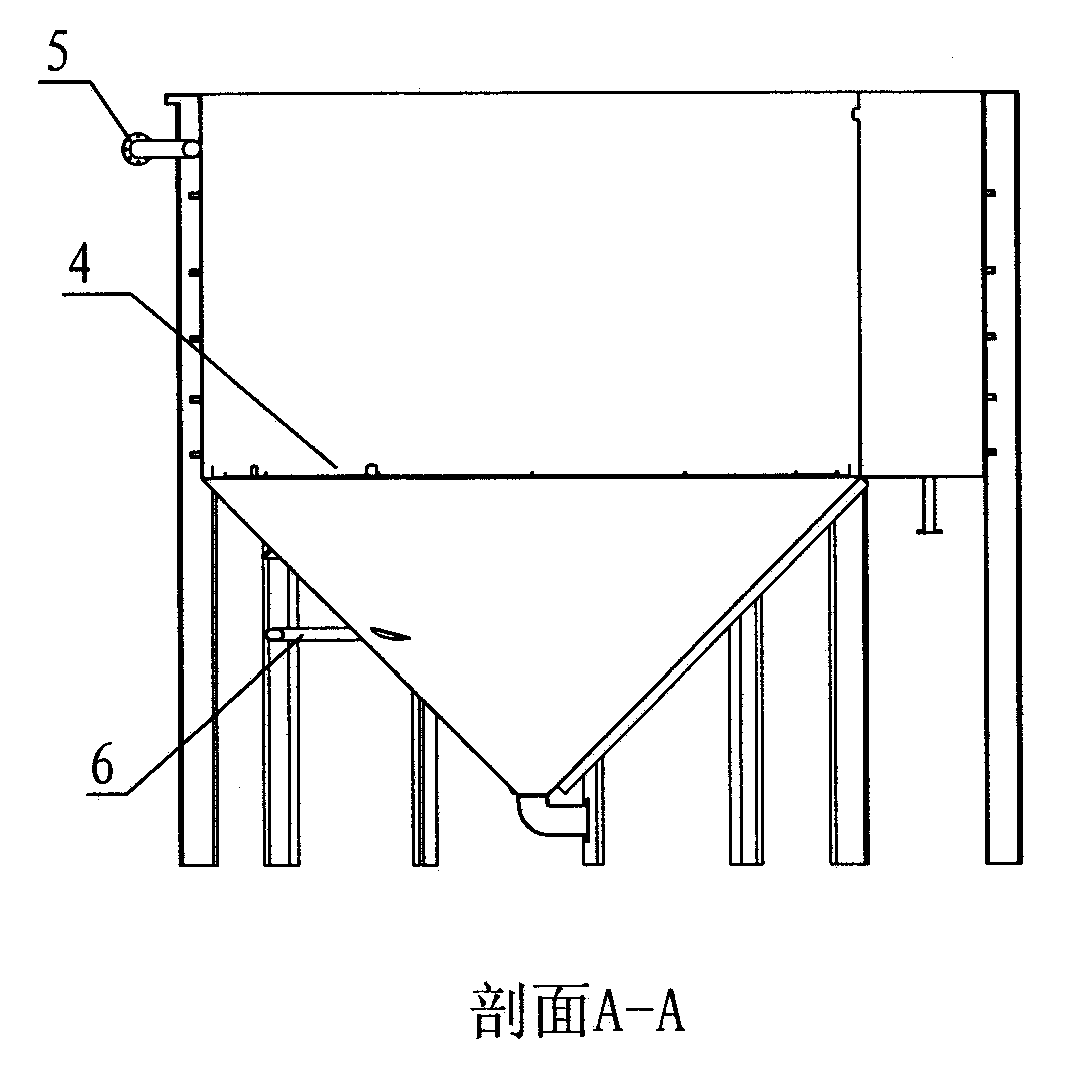

Phosphorization and phosphorization deslagging integrated device and process

InactiveCN103668145AFully contactedImprove the quality of phosphatingMetallic material coating processesRustIntegrated devices

The invention discloses a phosphorization and phosphorization deslagging integrated device and process. The device comprises a main tank body, a conical tank bottom, an overflow tank, a filtering device, a liquid inlet and a liquid outlet, wherein the main tank body is positioned above the conical tank bottom; the liquid outlet is formed in the conical tank bottom; the overflow tank is arranged at one side of the main tank body; the liquid inlet is formed in the other side of the main tank body; and the filtering device is arranged at the lower part in the main tank body. The process comprises the steps of on-line checking, oil removal, washing, rust removal, washing, neutralizing, washing, surface adjustment, phosphorization, washing, washing, sealing treatment and drying. The phosphorization treatment in the phosphorization process step comprises the step of tank building, parameter test, adjustment of a phosphorization liquid and control and clearing of sediments. The device and the process are used for coating flow line production, so that phosphorization and deslagging integration is realized, and therefore, the device and process are novel.

Owner:洛阳艾笛曼机械设备有限公司

Water based metal cleaner

This invention relates to a water-based metal cleaning agent which is specially prepared from raw materials with a following mass proportion: 3 shares of 0ªð-10, 97 shares of EO, 5 shares of AES, 5 shares of TEA, 7 shares of PPG, 5 shares of ethanol, 5 shares of glycol butyrate and 50 shares of flavors and water. This invention has the advantages of: a) wide application in de-oiling and decontamination and a good cleaning effect. It can be adopted for cleaning away the dirt such as lubricants, pressure oil, metalworking fluids and grinding fluids on the surface of stainless steels, low-carbon steels, aluminium and aluminium alloys, copper and copper alloys, high-iron alloys and nickel alloys. b) Strong cleaning capacity and high cleaning speed. c) Reusability, no pollution and rusting resistance.

Owner:天津市怡佳商贸有限公司

Water-borne aluminum foil working fluid

Owner:FOSHAN SHUNDE FUYANSHENG LUBRICANT

Reusable metal equipment cleaning agent

The invention discloses a reusable metal equipment cleaning agent. The reusable metal equipment cleaning agent is prepared from 6.2-8.4 parts by weight of fatty acid methyl ester ethoxylate (FMEE), 5.2-8.7 parts by weight of aspartic acid, 5.5-7.5 parts by weight of fatty alcohol-polyoxyethylene ether, 2.8-4.5 parts by weight of carboxymethyl cellulose sodium, 4.2-5.3 parts by weight of fatty alcohol diethanol amide, 4.5-5.6 parts by weight of sodium pyrophosphate, 1.3-2.5 parts by weight of a fire retardant and 1.8-4.5 parts by weight of an antifoaming agent. The reusable metal equipment cleaning agent has excellent cleaning effects, can be widely used in fields of cleaning metal equipment such as tractors, automobiles, construction machinery, aviation machinery, weaving machinery and chemical machinery or metal parts such as bearings, can be reused, has no pollution and has an antirust capability.

Owner:QINGDAO HUIERTONG TRADING

Lubricating oil for electrical equipment and preparation method of lubricating oil

InactiveCN107189846AIncrease polarityReduce evaporation lossLubricant compositionViscosity indexSilicone oil

The invention discloses lubricating oil for electrical equipment, and belongs to the technical field of lubricating oil. The lubricating oil comprises the following raw materials, by weight part, 60-70 parts of polyol ester, 14-20 parts of silicone oil, 32-35 parts of flaxseed oil, 2-4 parts of essence, 3-5 parts of a viscosity index improver, 1-4 parts of an anti-corrosive agent, 0.5-1 part of an anti-oxidant, 5-7 parts of an oiliness agent, 4-6 parts of a cleaning dispersant, 1-2 parts of a metal deactivator, and 2-5 parts of an antifreezing agent. The invention discloses a preparation method of the lubricating oil. The lubricating oil is good in corrosion resistance, freezing resistance, and oxidation resistance and has delicate fragrance.

Owner:合肥轻风飏电气科技有限责任公司

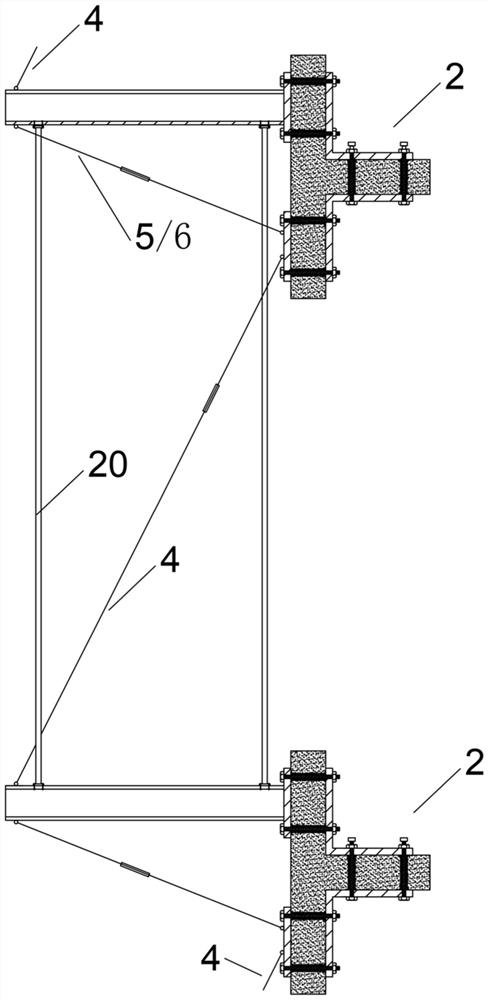

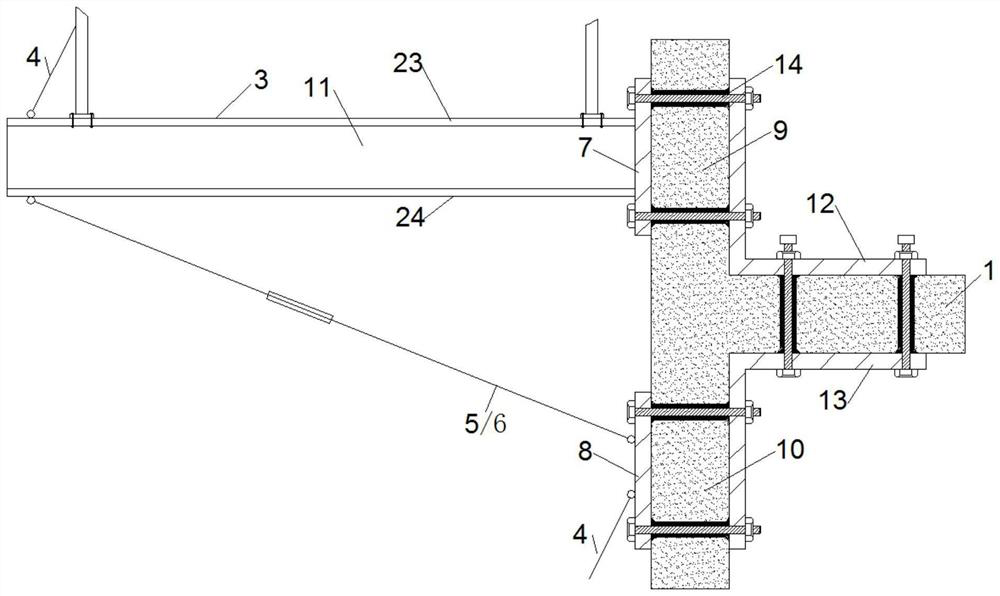

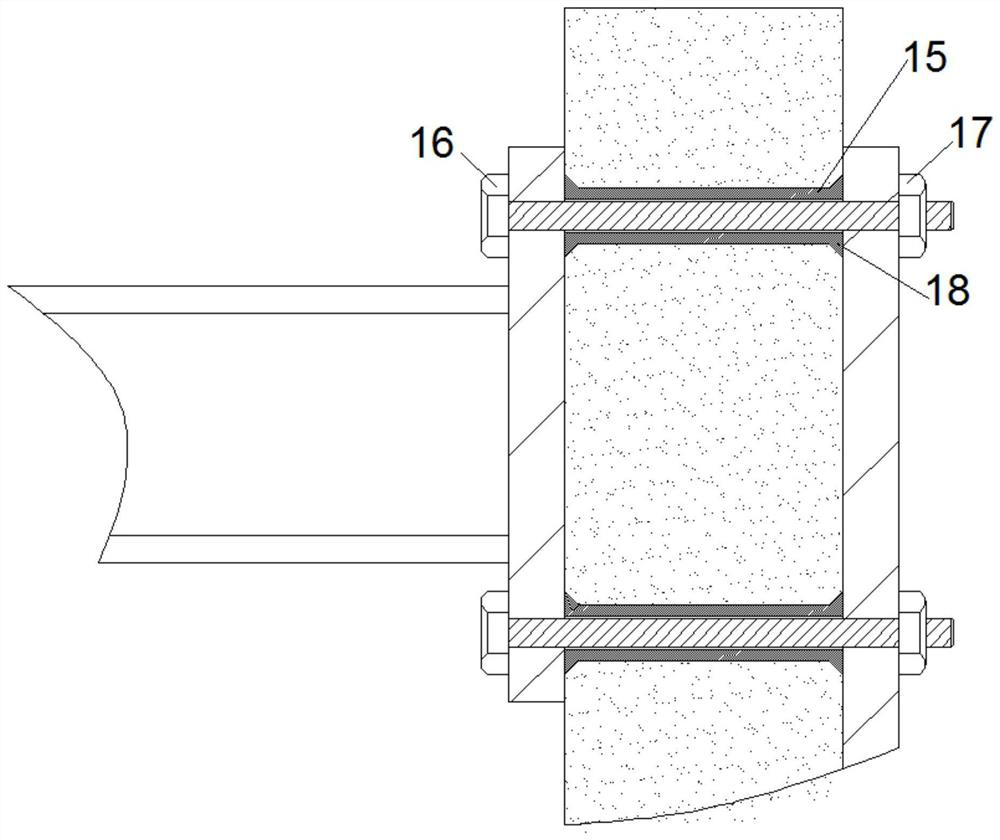

Cantilever frame system

PendingCN111851986AEasy to fixGuaranteed protective effectProtective buildings/sheltersBuilding insulationsArchitectural engineeringBuilding construction

The invention discloses a cantilever frame system, and belongs to the technical field of building operations. The cantilever frame system comprises a plurality of cantilever frame components. The rearend of I-steel of each cantilever frame component is provided with an upper base. The upper base is fixed to the outside of an upper side wall. Lower base is fixed to the outside of an lower side wall. The two end of a upper pulling rod is respectively connected with the I-steel and the lower base of the cantilever frame component, and the lower base is arranged above the cantilever frame component corresponding to the I-steel, and is used for providing the rear upper tension to the I-steel. The two ends of a left lower supporting rod and a right lower supporting rod are respectively connected with the I-steel and the lower base. The left lower supporting rod and the right lower supporting rod are symmetrically arranged on a vertical plate of the I-steel. The intersection of the extensionlines the left lower supporting rod and the right lower supporting rod is located on the upward extending surface of the vertical plate the I-steel. According to the cantilever frame system, the I-steel is more stable and reliable to perform fixing with multiple stress support and safety protection, is easy to install and disassemble, and has a certain seismic capacity and rust-resistant performance.

Owner:CONSTR COMPANY OF CHINA RAILWAY NO 8 ENGNEERING GRP +1

One-component self-drying water-based hammer paint and preparation method thereof

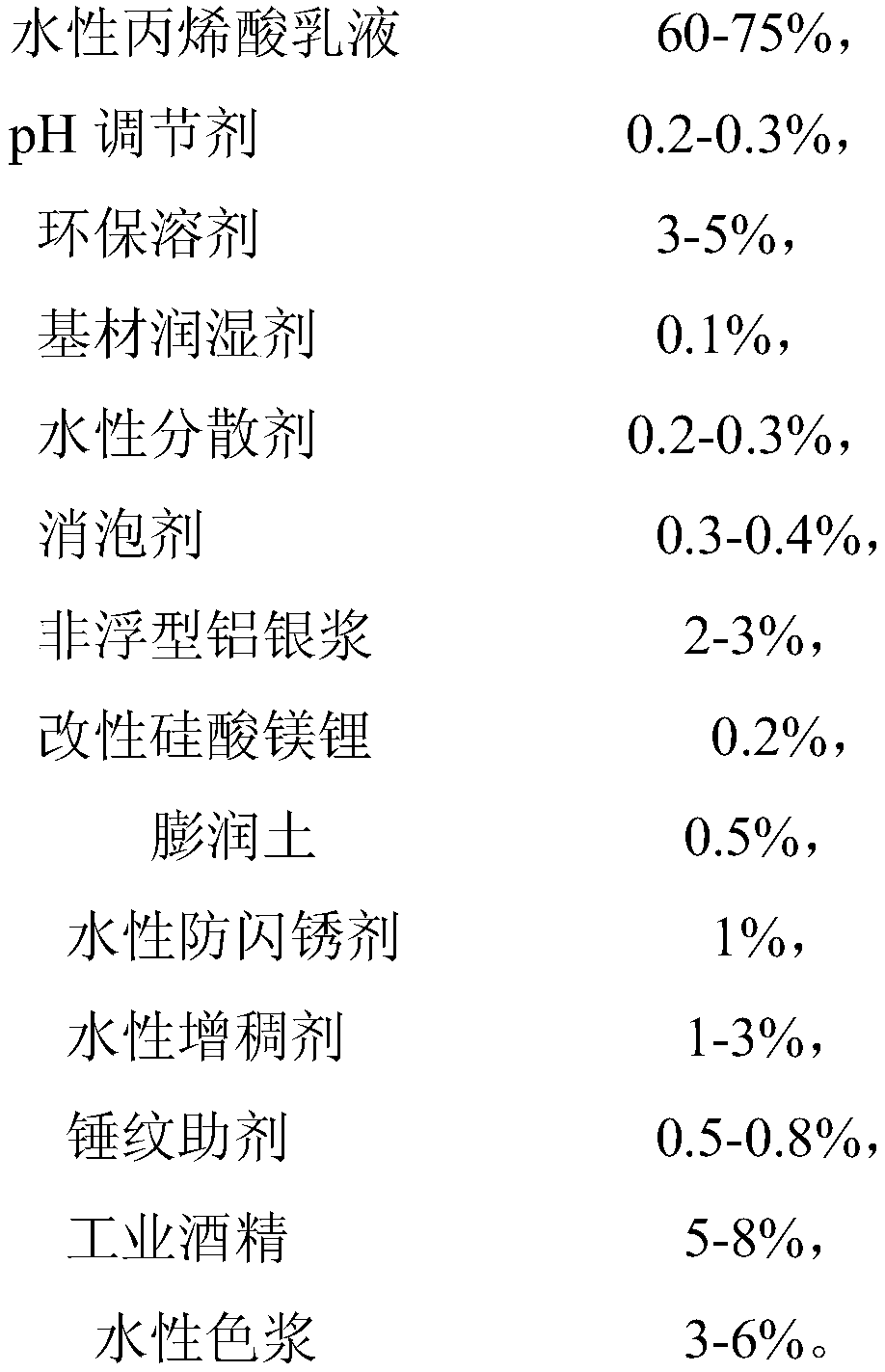

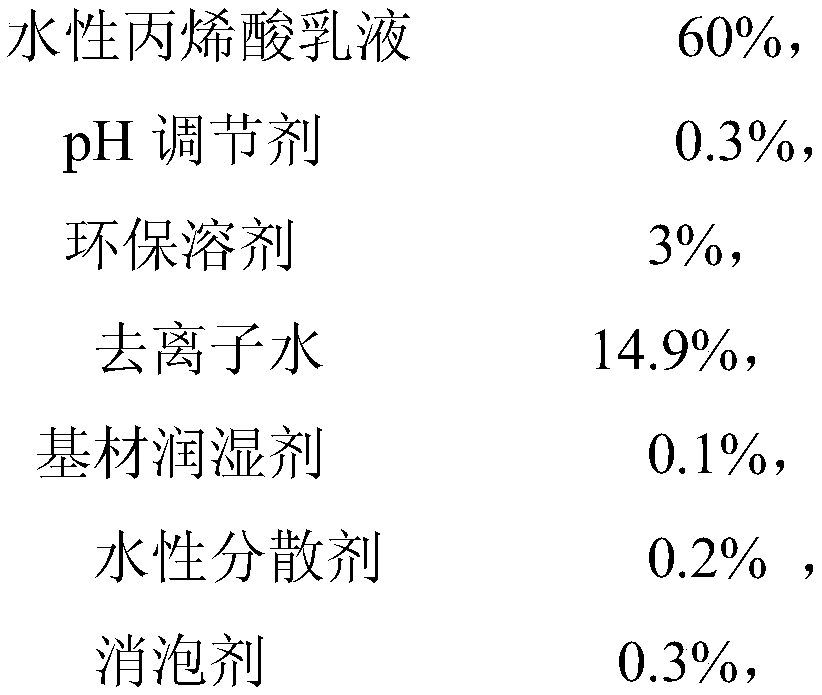

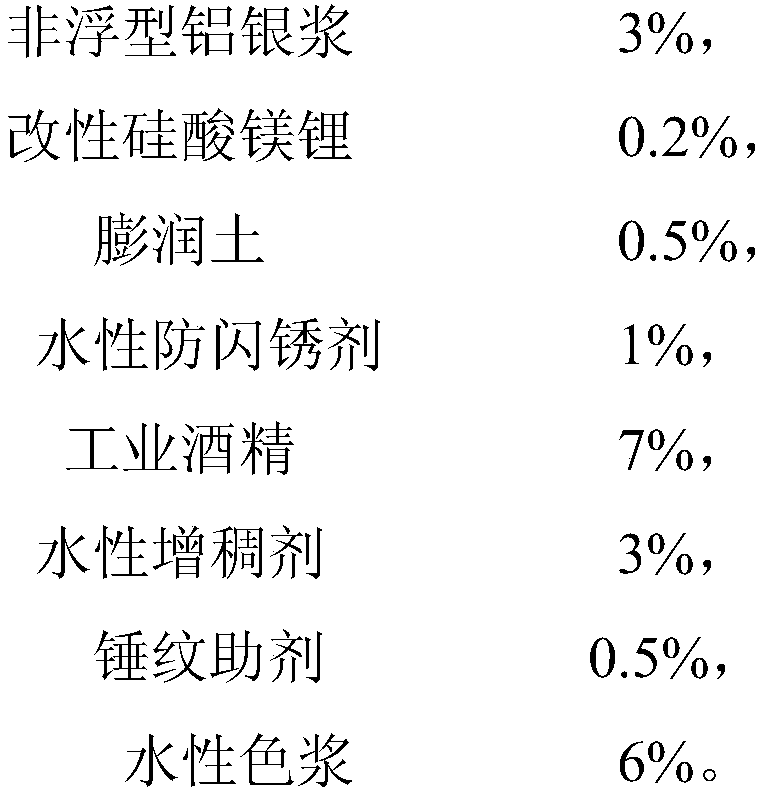

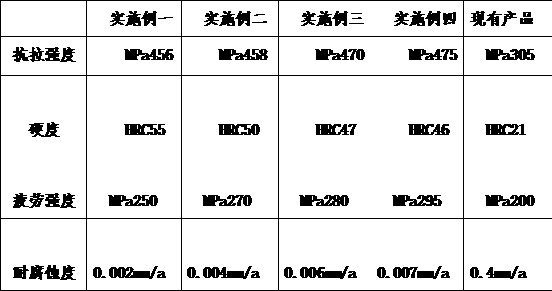

InactiveCN109111799AWith anti-rust abilityGood construction performanceAnti-corrosive paintsWater basedSolvent

The invention discloses a one-component self-drying water-based hammer paint and a preparation method thereof. The one-component self-drying water-based hammer paint comprises the following componentsby mass: 60-75% of a water-based acrylic emulsion, 0.2-0.3% of a pH value regulator, 3-5% of an environmentally-friendly solvent, 0.1% of a substrate wetting agent, 0.2-0.3% of a water-based disperser, 0.3-0.4% of a defoamer, 2-3% of a non-floating aluminum paste, 0.2% of modified lithium magnesium silicate, 0.5% of bentonite, 1% of a water-based flash rust inhibitor, 1-3 % of a water-based thickener, 0.5-0.8% of a hammer finish additive, 5-8% of industrial alcohol and 3-6% of water-based color paste. The one-component self-drying water-based hammer paint of the invention has the advantages of environmental protection, equivalent cost, simple construction, no needfor a diluent, no defects such as prickly heat and pinholes, and fast drying.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Pipe casting method based on stainless steel and carbon steel bimetallic mixed solution

InactiveCN108372281AWith anti-rust abilityAvoid affecting service lifeSolid state diffusion coatingSS - Stainless steelHardness

The invention discloses a pipe casting method based on a stainless steel and carbon steel bimetallic mixed solution, and relates to the technical field of metal casting. The pipe casting method comprises the following steps of weighing stainless steel and carbon steel raw materials in percentage by weight, respectively adding the weighed stainless steel and carbon steel raw materials into two fusion casting furnaces to fuse and cast into a casting solution, fetching out when the temperature of the mixed casting solution is 1630 to 1650 DEG C, casting the mixed casting solution into a mold cavity of a mold of a centrifugal casting machine, and starting the centrifugal casting machine; after casting and cooling are completed, fetching out the completed pipe blank, and hardening; fetching outthe pipe blank, polishing, and flattening the end, so as to obtain the finished pipe. The pipe casting method based on the stainless steel and carbon steel bimetallic mixed solution has the advantages that the antirust ability of the stainless steel and the high hardness of the carbon steel are simultaneously realized; the anti-fatigue strength is higher, the rust of the finished pipe in the useprocess is avoided, the good anti-cracking ability is realized, and the service life of the finished pipe is greatly prolonged.

Owner:北京鼎翰科技有限公司

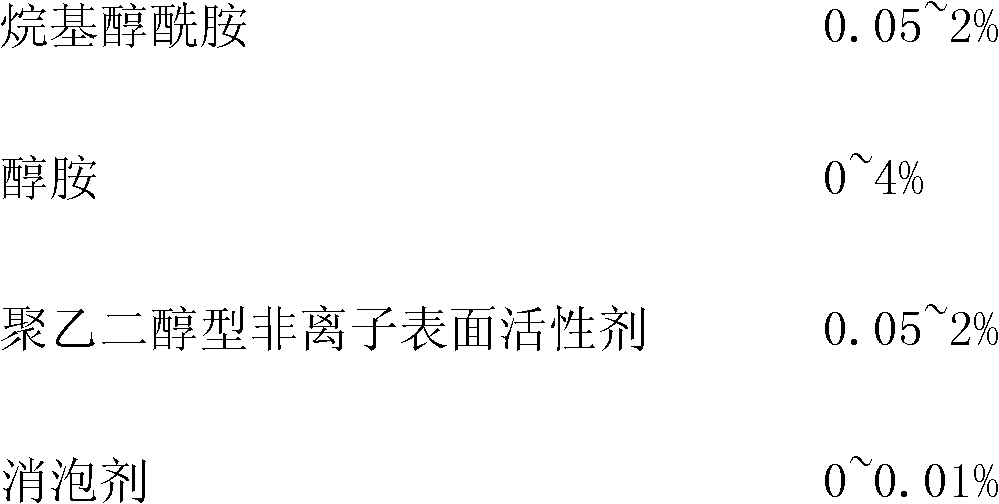

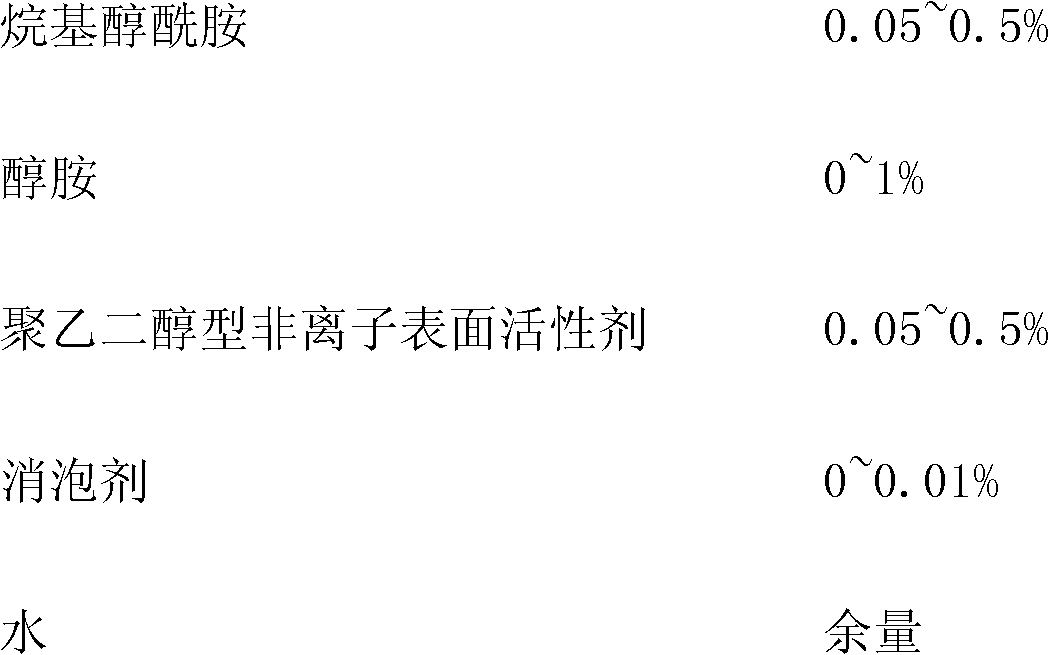

Waterborne cleaning agent and preparation method thereof

InactiveCN101624558AStrong degreasing abilityLow decontamination costNon-ionic surface-active compoundsDetergent materialsActive agentCorrosion

Owner:XINAN TOOLS GUIZHOU PROV

High-temperature-curing inorganic anticorrosive coating for automobile brake disc

InactiveCN110845877AStrong adhesionImprove anti-corrosion performanceAnti-corrosive paintsZinc phosphateFirming agent

The invention relates to the technical field of anticorrosive paint, in particular to high-temperature-curing inorganic anticorrosive coating for an automobile brake disc and a preparation method thereof. The inorganic anticorrosive coating comprises the following components in parts by mass: 40-45 parts of inorganic resin, 3-5 parts of modified zinc phosphate, 5-6 parts of composite ferrotitaniumpowder, 3-4 parts of a curing agent, 10-15 parts of water, 20-25 parts of talcum powder, 0.8-2 parts of dispersing agents, 0.5-0.8 part of a defoaming agent, 0.5-1 part of a neutralizing agent and 0.5-1 part of bentonite. According to the inorganic anticorrosive coating, on the premise that coating thickness is 30 microns, salt spray resistance time can reach 1000 hours, and adhesive force is good; different types of dispersing agents are selected, so the influence on the salt spray resistance of a paint film is very outstanding; a hydrophobic ammonium salt forms a good water-resistant film,and a sodium salt hydrophilic dispersing agent is low in relative molecular mass, so the water resistance and salt fog resistance of a coating film are reduced; and the polycarboxylate ammonium salt with a special structure and high relative molecular mass is selected as the dispersing agent, so the corrosion resistance of the coating is remarkably improved.

Owner:Jiangsu Jiunuo Architectural Materials Technology Co Ltd

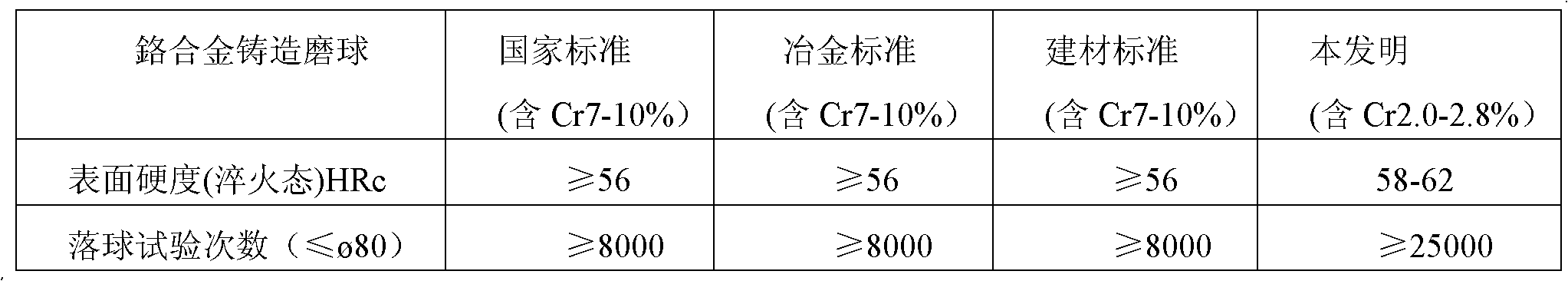

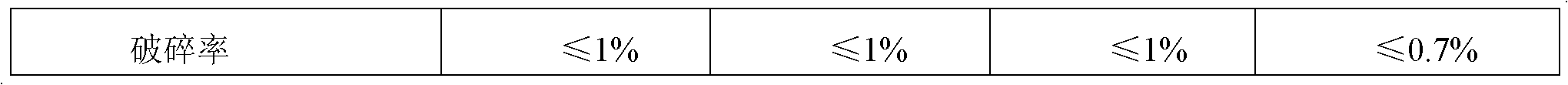

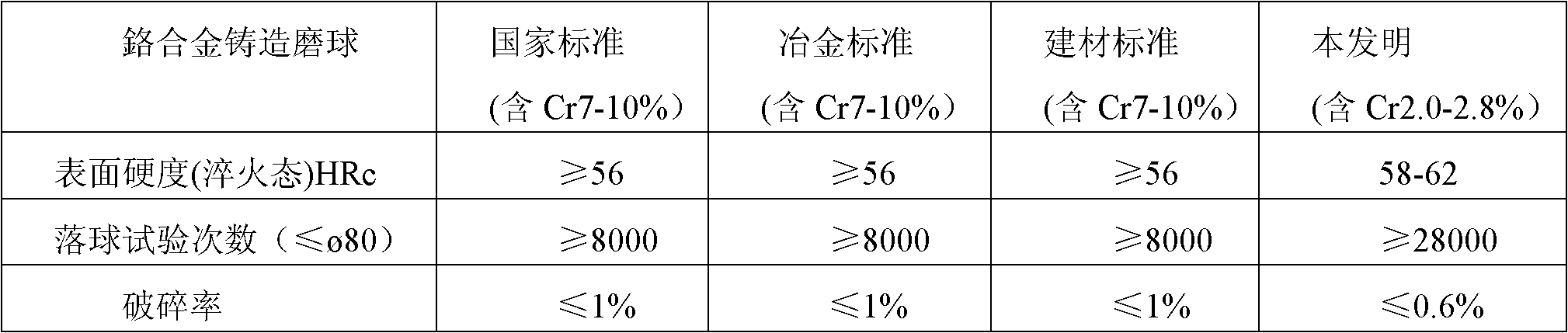

Oil quenching heat treatment process for high-hardness low-chromium multicomponent alloy casting ball

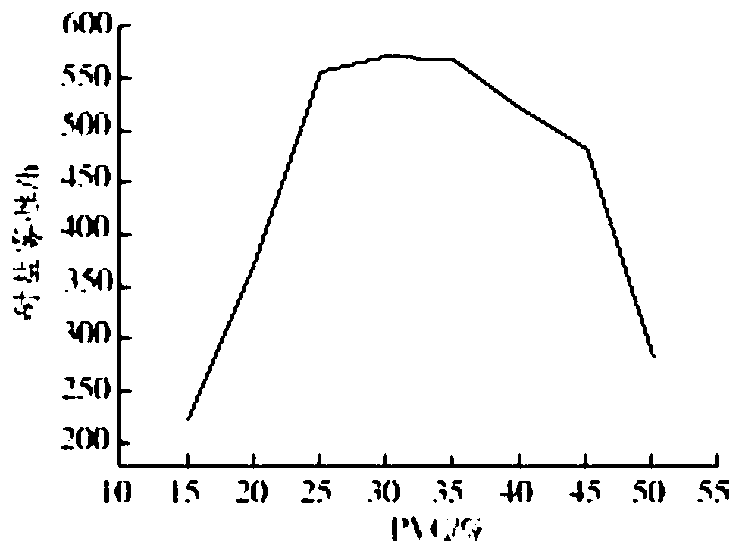

ActiveCN102560018AExtended service lifeWith anti-rust abilityQuenching agentsQuenching devicesOil coolingToughness

The invention discloses an oil quenching heat treatment process for high-hardness low-chromium multicomponent alloy casting ball. The high-hardness low-chromium multicomponent alloy casting ball contains the following components in percentage by weight: 1.5 to 2.0 percent of C, 0.3 to 1.0 percent of Mn, 2.0 to 2.8 percent of Cr, 0.78 to 0.80 percent of Si, 0.05 to 0.055 percent of Cu, less than or equal to 0.02 percent of S and less than or equal to 0.03 percent of P, wherein Fe is used as a substrate. The oil quenching heat treatment process comprises the following steps of: heating the high-hardness low-chromium multicomponent alloy casting ball to the temperature of between 950 and 1,050 DEG C, and keeping the temperature for 2 to 3 hours; performing oil cooling; after the surface temperature of the high-hardness low-chromium multicomponent alloy casting ball is reduced to be below 250 DEG C, taking the casting ball out of an oil sump, and stopping performing the oil cooling; and putting the casting ball into a tempering furnace for tempering, and after the tempering is finished, quenching the casting ball again. By the oil quenching heat treatment process, the problem of poor cast quality of the high-hardness low-chromium multicomponent alloy casting ball is solved, the casting ball does not have cracks, the hardness and toughness are improved, the antifatigue impact service life is prolonged, consumption is reduced, the ball crushing rate is low, a large number of chromium alloy resources of the country are saved, and the running cost of users is also reduced.

Owner:安徽纽亚达科技有限责任公司

Improved detersive and antirust cleaning solution

InactiveCN103668287AWide range of decontaminationGood cleaning effectSodium acid carbonateDichloromethane

The invention discloses an improved detersive and antirust cleaning solution. The cleaning solution is prepared from the following raw materials in parts by weight: 2.3-3.5 parts of dichloromethane, 2.3-5.7 parts of cosolvent, 2.5-3.7 parts of serine, 1.5-3.2 parts of sodium carbonate, 1.2-3.4 parts of pentaerythritol stearate, 4.5-6.5 parts of bleaching agent and 3.2-5.5 parts of octadecyl dihydroxyethyl amine oxide. The cleaning solution has the beneficial effects that the cleaning solution has wide degreasing and detergence ranges, can be separated from greasy dirt, has good cleaning effects, can be used for cleaning dirt such as lubricating oil, pressure oil, metalworking fluids, grinding fluid and the like on the surfaces of stainless steel, low carbon steel, aluminium and aluminium alloys, copper and copper alloys, high iron alloys, nickel alloys and the like, has strong cleaning capacity and high cleaning speed, can be reused, is pollution-free and has antirust capacity.

Owner:QINGDAO HUIERTONG TRADING

Improved detergent for metal equipment

The invention discloses an improved detergent for metal equipment. The detergent is prepared from the following raw materials in parts by weight: 1.5-3.7 parts of fatty acid polyoxyethylene ether, 2.5-3.8 parts of synthetic fatty acid triethanolamine salt, 2.3-3.6 parts of sulfolane, 7.5-8.6 parts of alkylphenol ethoxylates, 3.2-4.5 parts of adsorbent, 3.5-5.7 parts of deionized water, 6.2-8.4 parts of lauryl amine oxide, 3.4-5.3 parts of methylisothiazolone and 3.5-5.6 parts of sodium sulfosuccinate. The detergent can be easily rinsed, has the beneficial effects of extremely strong permeability, excellent oil removing performance, small additive usage, low cleaning cost, strong cleaning capability, high speed, repeated using availability, no pollution, rust resistance, good quality of workpiece surface, low treatment cost, simple preparation process, convenience in use, low bubble, high efficiency, no corrosion to metal surface, high stability and cleaning degree reinforcement, and has a popularization value.

Owner:QINGDAO KERUN PLASTIC MACHINERY

Metal zipper protective agent

InactiveCN105386022APrevent oxidationGood safety performanceMetallic material coating processesPotassium palmitateActive agent

The invention discloses a metal zipper protective agent. The metal zipper protective agent is prepared from, by weight, 12-24 parts of beewax, 6-10 parts of triethanolamine, 8-14 parts of ethylene glycol, 5-9 parts of sodium metasilicate, 4-7 parts of hydroxyl sodium sulfonate, 3-6 parts of linear alkylbenzene sulphonic acid, 1.5-3.2 parts of amino tri methylene phosphonic acid, 2-4 parts of surface active agent, 2-3.5 parts of oxyfluorfen, 2.5-3.4 parts of N-caprylyl pyrrolidone, 2-4 parts of p-toluenesulfonic acid, 3-6 parts of sodium hypophosphite, 0.5-1.2 parts of diazolidinyl urea, 2-3.5 parts of potassium palmitate, 2-3.2 parts of oxyfluorfen, 12-16 parts of lithium fluoride and 6-12 parts of aluminum nitride. The metal zipper protective agent has the beneficial effects that a zipper is effectively prevented from being oxidized and faded, a protective layer can be formed on the surface of the zipper, safety performance is good, and rust-prevention capability is achieved.

Owner:QINGDAO XIANGJIA INTPROP SERVICE CO LTD

Water-based metal cleaner

InactiveCN106757104AWide range of degreasing and decontaminationEasy to cleanSodium bicarbonateWater based

The invention discloses a water-based metal cleaner. The water-based metal cleaner is composed of the following raw materials: TX-10, AE0-9, AES, sodium bicarbonate, PPC, ethanol, ethylene glycol butyrate and water. The water-based metal cleaner disclosed by the invention has the following advantages: the product is capable of cleaning lubricating oil, pressure oil, metal machining liquid, grinding liquid and other dirt on the surfaces of stainless steel, low-carbon steel, aluminium and alloy thereof, copper and alloy thereof, high-iron alloy, nickel alloy and the like. (1) The product is wide in oil removal and decontamination range, capable of being separated from oil contamination and good in cleaning effect. (2) The product is high in cleaning capacity and speed. (3) The product can be repeatedly used, is pollution-free and has anti-rust capacity.

Owner:荆门市易轩表面处理科技有限公司

Composite cleaning agent for medical apparatuses and preparation method thereof

InactiveCN107937164AEasy to cleanImprove permeabilityInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsVegetable oilAdjuvant

The invention relates to a composite cleaning agent. Firstly, compound enzyme serving as the main agent composes a multi-enzyme cleaning component of the cleaning agent, and can achieve targeted cleaning of residual protein, organic matters and the like on medical apparatuses; secondly, a scale inhibitor serving as the adjuvant composes an organic cleaning component of the cleaning agent, and canachieve effective cleaning of mineral oil, animal and vegetable oil spot and the like on medical apparatuses; at the same time, inorganic base serving as the adjuvant on the one hand can provide an alkaline cleaning environment, and on the other hand, weak base composes an inorganic cleaning component in the cleaning agent, can achieve effective cleaning of inorganic matters on medical apparatuses, therefore, the multi-component compounded cleaning agent can realize efficient cleaning of medical apparatuses.

Owner:付一辰

Metal cleaning solution with rust-proof function

InactiveCN103668266AWide range of degreasing and decontaminationEasy to cleanEpoxyMetalworking fluid

The invention discloses a metal cleaning solution with a rust-proof function. The cleaning solution is prepared from the following raw materials in parts by weight: 3.4-5.2 parts of sodium dihydrogen citrate anhydrous, 1.5-4.3 parts of zinc stearate, 10-14 parts of 1,2-epoxy butane, 8.4-11.5 parts of benzotriazole, 4.3-7.5 parts of N-phosphonomethyl iminodiacetic acid, 2.3-3.5 parts of olive oil fatty acid, 4.2-5.5 parts of a dispersing agent, and 3.4-5.5 parts of sodium silicate. The metal cleaning solution with the rust-proof function has the benefits as follows: the scope of removing oil and dirt is wide, the metal cleaning solution can be separated from oil stain, the cleaning effect is good, the metal cleaning solution can be used for cleaning dirt such as lubricating oil, pressure oil, metal working fluid, grinding fluid and the like on the surfaces of stainless steel, low-carbon steel, aluminum and aluminum alloy, copper and copper alloy, high ferroalloy, nickel alloy and the like, the cleaning capability and the cleaning speed are high, and the metal cleaning solution can used repeatedly, is pollution free and has rust prevention capability.

Owner:QINGDAO CHENXUTONG COMMERCE & TRADE

Oil quenching heat treating process for low chrome multielement alloy cast balls

InactiveCN102560019AExtended service lifeWith anti-rust abilityFurnace typesQuenching agentsCold treatmentManganese

The invention discloses an oil quenching heat treating process for low chrome multielement alloy cast balls. The main constituents of the low chrome multielement alloy cast balls includes, by weight percentage, C (carbon) 1.5-2.0, Mn (manganese):0.3-1.0, Cr (chromium):2.0-2.8, S (sulphur): <=0.02, P (phosphorus) : <=0.03, and the matrix iron. The heat treating process includes heating as-cast low chrome multielement alloy cast balls to 950-1000 DEG C, subjecting the cast balls to an oil cold treatment after 2-3 hours of heat insulation, when the surface temperature of the as-cast low chrome multielement alloy cast balls is reduced below 250 DEG C, removing the product from an oil pool, stopping the oil cold treatment, subjecting the product to a tempering treatment in a tempering furnace, and subjecting the cast balls to a quenching treatment again after the tempering treatment. The oil quenching heat treating process solves the problem of poor quality in use of the low chrome multielement alloy cast balls in the as cast condition. By means of the oil quenching heat treating process, the products have no cracks; rigidity, toughness and anti-fatigue impact life are increased, consumption is reduced, ball crushing rate is low, a mass of chromium alloy resources are saved and operating cost is reduced for users.

Owner:安徽纽亚达科技有限责任公司

Metal cleanout fluid containing zinc stearate

InactiveCN105401156AWide range of degreasing and decontaminationEasy to cleanMetalworking fluidSS - Stainless steel

The invention discloses metal cleanout fluid containing zinc stearate. The metal cleanout fluid comprises, by weight, 3.4-5.2 parts of rosin glyceride polyoxyethylene ether, 1.5-4.3 parts of the zinc stearate, 10-14 parts of 1,2-epoxybutane, 8.4-11.5 parts of magnesium oxide, 4.3-7.5 parts of N- amino acetic acid phosphine glycolate heartland, 2.3-3.5 parts of olive oil fatty acid, 4.2-5.5 parts of a dispersing agent and 3.4-5.5 parts of dodecyl dimethyl betaine. The metal cleanout fluid has the beneficial effects that the oil removal scope is wide, the metal cleanout fluid can be separated from oil contamination, and the cleaning effect is good; dirt such as lubricating oil, pressure oil, metal working fluid and grinding fluid on surfaces of stainless steel, low-carbon steel, aluminum and aluminum alloys, copper and copper alloys, high-iron alloys, nickel alloys and the like can be cleaned; and the cleaning capacity is high, and the speed is high; and the metal cleanout fluid can be repeatedly used, is free of pollution, and has the anti-rusting capacity.

Owner:宁贻伟

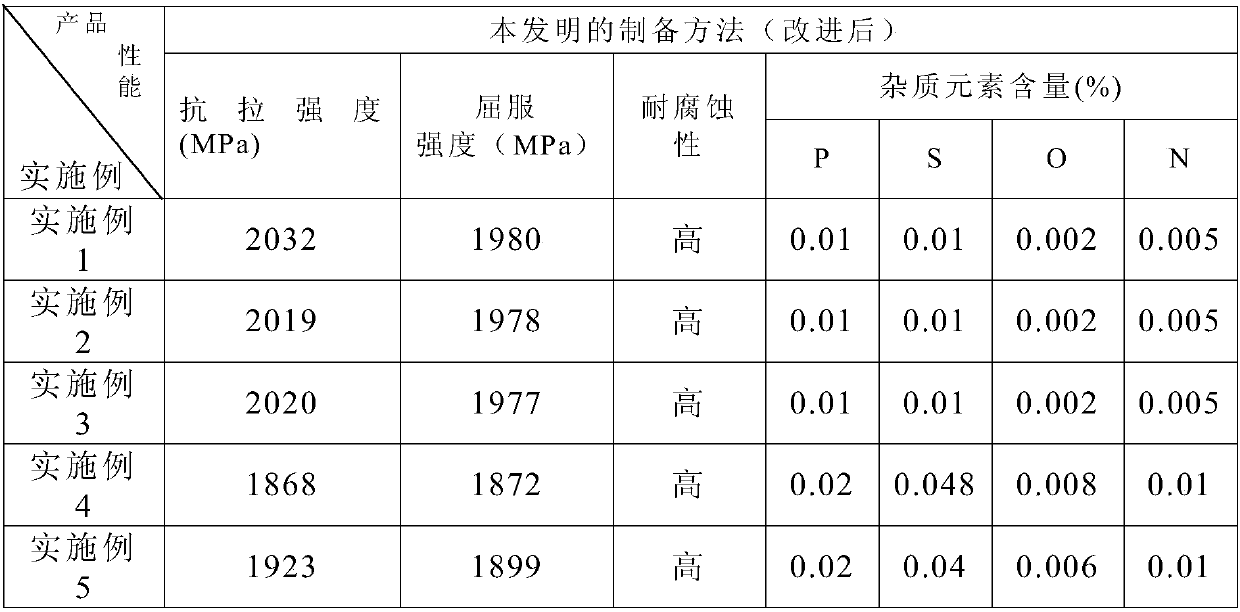

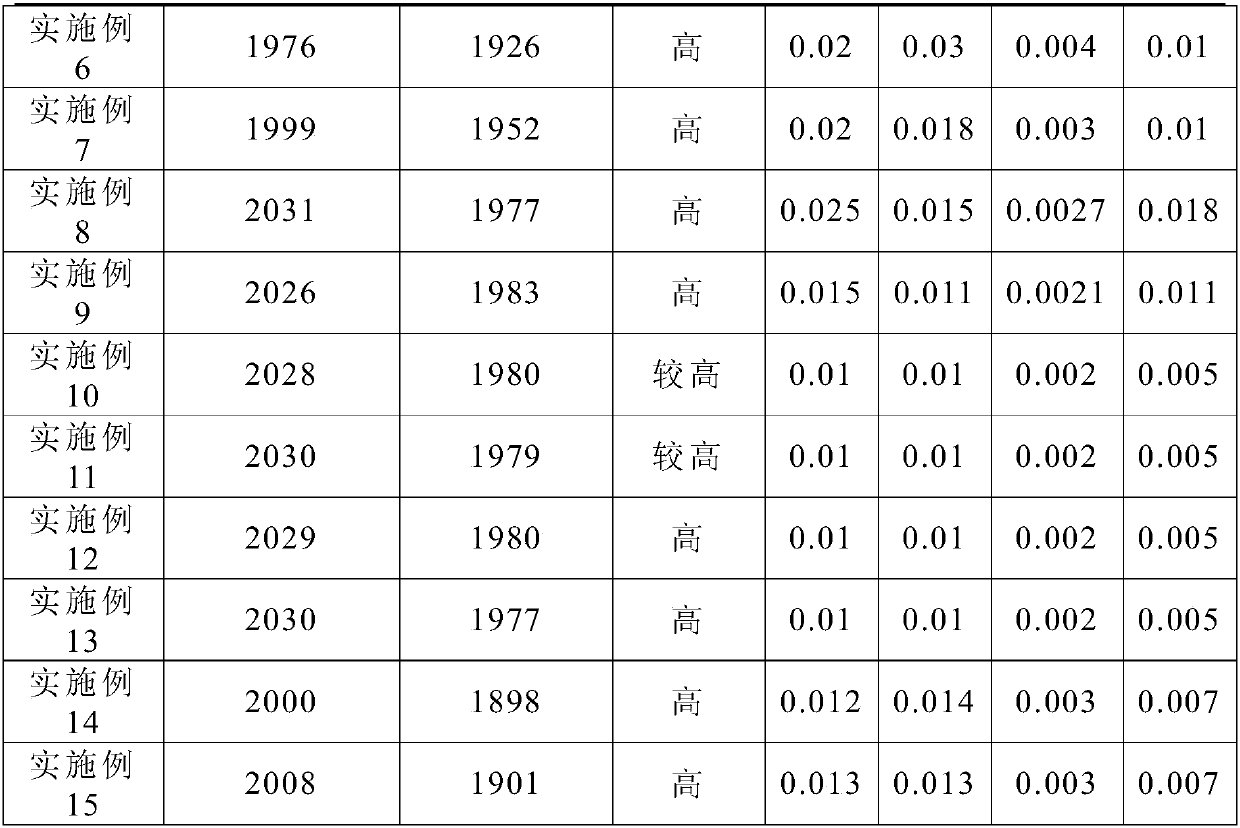

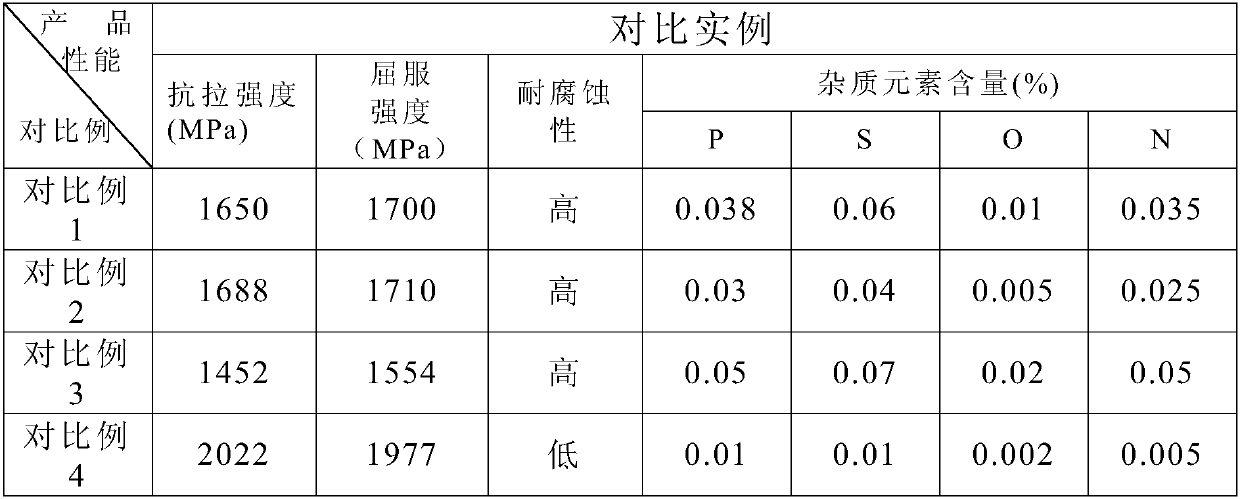

Engine cooling water pipe and preparing process thereof

ActiveCN107604264AUniform densityDiffusion distance is shortSolid state diffusion coatingMachines/enginesUltimate tensile strengthToughness

The invention discloses an engine cooling water pipe and a preparing process thereof, and belongs to the technical field of powder metallurgy. The engine cooling water pipe comprises, by percentage composition, 0.2%-2% of Be, 0.3%-0.6% of Zr, 0.01%-0.1% of C, 0.4%-0.8% of Si, 0.5%-1% of Cr, 2%-4% of Ni and the balance Fe and impurities. By means of the Be and the Zr in raw materials, the contentsof impurity elements including P, S, O and N in the product can be greatly reduced, and steel tools can be higher in temperature strength, creep property and low temperature toughness. Meanwhile, in cooperation with a powder coating process, the Ni is evenly distributed in a shallow layer of steel, the even microscopic structure is easily obtained during sintering, and improving of the corrosion resistance of the product is facilitated.

Owner:宁波名古屋工业有限公司

Antirust material applied to bead wire and preparation method thereof

The invention relates to a rust-proof material applied to a tire bead wire. The rust-proof material is characterized by comprising an abrasion-resistant layer, a seepage-proof layer, a volatilization layer and a protective layer; the abrasion-resistant layer is the outermost layer and is a polyurethane film layer; the thickness of the polyurethane film layer is 35-40 [mu]m; the volatilization layer is a non-woven layer; and the thickness of the non-woven layer is 60-80 [mu]m. The invention further provides a preparation method of the rust-proof material applied to the tire bead wire. The preparation method comprises the coating step, specifically, a rust-proof agent solution is uniformly coated on non-woven cloth; and in the coating step, the coating quantity is 15-20 / g.m<-2>. According to the rust-proof material prepared through the preparation method, special protection can be formed on the rust-proof material; premature aging of a rust-proof film is prevented; the service life of the rust-proof film is prolonged; and after being damaged, the rust-proof material prepared through the preparation method still has a long-time rust-proof capacity.

Owner:SHANDONG DAYE

Improved multi-functional detergent

The invention discloses an improved multi-functional detergent. The improved multi-functional detergent is prepared from the following raw materials in parts by weight: 6.2-8.4 parts of methyl silicone oil, 5.2-8.7 parts of aspartic acid, 5.5-7.5 parts of vegetable oil methyl ester, 2.8-4.5 parts of hydroxymethyl cellulose sodium, 4.2-5.3 parts of fatty acid diethanolamide, 4.5-5.6 parts of sodium pyrophosphate, 1.3-2.5 parts of cleaning additive and 1.8-4.5 parts of a defoaming agent. The improved multi-functional detergent has an excellent cleaning effect, no pollution and rust resistance, can be repeatedly utilized and can be widely applied in cleaning of bearings, tractors, automobiles, metal devices and parts in construction machinery, aerospace machinery, textile machinery, chemical machinery and the like.

Owner:王璐

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com