Water-based normal-temperature rustproof spray cleaning agent and preparation method thereof

A cleaning agent, room temperature technology, used in water-based room temperature antirust spray cleaning agent and its preparation, in the field of antirust cleaning agent, it can solve the problems of workpieces failing to meet cleaning quality standards, no antirust effect, and corrosion of parts , to achieve the effect of easy access, protection against corrosion, and low usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

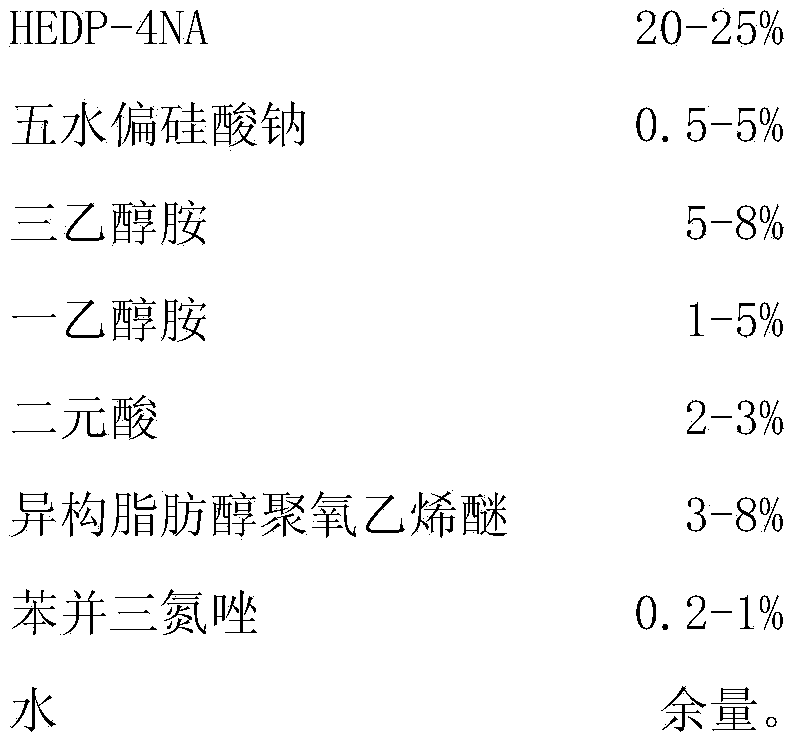

[0020] A water-based normal temperature anti-rust spray cleaning agent, its raw material composition and weight percentage are respectively:

[0021]

[0022] A preparation method of a water-based normal temperature anti-rust spray cleaning agent, the steps are as follows:

[0023] (1) Add the reaction amount of water into the reaction kettle, add the reaction amount of HEDP-4NA and sodium metasilicate pentahydrate at 25-40°C, keep the reaction for 20 minutes, then add the surfactant H-381 to keep the reaction for 20 minutes Minutes to get solution A;

[0024] (2) Add triethanolamine, monoethanolamine, dibasic acid, and benzotriazole to the reaction kettle until the reaction is complete. During the reaction, keep the temperature of the reaction kettle at 40-60°C and keep stirring for 3 hours until the solution is clear and transparent. Get solution B;

[0025] (3) The above two solutions A and B are mixed and reacted to a transparent liquid, which becomes a normal tempera...

Embodiment 2

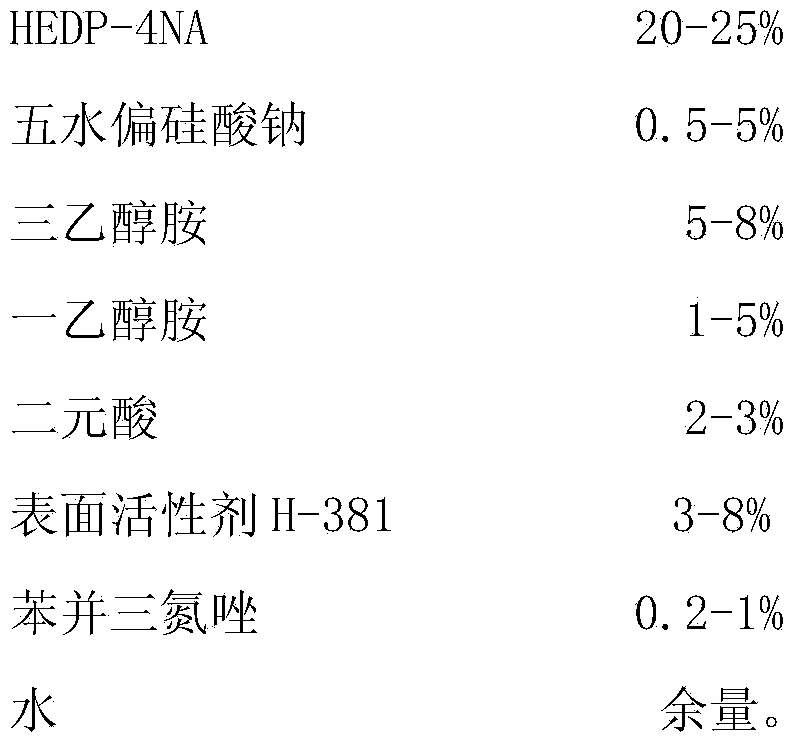

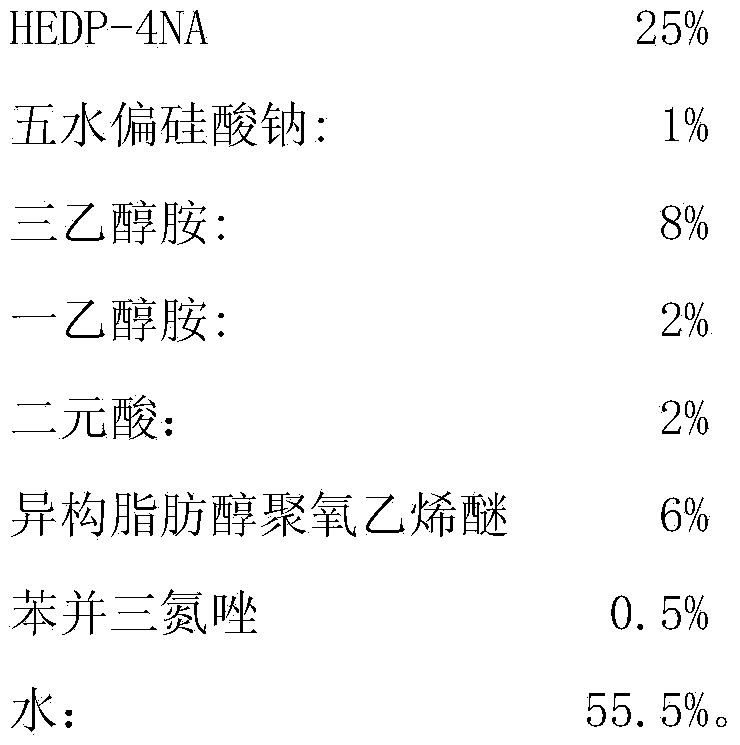

[0029] A water-based normal temperature anti-rust spray cleaning agent, its raw materials and weight percentages are respectively:

[0030]

[0031] The preparation method of this embodiment is the same as that of Example 1.

[0032] Application example: the concentration of the first tank according to the ratio of water and normal temperature anti-rust spray cleaning agent 20:1 (add the normal temperature anti-rust spray cleaning agent of Example 2), the normal temperature anti-rust spray cleaning agent of Example 2 and water Put the metal parts to be cleaned (aluminum, copper and assemblies) in the spray cleaning equipment, adjust the spray pressure to 0.3MPa, control the cleaning temperature at 25-30°C, and adjust the running speed of the spray cleaning equipment assembly line , start spray cleaning, so that the effective spray time of metal parts is controlled at 2 minutes, and the second tank is sprayed and rinsed with clean water for 2 minutes, and then dried with hot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com