Surface treatment method for magnesium and magnesium alloys

A surface treatment, magnesium alloy technology, applied in the direction of metal material coating technology, etc., can solve problems such as unfavorable industrial production, and achieve the effects of low production cost, improved corrosion resistance, and excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

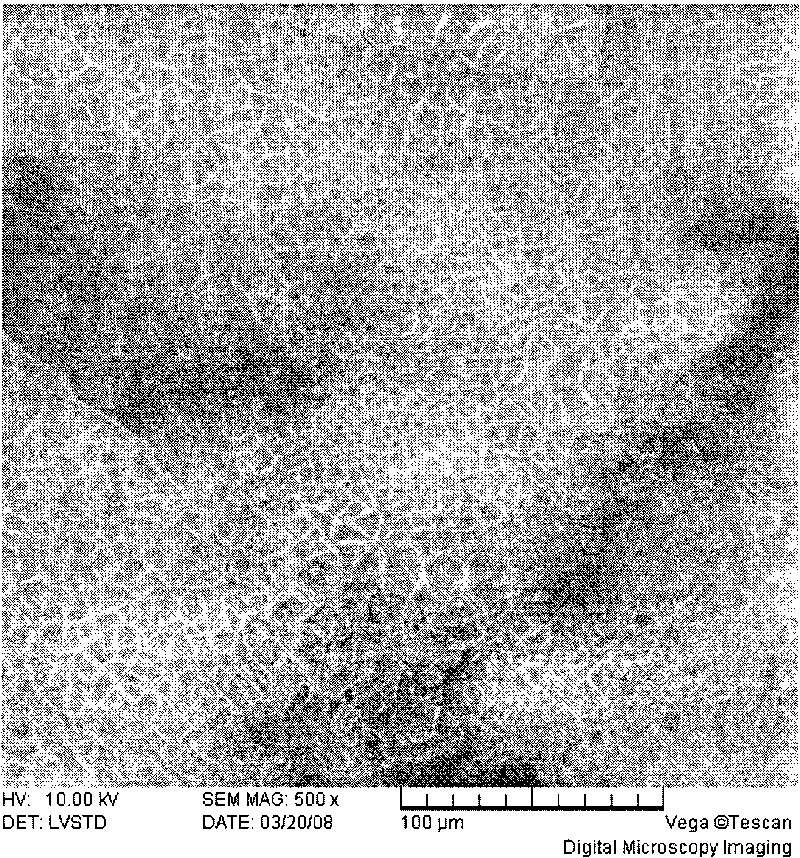

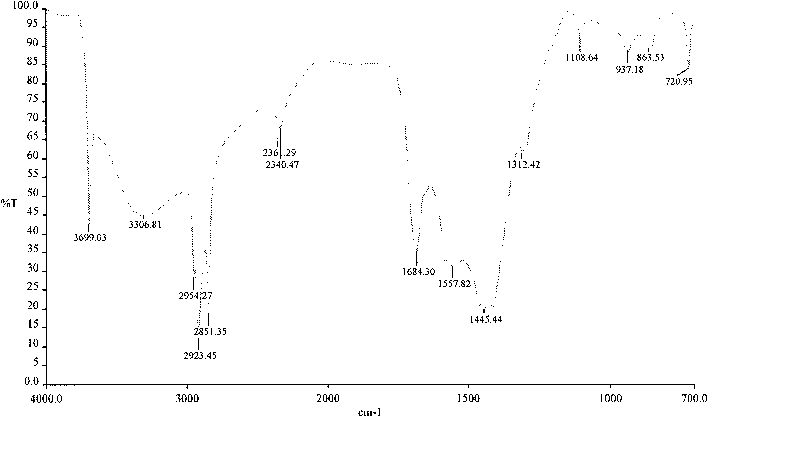

Image

Examples

Embodiment 1

[0025] Get 99.99% pure magnesium to carry out the surface treatment of stearic acid according to the inventive method:

[0026] A. Mechanical decontamination and cleaning: clean the metal magnesium after sandblasting or polishing with sandpaper, ultrasonic cleaning with acetone for 10 minutes, and ultrasonic cleaning in absolute ethanol for 10 minutes after washing with water. The above cleanings are all carried out at room temperature;

[0027] B. heat treatment: the above-mentioned metal magnesium is heated to 500 ℃, the holding time is 10 hours, and slowly cooled to room temperature with the furnace;

[0028] C. Cleaning: heat-treated samples were ultrasonically cleaned in distilled water and absolute ethanol for 10 minutes respectively, and the above cleanings were all performed at room temperature;

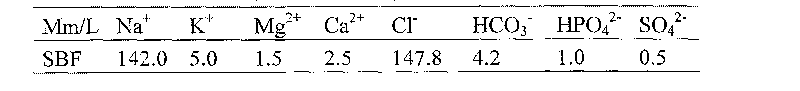

[0029] D. Immersion film: at a water bath temperature of 37°C, immerse the film for 2 hours to obtain an organic film layer on the surface of metal magnesium, wherein the con...

Embodiment 2

[0032] The difference from Example 1 is that the Mg0.88Ca alloy is used for surface treatment, the immersion solution for the immersion film is 0.4mol stearic acid ethanol solution, and the immersion treatment time of the magnesium alloy is 1.5 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com