High-temperature-curing inorganic anticorrosive coating for automobile brake disc

A high-temperature curing, automobile braking technology, used in anti-corrosion coatings, coatings, etc., can solve the problems of easy peeling of paint films, water resistance, salt spray resistance, poor oil resistance, and difficult drying of paint films, and achieve adhesion. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

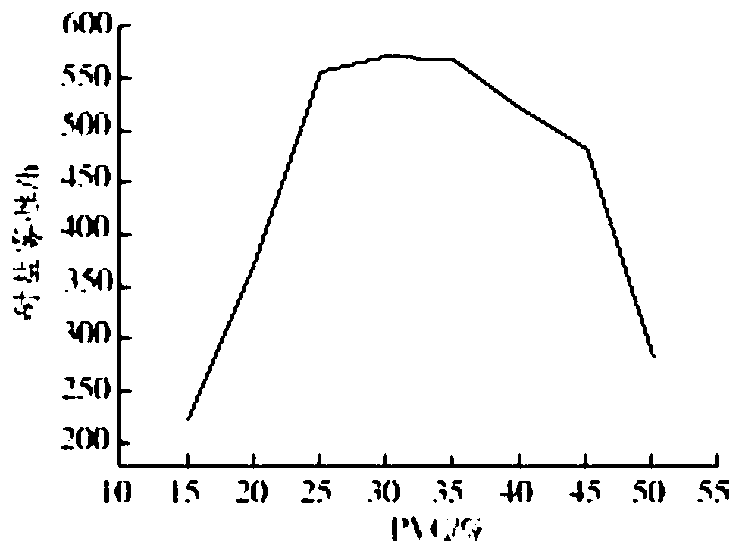

[0030] Inorganic anti-corrosion coating with pigment volume concentration PVC of 15%

[0031] A kind of high-temperature curing inorganic anti-corrosion coating for automobile brake discs, its composition by mass is as follows: 55 parts of reactive inorganic silicate resin with silicate as the matrix, 2 parts of modified zinc phosphate, 3 parts of composite iron-titanium powder, Aluminum hydroxide 3.2 parts, water 22 parts, talc powder 10 parts, dispersant BYK2012 2 parts, defoamer BYK035 0.8 parts, neutralizer AMP-95 1 part, bentonite 1 part.

Embodiment 2

[0033] Inorganic anti-corrosion coating with pigment volume concentration PVC of 20%

[0034] A high temperature curing inorganic anti-corrosion coating for automobile brake discs, the composition of which is as follows in parts by mass: 50 parts of reactive inorganic silicate resin based on silicate, 3 parts of modified zinc phosphate, 5 parts of composite iron-titanium powder, 3.2 parts of fluorosilicate, 22 parts of water, 12 parts of talc, 2 parts of dispersant, 0.8 part of defoamer BYK035, 1 part of neutralizing agent AMP-95, and 1 part of bentonite.

Embodiment 3

[0036] Inorganic anti-corrosion coating with pigment volume concentration PVC of 25%

[0037] A high temperature curing inorganic anti-corrosion coating for automobile brake discs, the composition of which is as follows in parts by mass: 50 parts of reactive inorganic silicate resin based on silicate, 3 parts of modified zinc phosphate, 5 parts of composite iron-titanium powder, 3.7 parts of borate, 20 parts of water, 17 parts of talc, 0.8 part of dispersant, 0.5 part of defoamer BYK035, 0.5 part of neutralizing agent AMP-95, 0.5 part of bentonite.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com