Environmental protection water base dewaxing agent and preparation method thereof

A dewaxing agent and water-based technology, applied in chemical instruments and methods, detergent compounding agents, detergent compositions, etc., can solve problems such as environmental pollution, high toxicity, and ozone layer destruction, and achieve simple preparation methods and effective mechanisms The effect of simple science and a wide range of raw material sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The raw materials in the examples of the present invention are all commercially available raw materials.

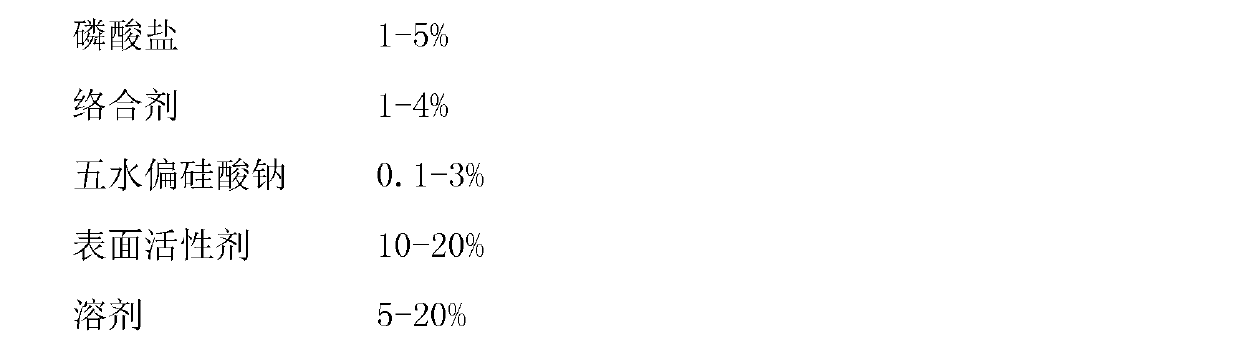

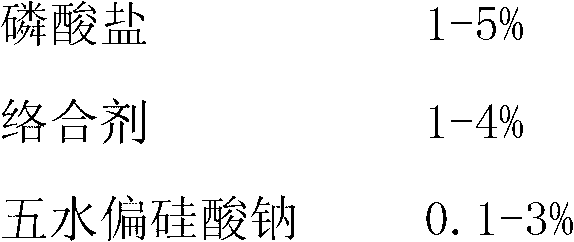

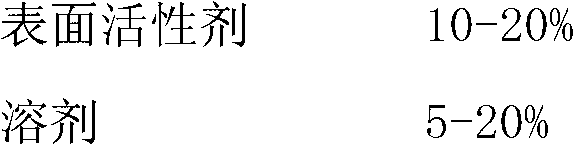

[0030] An environmentally friendly water-based dewaxing agent, the composition of which is (taking 1000g of water-based dewaxing agent as an example):

[0031] Potassium pyrophosphate: ratio 30g;

[0032] EDTA-4Na: Proportion 20g;

[0033] Sodium Metasilicate Pentahydrate: Proportion 5g

[0034] The total alkali content of sodium metasilicate pentahydrate (calculated as Na2O) is 28.5-30.5%;

[0035] TX-10: Proportion 70g;

[0036] FMEE: Proportion 70g;

[0037] Isopropyl alcohol: ratio 30g;

[0038] Diethylene glycol ether: ratio 100g;

[0039] Distilled water: The ratio is 675g.

[0040] The steps of a preparation method of a water-based dewaxing agent are as follows:

[0041] (1) Add distilled water into the reaction kettle, add solid materials such as phosphate, complexing agent and sodium metasilicate pentahydrate in the reaction amount, and stir for 20...

Embodiment 2

[0045] The composition of a water-based dewaxing agent is (take 1000g of water-based rust inhibitor as an example):

[0046] Sodium tripolyphosphate: ratio 15g;

[0047] EDTMPS: Proportion 40g;

[0048] Sodium Metasilicate Pentahydrate: Proportion 10g

[0049] The total alkali content of sodium metasilicate pentahydrate (calculated as Na2O) 28.5-30.5%;

[0050] AEO-9: Proportion 50g;

[0051] FMEE: Proportion 60g;

[0052] Isopropyl alcohol: ratio 40g;

[0053] Ethylene glycol butyl ether: ratio 80g;

[0054] Distilled water: The ratio is 705g.

[0055] The steps of its preparation method are the same as those in Example 1.

[0056] The action mechanism of the present invention: through the rational compounding of various surfactants, solvents, alkaline additives and complexing agents, the purpose of removing oil, wax and metal oxides can be achieved. Relying on the emulsification and stripping of surfactants; the dissolution of solvents, the penetration, dissolution a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com