Environment-friendly type cleaning water cutting agent and preparation method thereof as well as displacer for same

An environmentally friendly, replacement agent technology, applied in the field of chemical cleaning, can solve problems such as residues and affecting appearance, and achieve the effects of prolonging service life, easy access, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

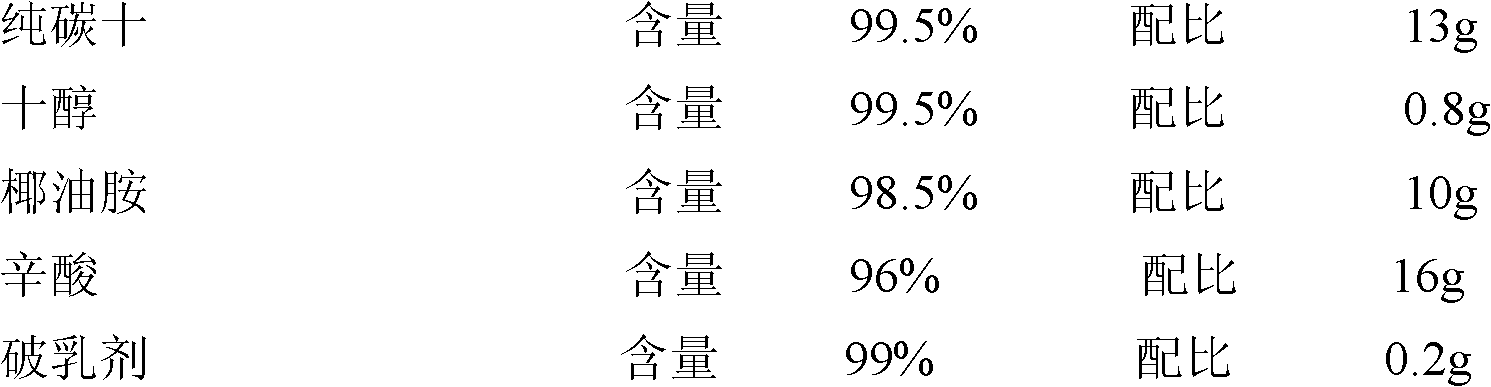

[0027] A displacing agent used for cleaning water cutting agent, its composition and weight are as follows:

[0028]

[0029] The demulsifier is polyether polyol.

[0030] The demulsifier is a commercially available product. The manufacturer is Shandong Bluestar Dongda Co., Ltd., model EP553

[0031] An environmentally friendly cleaning water cutting agent, its composition and weight are as follows: (take 1000g product as an example):

[0032] Pure carbon ten content 99.5% ratio 960g

[0033] Displacer 40g

[0034] The steps of a preparation method of an environment-friendly cleaning water cutting agent are as follows:

[0035] (1) Preparation of displacing agent: Add 13g of hydrocarbon solvent into reaction kettle A, add 0.8g of decanol and 10g of cocoamine and stir evenly, slowly add 16g of octanoic acid under stirring, and keep the temperature at 40°C-50°C for 2 hours , Add 0.2g of demulsifier and stir evenly to be the replacement agent.

[0036] (2) Preparation of ...

Embodiment 2

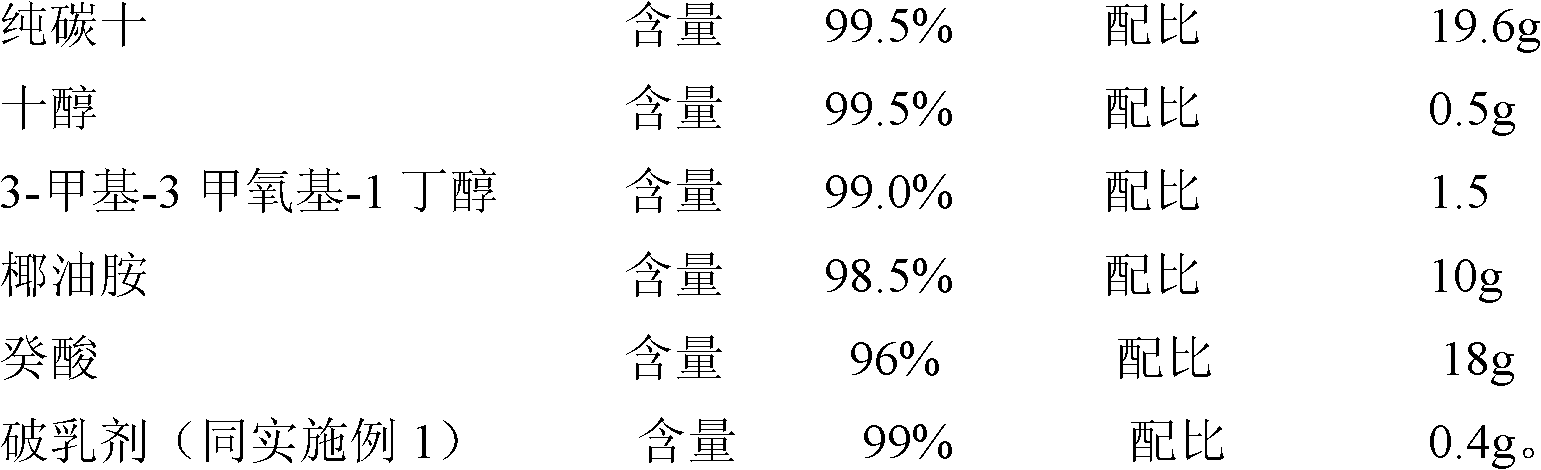

[0038] A displacing agent used for cleaning water cutting agent, its composition and weight are as follows:

[0039] Displacer composition

[0040]

[0041] An environmentally friendly cleaning water cutting agent, its composition and weight are as follows: (take 1000g product as an example):

[0042] Isoparaffins of carbon ten: content 99.5% ratio 950g

[0043] Replacement agent: Proportion 50g.

[0044] The steps of its preparation method are the same as in Example 1.

[0045] Mechanism of action of the present invention:

[0046] A new surface-active substance is formed by the reaction of film-forming amine and organic carboxylic acid, which has a strong adsorption force on the metal surface. Under the synergistic action of alcohol and ether substances, the water on the metal surface is squeezed into the solvent, and the water Beads strip off quickly. The demulsifier makes the oil and water separate quickly, and the water quickly rolls down to the bottom of the solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com