Protective agent for copper and copper alloy and preparation method thereof

A copper alloy and protective agent technology, applied in the field of protective agent and metal protective agent, can solve the problems of unsatisfactory passivation effect, flow marks on the surface, high passivation temperature, etc., and achieve easy acquisition, best corrosion resistance effect, and preparation The effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] A preparation method for copper and copper alloy protective agent, the steps are as follows:

[0042] ⑴First make the semi-finished product H-01, the preparation method is as follows:

[0043] Add water to a reaction kettle, add potassium hydroxide, add tribasic carboxylic acid N485 under stirring, and maintain the temperature at 40-50°C for 2 hours, stop stirring and let stand for 24 hours before use;

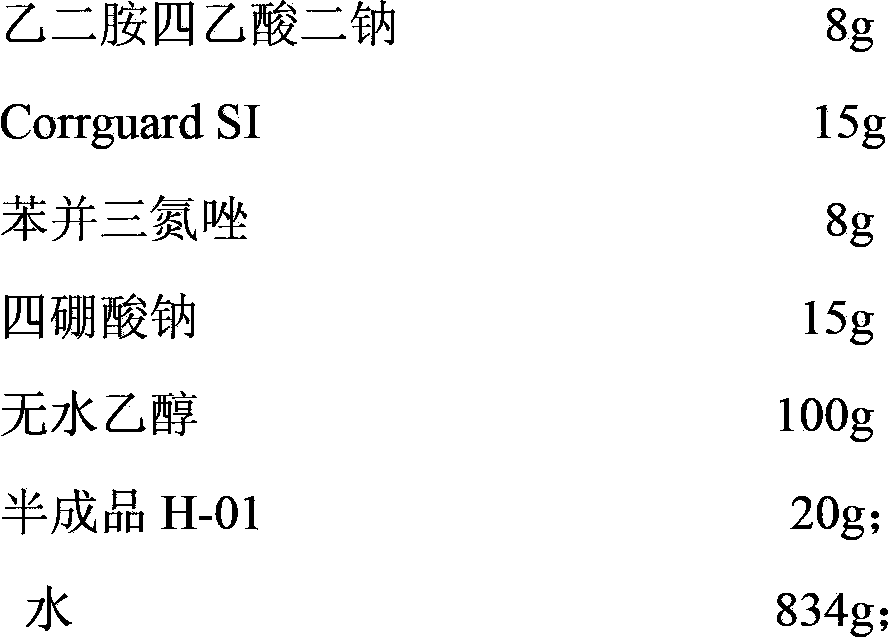

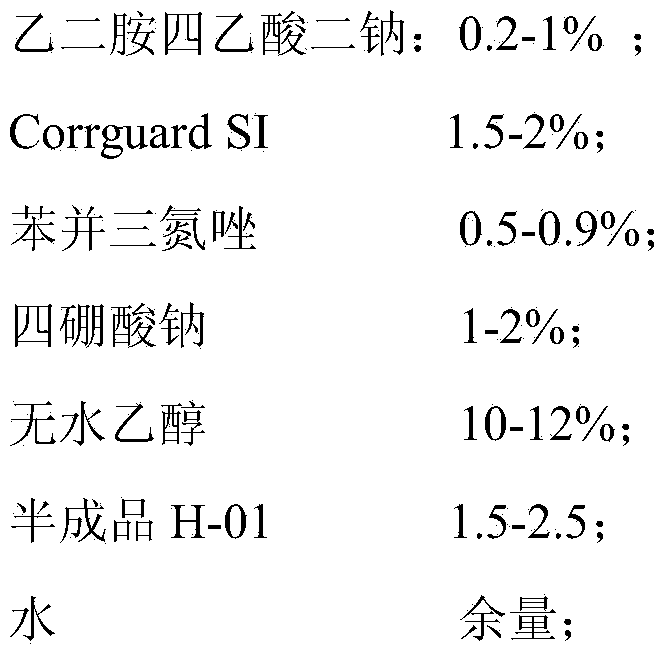

[0044] ⑵In another reaction kettle, add water and mix ethylenediaminetetraacetic acid disodium, borax, Corrguard SI, benzotriazole, semi-finished product H-01, and absolute ethanol in sequence under stirring;

[0045] (3) Stir the materials in the reaction kettle evenly for 60-80 minutes, and the finished copper and copper alloy protective agent will be finished after the solution becomes a uniform transparent liquid.

[0046] The quality standard of copper and copper alloy protective agent:

[0047] Appearance: colorless transparent liquid;

[0048] Specific gravity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com