Cantilever frame system

A suspension frame and I-beam technology, applied in the field of suspension frame system, can solve the problems of insufficient shock resistance and rust resistance, inconvenient installation and disassembly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

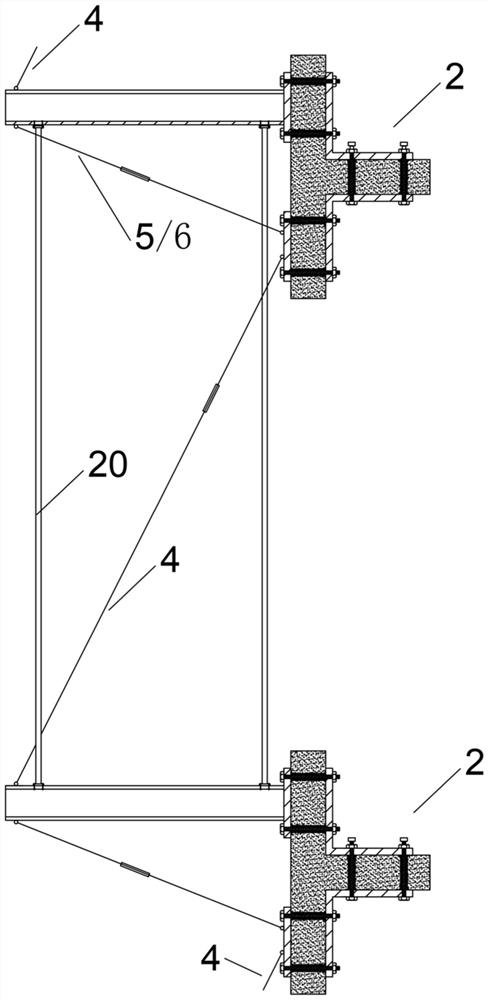

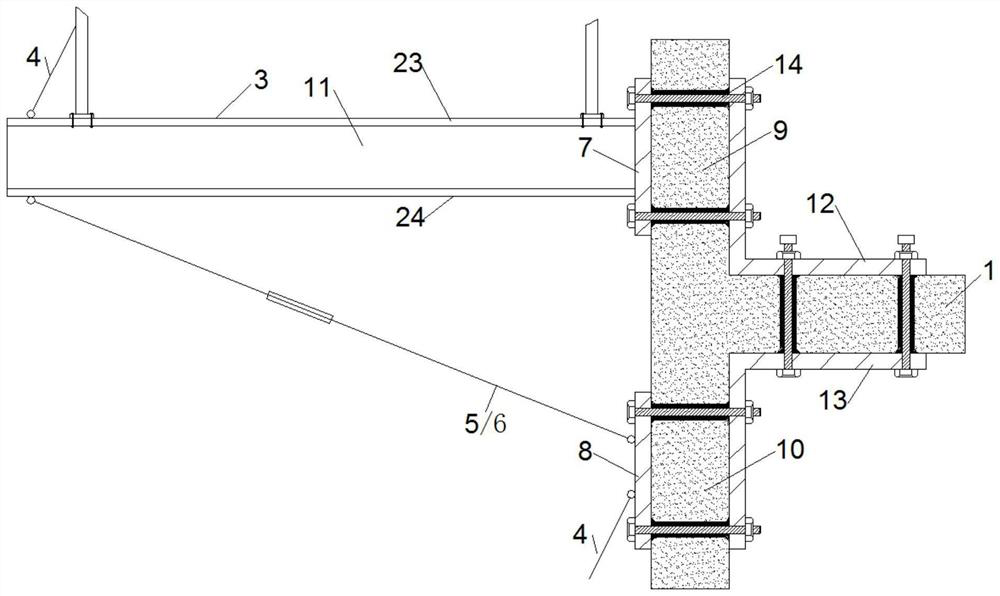

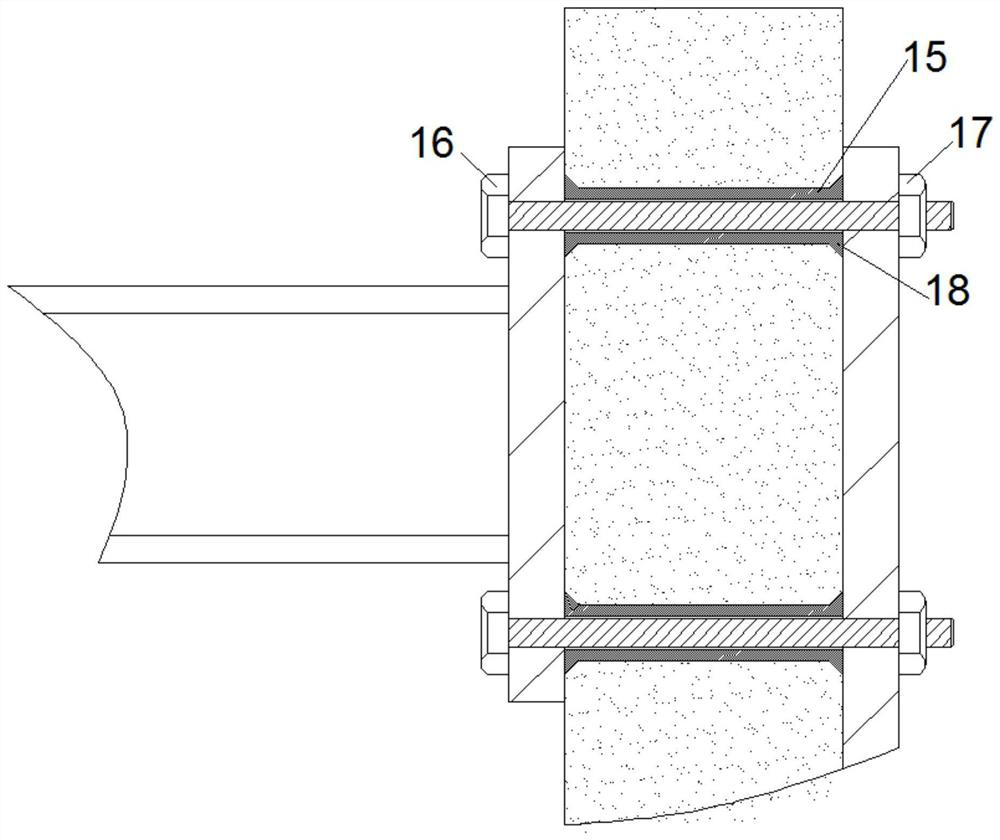

[0026] See attached Figure 1-7 . A cantilever frame system, including several cantilever frame assemblies 2 corresponding to the floor 1 one-to-one; , an upper seat 7 and a lower seat 8; the rear end of the I-beam 3 is provided with an upper seat 7; the upper seat 7 is fixed on the outside of the upper side wall 9 adjacent to the floor 1; the lower seat 8 is fixed on the adjacent wall 1 The outer side of the lower side wall 10; the two ends of the upper pull rod 4 are respectively connected to the I-beam 3 and the lower seat 8 of the cantilever frame assembly 2 above the corresponding cantilever frame assembly 2 of the I-beam 3, for giving the I-beam Steel 3 provides the pulling force on the upper rear; the two ends of the lower left support rod 5 and the lower right support rod 6 are respectively connected to the I-beam 3 and the lower seat 8; the lower left support rod 5 and the lower right support rod 6 are about the The vertical plate 11 of 3 is symmetrically arranged, ...

Embodiment 2

[0028] See attached Figure 1-7 . A cantilever frame system, including several cantilever frame assemblies 2 corresponding to the floor 1 one-to-one; , an upper seat 7 and a lower seat 8; the rear end of the I-beam 3 is provided with an upper seat 7; the upper seat 7 is fixed on the outside of the upper side wall 9 adjacent to the floor 1; the lower seat 8 is fixed on the adjacent wall 1 The outer side of the lower side wall 10; the two ends of the upper pull rod 4 are respectively connected to the I-beam 3 and the lower seat 8 of the cantilever frame assembly 2 above the corresponding cantilever frame assembly 2 of the I-beam 3, for giving the I-beam Steel 3 provides the pulling force on the upper rear; the two ends of the lower left support rod 5 and the lower right support rod 6 are respectively connected to the I-beam 3 and the lower seat 8; the lower left support rod 5 and the lower right support rod 6 are about the The vertical plate 11 of 3 is symmetrically arranged, ...

Embodiment 3

[0031] See attached Figure 1-7 . A cantilever frame system, including several cantilever frame assemblies 2 corresponding to the floor 1 one-to-one; , an upper seat 7 and a lower seat 8; the rear end of the I-beam 3 is provided with an upper seat 7; the upper seat 7 is fixed on the outside of the upper side wall 9 adjacent to the floor 1; the lower seat 8 is fixed on the adjacent wall 1 The outer side of the lower side wall 10; the two ends of the upper pull rod 4 are respectively connected to the I-beam 3 and the lower seat 8 of the cantilever frame assembly 2 above the corresponding cantilever frame assembly 2 of the I-beam 3, for giving the I-beam Steel 3 provides the pulling force on the upper rear; the two ends of the lower left support rod 5 and the lower right support rod 6 are respectively connected to the I-beam 3 and the lower seat 8; the lower left support rod 5 and the lower right support rod 6 are about the The vertical plate 11 of 3 is symmetrically arranged, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com