Steel/cast iron metal protective agent and preparation method thereof

A metal protective agent, cast iron technology, applied in the direction of metal material coating technology and other directions, can solve the problems of undiscovered patent documents and other problems, and achieve the effects of easy acquisition, long rust prevention time, and dense film formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

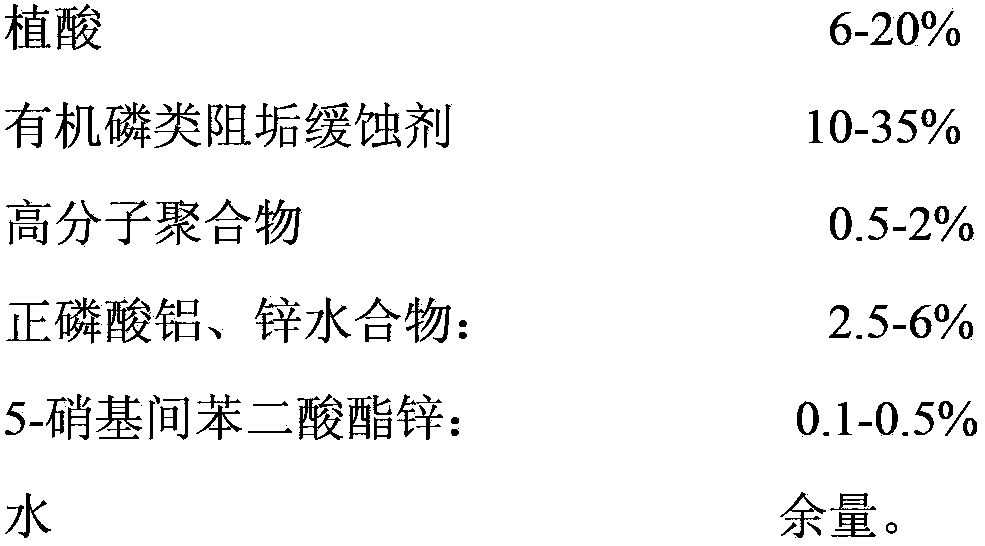

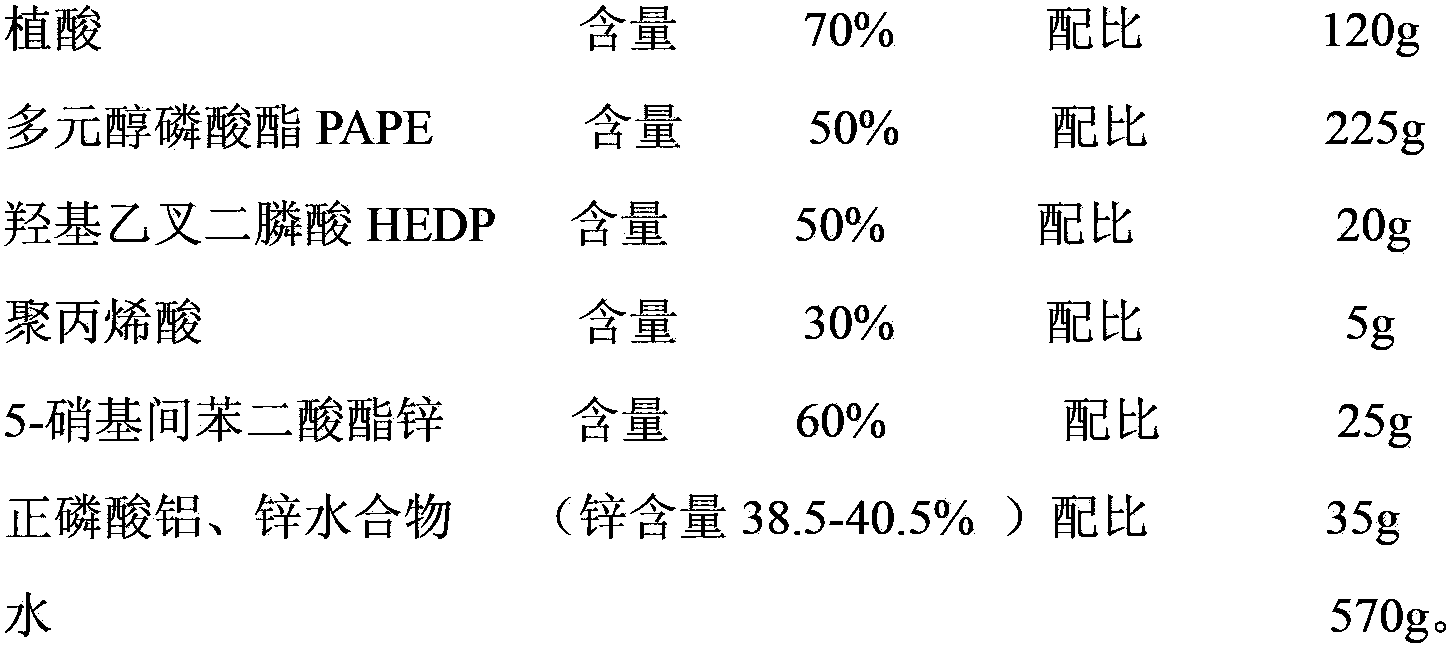

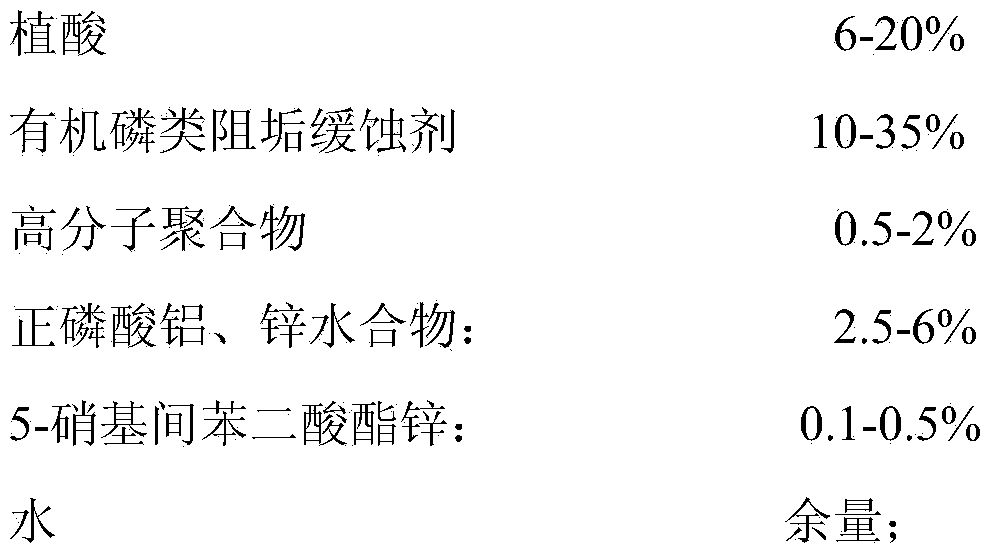

[0021] A steel / cast iron metal protective agent, its composition and weight are as follows: (take 1000g product as an example)

[0022]

[0023] A preparation method of steel / cast iron metal protective agent, the steps are as follows:

[0024] ⑴Pump phytic acid, polyol phosphate PAPE, hydroxyethylidene diphosphonic acid HEDP, and polyacrylic acid into the reactor according to the ratio and stir evenly;

[0025] ⑵ Mix aluminum orthophosphate, zinc hydrate and zinc 5-nitroisophthalate in turn according to the ratio, and stir for 60-120 minutes until the materials are completely dissolved, which is the steel / cast iron metal protective agent.

[0026] Quality Standard:

[0027] Appearance: translucent liquid (there is a small amount of sediment on the long-term substrate);

[0028] Specific gravity: 1.14g / ml;

[0029] pH (4%): 3-4

[0030] Copper sulfate spot etching time (4% solution, soak for 10 seconds) ≥ 90s

[0031] Mechanism of action of the present invention:

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com