Manual reversing valve for ship

A manual reversing valve, marine technology, applied in valve details, multi-port valves, valve devices, etc., can solve the problems of weak anti-rust ability handle impact resistance, steering mechanism corrosion and stuck, etc., to achieve easy batch production operation and Production and processing, low rotational friction, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

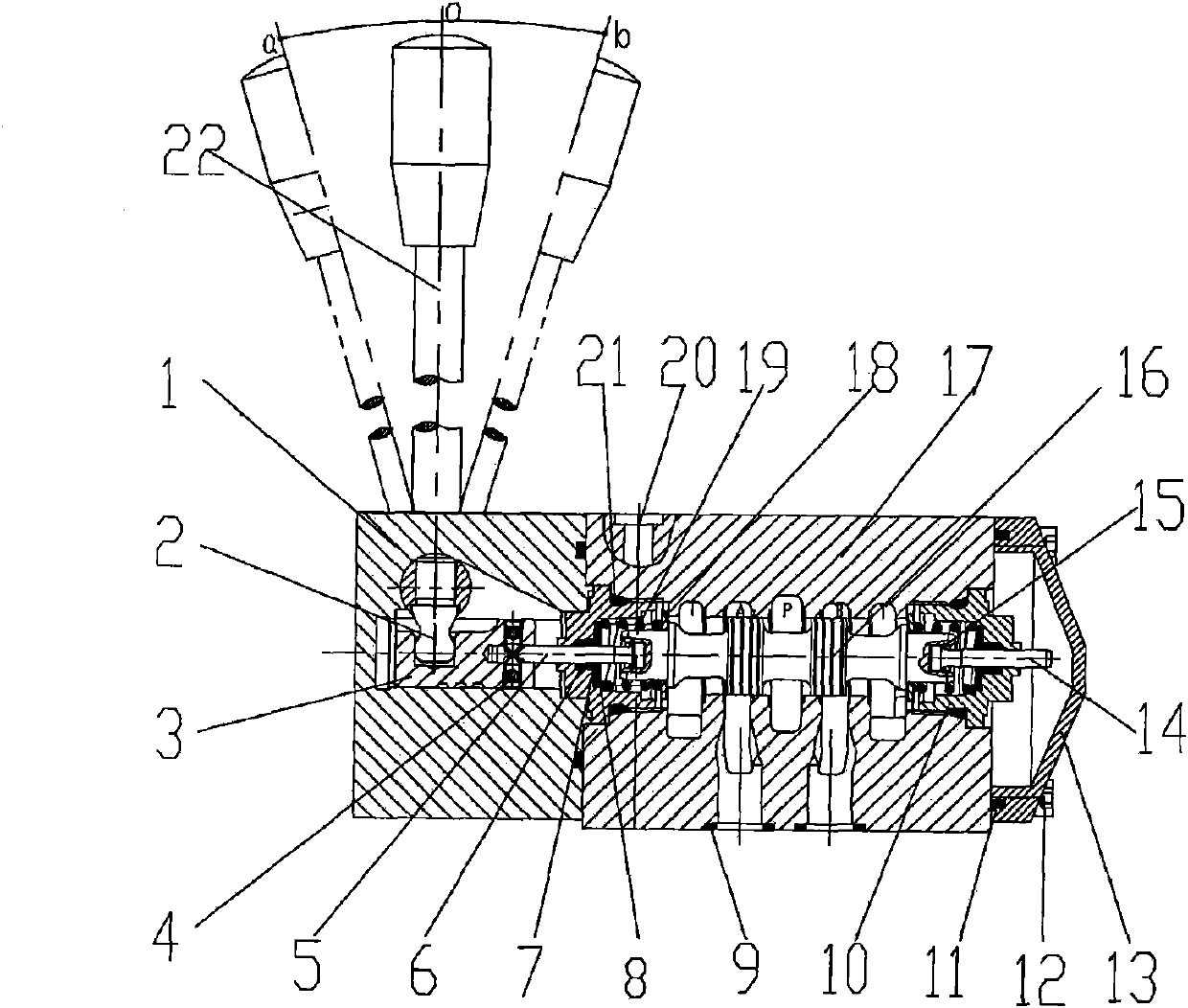

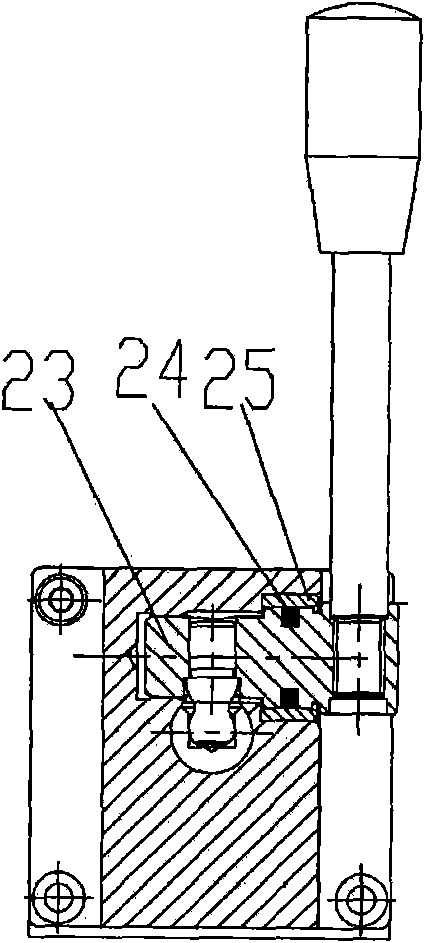

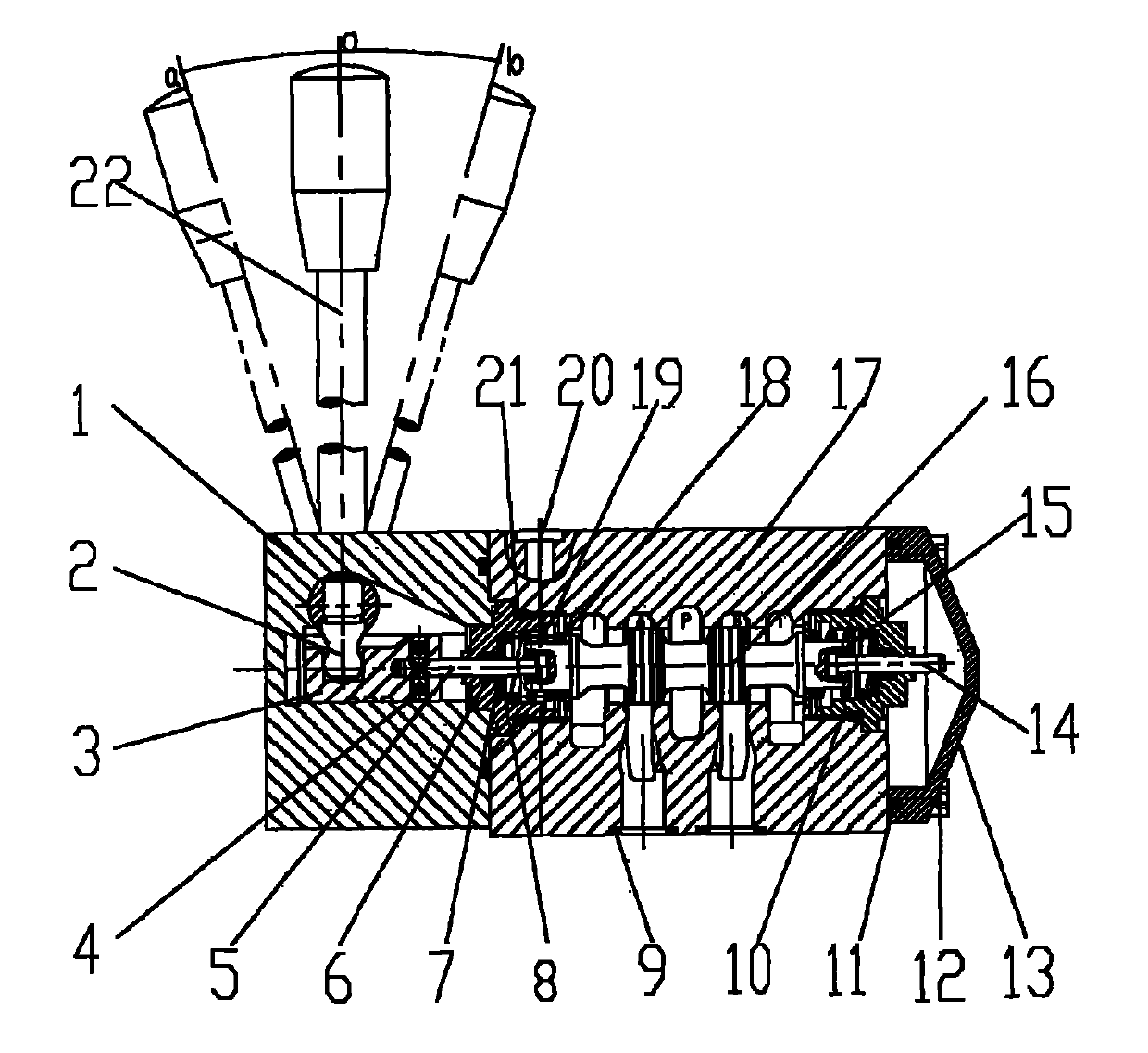

[0015] see figure 1 , figure 2 , a manual reversing valve. The oil passages are switched on and off mainly through the rotation of the handle 22, so as to realize the required functions. The effective gap between the valve body 17 and the spool 16 ensures the reliability of the movement of the spool 16 . A retaining ring 18 and a spring 19 are arranged at both ends of the valve core 16, the end face screw cap 10 is threadedly connected with the valve body 17 and sealed by a seal ring 21, and the pin shafts 5, 14 pass through the through hole of the end face screw plug 10 and the push Rod 3 is connected, and the short pin shaft 14 one end of right end is connected with spool 16 and the other end is vacantly sleeved in the end face screw cap 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com