Antirust material applied to bead wire and preparation method thereof

A technology of anti-rust material and bead steel wire, which is applied in the field of anti-rust material and its preparation, can solve the problems of easy oxidation of anti-rust film, insufficient anti-rust time, and discount of anti-rust effect, so as to improve anti-oxidation ability, Prolong anti-rust time and prevent premature aging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

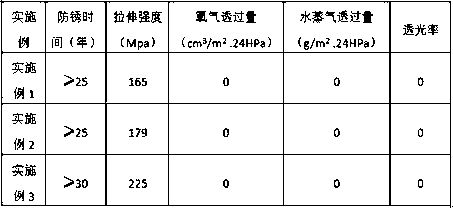

Embodiment 1

[0040] An antirust material applied to bead steel wires, including an anti-wear layer, an anti-seepage layer, a volatile layer and a protective layer.

[0041] The anti-wear is the outermost layer, which is a polyurethane film layer; the thickness of the polyurethane film layer is 35-40 μm;

[0042] The permeable layer is an ordinary PVC film, sold; the anti-wear layer and the anti-seepage layer are heat-pressed together by heat-sensitive adhesive;

[0043] The volatile layer is a non-woven fabric layer; the thickness of the non-woven fabric layer is 60-80 μm; the non-woven fabric is coated;

[0044] Both sides of the non-woven fabric layer are coated with PU foam glue; the PU foam glue is produced by Guangzhou Zhengguanghe New Building Materials Co., Ltd. and is commercially available;

[0045] The PU foam glue is mixed with 16% antirust agent solution;

[0046] The protective layer is a protective tear film and a PE antirust film; the protective tear film and the PE antiru...

Embodiment 2

[0063] An antirust material applied to bead steel wires, including an anti-wear layer, an anti-seepage layer, a volatile layer and a protective layer.

[0064] The anti-wear is the outermost layer, which is a polyurethane film layer; the thickness of the polyurethane film layer is 35-40 μm;

[0065] The permeable layer is an ordinary PVC film, sold; the anti-wear layer and the anti-seepage layer are heat-pressed together by heat-sensitive adhesive;

[0066] The volatile layer is a non-woven fabric layer; the thickness of the non-woven fabric layer is 60-80 μm; the non-woven fabric is coated;

[0067] Both sides of the non-woven fabric layer are coated with PU foam glue; the PU foam glue is produced by Guangzhou Zhengguanghe New Building Materials Co., Ltd. and is commercially available;

[0068] The PU foam glue is mixed with 18% antirust agent solution;

[0069] The protective layer is a protective tear film and a PE antirust film; the protective tear film and the PE antiru...

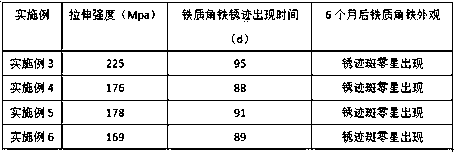

Embodiment 3

[0086] An antirust material applied to bead steel wires, including an anti-wear layer, an anti-seepage layer, a volatile layer and a protective layer.

[0087] The anti-wear is the outermost layer, which is a polyurethane film layer; the thickness of the polyurethane film layer is 35-40 μm;

[0088] The permeable layer is an ordinary PVC film, sold; the anti-wear layer and the anti-seepage layer are heat-pressed together by heat-sensitive adhesive;

[0089] The volatile layer is a non-woven fabric layer; the thickness of the non-woven fabric layer is 60-80 μm; the non-woven fabric is coated;

[0090] Both sides of the non-woven fabric layer are coated with PU foam glue; the PU foam glue is produced by Guangzhou Zhengguanghe New Building Materials Co., Ltd. and is commercially available;

[0091] 17% rust inhibitor solution is mixed in the PU foam

[0092] The protective layer is a protective tear film and a PE antirust film; the protective tear film and the PE antirust film ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com