Cleaning agent for removing heavy dirt and greasy dirt

A cleaning agent and oil stain technology, applied in the direction of detergent compounding agent, detergent composition, surface active detergent composition, etc., can solve the problems of hard surface corrosion, heavy dirt on hard surface and incomplete cleaning of oil stains, etc., to achieve Increase solubility, easy to wipe off, prevent redeposition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

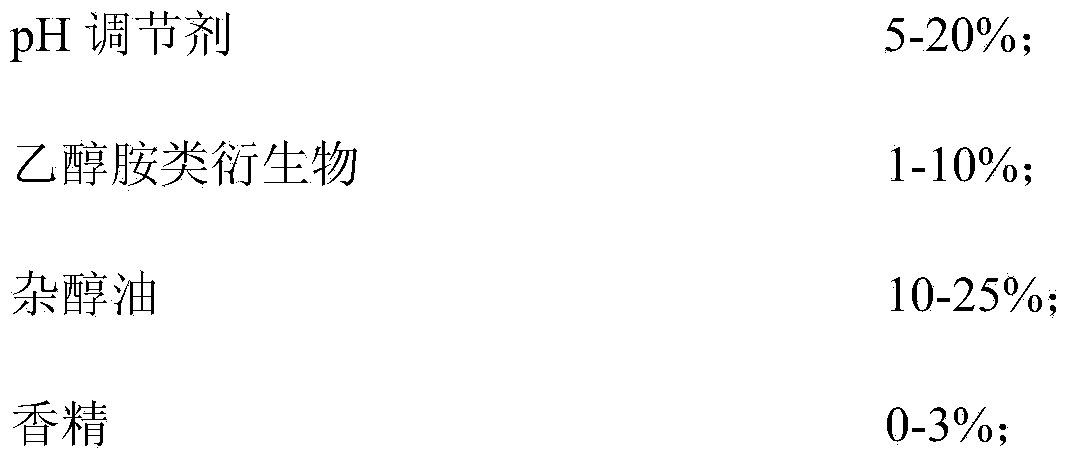

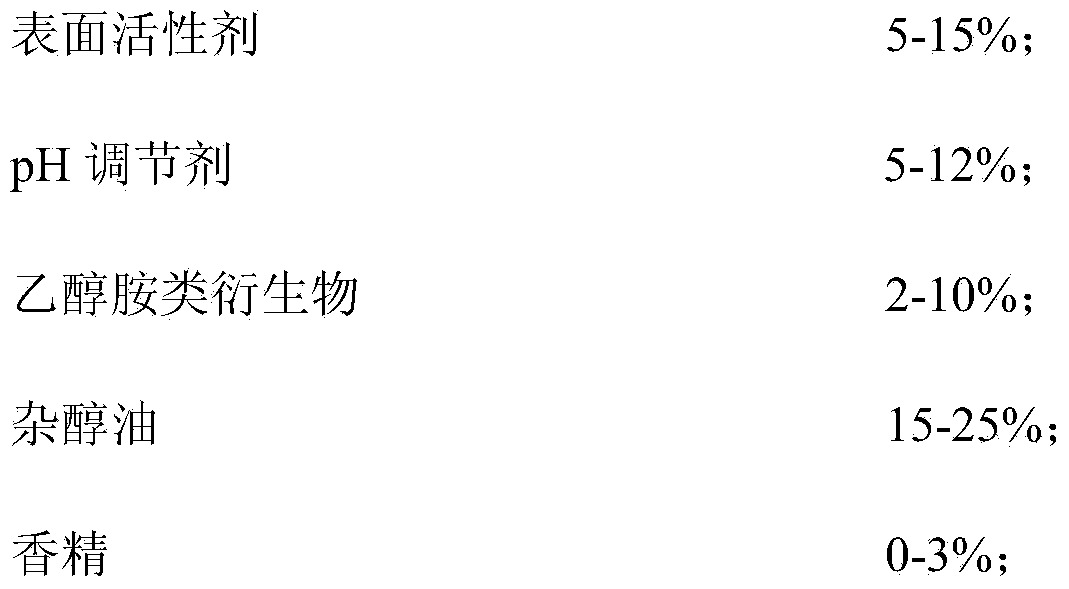

Method used

Image

Examples

Embodiment 1

[0031] In a stainless steel reaction kettle equipped with a mechanical stirring device, add 6 parts of sodium dodecylbenzenesulfonate, 3 parts of sodium hydroxide, 3 parts of sodium silicate, 4 parts of triethanolamine, and 50 parts of water, and heat up to 45-50 ℃, after the solid matter is completely dissolved, add 15 parts of fusel oil, 1 part of 10% essence alcohol solution, and 18 parts of water, stir until uniform, cool and filter to obtain the finished product.

Embodiment 2

[0033] In a stainless steel reaction kettle equipped with a mechanical stirring device, add 6 parts of nonylphenol polyoxyethylene (10) ether, 3 parts of sodium hydroxide, 3 parts of sodium silicate, 4 parts of triethanolamine, and 50 parts of water, and heat up to 45 -50°C, after all the solids are dissolved, add 15 parts of fusel oil, 1 part of 10% essence alcohol solution, and 18 parts of water, stir until uniform, cool and filter to obtain the finished product.

Embodiment 3

[0035] In a stainless steel reaction kettle equipped with a mechanical stirring device, add 2 parts of sodium dodecylbenzenesulfonate, 4 parts of nonylphenol polyoxyethylene (10) ether, 3 parts of sodium hydroxide, 3 parts of sodium silicate, three parts 4 parts of ethanolamine, 50 parts of water, heat up to 45-50 ° C, after all solids are dissolved, add 15 parts of fusel oil, 1 part of 10% essence alcohol solution, 18 parts of water, stir until uniform, cool and filter to obtain the finished product .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com