Magnesium-lithium alloy molybdate and phosphate conversion solution and method for forming conversion coating

A technology of magnesium-lithium alloy and phosphate, which is applied in the field of alloy surface treatment liquid and alloy surface treatment, can solve the problems of the corrosion resistance of magnesium-lithium alloy, the reduction of corrosion current, and the toxicity of hexavalent chromium, etc. Good recycling value, uniform anti-corrosion ability, good anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

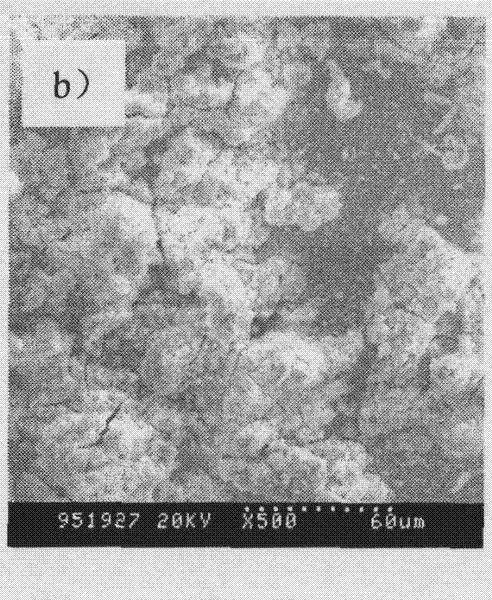

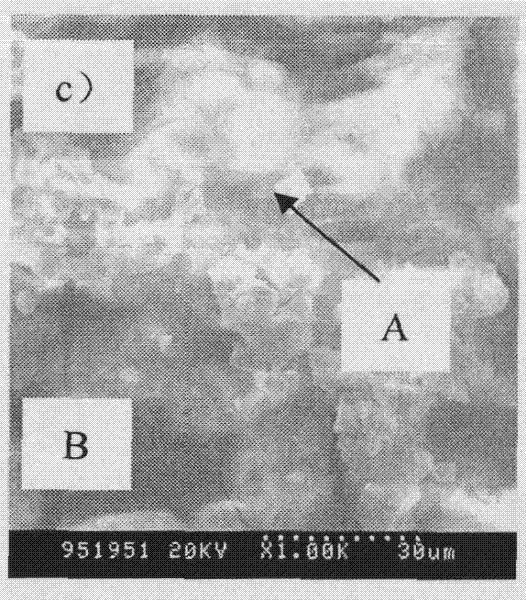

[0057] The present invention is described in more detail below in conjunction with accompanying drawing example:

[0058] This embodiment provides a magnesium-lithium alloy molybdate with glacial acetic acid as a pH regulator that is easy to operate, mild in condition, energy-saving, less toxic and low in cost, and can greatly improve the corrosion resistance of magnesium-lithium alloys. - A new method for the preparation of phosphate conversion membranes.

[0059] A) The magnesium-lithium alloy sample was polished, degreased by ultrasonication with acetone, and then pickled with 10g / L oxalic acid at room temperature for 5 minutes;

[0060] B) Wash the sample after A) with warm water, then with running water, and blow dry;

[0061] C) put the sample after B) into 160g / L phosphoric acid, 90g / L ammonium bifluoride solution for activation, the temperature is room temperature, and the time is 2min;

[0062] D) wash the sample after C) activation with running water, and blow dry;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| corrosion potential | aaaaa | aaaaa |

| corrosion potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com